Prestressed concrete box girder structure with frequency modulation liquid damper

A frequency modulation liquid damping, concrete box girder technology, applied in bridges, bridge parts, bridge construction, etc., can solve problems affecting structural safety, and achieve the effects of reducing temperature stress, reducing vibration frequency and amplitude, and reducing structural temperature difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

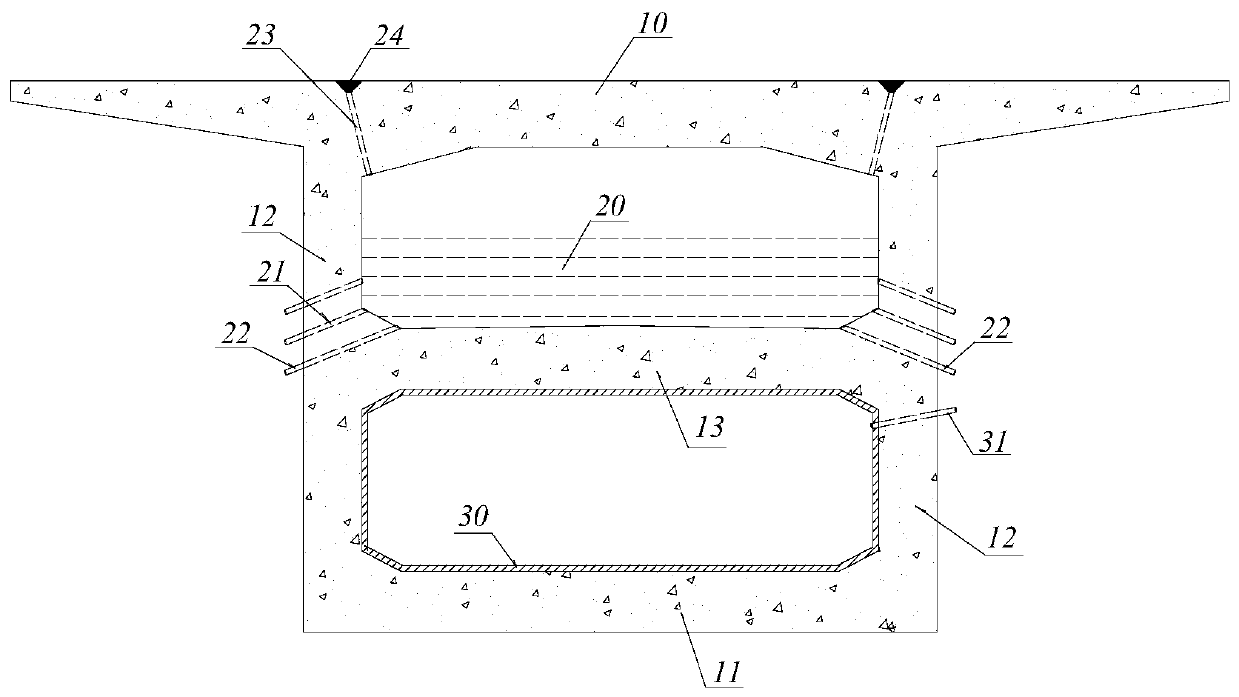

[0013] refer to figure 1 , a prestressed concrete box girder structure with a frequency modulation liquid damper of the present invention, the main body of the box girder structure is composed of a top plate 10, a bottom plate 11 and two side webs 12, and the main body of the box girder structure is arranged with the two side webs 12 A transverse diaphragm 13 consolidated into one body, which divides the internal chamber of the box girder structural body into an upper chamber and a lower chamber. The frequency modulation liquid 20 is injected into the upper chamber to form a frequency modulation liquid damper for absorbing the vibration energy of the structure, and the dynamic side force generated by the liquid in the upper chamber during the sloshing process is used to provide vibration damping effect, effectively reducing the vibration frequency and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com