Patents

Literature

43 results about "Current Leakage Testing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Leakage Current Tester. Hipot is an abbreviation for high potential. Traditionally, Hipot is a term given to a class of electrical safety testing instruments used to verify electrical insulation in finished appliances, cables or other wired assemblies, printed circuit boards, electric motors, and transformers.

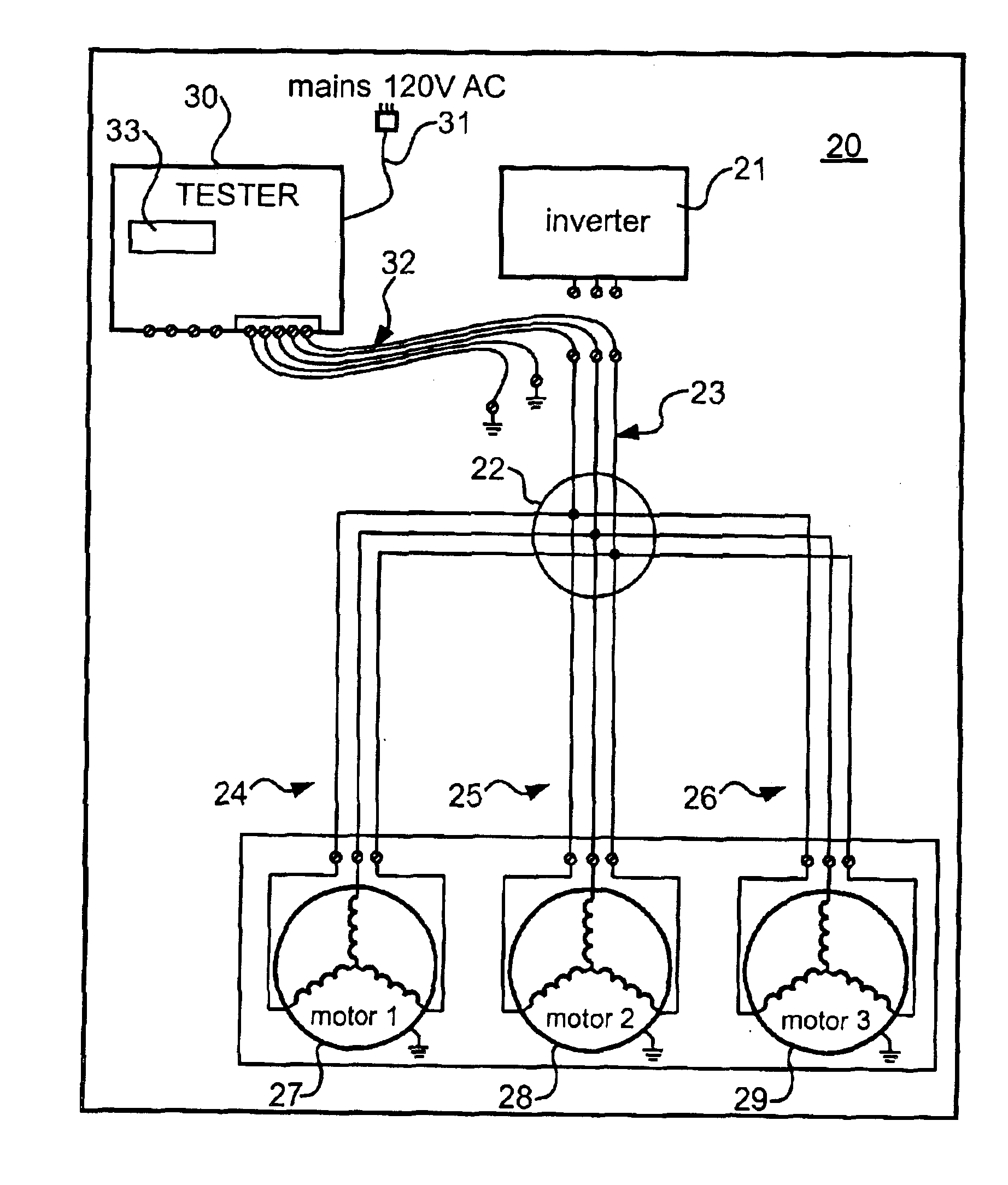

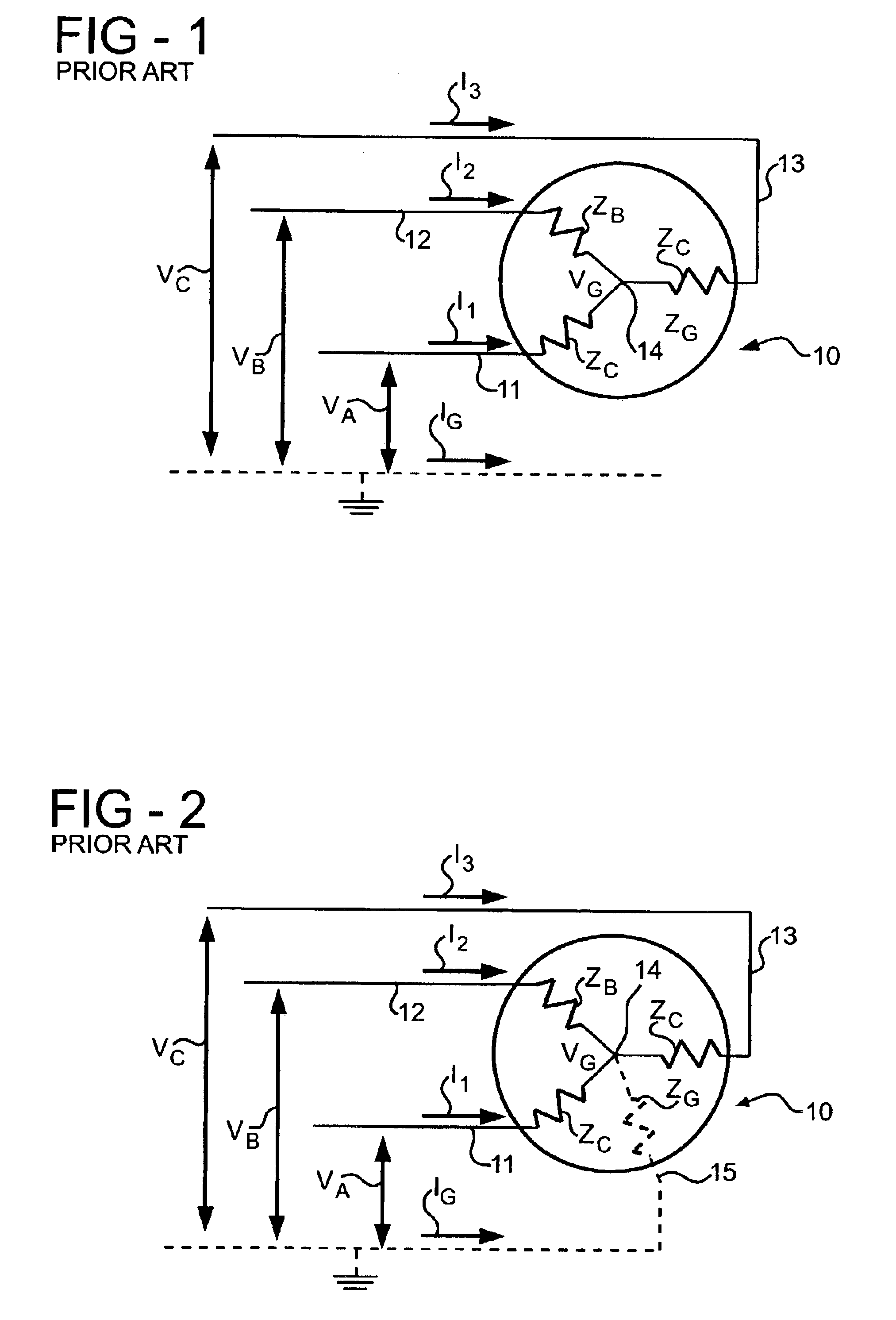

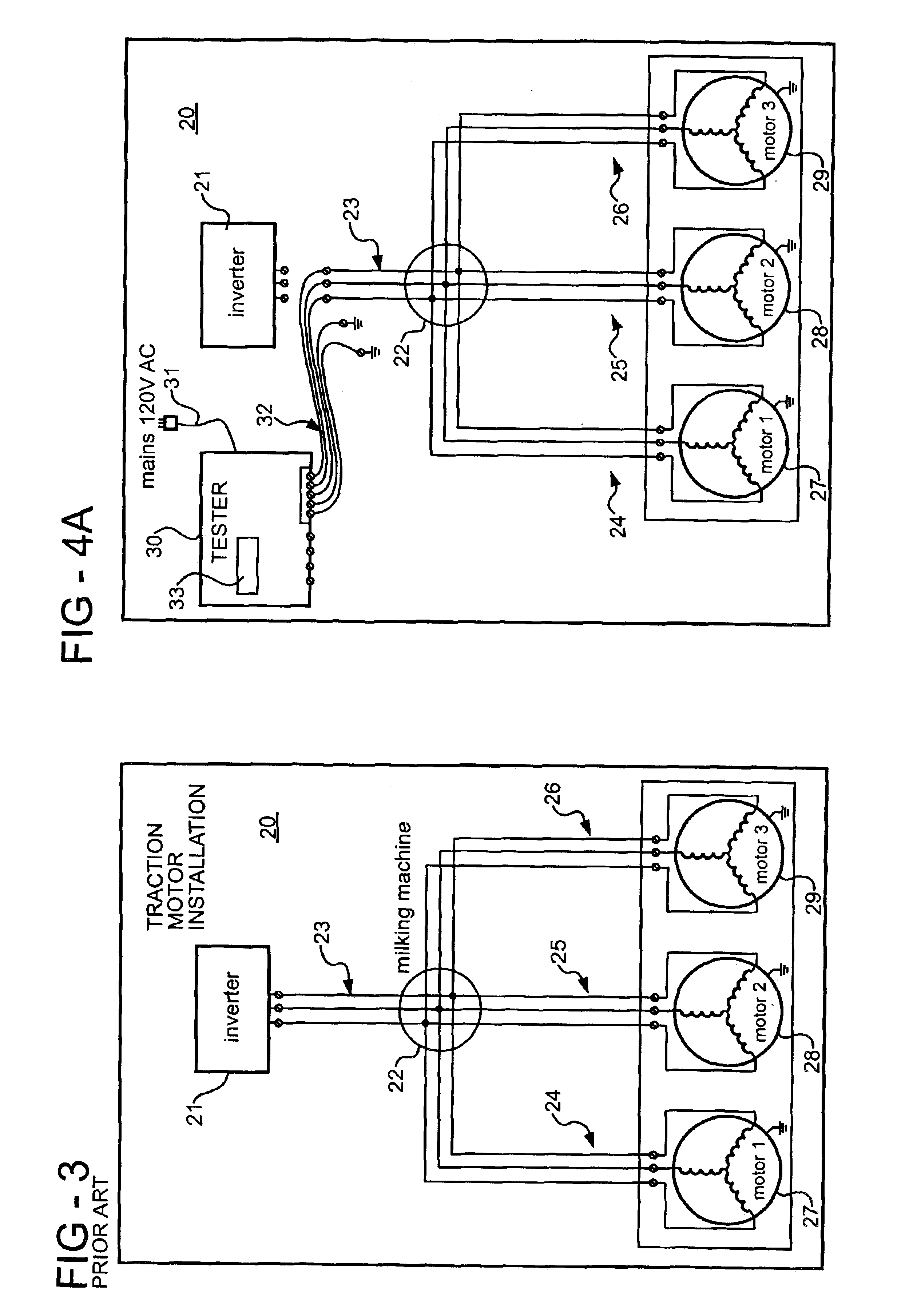

Traction motor fault detection system

InactiveUS6930490B2Reduce mean time between failuresMotor/generator/converter stoppersDC motor speed/torque controlElectric cablesElectrical current

A method of detecting faults in a traction motor installation having a plurality of AC traction motors powered from a common power source, each of the traction motors being connected by associated motor cables to a cable junction and the common power source being connected to the cable junction by main cables, includes disconnecting the power source from the main cables and performing initial short circuit to ground, short circuit between phases and leakage to ground tests on the traction motors through the main cables. When a fault is detected by the initial tests, at least one detailed test is performed by applying a predetermined voltage to the main cables and sensing current flow in the motor cables connected to each of the motors. The detailed test is one of a detail short circuit to ground test, a detail short circuit phase to phase test, and a detail leakage to ground test.

