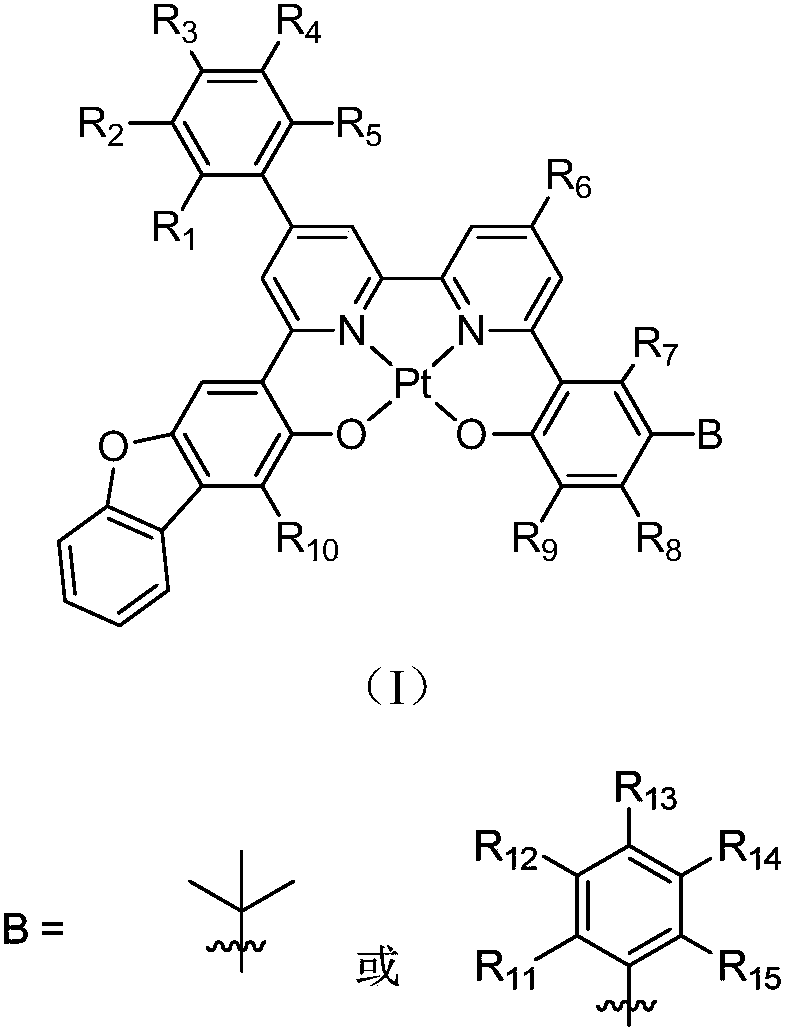

Platinum (II) tetradentate ONNO complex luminescent material, preparation method and application thereof in organic light emitting diode (OLED)

A technology of luminescent materials and complexes, which can be used in luminescent materials, platinum-based organic compounds, platinum-based organic compounds, etc., and can solve problems such as reducing self-quenching constants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

