A device for opening holes in a grid cover plate

A grid and cover plate technology, which is applied in the field of grid cover plate opening devices, can solve the problems of screw inclination, screw passing through the opening, and opening inclination, etc., so as to improve the speed of opening holes and facilitate subsequent installation and opening. uniform hole effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

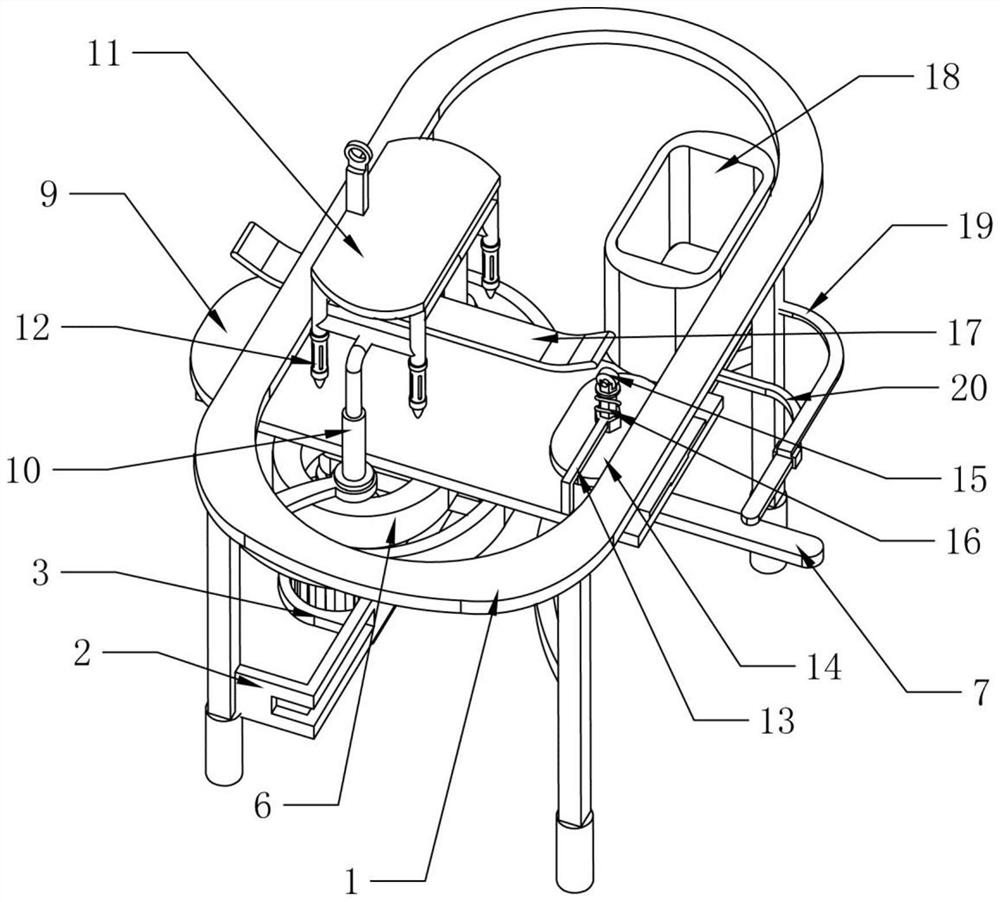

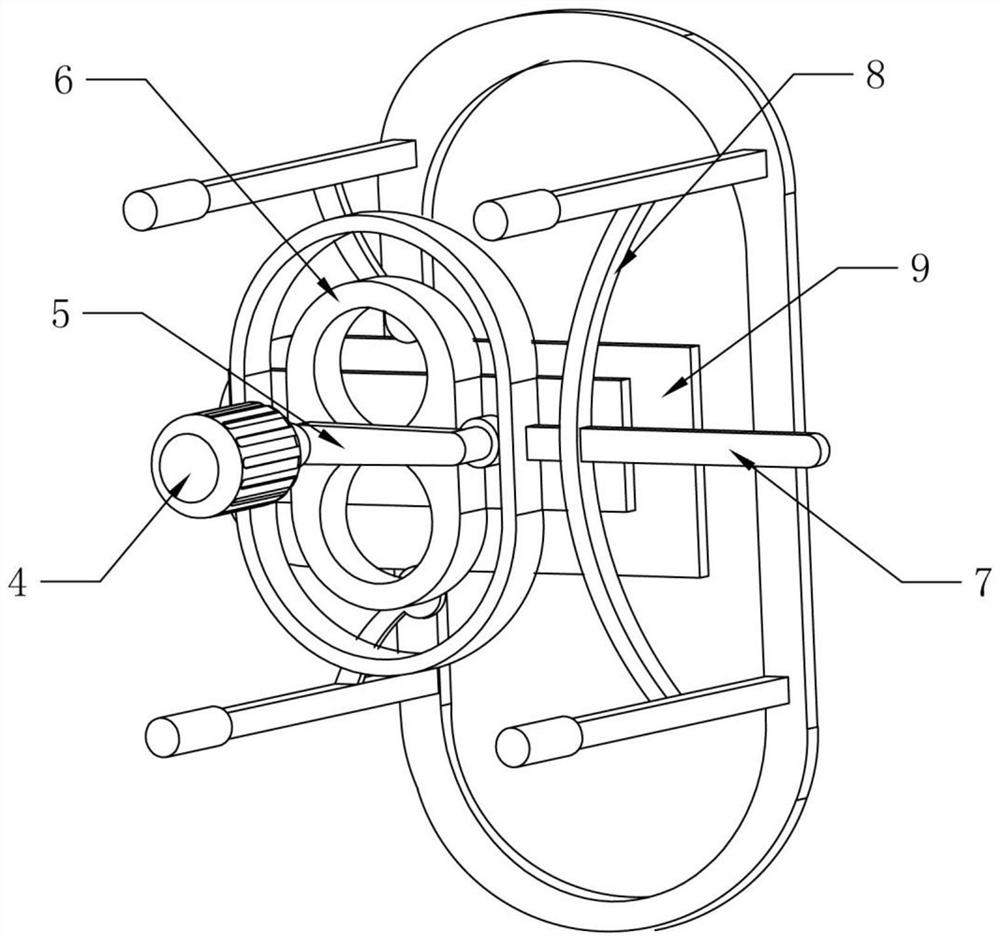

[0024] A grid cover opening device, such as Figure 1-5 As shown, it includes a frame 1, a connecting plate 2, a motor base 3, a servo motor 4, a moving mechanism, a hole opening device and a pressing mechanism. On the two supporting feet, which extend to the inside of the frame 1, the motor base 3 is consolidated with the connecting plate 2, the servo motor 4 is installed on the motor base 3, the output shaft of the servo motor 4 faces upward, and the moving mechanism is arranged on the frame 1 and Connected with the servo motor 4, the hole opening device is arranged on the frame 1, the hole opening device is located above the moving mechanism, and the pressing mechanism is arranged on the frame 1 and the moving mechanism.

[0025] When working, put the grid cover plate under the pressing mechanism on the moving mechanism, start the servo motor 4, and the servo motor 4 drives the moving mechanism to move towards the opening device. When the tightened grid cover plate moves to...