Owner:ELECTRO-MOTIVE DIESEL

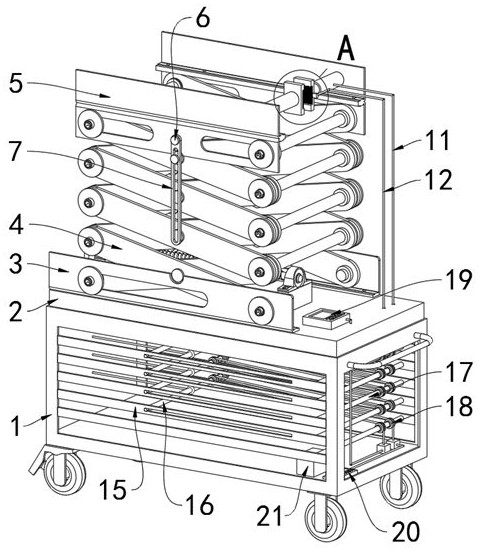

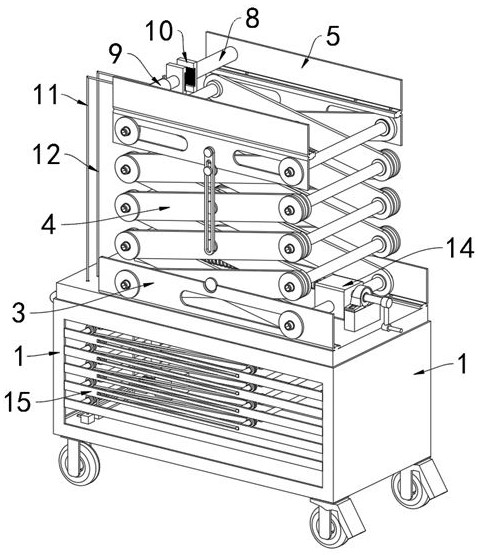

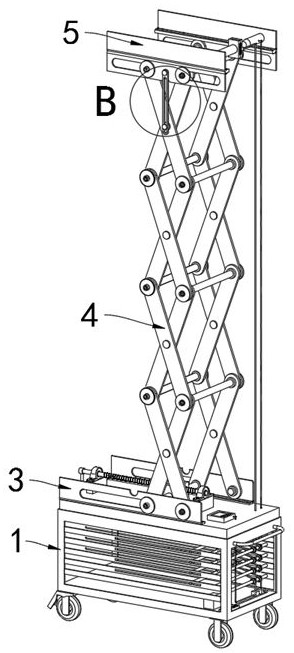

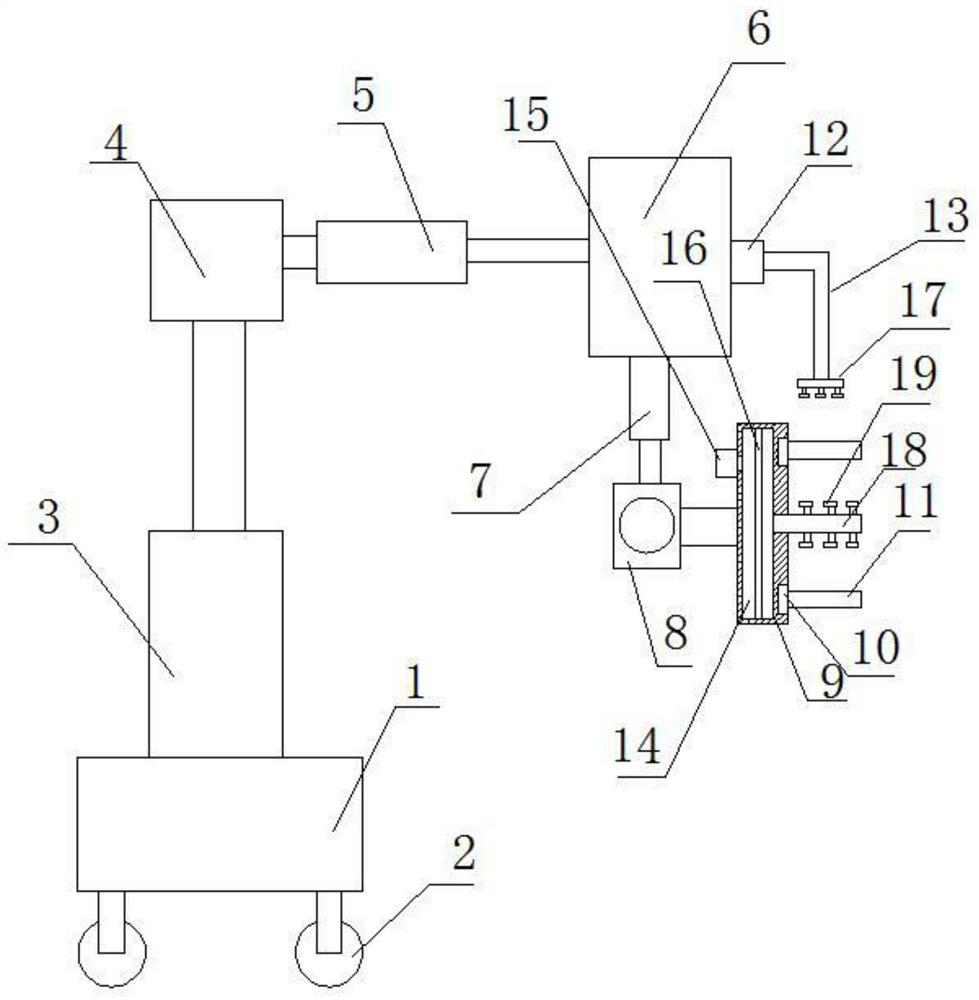

Insulativity detection device for cable maintenance

InactiveCN112230110AReduce fatigueThe test result is accurateTesting dielectric strengthLifting framesTester deviceCurrent Leakage Testing

The invention discloses an insulativity detection device for cable maintenance, relates to the technical field of insulativity detection, and solves the problems that the operation is too tired when an erected cable is detected at present, and the wire take-up and pay-off are very inconvenient when the wire take-up and pay-off are detected. The insulativity detection device comprises a vehicle body; a supporting plate is fixedly arranged at the top of the vehicle body; four first supporting rods are installed among the four sets of side supporting plates at the top in a sliding mode. Five second supporting rods are fixedly connected to the right sides between the five sets of side supporting plates in a welded mode. The outer sides of the four first supporting rods and the outer sides of the five second supporting rods are each rotationally provided with two rotating wheels. An electric leakage tester is further fixedly mounted on the right side of the top of the supporting plate. Thedevice is supported by the shear fork mechanism during detection, a detector does not need to hold the device by hand all the time, the fatigue degree of workers is greatly reduced, more labor is saved during detection, manual operation is not needed during winding of a wire, the wire can be automatically pulled into the vehicle body, and the winding convenience is greatly improved.

