Outer fin heat exchange tube with spiral inner core and manufacturing method of outer fin heat exchange tube

A manufacturing method and technology of heat exchange tubes, which are applied in the direction of tubular elements, heat exchange equipment, lighting and heating equipment, etc., can solve the problem that the compound agent between the inner fin and the base tube is difficult to clean, and the heat exchange tube is limited by the width of the inner fin coil. Limitation, high cost of heat exchange tubes, etc., to achieve the effect of small fluid resistance, increase cleaning process, and improve heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0029] This specific embodiment is only an explanation of the present invention, and it is not a limitation of the present invention. Those skilled in the art can make modifications to this embodiment as required after reading this specification, but as long as they are within the rights of the present invention All claims are protected by patent law.

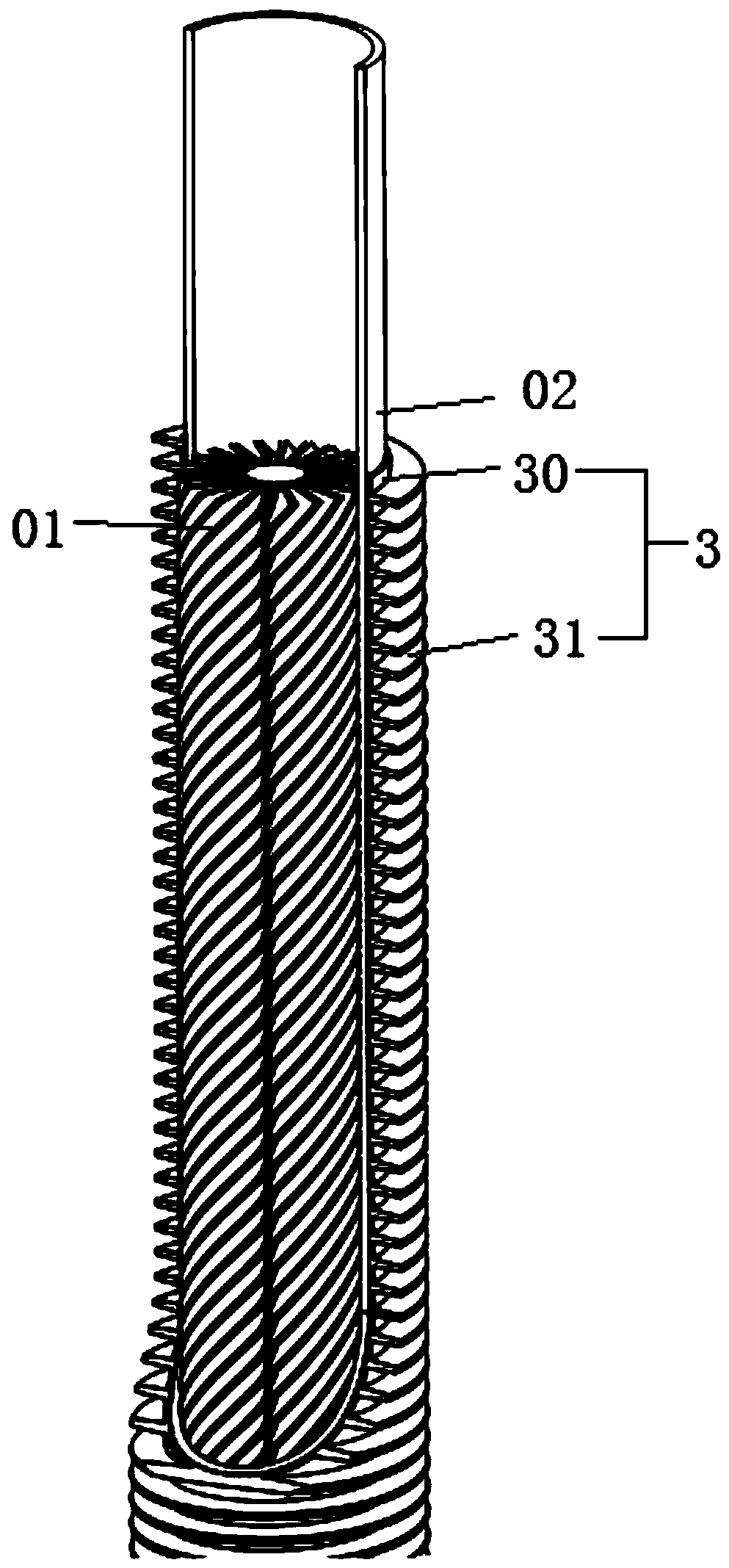

[0030] This embodiment relates to a method for manufacturing an outer-fin heat exchange tube with a spiral inner core, the method comprising: S1: obtaining the spiral inner core 01;

