Circulating water temperature control device for growing single crystal by VGF method and application

A technology of circulating water temperature and growing single crystal, which is applied in the direction of single crystal growth, crystal growth, single crystal growth, etc. It can solve the problem of how much compactness of insulation cotton and the degree of uniformity of quartz sand is difficult to control, and crystals are prone to flower crystals or crystals , high single crystal dislocation density and other problems, to achieve the effect of shortening the materialization time, reducing heat inconsistency, reducing production time and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

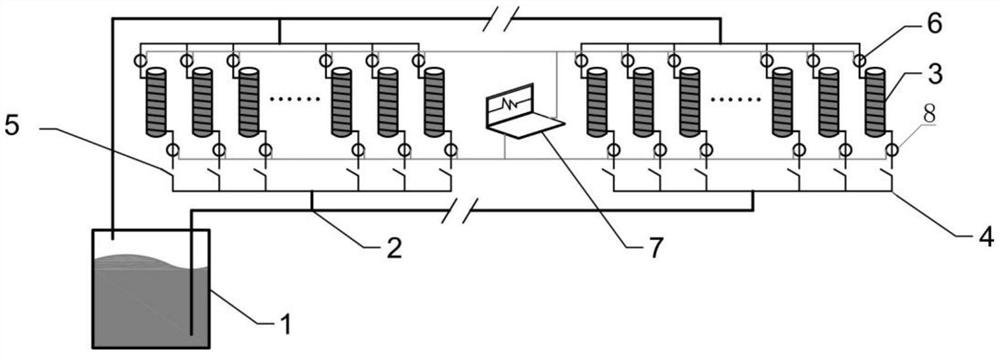

[0029] Such as figure 1 As shown, a circulating water temperature control device for growing single crystals by the VGF method includes a single crystal furnace 3 and a circulating water system. The circulating water system includes a circulating water tank 1, a main pipeline 2 and a branch pipeline 4. The circulating water passes through the main pipeline in turn 2. The branch pipeline 4 to the single crystal furnace 3 passes through the single crystal furnace 3 and then flows back to the circulating water tank 1 through the branch pipeline 4 and the main pipeline 2 in sequence. 5 and a temperature control device 8, a temperature measuring device 6 is arranged on the water outlet pipe of the single crystal furnace 3.

[0030] During specific operation, the circulating water flows out from the main pipeline of the circulating water tank and enters the branch pipeline n (n=1, 2, 3, 4...), the branch pipeline can be divided into a first-level branch pipeline, a second-level bran...

Embodiment 2

[0033] According to the type and model of the single crystal grown, different circulating water temperatures need to be set during the growth of the single crystal so as to assist the growth of the single crystal in real time. In the present invention, the grown single crystal is InP with a size of 6 inches. The equipment model of the single crystal furnace used is GGQ, specifically combined with the circulating water temperature control device of the present invention, the whole process of crystal growth under this equipment model is regulated.

[0034] When the crystal is in the stage of heating the material: the temperature in the furnace increases from about 30°C to the melting point of the crystal, and the heating process takes 40 hours. When the temperature in the furnace reaches the melting point of the crystal, a constant temperature time of 10 hours is required to fully melt the material. Strong heat preservation and low longitudinal temperature gradient are required d...

Embodiment 3

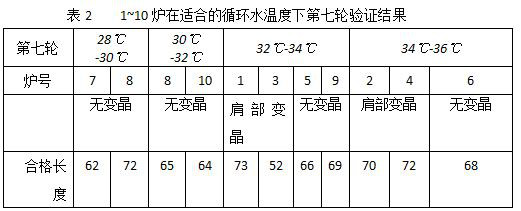

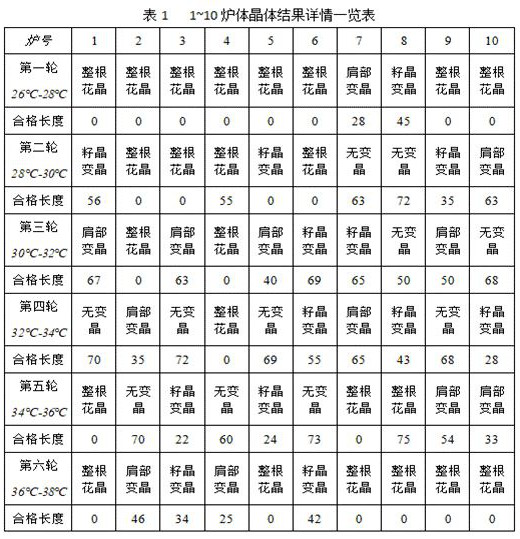

[0038] The application of the circulating water temperature control device in judging the suitable circulating water temperature of different single crystal furnaces during the single crystal growth process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com