Solid control processing device and processing method capable of preventing mud from falling to ground

A technology for processing equipment and mud, which is used in earth-moving drilling, wellbore/well components, construction, etc., can solve the problems of repeated processing of drilling fluid, increase the difficulty of processing, and high equipment failure rate, and achieve excellent mud performance. , to avoid blockage, the effect of high treatment efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0051] It should be noted that the structures, proportions, sizes, etc. shown in the drawings attached to this specification are only used to match the content disclosed in the specification, for those who are familiar with this technology to understand and read, and are not used to limit the implementation of the present invention Any modification of the structure, change of the proportional relationship or adjustment of the size shall still fall within the scope of the technical content disclosed in the present invention without affecting the effect and the purpose of the present invention. within the scope covered.

[0052] At the same time, terms such as "upper", "lower", "left", "right", "middle" and "one" quoted in this specification are only for the convenience of description and are not used to limit this specification. The practicable scope of the invention and the change or adjustment of its relative relationship shall also be regarded as the practicable scope of the...

Embodiment

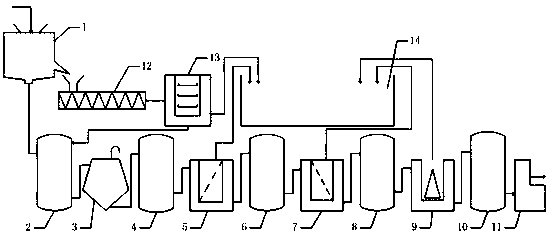

[0054] combine Figure 1-3 , a solid control treatment device for mud not falling to the ground, comprising: a vibrating screen 1, a vacuum degasser 3, a desander 5, a desilter 7, and a centrifuge 9, and the waste mud pipeline is connected to the inlet of the vibrating screen 1 ,

[0055] Also includes: No. 1 mud tank 2, No. 2 mud tank 4, No. 3 mud tank 6, No. 4 mud tank 8, No. 5 mud tank 10, mud pump 11, screw conveyor 12, cuttings dryer 13, solid Phase collection box 14;

[0056] The solid phase outlet of the vibrating screen 1 is connected to the feed port of the screw conveyor 12, and the discharge port of the screw conveyor 12 is connected to the inlet of the cuttings drying machine 13, and the cuttings drying The solid phase outlet of the dryer 13 is connected to the inlet of the solid phase collection box 14, the liquid phase outlet of the drill cuttings dryer 13 is connected to the inlet of the No. 1 mud tank 2,

[0057] The liquid phase outlet of the vibrating scre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Mesh | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap