Sectional material and formwork structure

A profile, in-line technology, applied in the direction of formwork/formwork components, building structure, formwork/formwork/work frame, etc., can solve the problems of assembly, disassembly, labor and time, damage, profile deformation, etc., to achieve easy disassembly Effort-saving, easy assembly or disassembly, the effect of reducing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

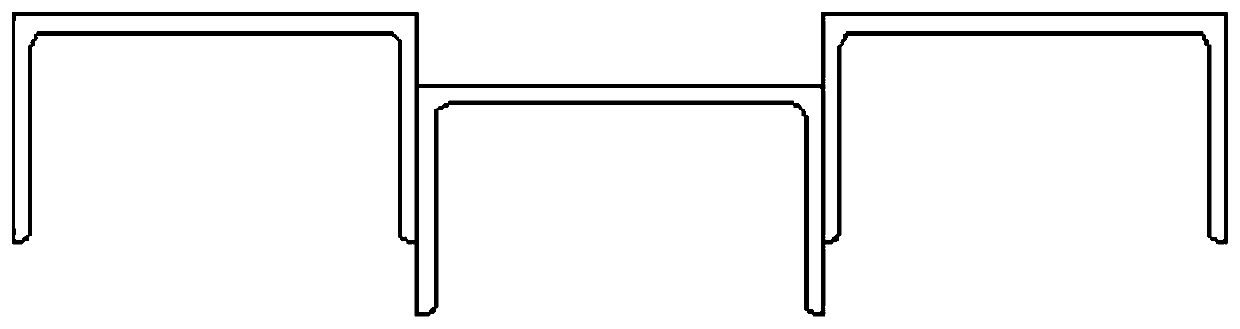

Image

Examples

Embodiment 1

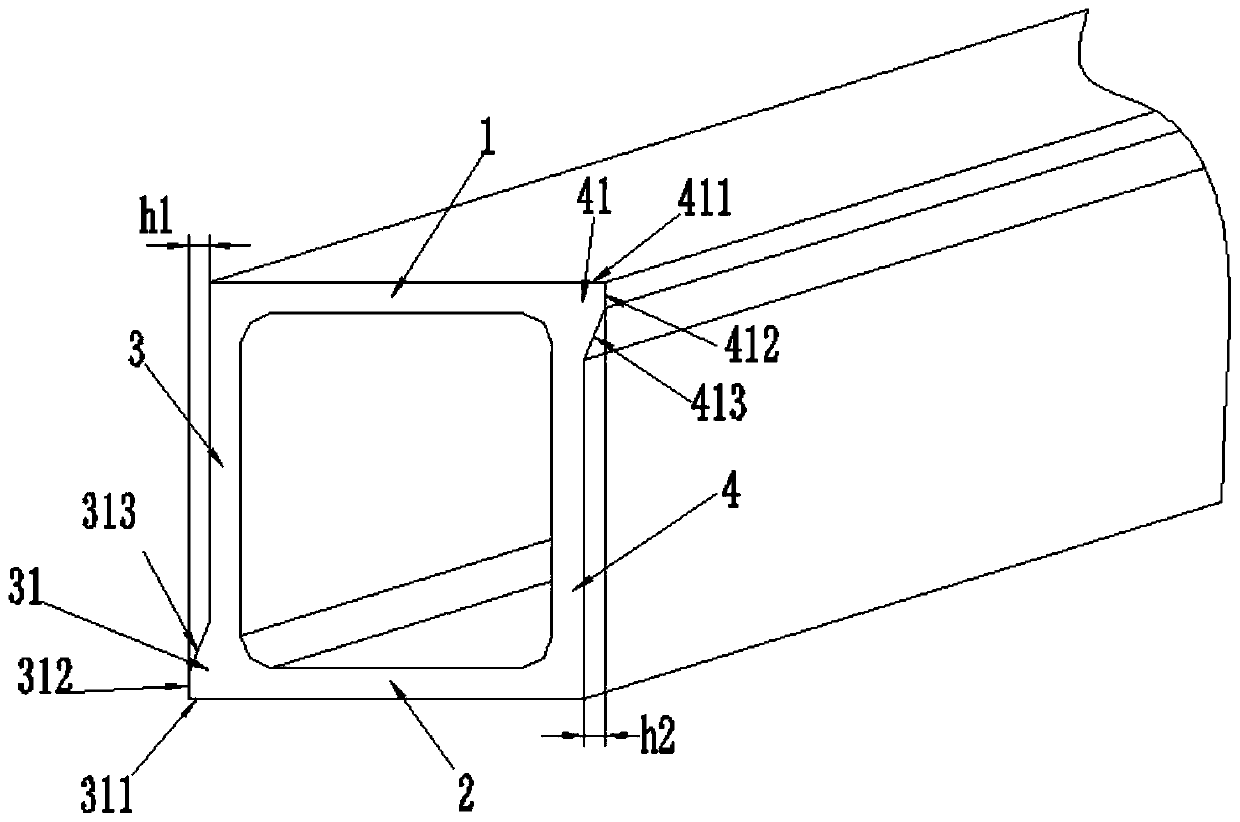

[0063] Such as figure 2 As shown, a profile provided in this embodiment includes a working edge 1 , a first splicing edge 3 , a second splicing edge 4 and a structural edge 2 . The first splicing edge 3 and the second splicing edge 4 are respectively connected to both ends of the working edge 1, and the structural edge 2 is connected between the first splicing edge 3 and the second splicing edge (4) to form Closed structure (square box).