Owner:胡丹萍

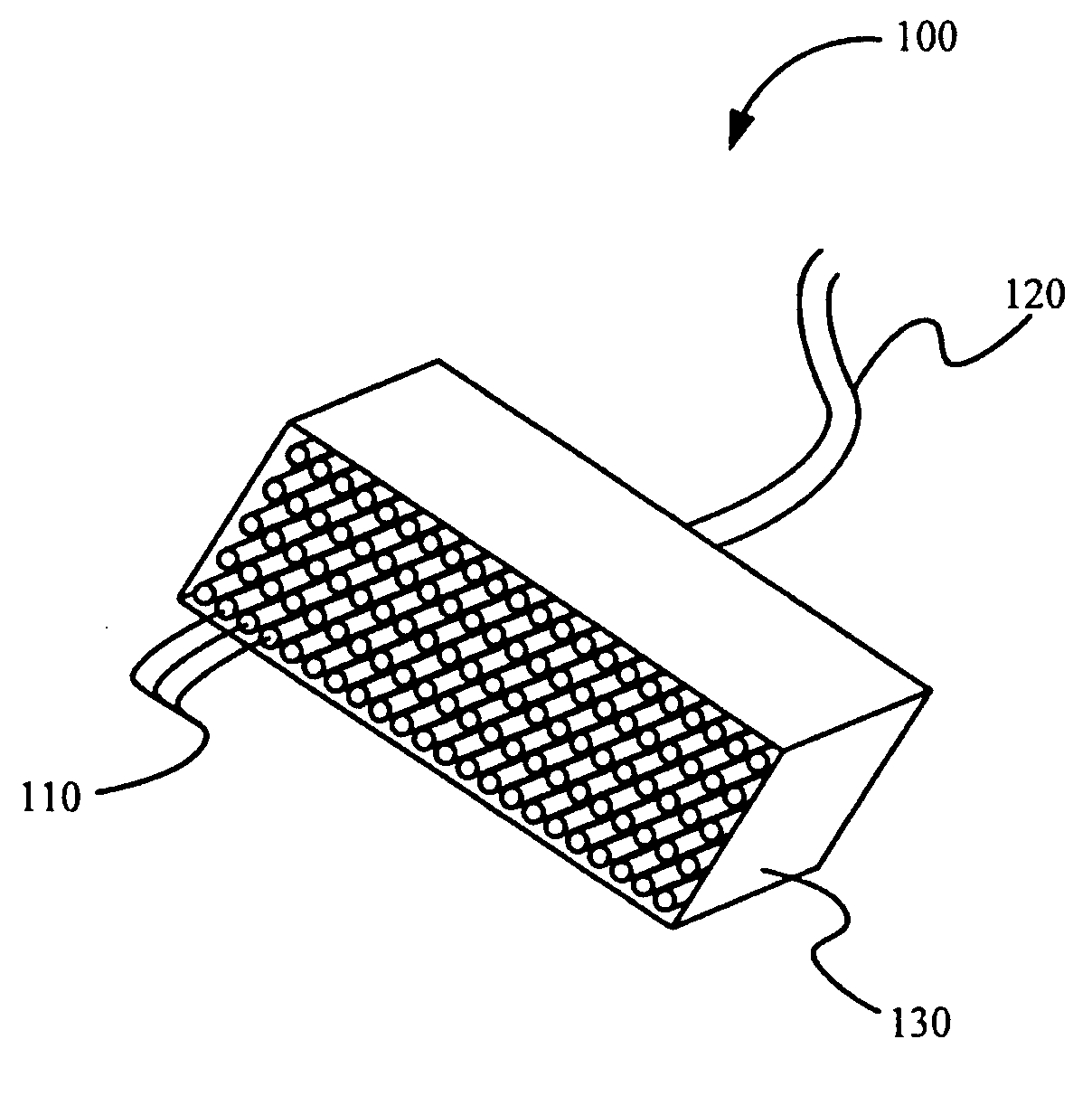

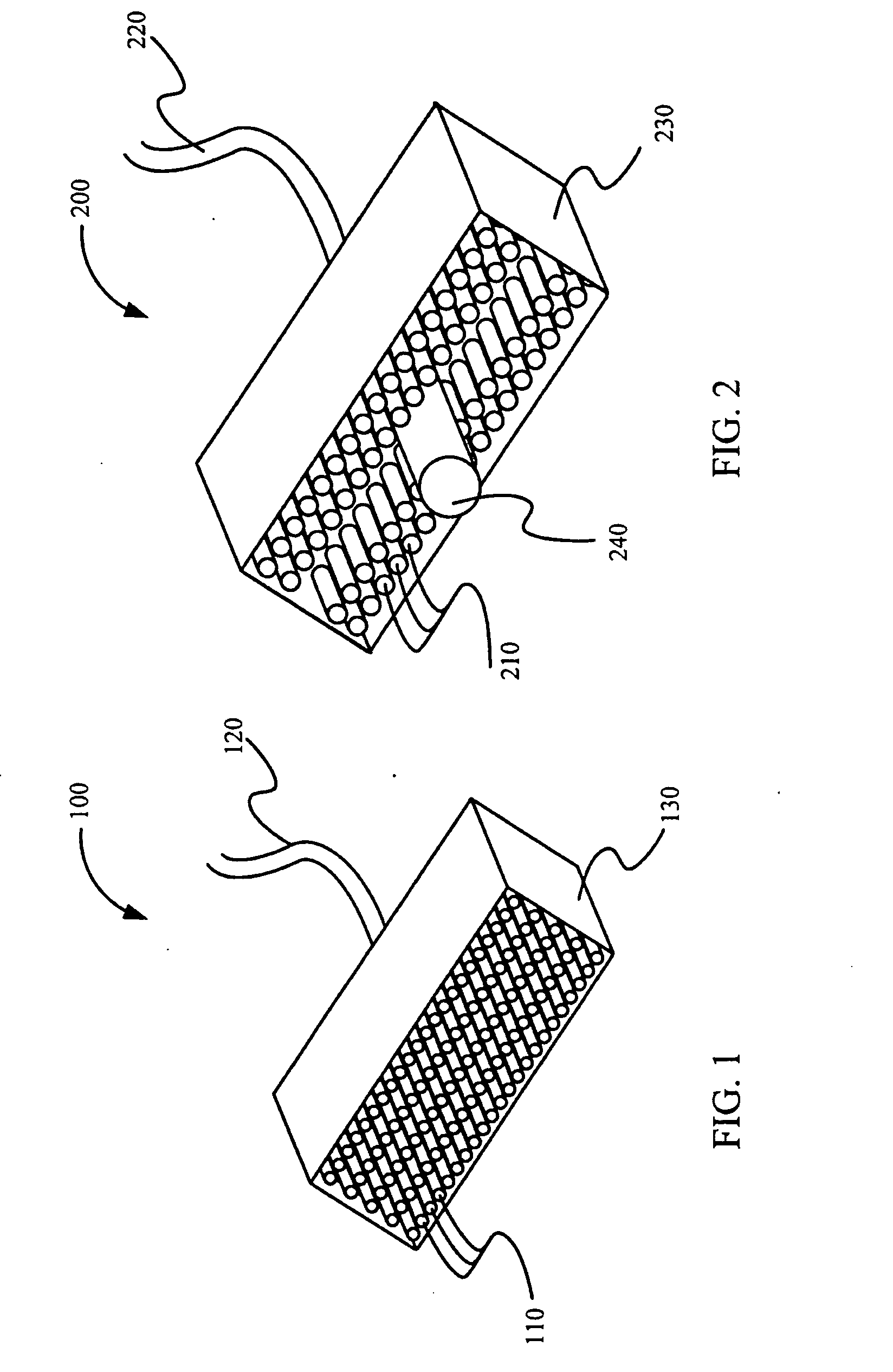

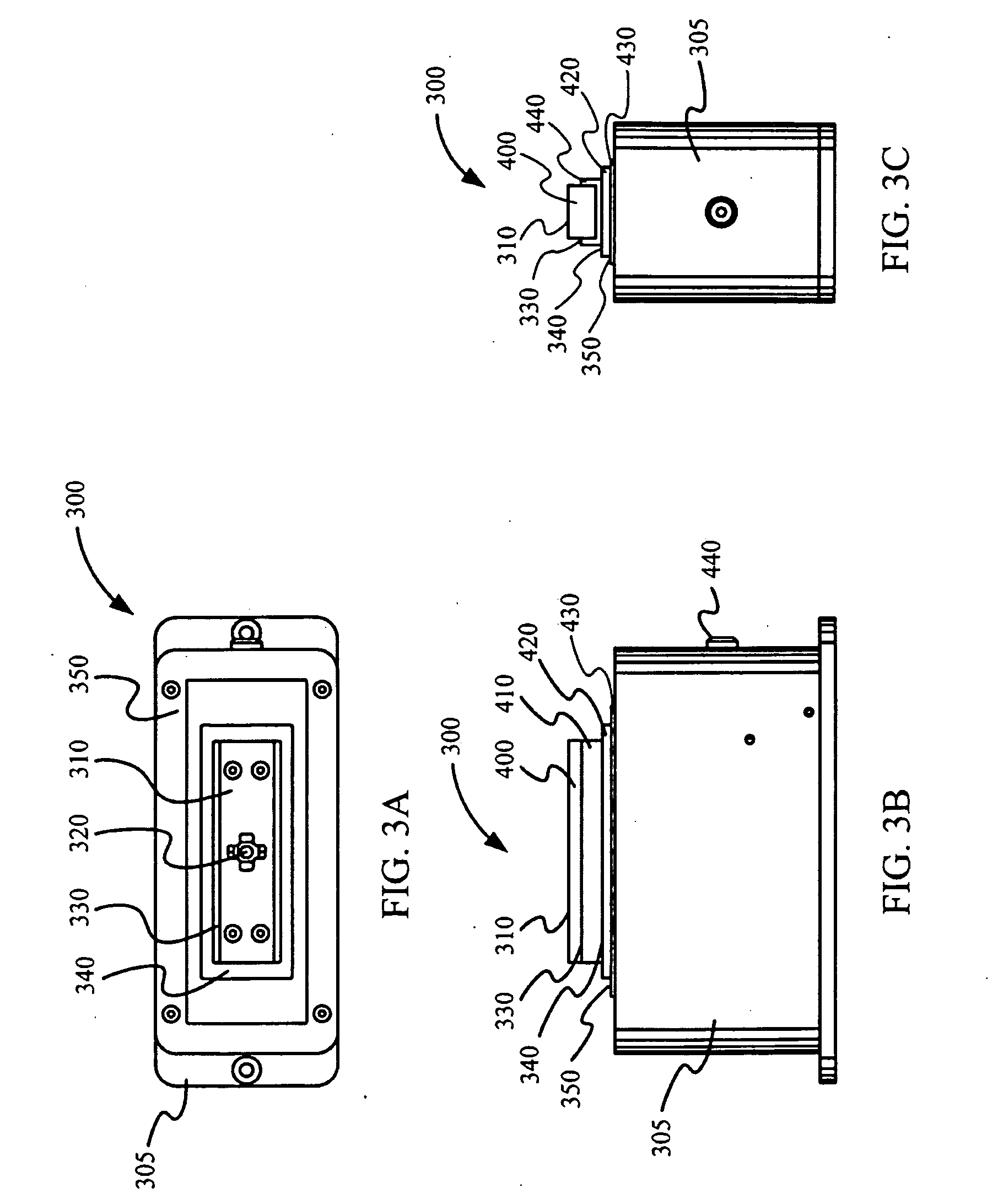

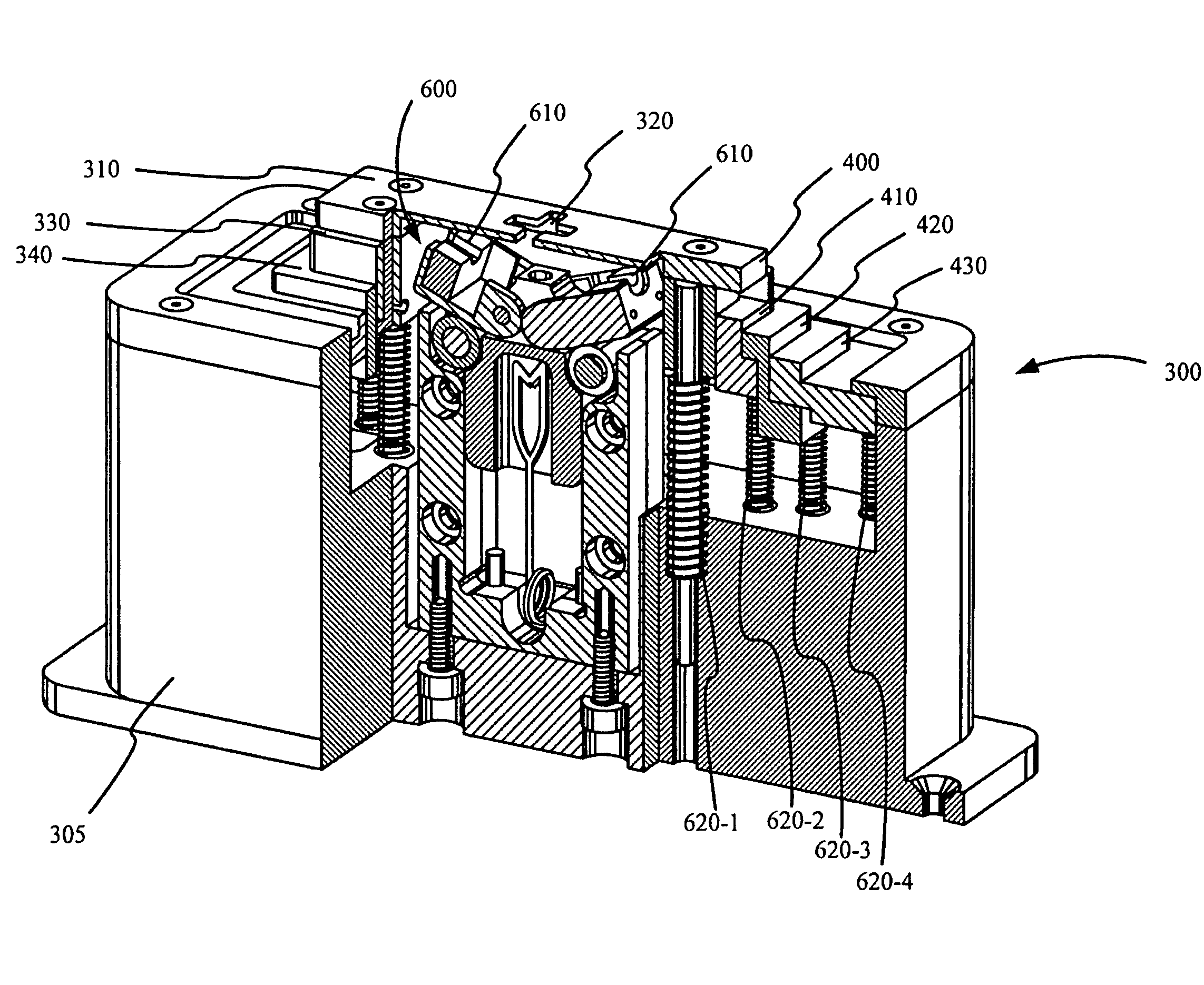

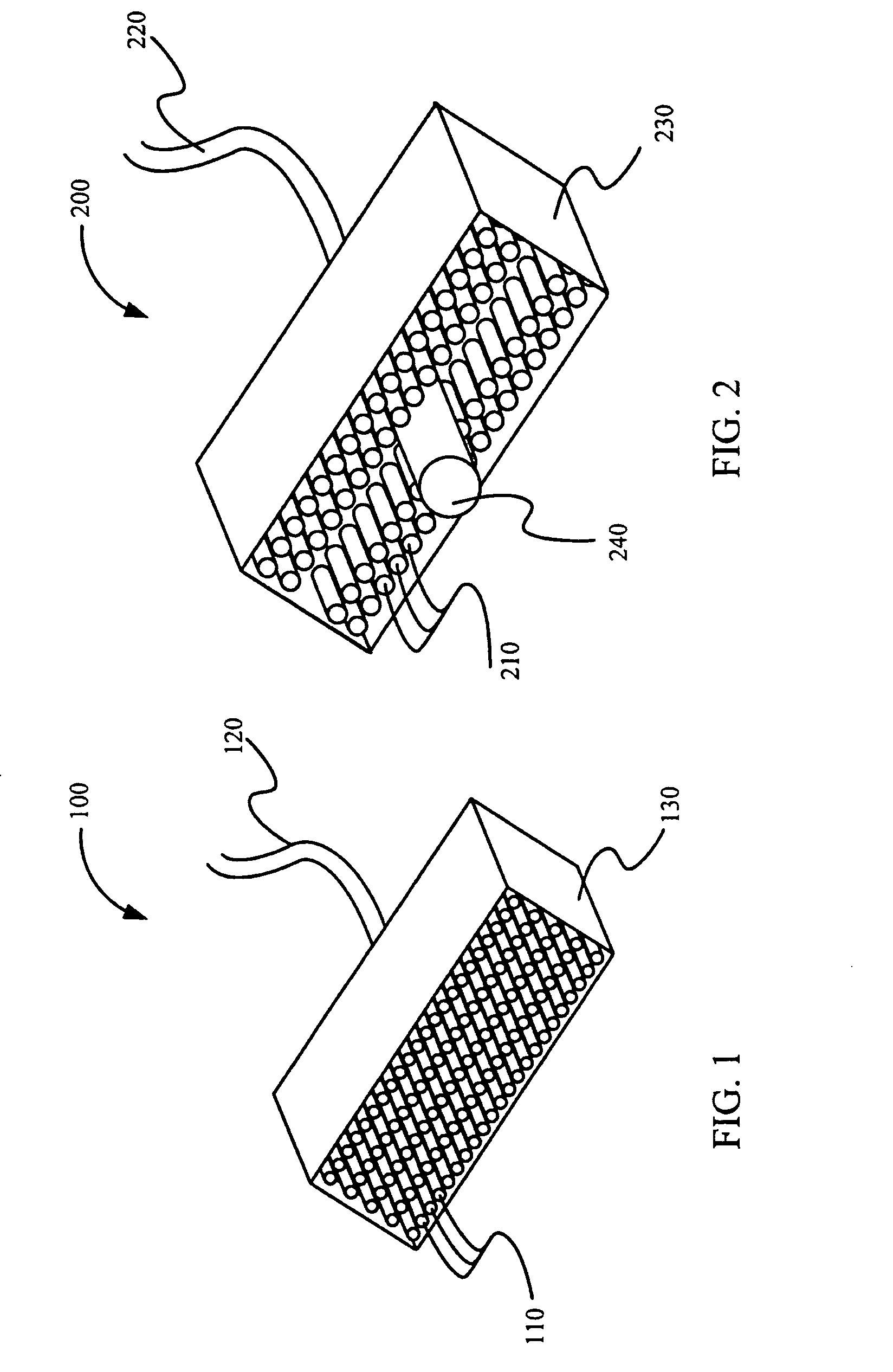

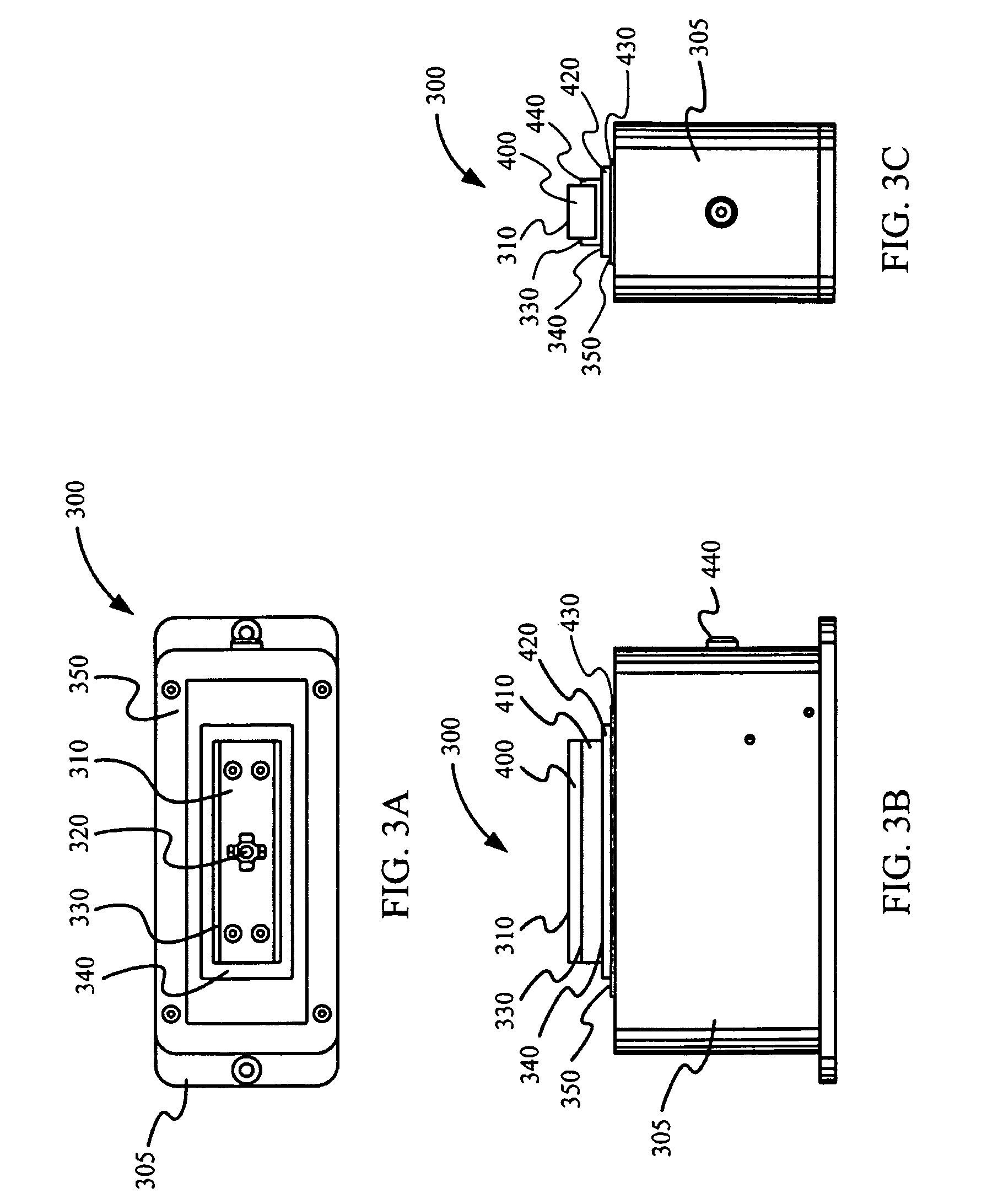

Universal current leakage testing adapter

ActiveUS20100109694A1Electronic circuit testingCoupling device detailsMeasurement deviceCurrent Leakage Testing

In one embodiment, a universal current leakage measurement device is disclosed. A universal current leakage testing adapter has the ability to couple with at least two differently sized or shaped probe connectors. The universal current leakage testing adapter is configured to couple with differently sized or shaped probe connectors by conductive planes either functioning independently or in concert to contact the pins of a probe connector.