Embodiment 2

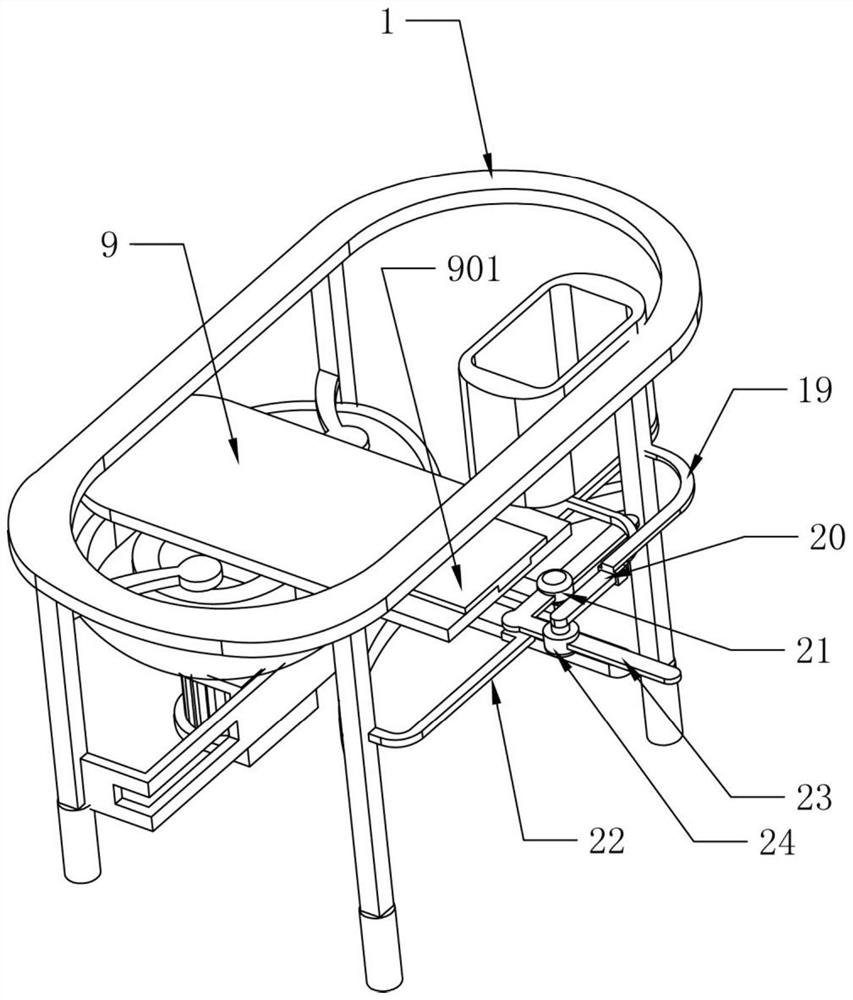

[0033] On the basis of Embodiment 1, a grid cover opening device also includes a grid box 18, a bent rod seat 19 and a feeding rod 20, the grid box 18 is fixed on the inner wall of the frame 1 ring frame, and Located on the rear side of the pressing mechanism, its bottom is located above the support plate 9 extending out of the baffle plate, the bent bar seat 19 is fixed on the support foot of the frame 1, and one end of the feeding rod 20 is slidably connected to the bent bar seat 19, and the feeding bar 20 It is irregularly curved, and the other end of the feeding rod 20 is bent to one end of the grid box 18 .

[0034] A grid cover plate can be placed in the grid box 18. When a hole needs to be opened, the feeding rod 20 only needs to be pulled forward, and the feeding rod 20 will pull the grid cover plate in the grid box 18 to just below the pressing mechanism. At this time, only need to start the moving mechanism, the grid cover plate can be tightened and sent to the botto...

Embodiment 3

[0038] On the basis of embodiment 2, a kind of grating cover plate opening device also includes push rod 25, swing rod 26, sliding wheel 27, right-angle plate 28, pressure spring 29 and stop bar 30, and push rod 25 rotates Connected to the extension seat of the support frame 11, the push rod 25 has a waist-shaped hole, and one end of the stroke plate 17 is fixed with a stop rod 30, and the push rod 25 is rotated through the waist-shaped hole to connect the stop rod 30, and the swing rod 26 rotates Connected to the right-angle plate 28, the right-angle plate 28 is fixed on the support plate 9, a sliding wheel 27 is installed at the end of the swing rod 26, and the sliding wheel 27 is in contact with the push rod 25, one end of the pressure spring 29 is connected to the right-angle plate 28, and the other end is connected to the swing rod 26.

[0039] When the moving mechanism moved to the left, the swing bar 26 moved to the left, and when the grid cover on the moving mechanism ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com