[0064] The outer surface of the end of the first splicing edge 3 away from the working edge 1 is provided with a protruding first splicing edge 31 along the length direction, and the second splicing edge 4 is adjacent to the outer surface of the end of the working edge 1 A second splicing edge 41 protruding along the length direction is provided on the top, and the protruding height h1 of the first splicing edge 31 is equal to the protruding height h2 of the second splicing edge 41 .

[0065] The first joint edge 3 includes a first top su...

Embodiment 2

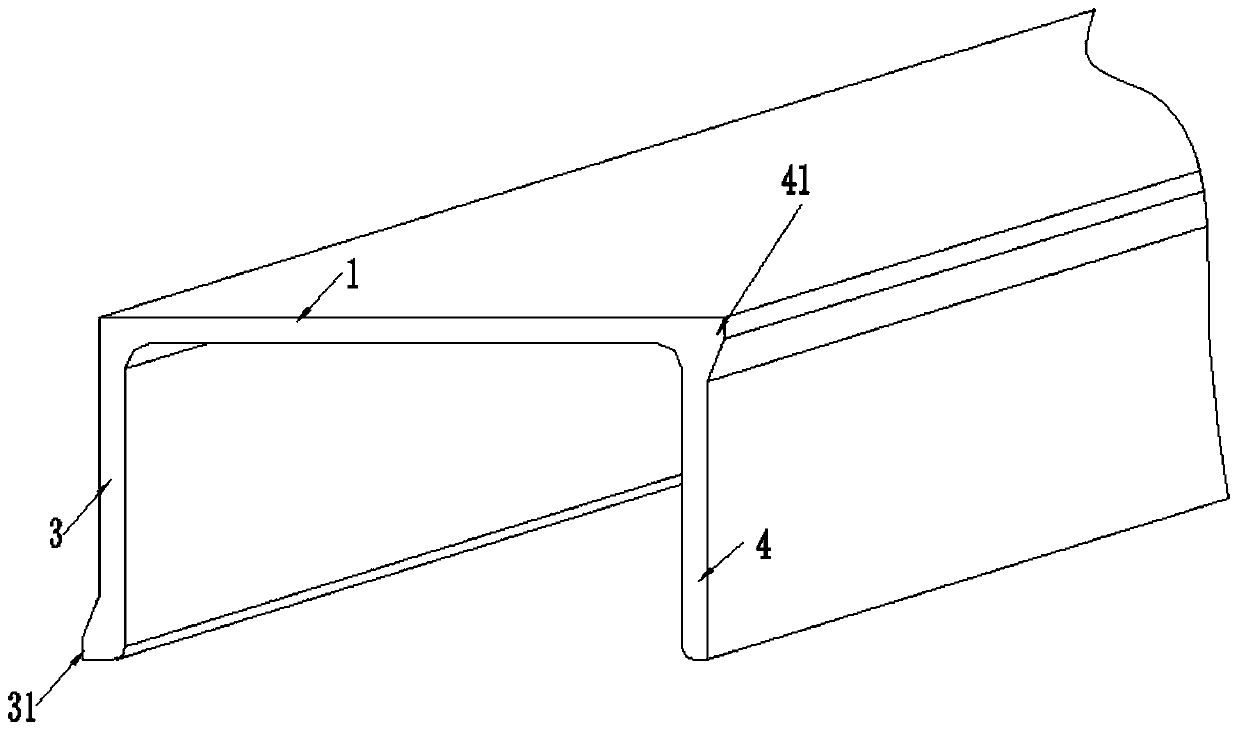

[0068] Such as image 3 As shown, a profile provided in this embodiment includes a working edge 1, a first splicing edge 3 and a second splicing edge 4, the first splicing edge 3 is connected to one end of the working edge 1, and the second splicing edge The side 4 is connected to the other end of the working side 1, and the working side 1, the first joining side 3 and the second joining side 4 form a U-shaped structure with one side closed and one side open.

[0069] The outer surface of the end of the first splicing edge 3 away from the working edge 1 is provided with a protruding first splicing edge 31 along the length direction, and the second splicing edge 4 is adjacent to the outer surface of the end of the working edge 1 A second splicing rib 41 protruding from the upper portion is provided along the length direction. The structures of the first joint edge 31 and the second joint edge 41 are the same as those in the first embodiment.

Embodiment 3

[0071] Such as Figure 4 As shown, the second embodiment is repeated. The difference from the second embodiment is that a first groove 33 is provided on the outer surface of the first joint edge 3, and a second groove 33 is provided on the outer surface of the second joint edge 4. Groove 43. Both the first groove 33 and the second groove 43 extend along the length direction of the profile.

[0072] The number of the first grooves 33 is multiple, the number of the second grooves 43 is multiple, the positions and opening sizes of the first grooves 33 and the second grooves 43 All symmetrical.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com