Owner:GENERAL ELECTRIC CO

Universal current leakage testing adapter

ActiveUS7880488B2Coupling device detailsShort-circuit testingMeasurement deviceCurrent Leakage Testing

In one embodiment, a universal current leakage measurement device is disclosed. A universal current leakage testing adapter has the ability to couple with at least two differently sized or shaped probe connectors. The universal current leakage testing adapter is configured to couple with differently sized or shaped probe connectors by conductive planes either functioning independently or in concert to contact the pins of a probe connector.

Owner:GENERAL ELECTRIC CO

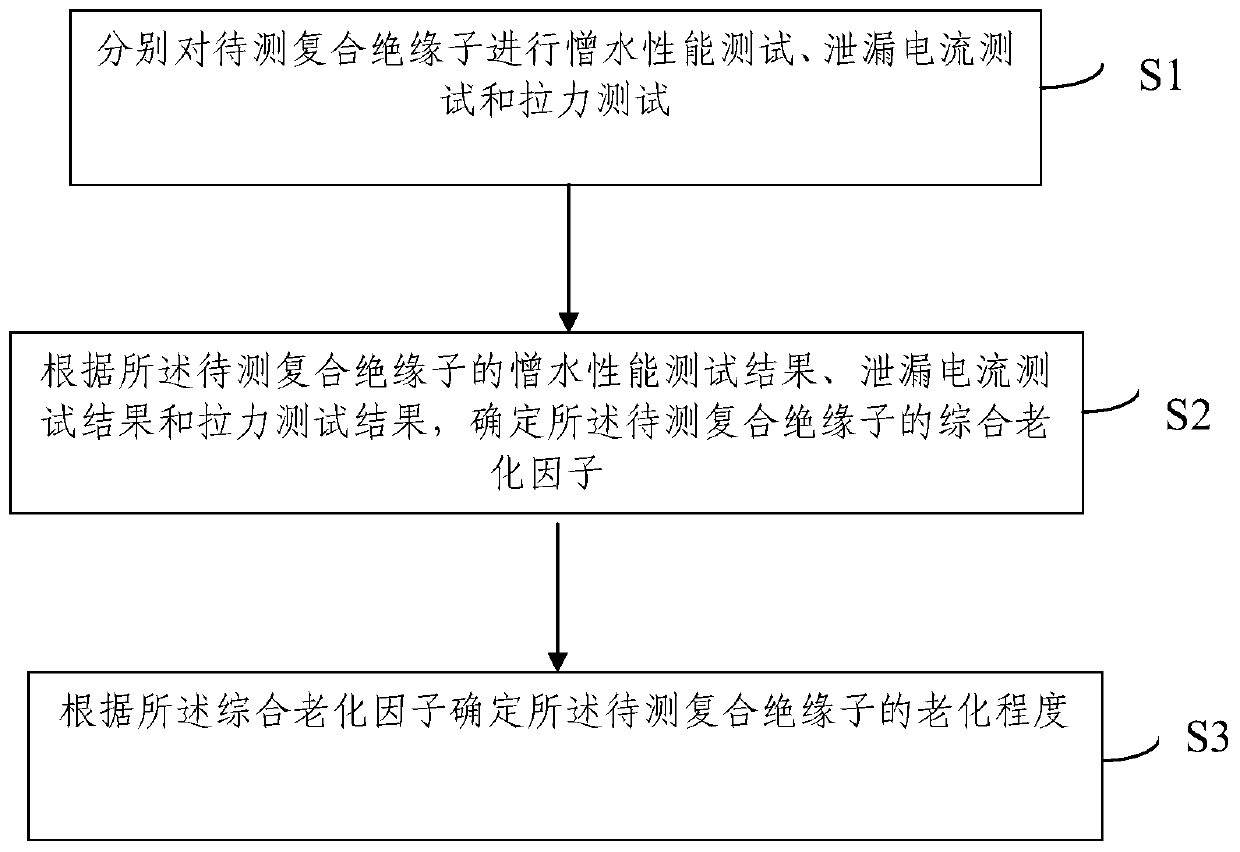

Judgment method of composite insulator aging degree

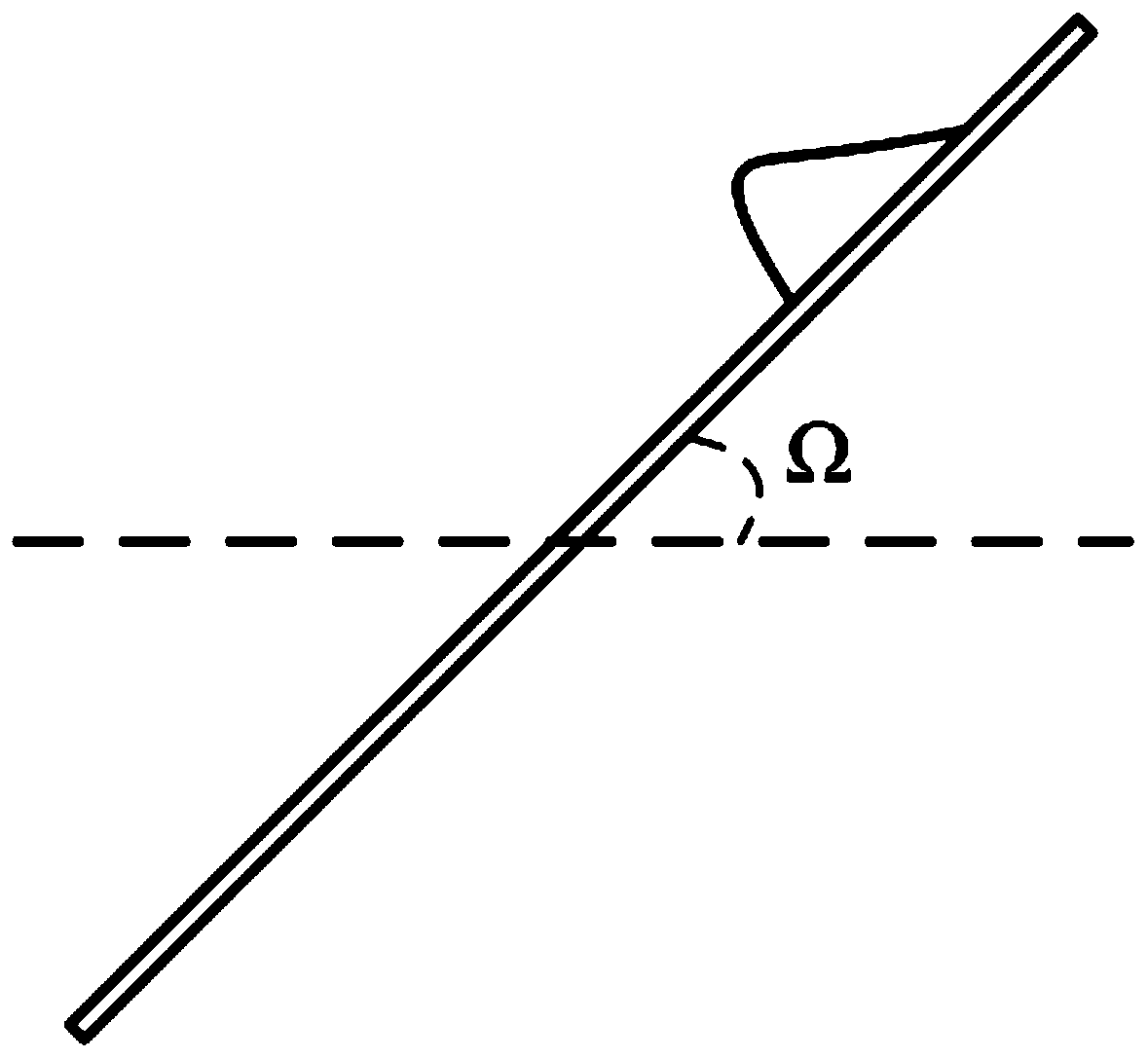

ActiveCN110426320AReflect the aging stateImprove accuracySurface/boundary effectElectrical testingComposite insulatorsCurrent Leakage Testing

The invention relates to a judgment method of composite insulator aging degree. The judgment method comprises the following steps: S1, performing hydrophobic performance testing, current leakage testing and tension testing on a to-be-tested composite insulator; S2, determining a comprehensive aging factor of the to-be-tested composite insulator according to a hydrophobic performance testing result, a current leakage testing result and a tension testing result of the to-be-tested composite insulator; and S3, determining the aging degree of the to-be-tested composite insulator according to the comprehensive aging factor. The judgment method has the following advantages: 1) the hydrophobic performance testing, the current leakage testing and the tension testing are combined to commonly detectthe aging degree of the composite insulator, and the aging state of the composite insulator can be well reflected in compared with the hydrophobic performance testing, the current leakage testing andthe tension testing, and the accuracy is high; and 2) compared with the judgment method of a scanning electron microscope and the infrared spectroscopy, the judgment method disclosed by the inventionis simpler and more convenient, and the cost is low.

