A magnetic field drive device for a micro-nano robot for a microscope with air-cooling function

A magnetic field drive, microscope technology, applied in the direction of electromagnet without armature, transformer/inductor parts, transformer/reactor installation/support/suspension, etc. Affecting problems such as micro-nano robot observation, to achieve the effect of large magnetic field strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

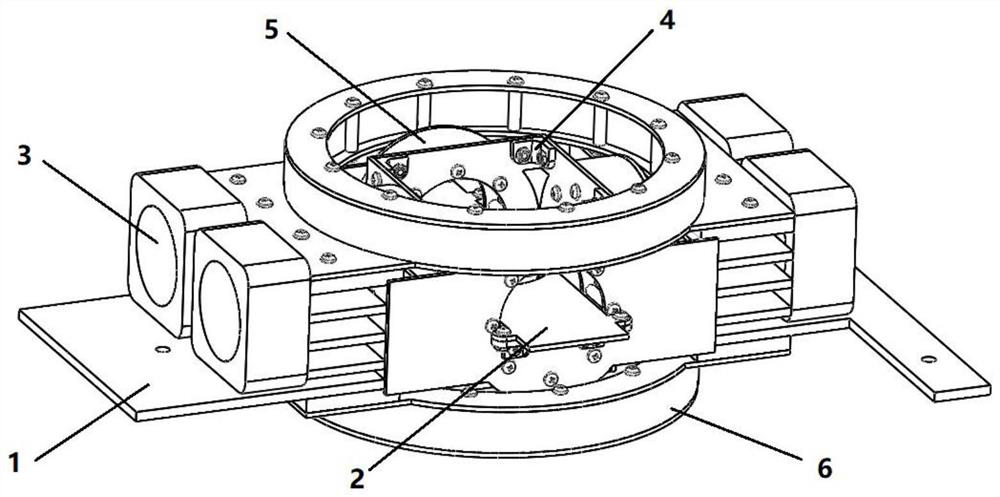

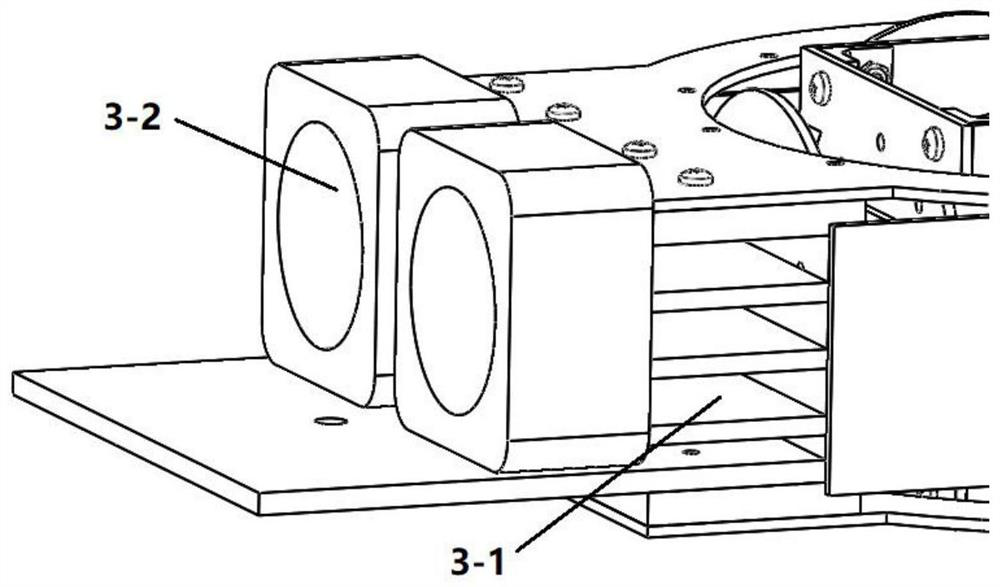

[0030] Combine below Figure 1-8 Describe this embodiment, a magnetic field drive device for a micro-nano robot with an air-cooling function, including a bottom support structure 1, a stage support structure 2, an air-cooled heat sink 3, a special-shaped Helmholtz coil 5, and a Z-direction A standard Helmholtz coil 6, the bottom support structure 1 is fixedly connected with a special-shaped Helmholtz coil 5, the special-shaped Helmholtz coil 5 is fixedly connected with a stage support structure 2, and the special-shaped Helmholtz coil The upper and lower sides of the 5 are fixedly connected with Z-direction standard Helmholtz coils 6, and both sides of the Y-direction of the special-shaped Helmholtz coil 5 are provided with air-cooled heat dissipation devices 3; The design can meet the requirements of the limited installation space of the microscope, and can generate a magnetic field with a large magnetic field strength and a wide range of uniform magnetic field according to t...