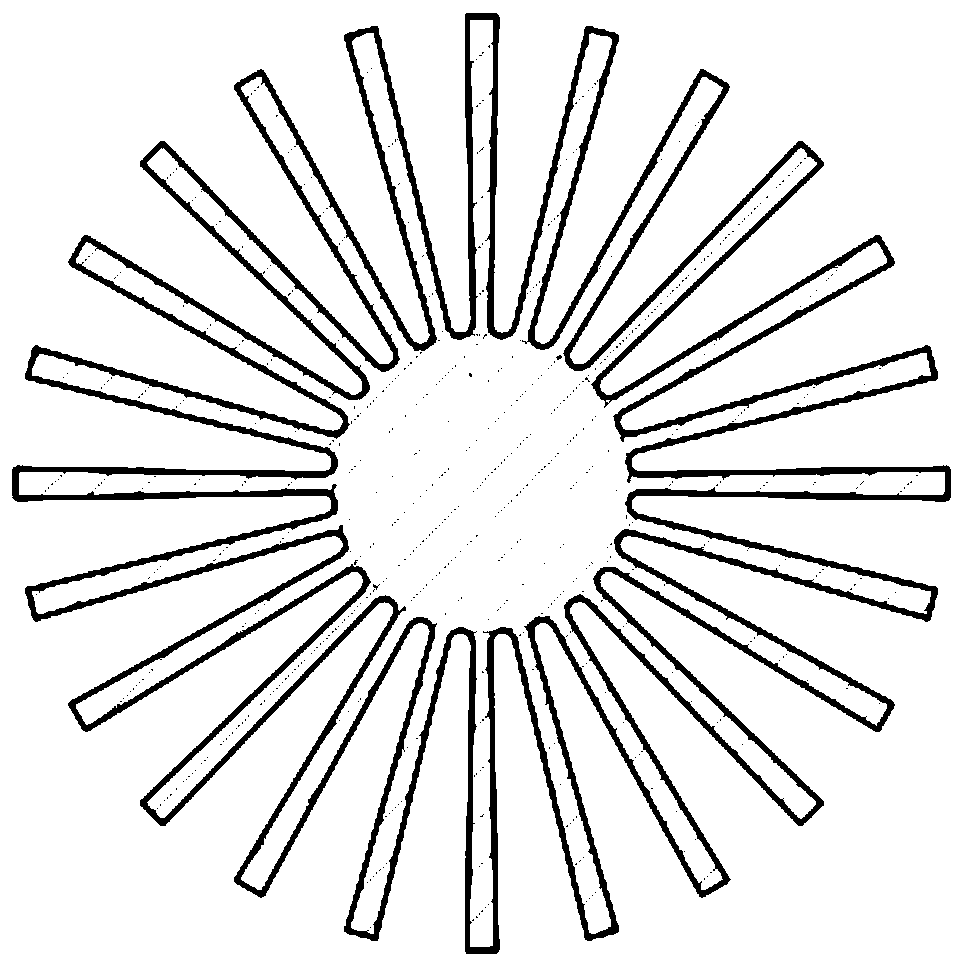

[0031] (1) The aluminum bar with good thermal conductivity and fast heat dissipation is processed into longitudinal fin profiles by hot extrusion, such as figure 1 shown;

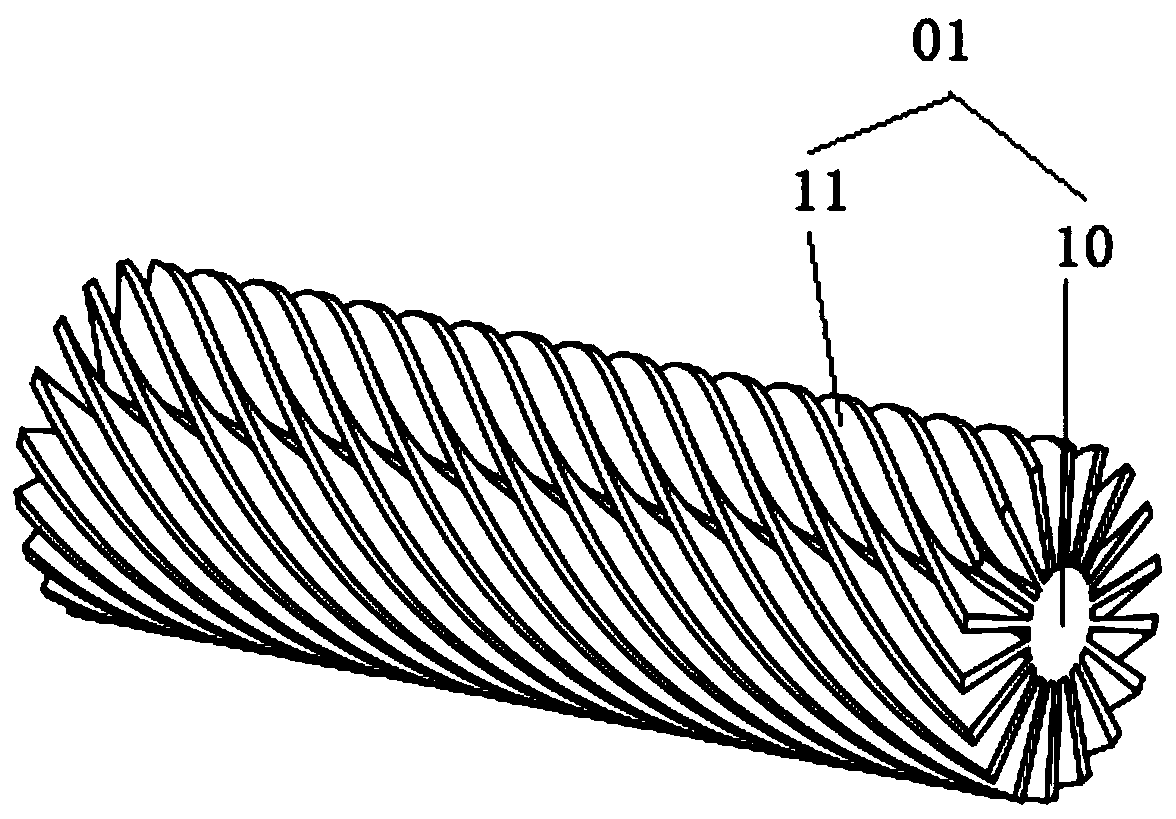

[0032] (2) While the profile is relatively hot and easy to deform, the profile extruded at a constant speed is passed through the twisting tool, and the rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com