Owner:STATE GRID HUNAN ELECTRIC POWER +2

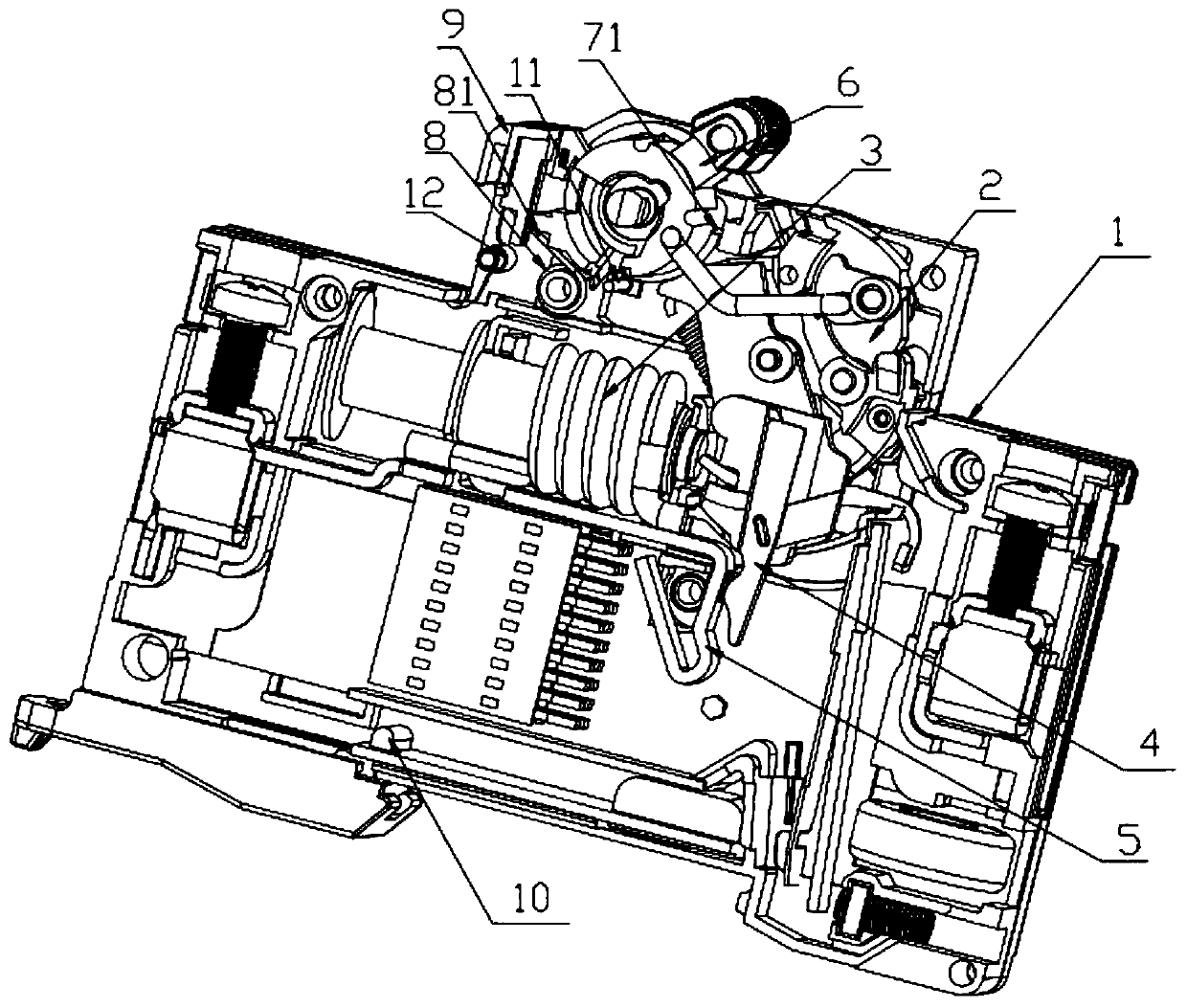

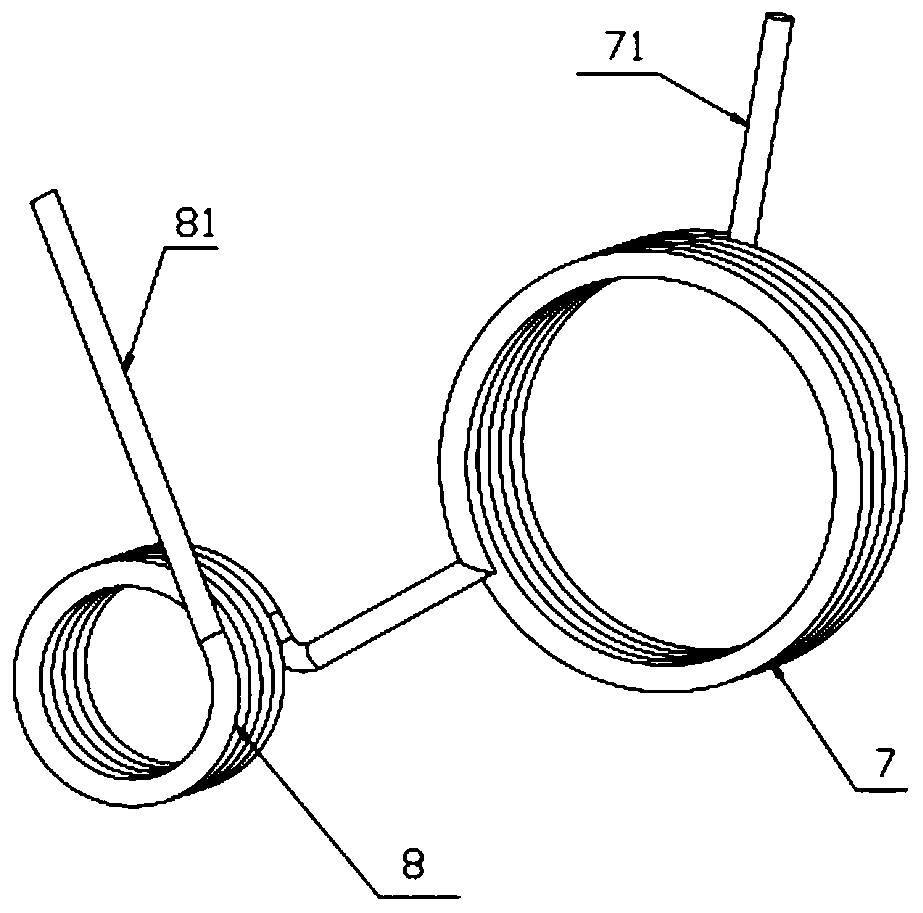

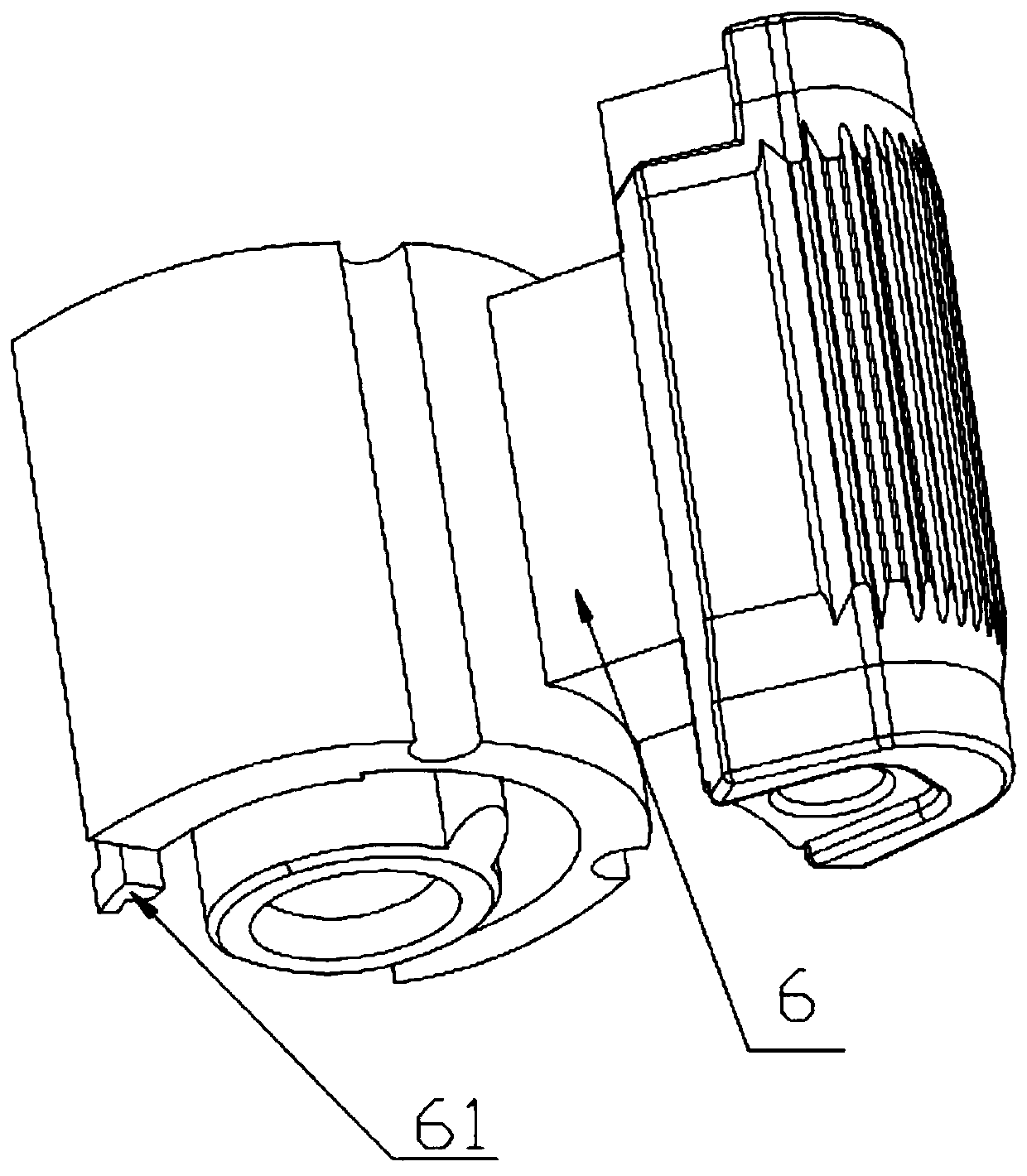

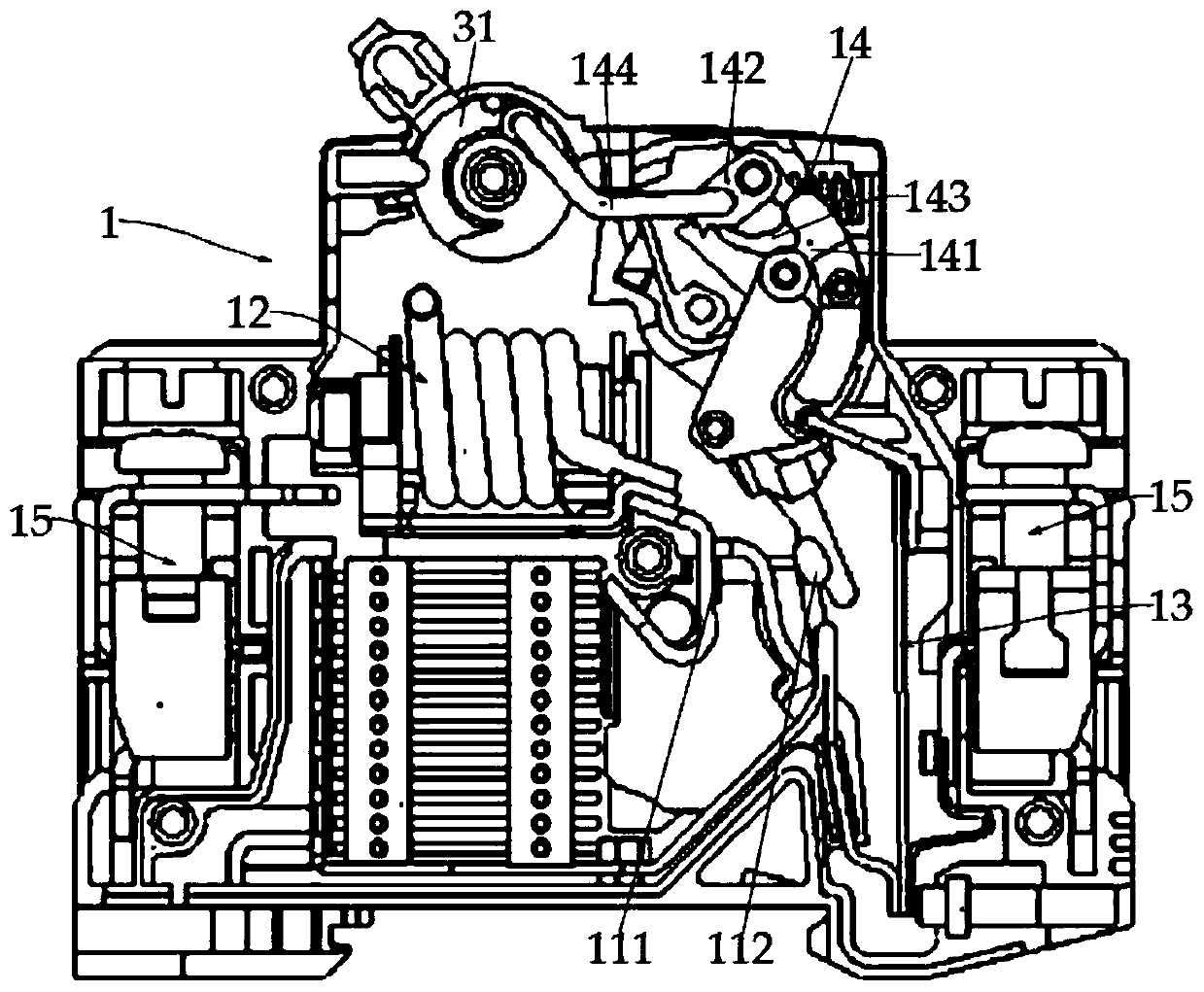

Circuit breaker test device and breaker utilizing the same

PendingCN110739194AAchieve separationSimple structureSwitch operated by earth fault currentsProtective switch operating/release mechanismsElectrical resistance and conductanceElectrical conductor

The invention provides a circuit breaker test device. The device comprises a handle, a handle spring, a test button spring, a test button, a connecting conductor, a test resistor, a first test contactand a second test contact, wherein the handle spring is at least provided with a movable end, the movable end of the handle spring rotates along with the handle, the test button spring is electrically connected with a handle spring, the movable end of the handle spring abuts against a first test contact after the handle spring is switched on along with rotation of the handle, and the movable endof the handle spring is disconnected from the first test contact after switching off or tripping, so an electric leakage test loop is in a disconnected state. The device is advantaged in that the handle spring is electrically connected with the test button spring, the movable end of the handle spring moves along with the handle, and thereby contact and separation of the handle spring and the firsttest contact are achieved, the structure of a test loop is achieved under the condition that the same purpose can be achieved, the number of parts is reduced, and the cost is saved.

