3D printing drilling template for self-adapting airplane curved surface skin drilling

A 3D printing and self-adaptive technology, applied in the direction of drilling dies for workpieces, etc., can solve the problems of long time period, inability to adapt to the surface skin of aircraft, increase the difficulty of hole making, etc., to achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

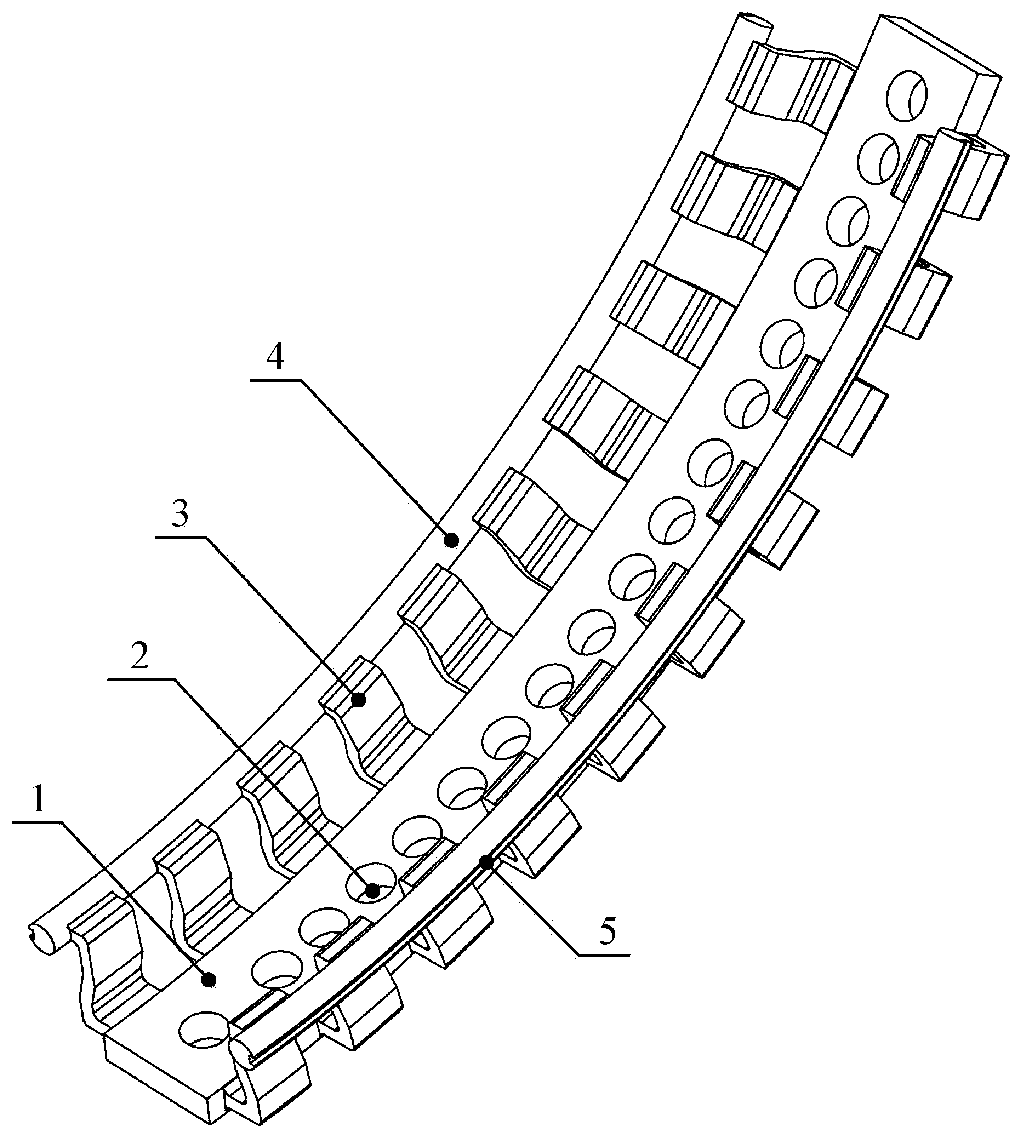

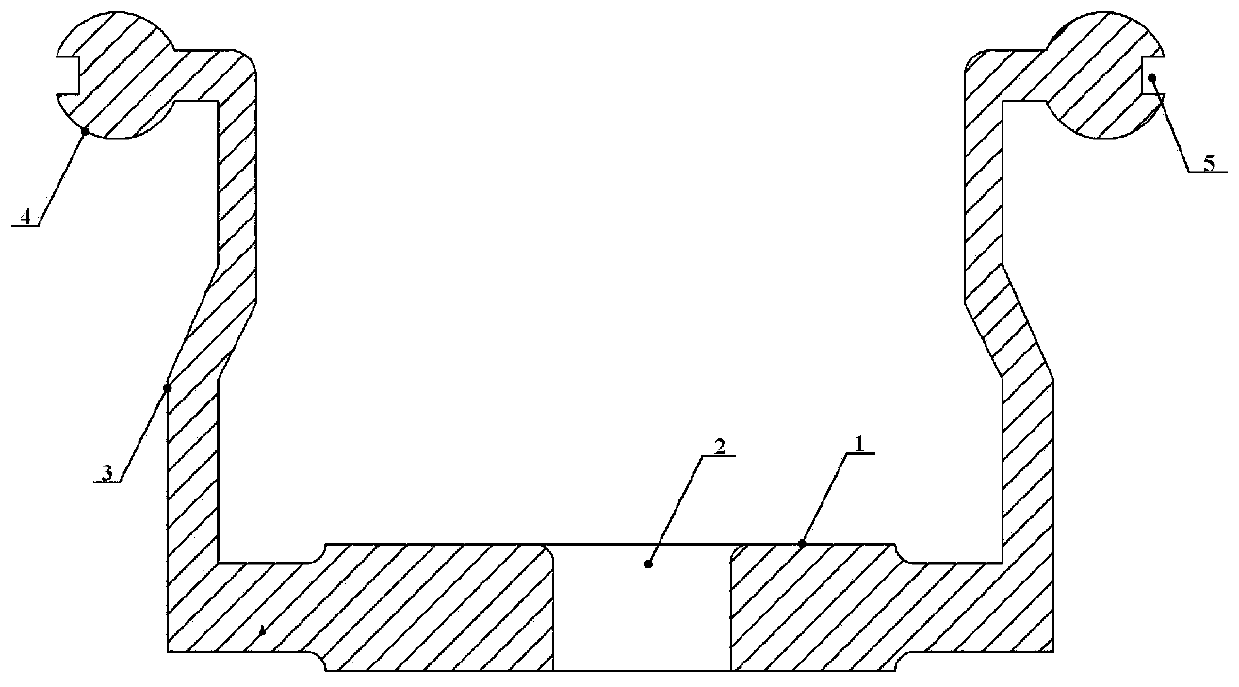

[0026] Such as Figure 1-Figure 3 As shown: this embodiment provides a 3D printing drilling template for self-adaptive aircraft curved surface skin drilling, including a bonding plate 1, a guide rail 4 and several ribs 3, and the curvature of the bonding plate 1 is equal to the curvature of the aircraft curved surface skin , a number of normal vector drill casing holes 2 are arranged on the bonding plate 1, the axis direction of the normal vector drill casing holes 2 is consistent with the normal vector of the hole making position on the aircraft curved surface skin, so as to ensure that the feeding process can be accurately guided for hole making, One end of several ribs 3 is fixedly connected to the laminated plate 1, and the other end of several ribs 3 is fixedly connected to the guide rail 4, the curvature of the guide rail 4 is equal to the curvature of the curved surface skin of the aircraft, and the guide rail 4 is used to install the automatic hole-making robot , where...

