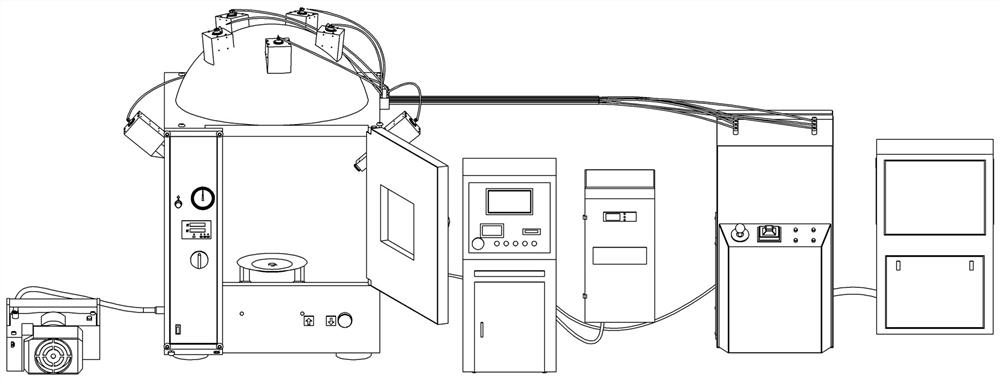

Laser source high-temperature heat treatment device and heat treatment method

A high-temperature heat treatment, laser source technology, applied in electric heating devices, electrical components, etc., can solve the problems of unsatisfactory heating effect of transparent objects, large working space, slow heating speed, etc., achieving significant energy saving effect, improving efficiency, and heating speed. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

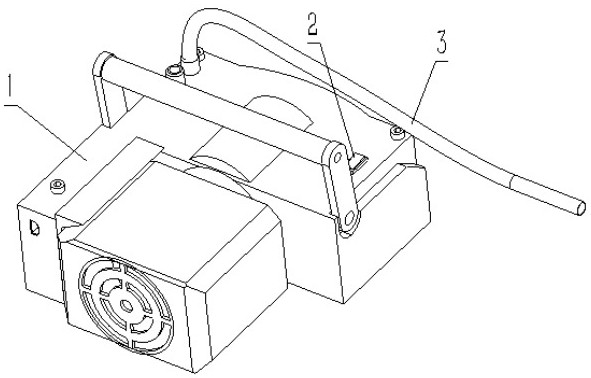

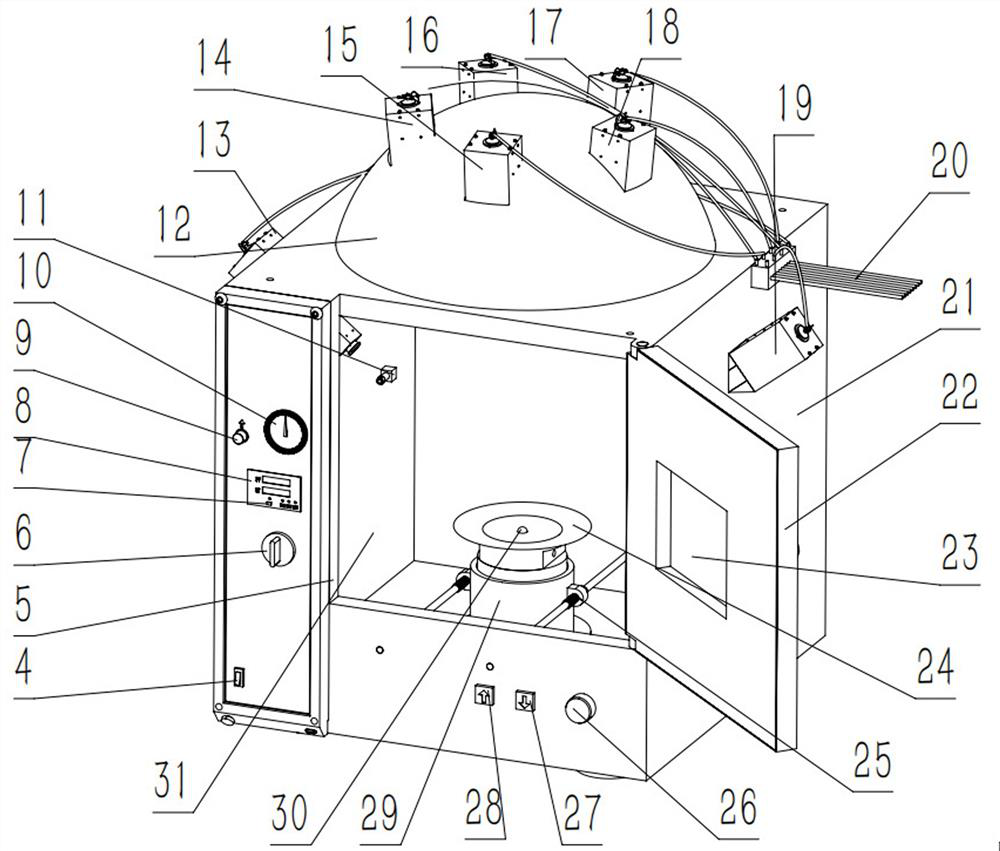

[0035] As shown in the drawings, a laser source high-temperature heat treatment device includes a closed metal cavity 21, a laser emitter 34, a cooling device 35, and a control system. The control system includes an industrial control computer 32 and a distribution box 33, the distribution box 33 is connected with the industrial control computer 32, and the industrial control computer 32 is connected and controls the metal chamber 21, the laser emitter 34 and the cooling device 35; the laser emitter 34 passes The laser tube 20 is connected in parallel with a first laser irradiation group and a second laser irradiation group, wherein the first laser irradiation group includes the second laser irradiation head 14, the third laser irradiation head 15, the fourth laser irradiation head 16, the fifth laser irradiation head 17 and the sixth laser irradiation head 18, the second laser irradiation group includes the first laser irradiation head 13 and the seventh laser irradiation head...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com