Owner:GACIA ELECTRICAL APPLIANCE

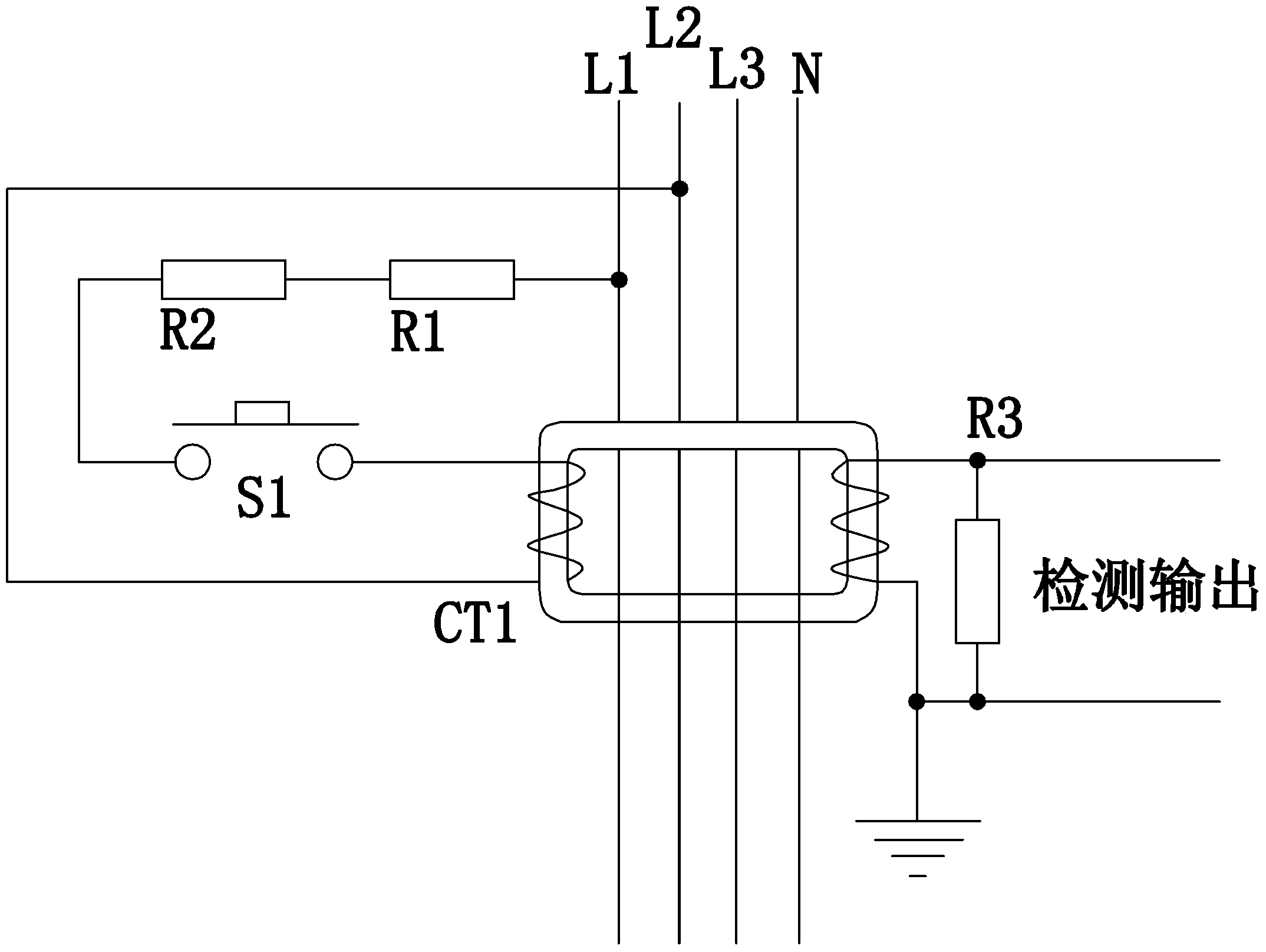

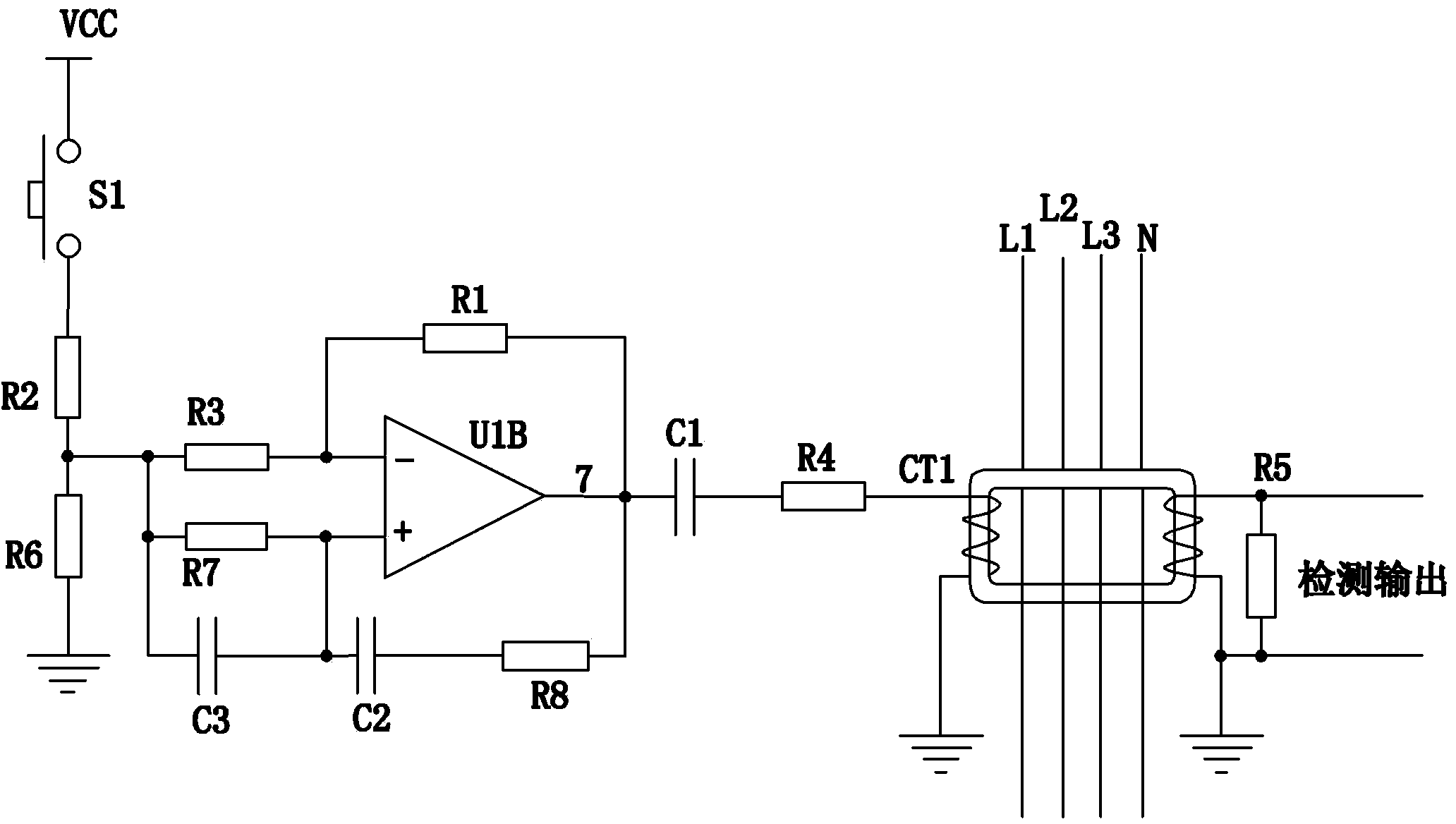

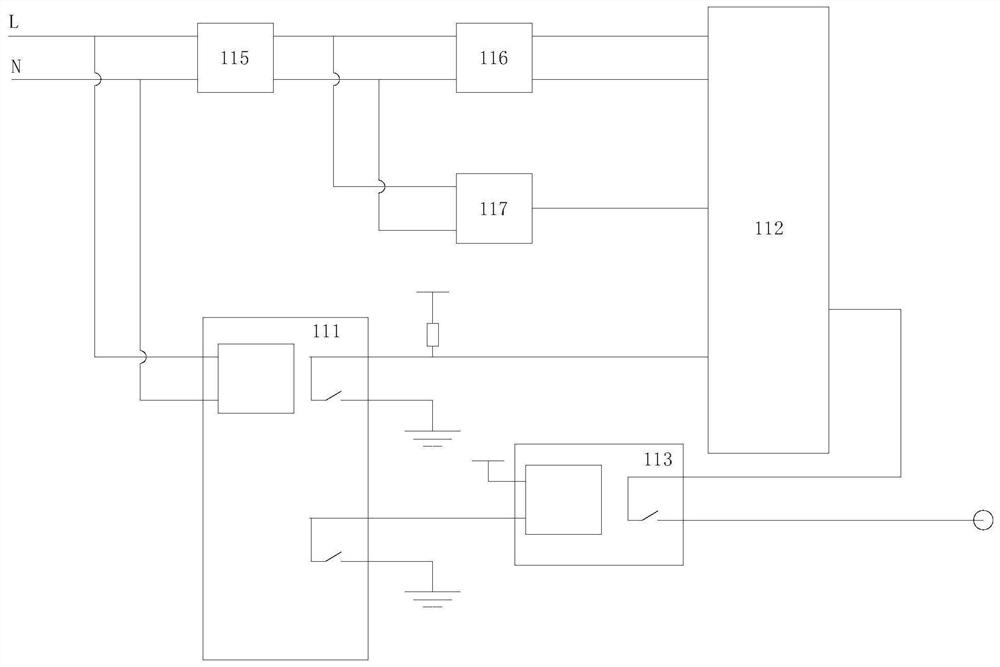

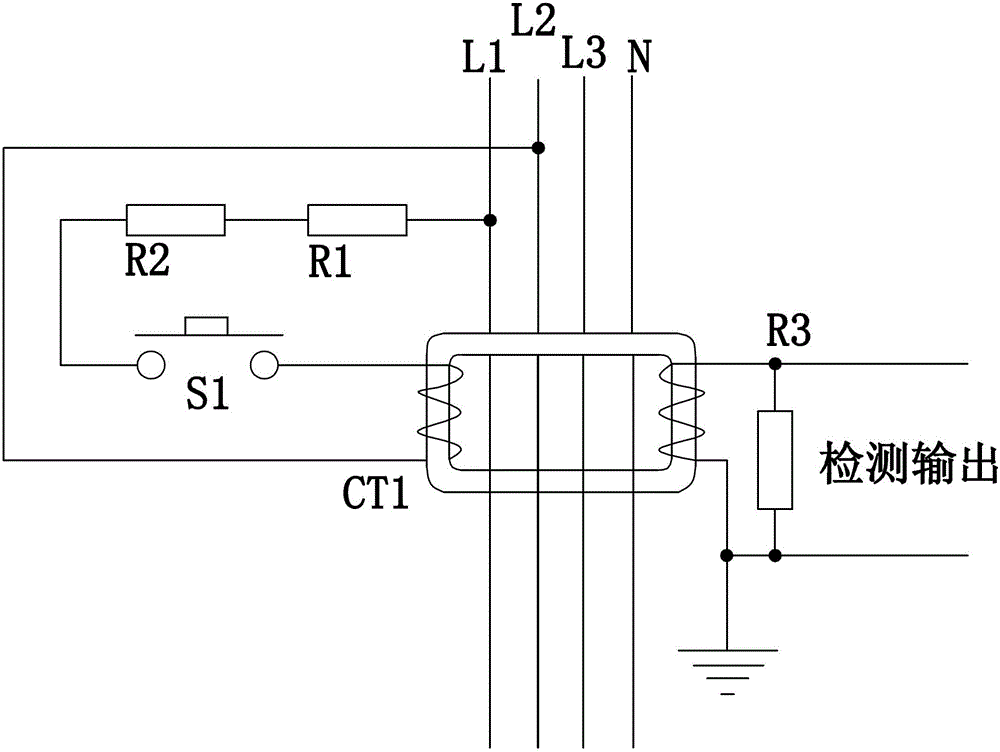

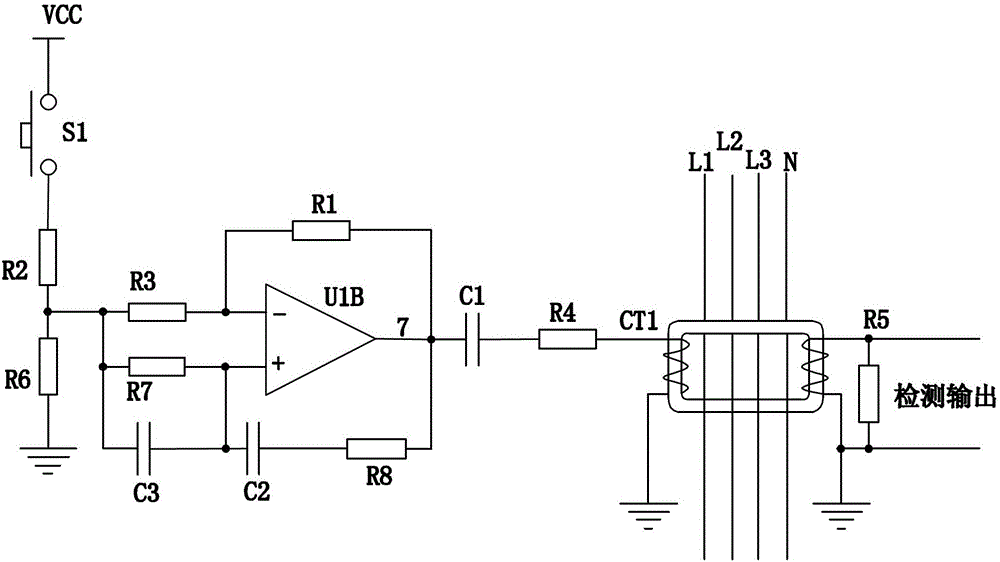

Residual current protection testing circuit

ActiveCN103399236AImprove reliabilityReduce power consumptionElectrical testingCircuit reliabilityLow voltage

The invention relates to a circuit, in particular to a residual current protection testing circuit in a device with residual current protection. The residual current protection testing circuit is characterized in that the residual current protection testing circuit comprises a testing button S1, an operational amplifier U1, a Wien bridge circuit, an output circuit and a current transformer CT, and the Wien bridge circuit comprises a resistor R7, a resistor R8, a capacitor C2 and a capacitor C3. By adopting the scheme, the novel residual current protection testing circuit provided by the invention has the advantages that the problems existing in the prior art are overcome; since a sine wave oscillating circuit is used for simulating output current leakage testing signals, the circuit reliability is high and the circuit is not influenced by open phase and under-voltage of a three-phase power supply; and since a low-voltage power supply is used for supplying power, the power consumption is low, and the problems that heat is produced and power resistors are apt to damage due to a reason that a high-power resistor is used for decreasing voltage are avoided.

