A kind of environment-friendly non-metal mute board and its manufacturing method

A non-metal and non-metal particle technology, applied in the field of building decoration materials, can solve the problems of low sound absorption coefficient, environmental pollution, fiber precipitation, etc., and achieve the effects of good stability in use, simple preparation steps, and easy cleaning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

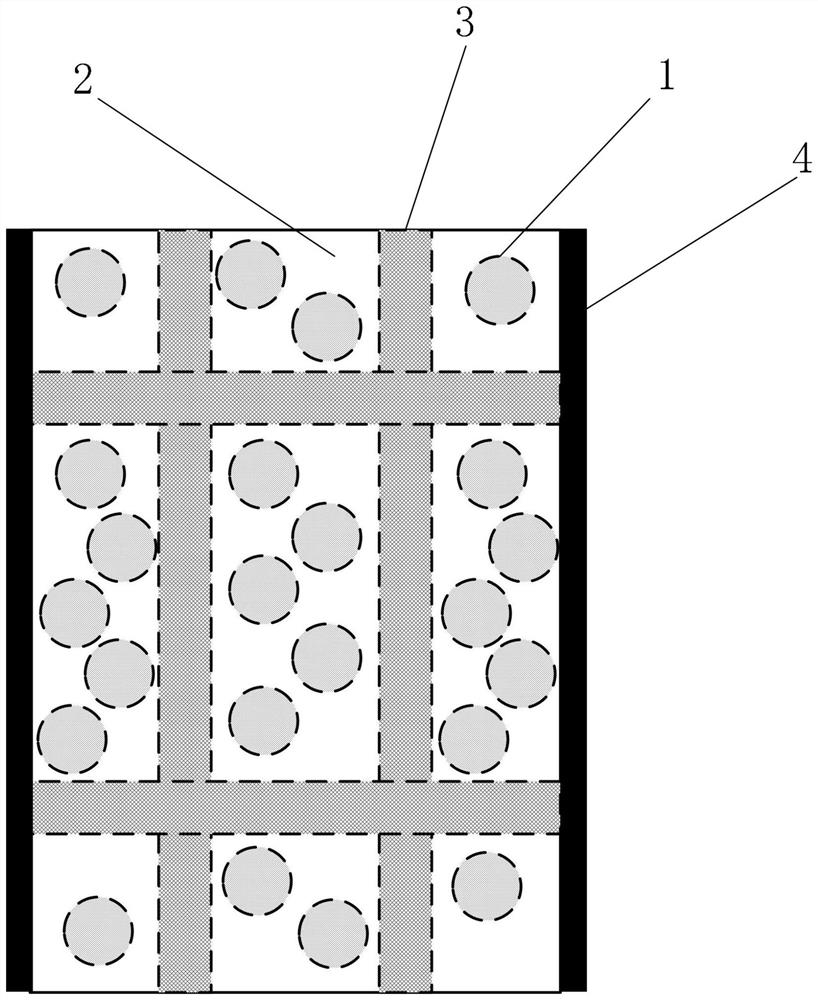

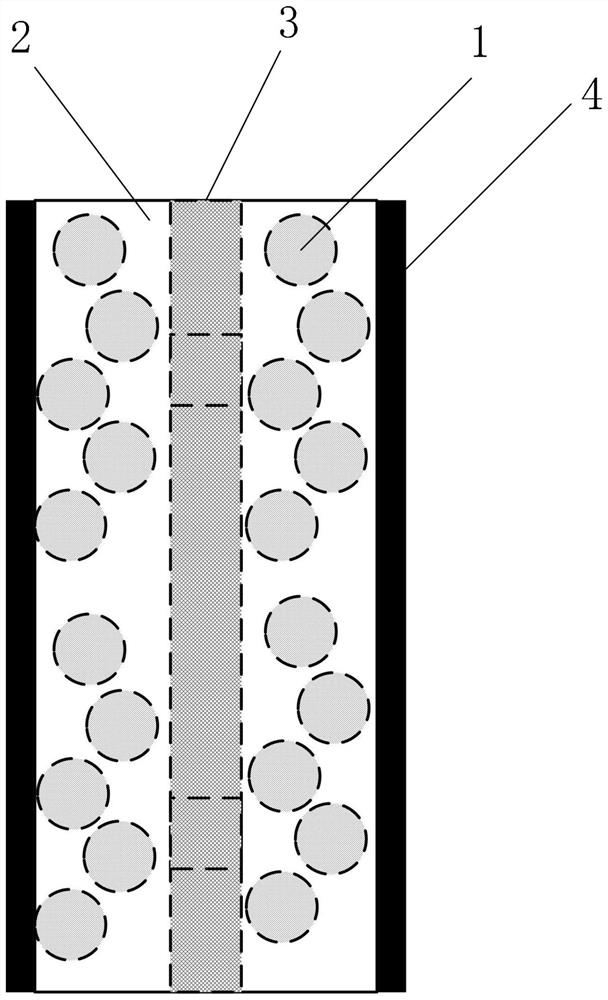

Embodiment 1

[0043] Example 1, according to the use environment and functions of the product in stations, tunnels, etc., the 20mm thick product should have sufficient rigidity and temperature resistance, and the unit weight should be controlled at about 30kg. The non-metallic particles 1 to be added for screening are natural dioxide Silica grit. According to the functional requirements, carry out active modification treatment on the adhesive to form active adhesive 2, the specific content is as follows: polyester polyol 30%, tackifying resin 3%, isocyanate 27%, hydroxymethyl resorcinol (HMR) coupling agent 1.5 %, 3A molecular sieve 6.5%, rutile titanium dioxide 1.0%, bismuth isooctanoate (ALLCHEM 360) 0.05%, low-shrinkage additive 2.5%, micro-quantity whisker carbon-zinc-silicon powder 1.5%, in the reactor by controlling the speed at 1100r / min, the temperature is 35°C and the time is 12min. The modified active adhesive 2 and the natural silica sand were measured at a ratio of 9:50, and t...

Embodiment 2

[0044] Example 2, according to the use environment and functional requirements of the product in the large space ceiling, the unit weight of the 20mm thick product is controlled within 10kg, and the non-metallic particles 1 to be added are screened as floating beads. According to the functional requirements, carry out active modification treatment on the adhesive to form active adhesive 2, the specific content is as follows: polyester polyol 26%, tackifying resin 2%, isocyanate 23%, hydroxymethyl resorcinol (HMR) coupling agent 1.4 %, 5.5% of 3A molecular sieve, 0.9% of rutile titanium dioxide, 0.15% of bismuth isooctanoate (ALLCHEM360), 1.5% of low-shrinkage additive, and 1.6% of micro-quantity whisker carbon-zinc-silicon powder. min, temperature 25°C and time 12min for modification. Measure the modified active adhesive 2 and floating beads according to the ratio of 2:3, and then carry out mixing and stirring treatment, so that the surface of the particles is evenly coated wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| sound absorption coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com