A product packaging protective film coating device

A technology of laminating device and product packaging, applied in the field of product packaging protective film laminating device, can solve the problems of easy adhesion of dust and impurities, easy occurrence of air bubbles in plates and film bodies, affecting the quality of lamination, etc., so as to improve the packaging effect, The effect of reducing static electricity and friction and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

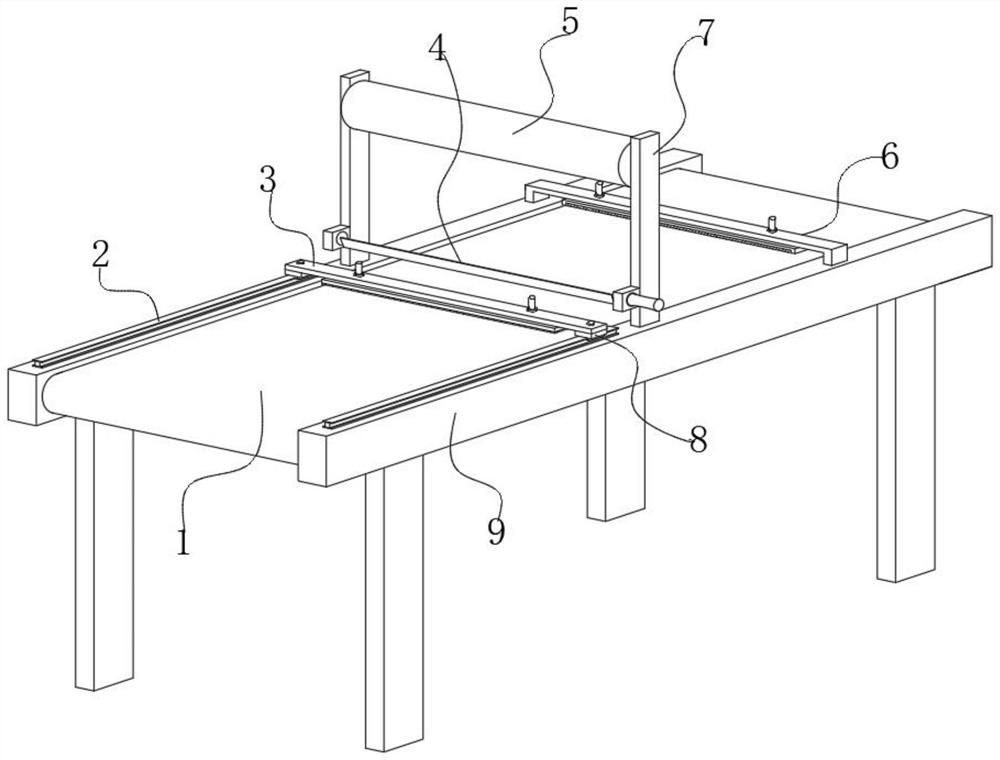

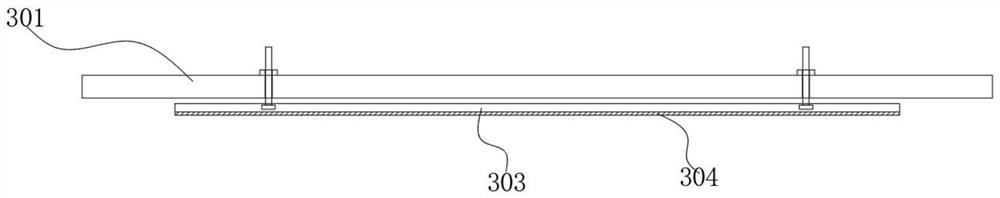

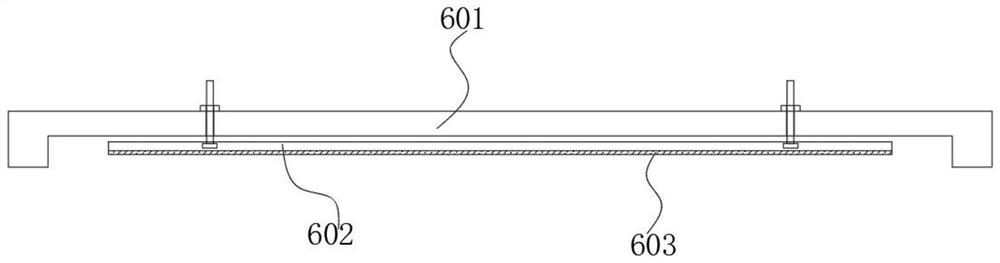

[0024] see Figure 1~6 , in an embodiment of the present invention, a product packaging protective film coating device, including a conveyor belt 1 for conveying plates, a film supply assembly 5, and a laminating assembly 3, and support seats are symmetrically arranged on both sides of the conveyor belt 1 9. The support base 9 is provided with the film supply assembly 5 and the laminating assembly 3, the film supply assembly 5 is set on the support base 9 with the installation frame 7, and the film supply assembly 5 can provide three different material, and the three kinds of membranes pass through the guide assembly 16 in turn, and cover the plate in one of the ways, so the device can select a suitable membrane for attachment according to different plates; the bonding component 3 is arranged at the discharge end of the conveyor belt 1, and the bonding component 3 is slidably arranged along the length direction of the support seat 9, and can make the film body and the plate cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com