Owner:DELIXI ELECTRIC

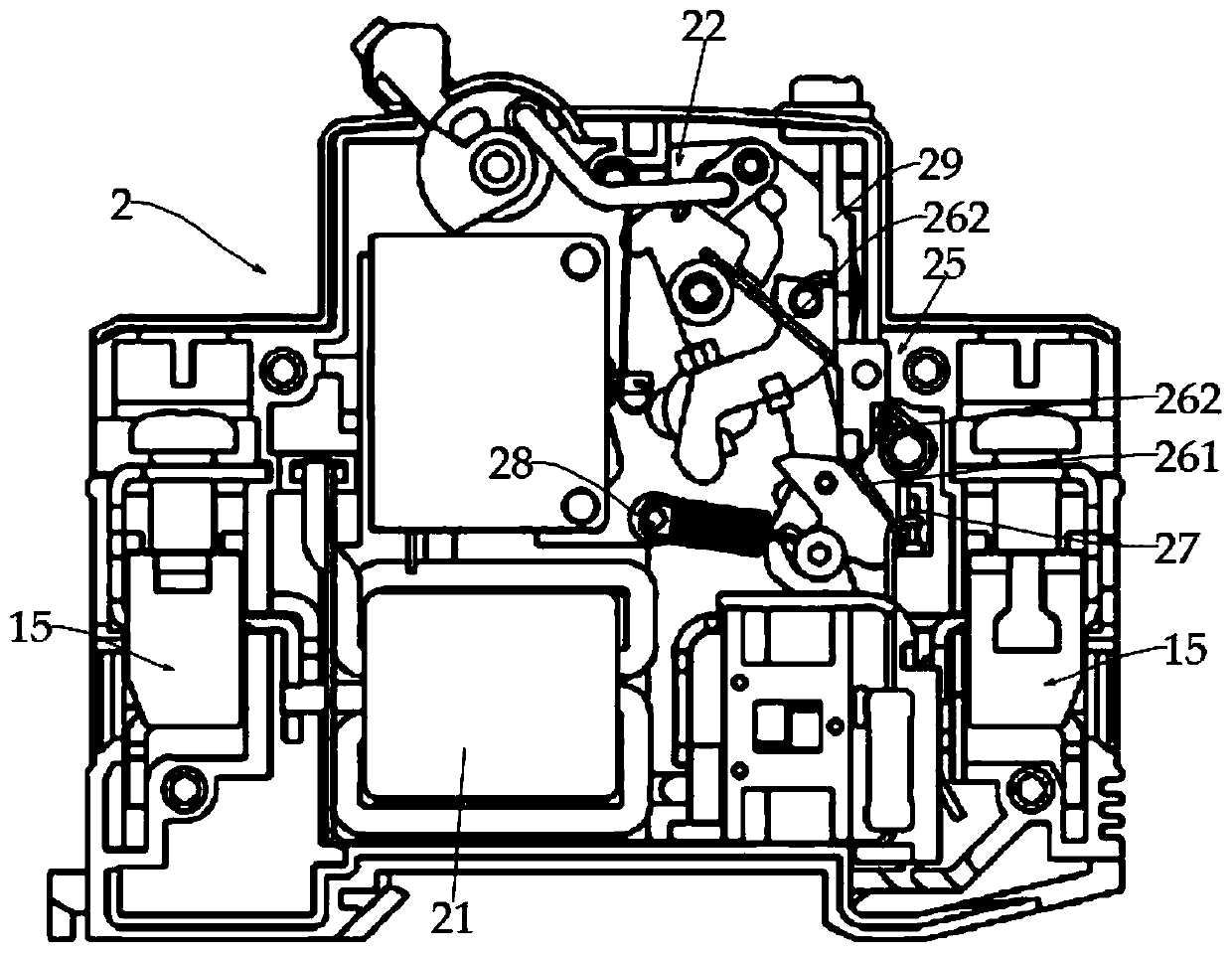

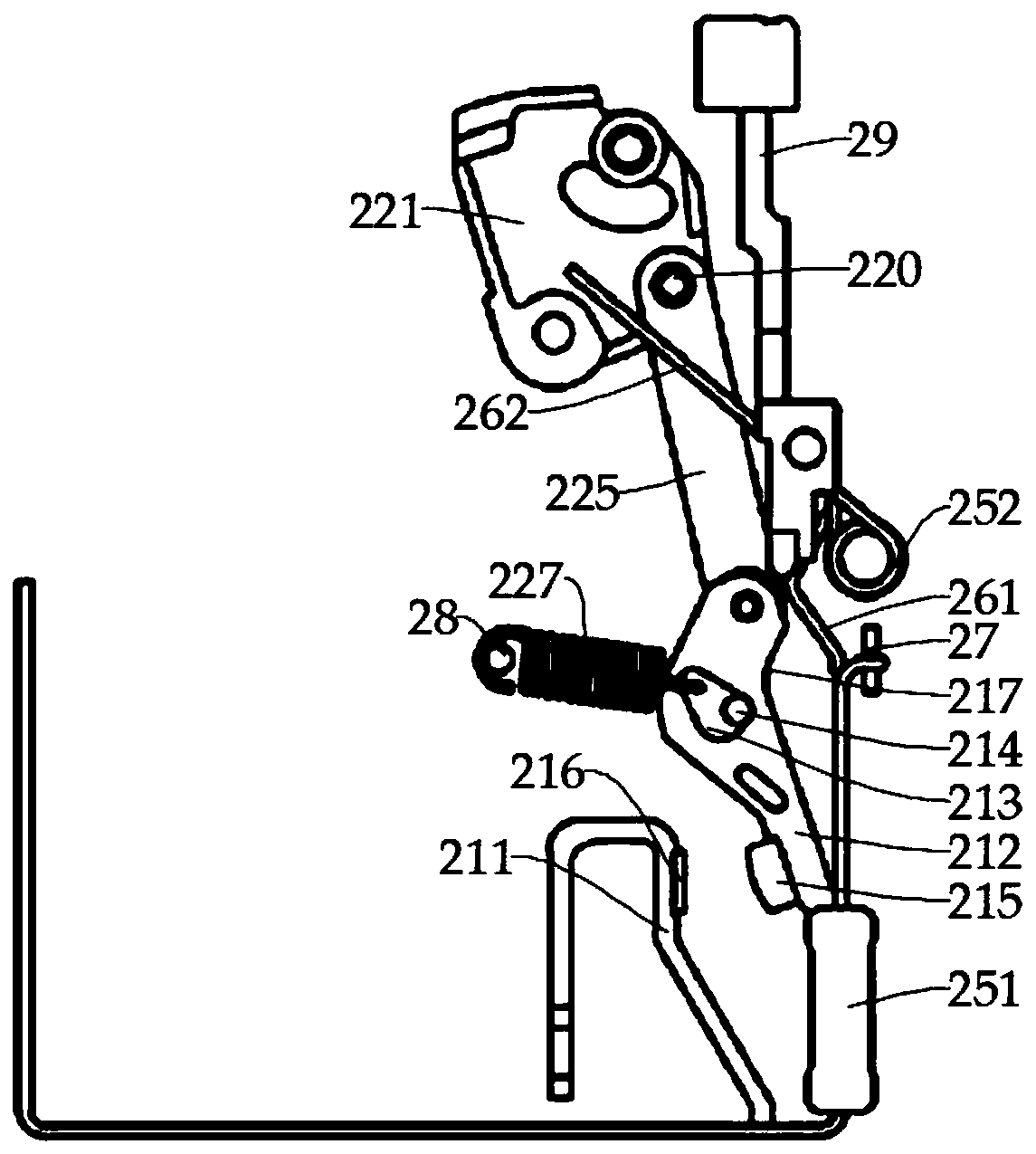

Circuit breaker

PendingCN111341612AImprove reliabilityFast actionSwitch operated by current/voltage unbalanceProtective switch operating/release mechanismsCurrent Leakage TestingEngineering

A circuit breaker comprises a shell, and a circuit breaker phase electrode and an electric leakage protection electrode which are arranged on two sides of the shell side by side. The circuit breaker is characterized in that the electric leakage protection electrode comprises a zero sequence current transformer, an electric leakage operation mechanism, an electric leakage test mechanism, a neutralpole static contact and a neutral pole moving contact which are oppositely arranged in the shell; the circuit breaker phase pole comprises a phase pole operating mechanism, a static contact and a moving contact which are oppositely arranged, wherein the moving contact is connected with the phase pole operating mechanism; the main loop of the phase pole of the circuit breaker passes through the zero sequence current transformer; the test mechanism forms a test loop with double breakpoints through two contacts of a first contact part and a second contact part on the elastic part; moreover, the first contact part is driven by the neutral line driving part connected with the neutral pole moving contact to be contacted with the first contact part, and the neutral line driving part is connectedwith the phase pole operating mechanism or the electric leakage operating mechanism, so the test button can be pressed down to disconnect the test loop when the phase pole of the circuit breaker is switched off, and the reliability of the circuit breaker is improved.

Owner:ZHEJIANG CHINT ELECTRIC CO LTD

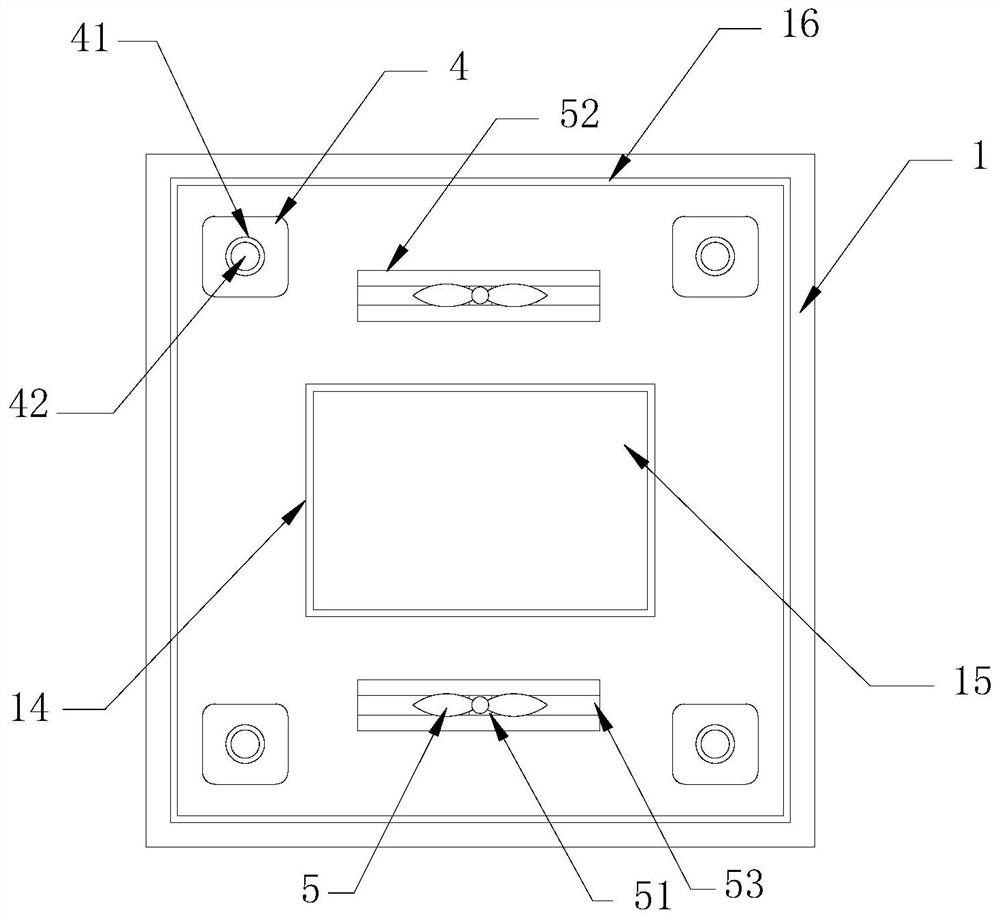

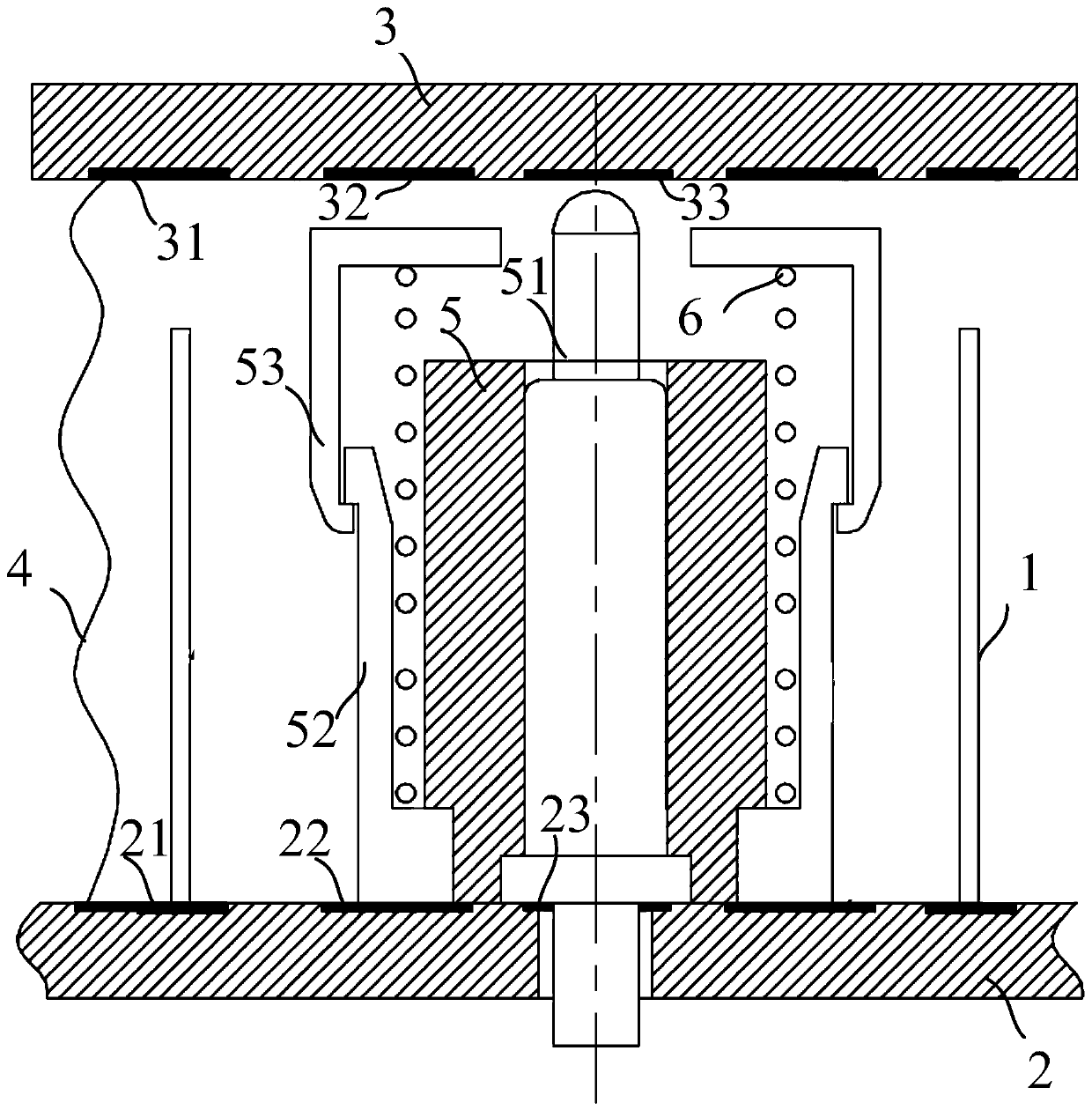

Tantalum capacitor measuring device

PendingCN112630699AImprove measurement productivityCapacitor testingTantalum capacitorCurrent Leakage Testing

The invention provides a tantalum capacitor measuring device, which comprises a track and a tooling plate suitable for moving along the track under the driving action of a moving mechanism, and a plurality of tantalum capacitors are arranged in the tooling plate. The device further comprises a measuring mechanism, the measuring mechanism at least comprises a surge test station, an electric leakage test station and a three-parameter test station which synchronously move, and the test stations are correspondingly arranged along the movement path of the tooling plate. The tooling plate is driven by the moving mechanism to move to the measuring mechanism along the track, the probes at the test stations are respectively in contact with the tantalum capacitors, and surge, electric leakage and three-parameter tests are respectively carried out at the surge test station, the electric leakage test station and the three-parameter test station. According to the technical scheme, a plurality of performances of the tantalum capacitors can be respectively tested at the same time, and the measurement work efficiency is high.

