Assembly type steel bar framework rapid forming lap joint structure

A steel skeleton and joint structure technology, applied in the direction of structural elements, building components, building structures, etc., can solve the problems of long length of steel bars, uneven binding and fixing of steel bars, heavy quality, etc., and achieve the advantages of adjusting side length and convenient and fast binding Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without making creative efforts belong to the protection scope of the present invention.

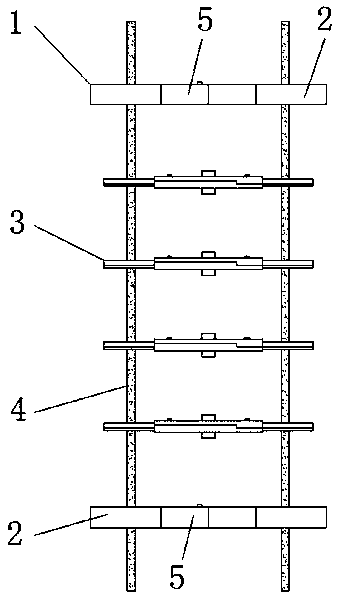

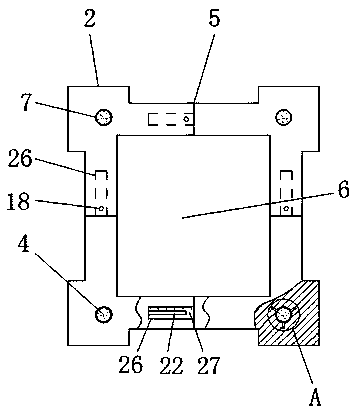

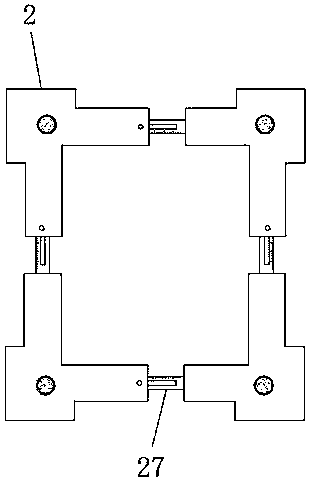

[0034] see Figure 1-11, the present invention provides a technical solution: an assembled steel bar skeleton rapid prototyping lap joint structure, including a lap joint structure body 1, an outer lap joint plate 2, a middle lap joint frame 3, steel bars 4, slots 5, and inner cavity holes 6. Limit hole 7, top tight block 8, limit chute 9, spring 10, top tight mouth 11, first support frame 12, second support frame 13, rotating shaft 14, connection groove 15, first adjustment groove 16. First adjusting frame 17, locking knob 18, rotating groove 19, clamping block 23, rotating shaft 21, top tightening groove 22, clamping port 20, pushing part 24, clamping part 25, second adjusting groove 26 With the second adjustment frame 27, the upper and lower ends of the lap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com