Integrated camellia oleifera making machine

An all-in-one, Camellia oleifera technology, applied in food forming, food science, application, etc., to achieve good taste effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

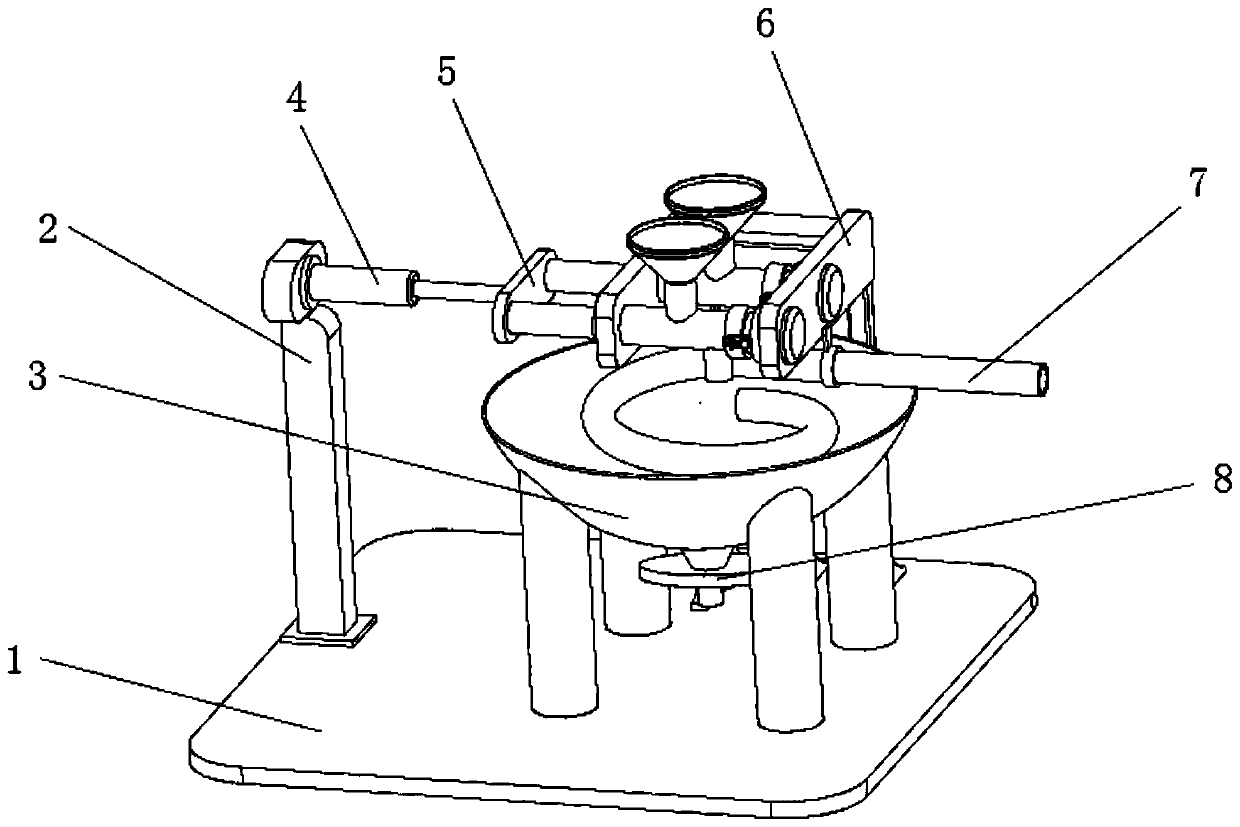

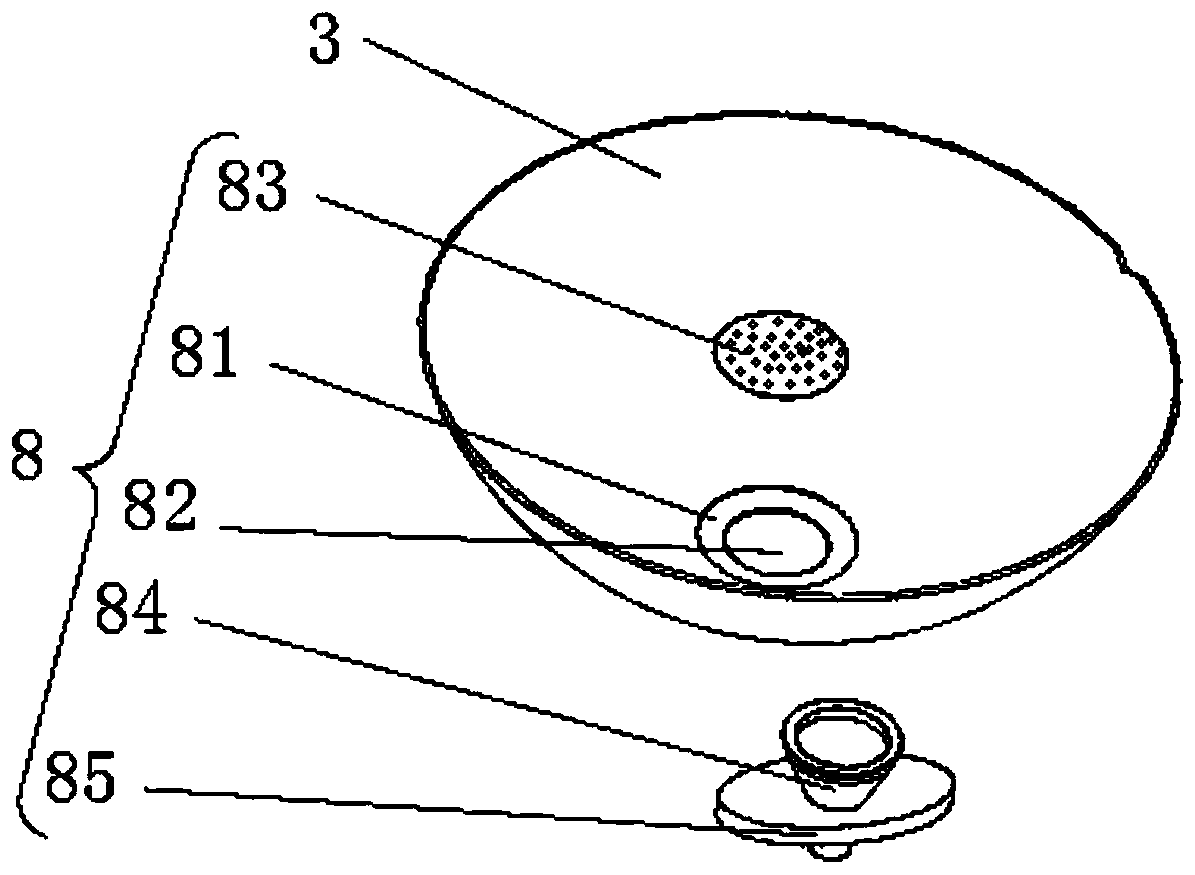

[0026] see Figure 1 to Figure 4 , In a preferred embodiment of the present invention, the integrated Camellia oleifera production machine includes a base plate 1 on which a cylinder 4, a knocking device 6, a processing pot 3 and a feeding pipe 7 are installed.

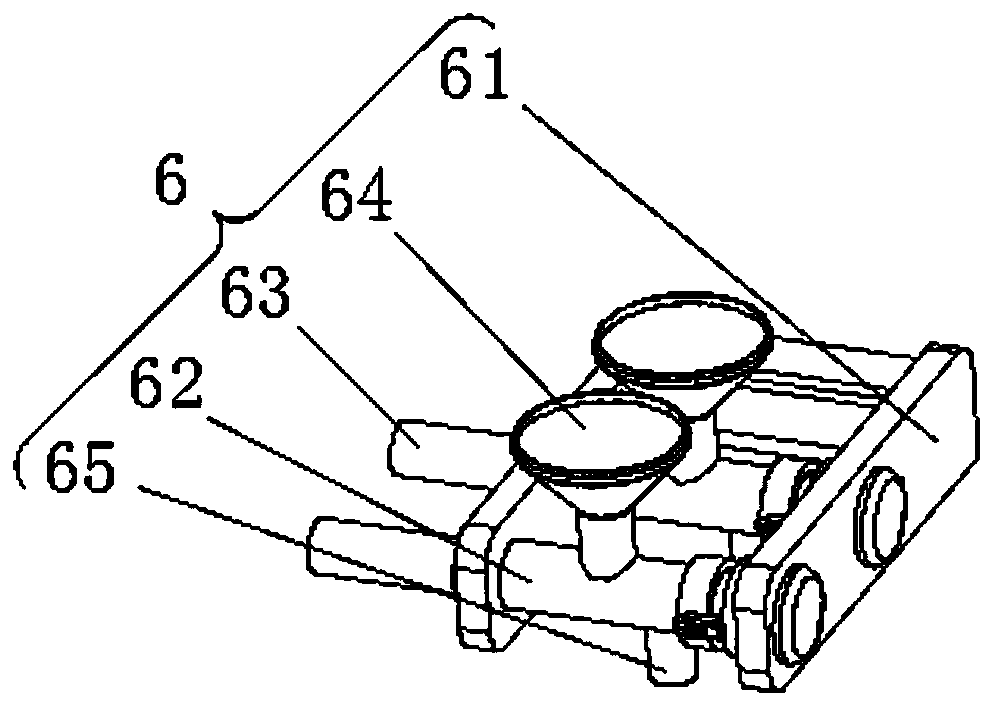

[0027] Wherein, the fixed end of the air cylinder 4 is installed on the base plate 1 through the installation arm 2, and the installation arm 2 is arranged perpendicular to the base plate 1, and the telescoping end of the airbag is connected to the percussion device 6, preferably making the expansion and contraction of the air cylinder 4 The direction is horizontal. The percussion device 6 is installed on the base plate 1 through the mounting bracket 61, the percussion device 6 includes a percussion column 63, a percussion cylinder 62, a feed funnel 64 and a first discharge valve 65, the percussion column 63 One end is connected to the telescopic end of the cylinder 4, and the other end is slidably inserted from one ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com