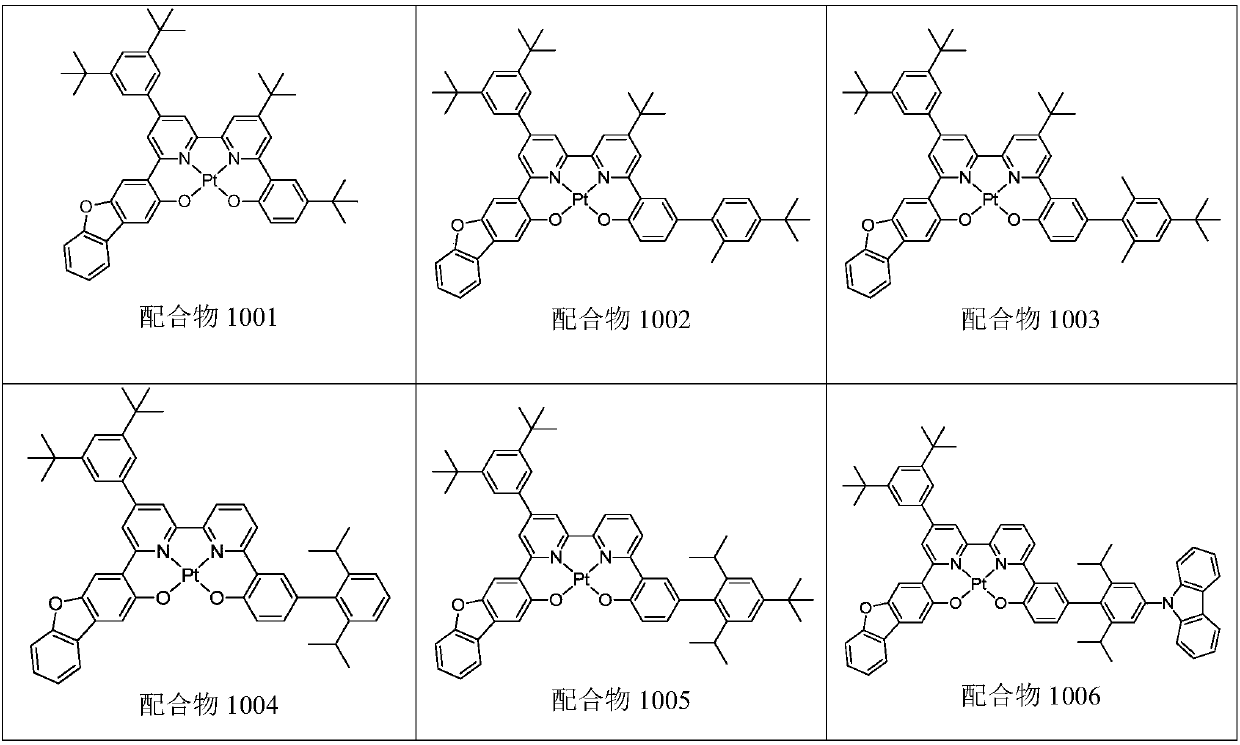

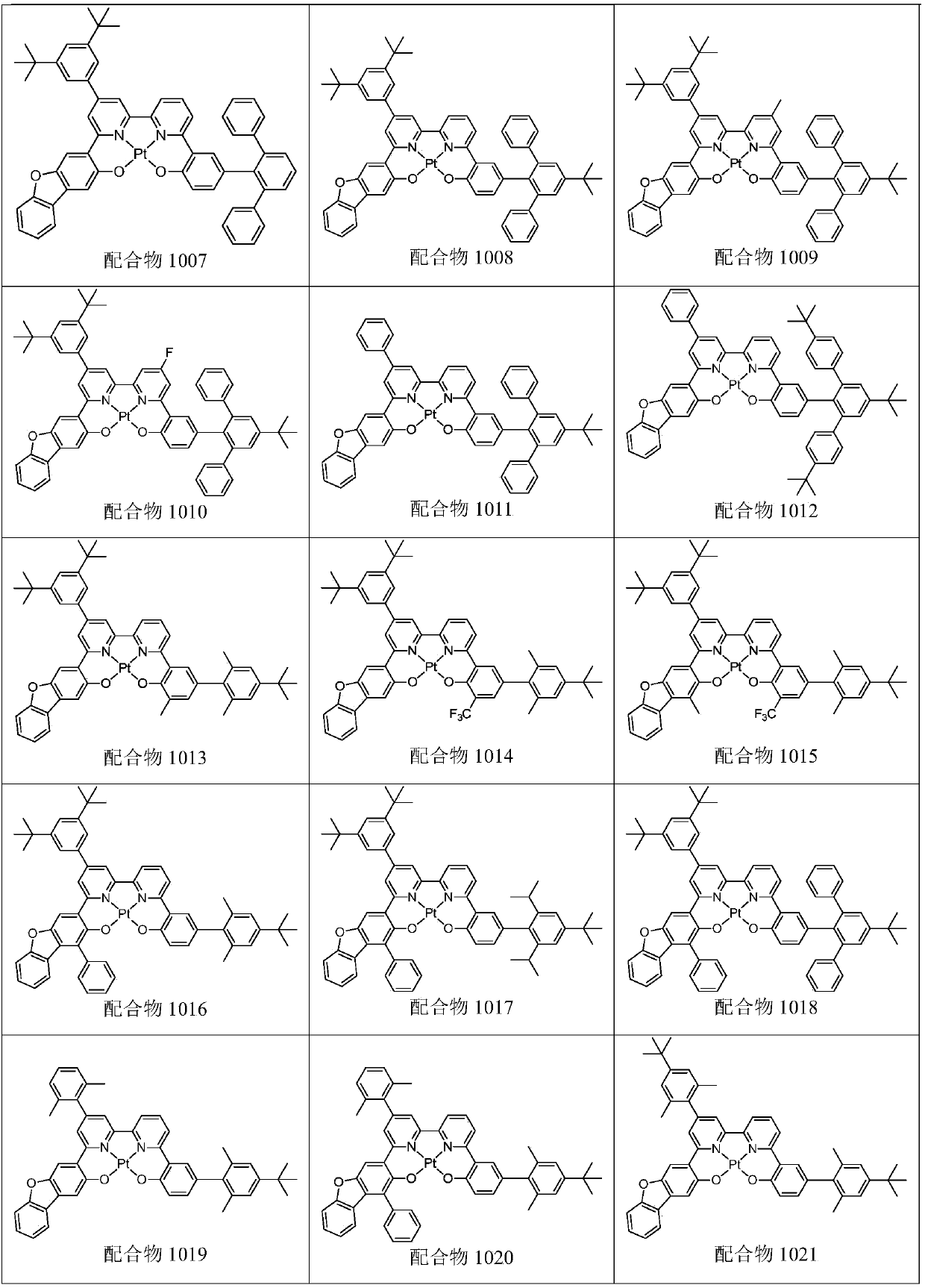

Examples

Embodiment 1

[0036] Embodiment 1-synthetic intermediate 3101

[0037]

[0038] Fill raw material 4101 (0.1mol), tert-butyl nitrite (0.1mol) in the round bottom flask, cuprous bromide (0.12mol), acetonitrile (200ml), the reaction mixture is warming up to 90 ℃ under stirring 4 Hour. After the reaction mixture was cooled to room temperature, water was added, followed by extraction with dichloromethane. After the solvent was removed by evaporation, a solid product was obtained and slurried with methanol at -20°C. Suction filtration and drying yielded a beige solid with a yield of 60%.

Embodiment 2

[0039] Embodiment 2-synthetic intermediate 3201

[0040]

[0041] Put intermediate 3201 (60mmol) and dry tetrahydrofuran (100mL) into a three-neck flask, stir at -78°C for 0.5 hours under a nitrogen atmosphere, then slowly add 1.2 equivalents of n-butyllithium solution (2M) dropwise, and continue stirring while maintaining the temperature After 0.5 hour, N-methoxy-N-methylacetamide (60 mmol) was added dropwise, then the temperature was kept and the mixture was stirred for 1 hour, then slowly raised to room temperature and stirred overnight. Quenched by adding saturated ammonium chloride solution, extracted with ethyl acetate, collected the organic phase solution, the crude product was separated by silica gel column chromatography, and then the solid was recrystallized with n-hexane, suction filtered and dried to obtain a light pink solid with a yield of 55% .

Embodiment 3

[0042] Embodiment 3-synthetic intermediate 3301

[0043]

[0044] Intermediate 3201 (30 mmol) and raw material 4201 (33 mmol) were charged into a round bottom flask, 100 mL of methanol was added and stirred to dissolve, and aqueous potassium hydroxide solution (10 mL, 50 mmol) was slowly added dropwise to the mixture. After the dropwise addition was completed, the reaction mixture was heated to 50° C. under a nitrogen atmosphere and stirred for 10 hours. After the reaction mixture was cooled to room temperature, 4M HCl solution was added to adjust the pH of the mixture to neutral, the filtered solid was dissolved in an organic solvent, and the insoluble matter was removed by filtration. After removing the solvent, the solid product obtained was slurried with methanol at -20°C. Suction filtration and drying gave a yellow solid with a yield of 80%.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap