Circuit breaker

A technology for circuit breakers and moving contacts, applied in circuits, parts of protection switches, electrical components, etc., can solve the problems of the coil of the circuit breaker being burned out, affecting the reliability of the circuit breaker, and the slow breaking speed of the breakpoint, etc. Achieve the effect of improving reliability, simple structure, and improving action speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The following is attached Figures 1 to 18 The given examples further illustrate the specific implementation of the circuit breaker created by the present invention. The circuit breaker created by the present invention is not limited to the description of the following embodiments.

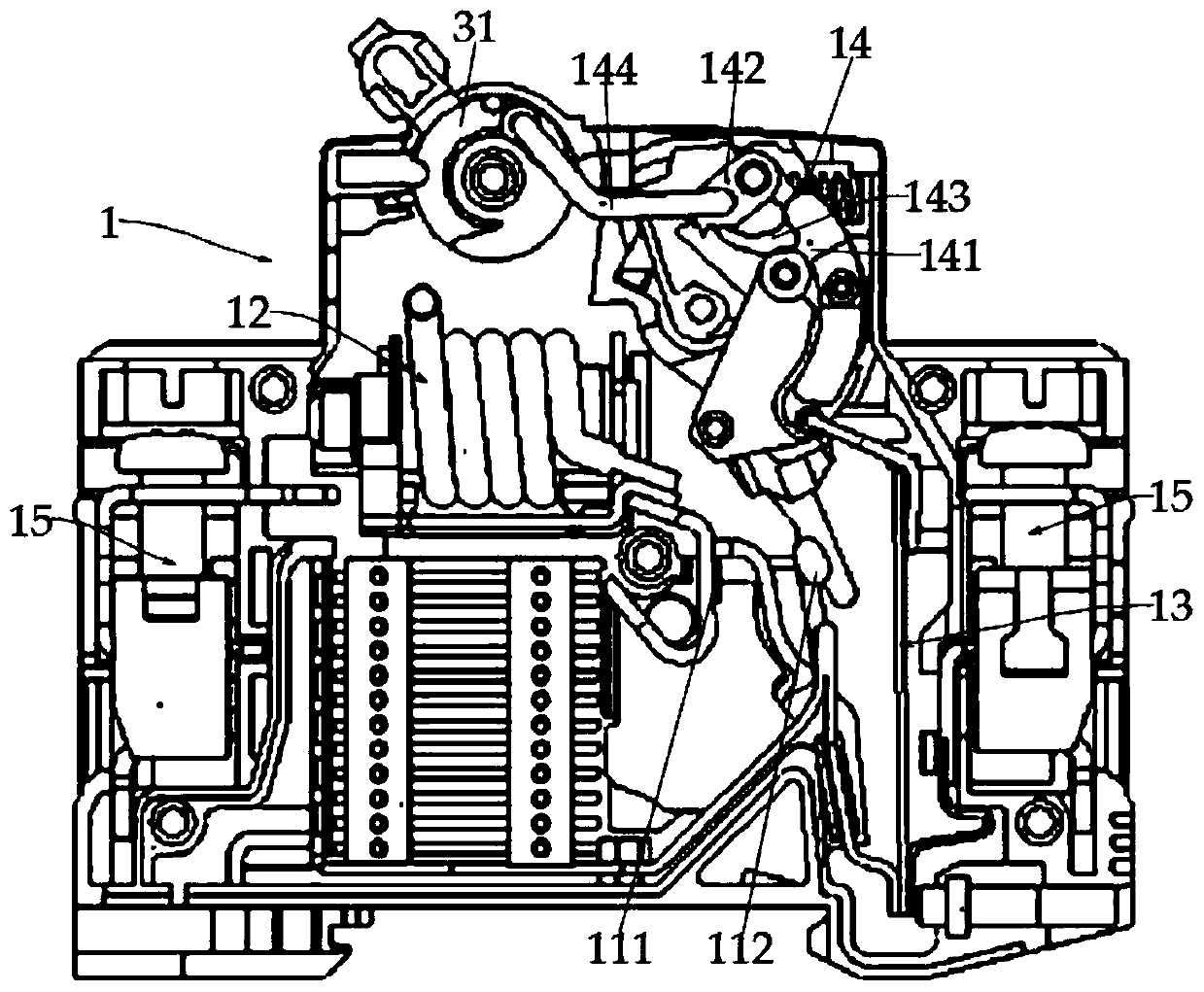

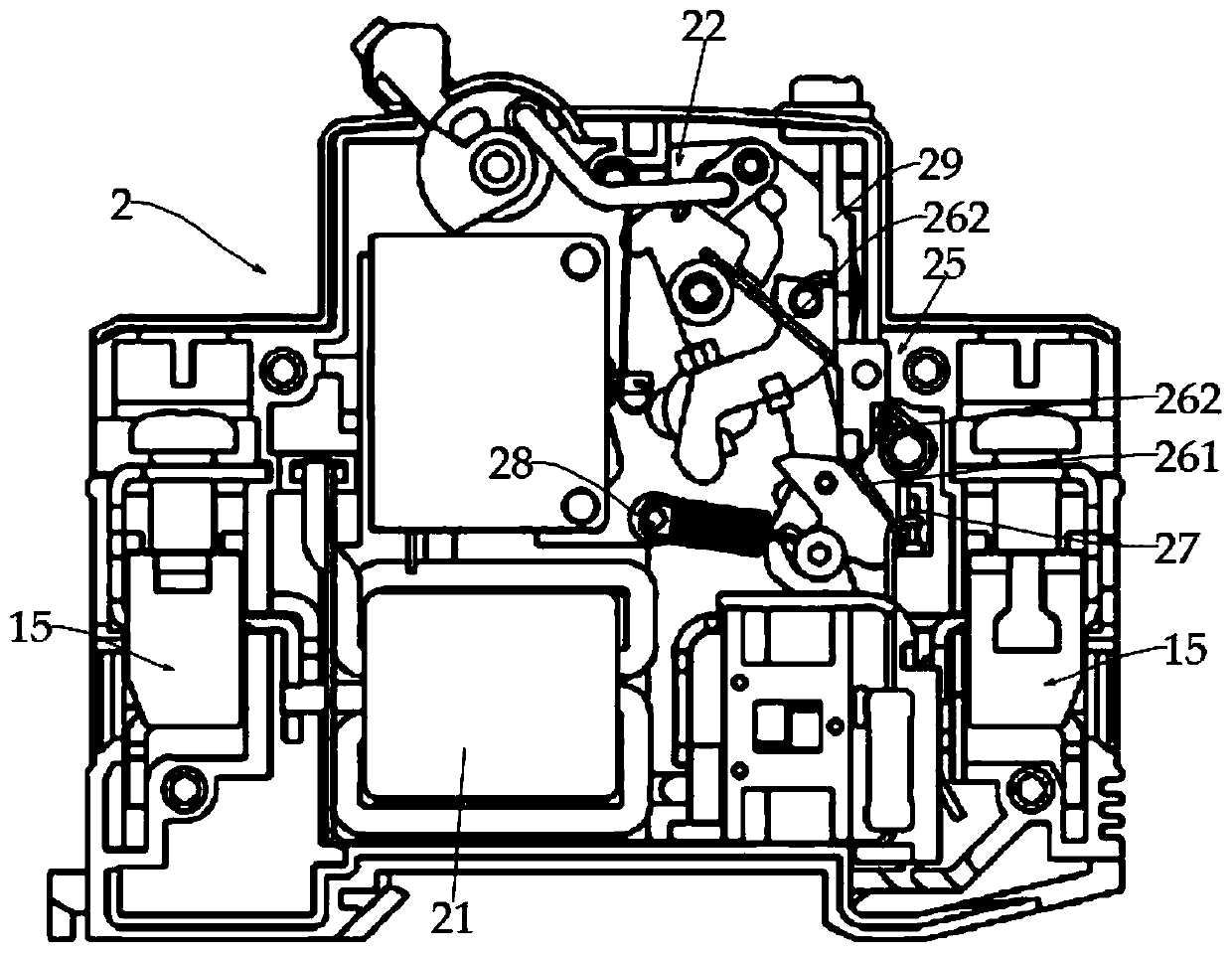

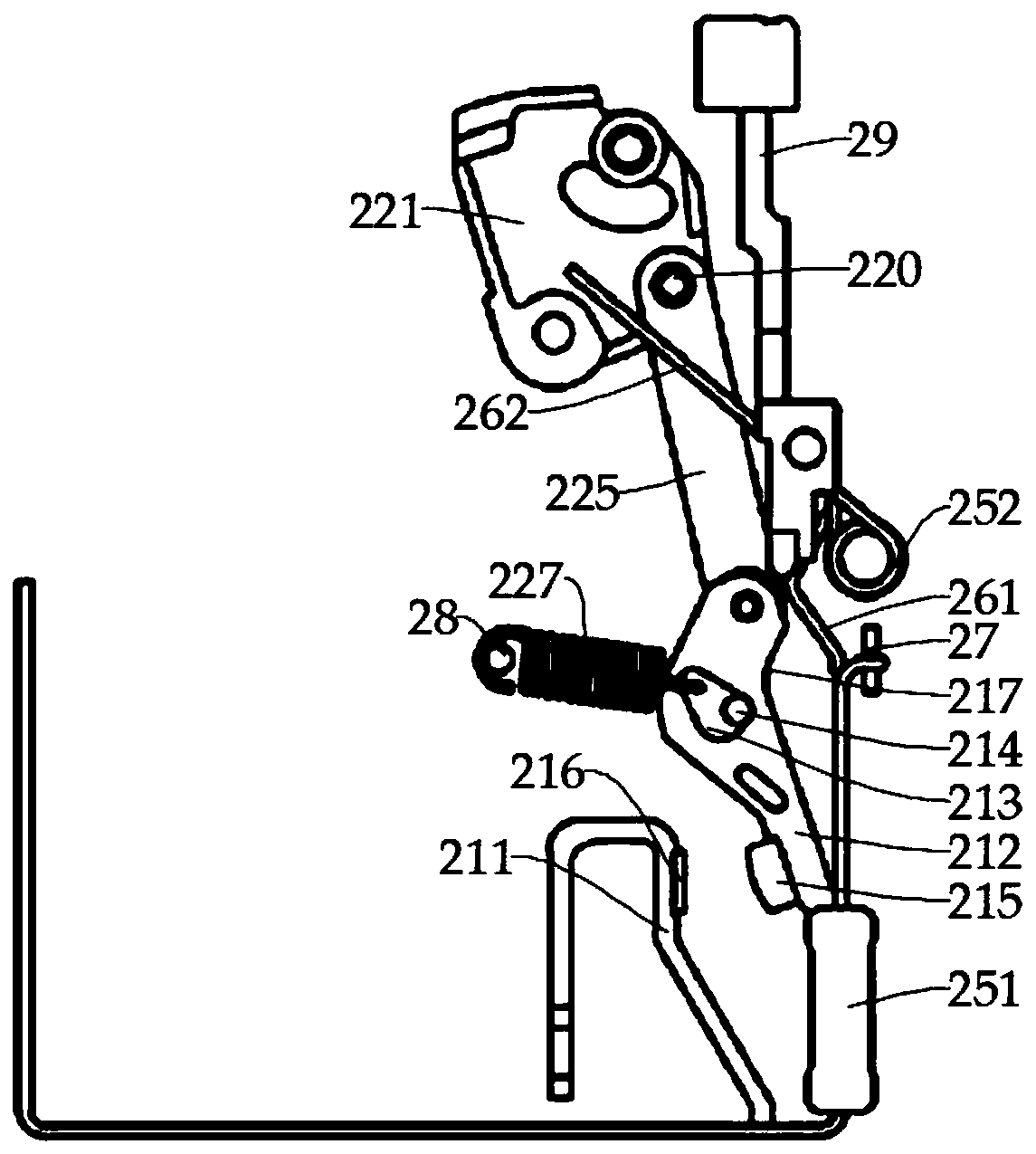

[0047] Such as Figure 1-2 As shown, the circuit breaker created by the present invention includes a casing and a circuit breaker phase pole 1 and a leakage protection pole 2 arranged side by side on both sides of the casing, and a partition 32 is provided between the circuit breaker phase pole 1 and the leakage protection pole 2 , the phase pole 1 of the circuit breaker includes a static contact 111 and a moving contact 112 that are oppositely arranged and connected to the circuit respectively. The moving contact 112 is installed on the phase pole operating mechanism 14 to swing and cooperate with the static contact 111. 2 Including zero-sequence current transformer 21, leakage operating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com