application example 1

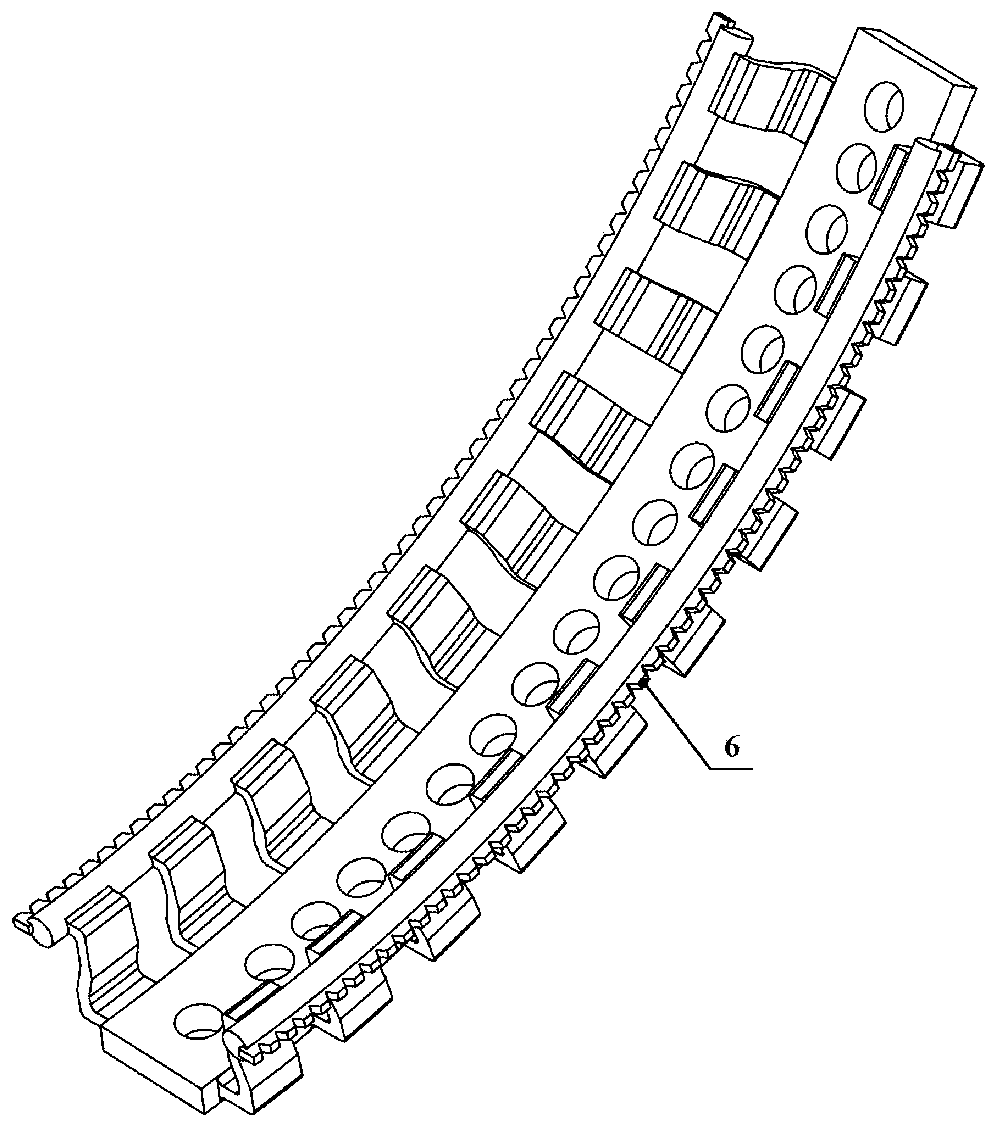

[0032] Such as Figure 4 Shown: This application case uses the 3D printing drill template in the above-mentioned embodiment, and assumes that the curvature of the aircraft surface skin-7 required for hole making is 1 / 900. The 3D print drill template is based on the aircraft surface skin-7 The curvature is designed, and the curvature of the design lamination plate 1, guide rail 4 and guide groove 5 is consistent with the curvature of the aircraft surface skin-7. After the design, 3D printing technology is used to quickly form an integral body. The bonding plate 1 is fully self-adaptive and seamlessly bonded to the curved skin of the aircraft, relying on the guiding function of the guide rail 4 and the guided movement of the rack 6 on the guide groove 5, allowing the automatic hole-making robot installed on the guide rail to perform precise hole-making operations.

application example 2

[0034] Such as Figure 5Shown: This application case applies the 3D printing drill template in the above-mentioned embodiment, and assumes that the curvature of the aircraft surface skin II 8 required for hole making is 0. The 3D printing drill template is processed according to the curvature of the aircraft curved surface skin II 8 Design, design The curvature of the laminating board 1, the guide rail 4 and the guide groove 5 is consistent with the curvature of the aircraft surface skin 2 8, and after the design, the 3D printing technology is used to quickly form an integral body. The bonding plate 1 is fully self-adaptive and seamlessly bonded to the curved skin of the aircraft, relying on the guiding function of the guide rail 4 and the guided movement of the rack 6 on the guide groove 5, allowing the automatic hole-making robot installed on the guide rail to perform precise hole-making operations.

[0035] It should be noted that the curvatures of the aircraft curved skins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com