Device for filling fill product

A technology of product and filling equipment, which is applied in the field of equipment for filling beverages into beverage containers, which can solve the problems of high structural height, no flow geometry, and difficult geometry, and achieve the effect of compact structure and light assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Hereinafter, preferred embodiments are described with reference to the accompanying drawings. Here, the same, similar or equivalent elements in the drawings are attached with the same reference numerals, and repeated descriptions of these elements are partially omitted to avoid redundancy.

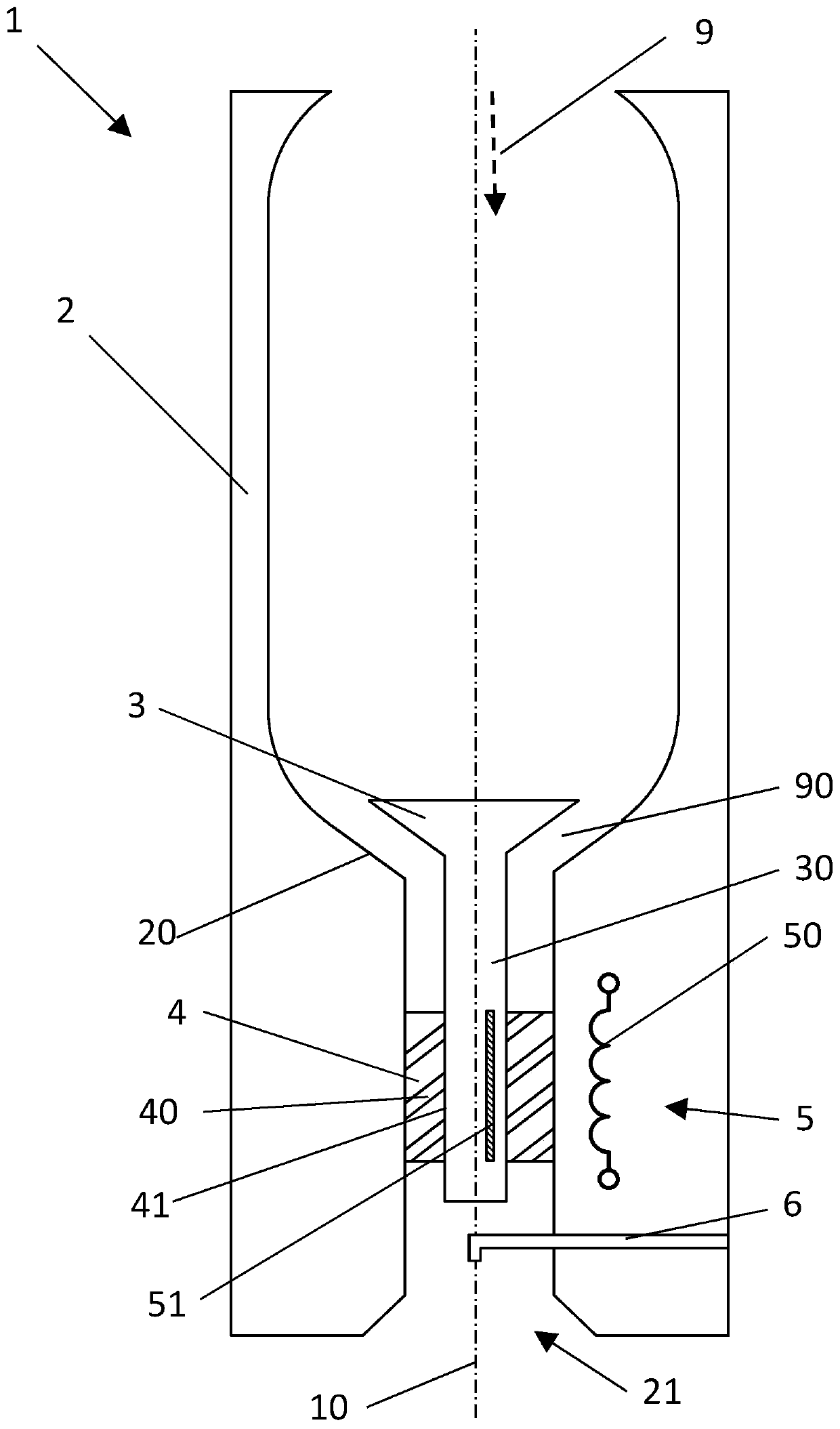

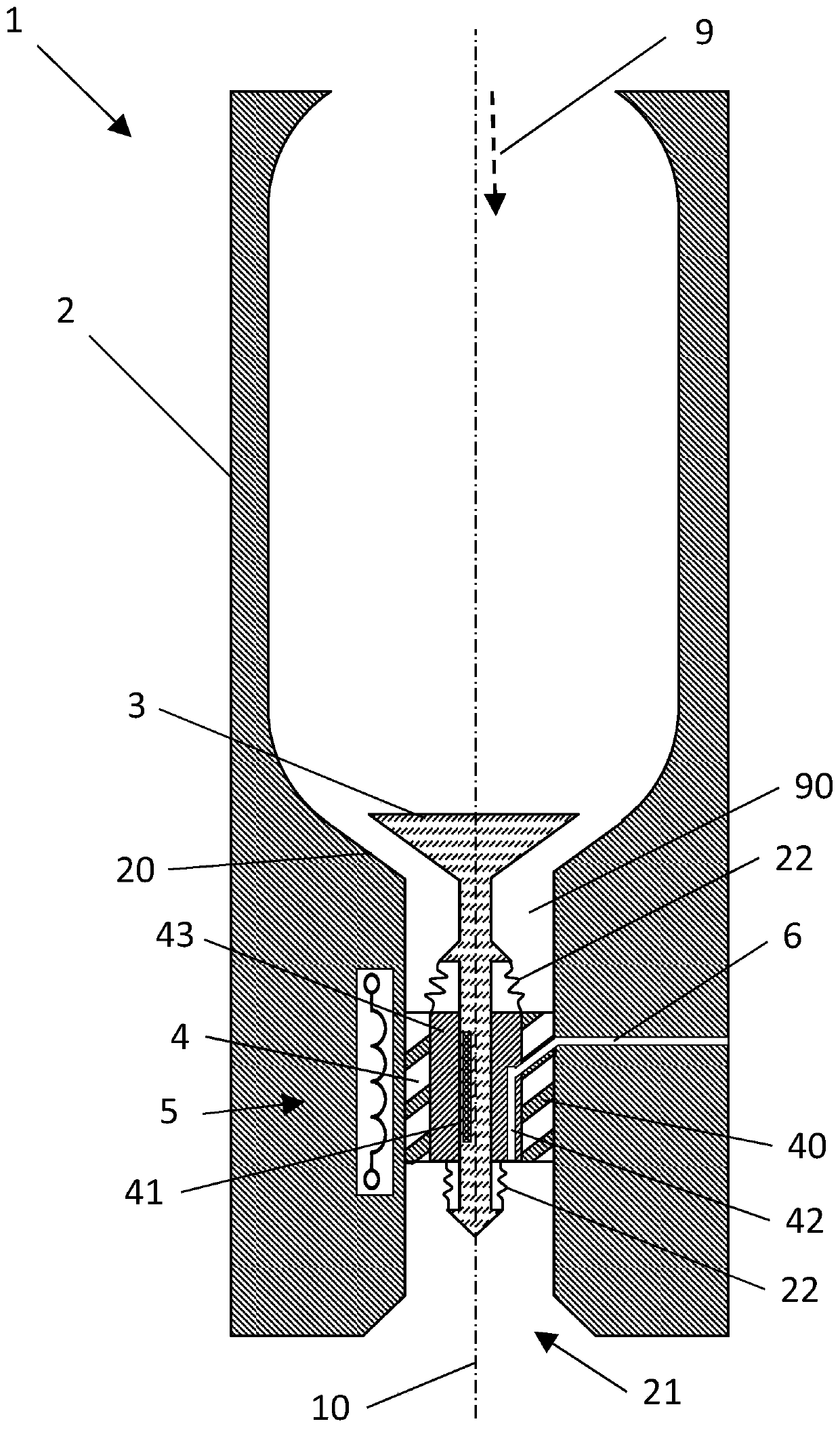

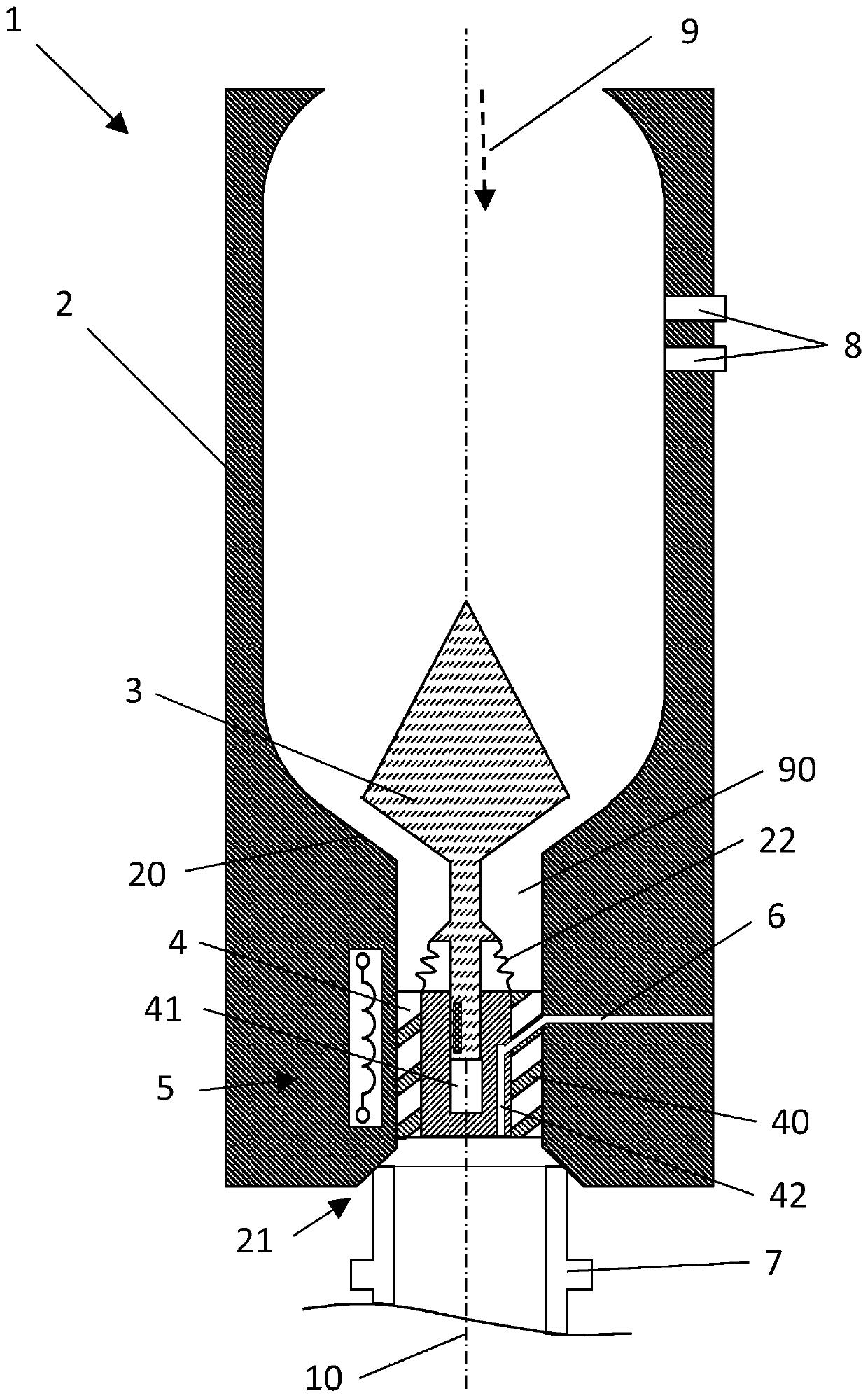

[0033] exist figure 1 A cross-sectional view of a device for filling filling products according to a preferred embodiment is schematically shown in .

[0034] The device 1 is designed to fill beverage containers, not shown here, such as glass or PET bottles, in a beverage filling plant. The device 1 comprises: a valve housing 2 with a valve seat 20; a valve cone 3 movable relative to the valve seat 20; and a swirl body 4 arranged downstream of the valve cone 3 for convecting the The filling product applies a swirl.

[0035] The valve cone 3 is supported on the valve housing 2 via the swirl body 4 such that the swirl body 4 is firmly arranged on the valve housing 2 and the valve c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com