specific Embodiment approach 2

[0031] Combine below Figure 1-8 Describe this embodiment, this embodiment will further explain Embodiment 1, the special-shaped Helmholtz coil 5 is composed of two X-direction special-shaped Helmholtz coils 5-1 and two Y-direction special-shaped Helmholtz coils 5 -2 components, X-direction special-shaped Helmholtz coil 5-1 and Y-direction special-shaped Helmholtz coil 5-2 have different center distances and coil theoretical radii; standard Helmholtz coils require coil theoretical radius and coil center The distances are equal. When the theoretical radius of the coil is determined, the center distance between the coils is determined accordingly. However, the diameter of the lens of the microscope is large, and the lens cannot be placed in the center of the coil. It is necessary to adjust the center distance between the coils to make the distance between the coil centers of the Helmholtz coil Not equal to the theoretical radius of the coil, the standard Helmholtz coil is design...

specific Embodiment approach 3

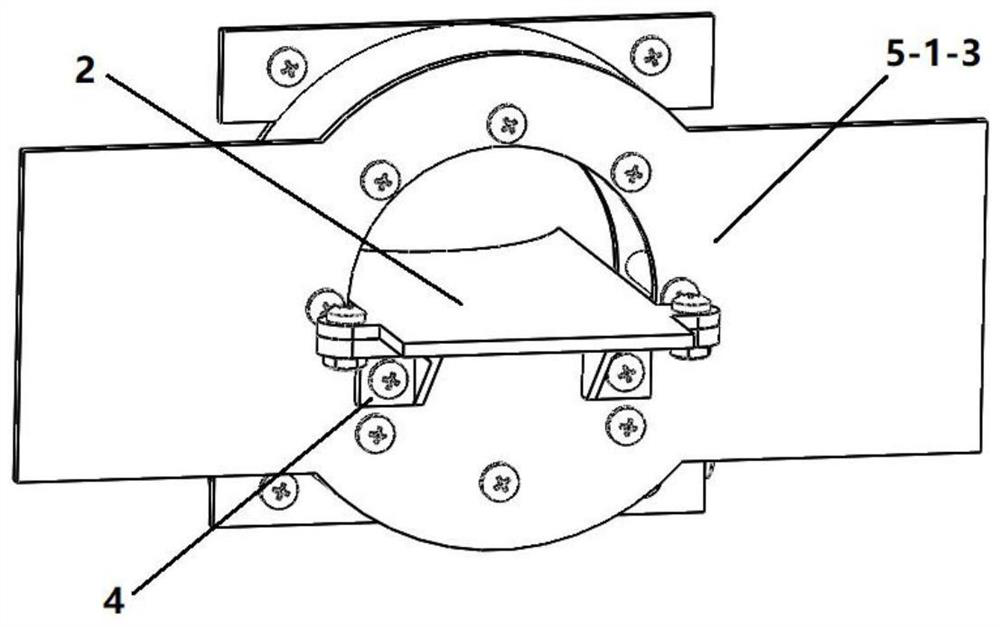

[0032] Combine below Figure 1-8This embodiment will be described. This embodiment will further describe the second embodiment. The X-direction special-shaped Helmholtz coil 5-1 includes an X-direction special-shaped Helmholtz coil inner support plate 5-1-1, a fixed connection copper Column 5-1-2 and X-direction special-shaped Helmholtz coil outer support plate 5-1-3, X-direction special-shaped Helmholtz coil inner support plate 5-1-1 and X-direction special-shaped Helmholtz coil outer The support plates 5-1-3 are connected by a plurality of fixedly connected copper columns 5-1-2, and the outer side of the plurality of fixedly connected copper columns 5-1-2 and the inner support plate 5- A U-shaped groove is formed between 1-1 and the outer support plate 5-1-3 of the X-direction special-shaped Helmholtz coil, and an X-direction special-shaped Helmholtz coil is wound in the U-shaped groove.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com