Owner:佛山明凯泰克机械有限公司

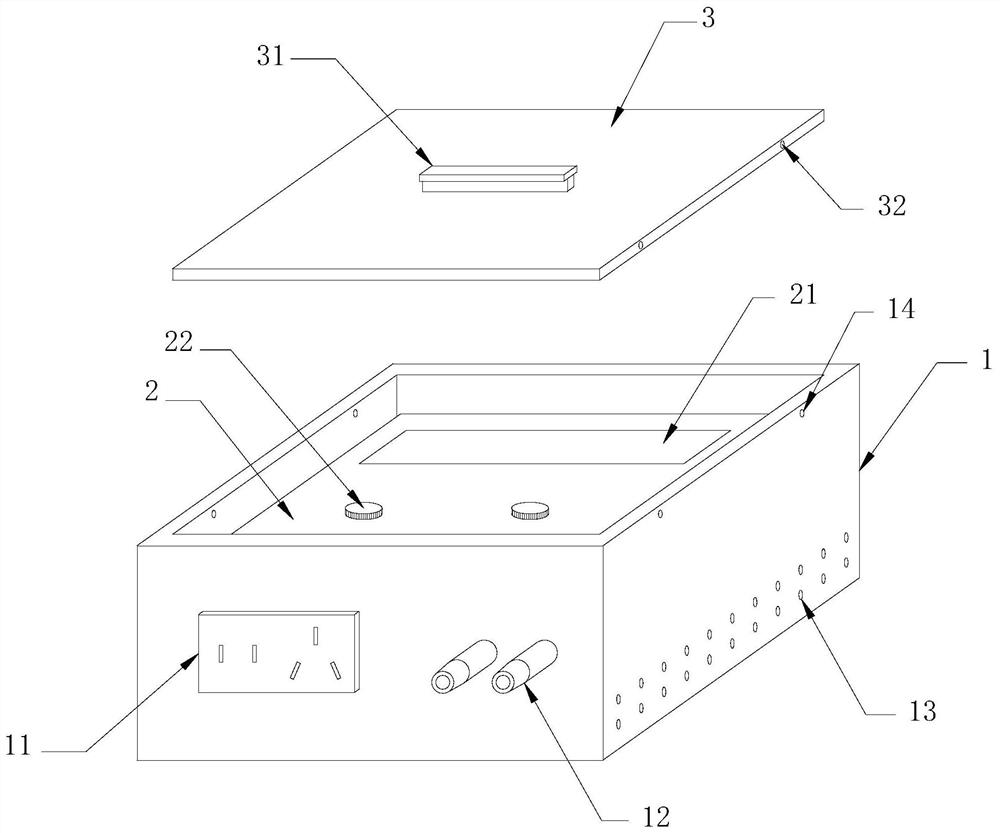

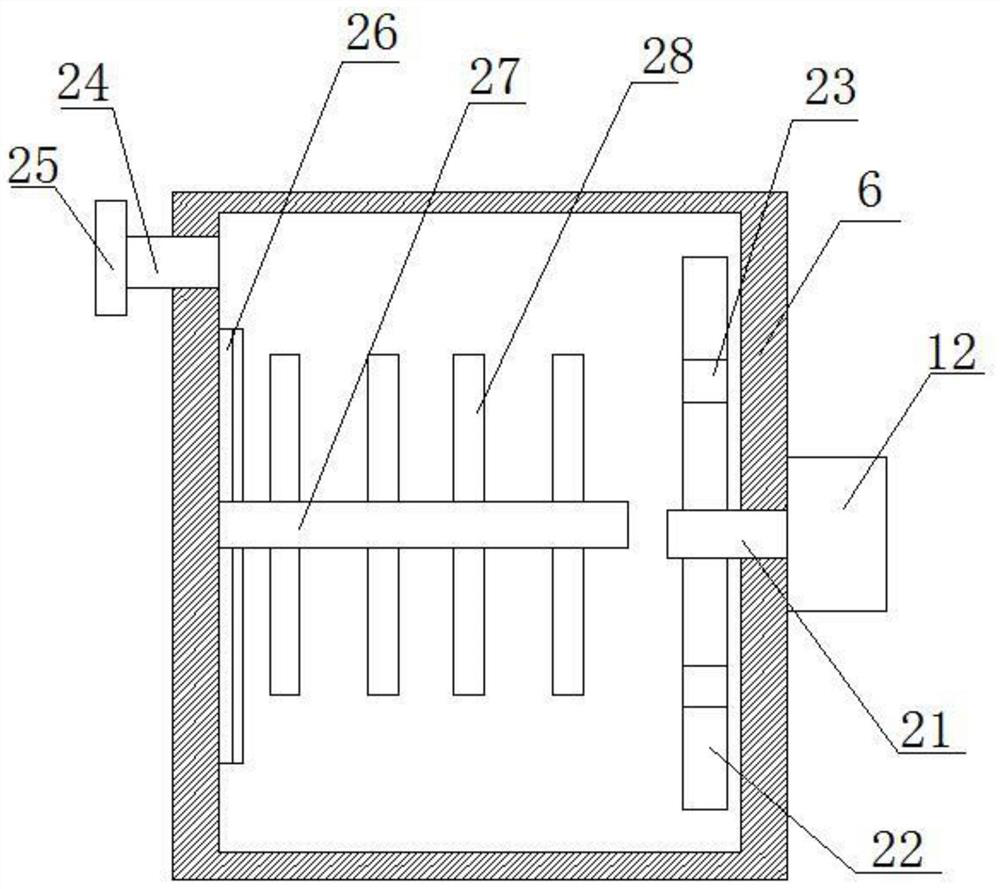

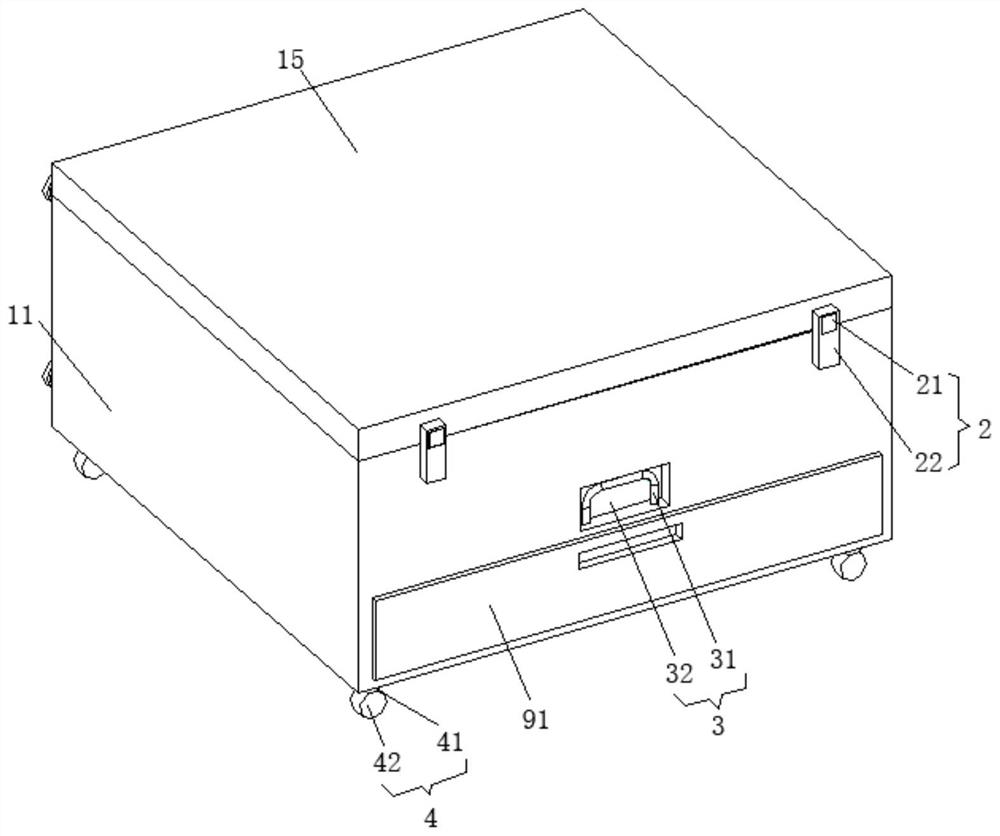

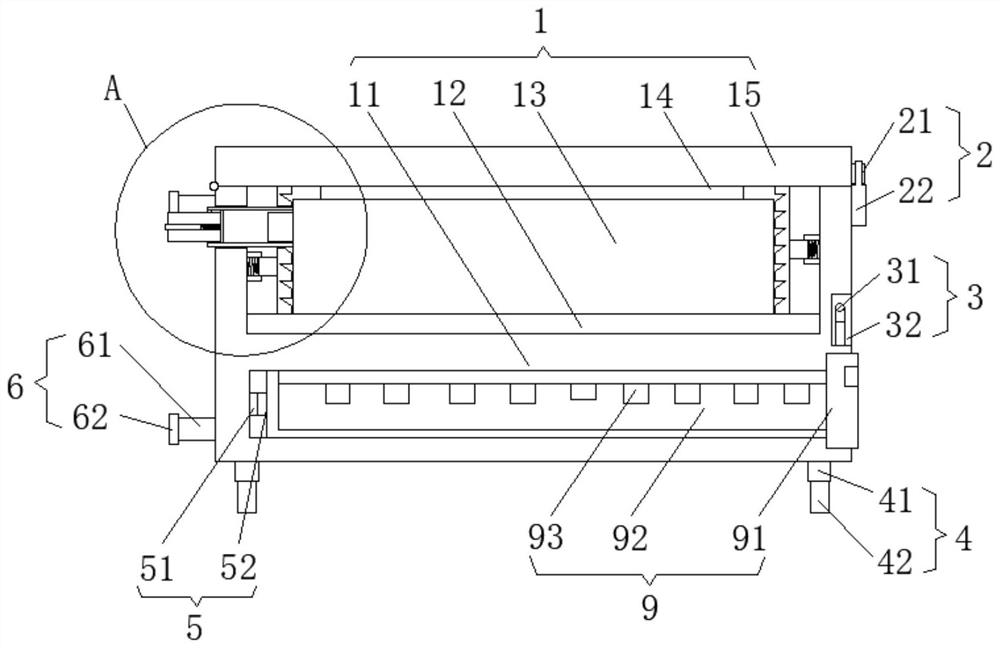

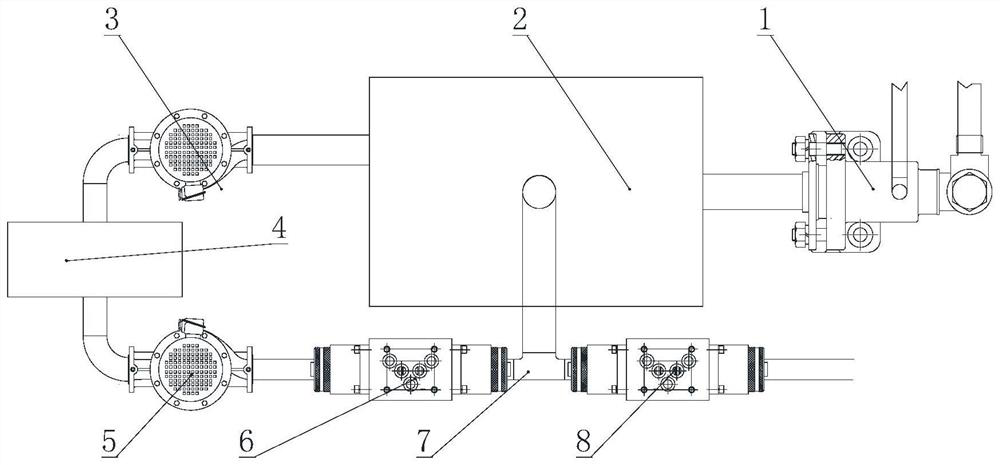

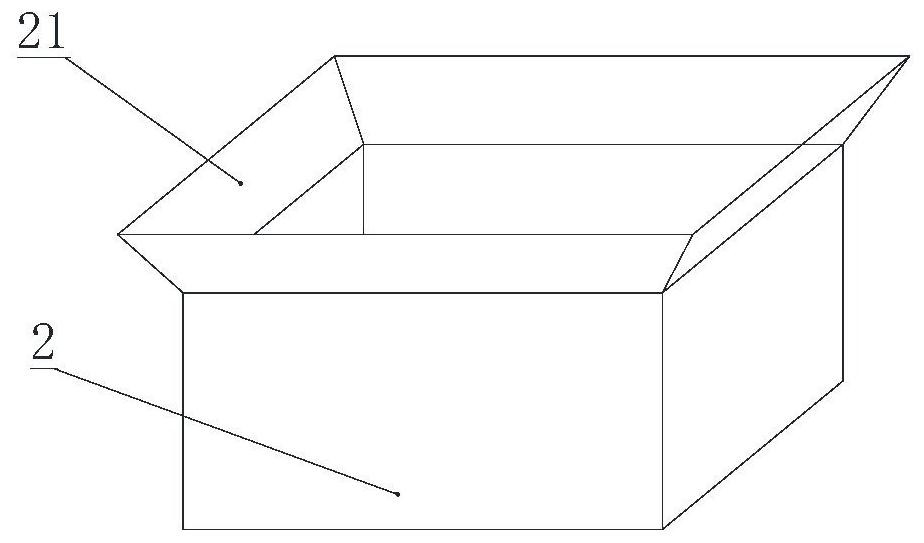

Leakage current testing device

PendingCN111679223AEasy to operateEasy maintenanceCasings/cabinets/drawers detailsShort-circuit testingCurrent Leakage TestingTester device

The invention relates to the technical field of electric leakage testing, and particularly discloses a leakage current testing device which comprises a box body, an electric leakage tester and a box cover, wherein the box body is hollow, and the electric leakage tester is installed in the box body; a socket and a wiring terminal are arranged on the outer side of the box body, the socket and the wiring terminal are electrically connected with the electric leakage tester, and a display panel and an adjusting knob are arranged on the electric leakage tester; the box cover is matched with an innergroove of the box body, a positioning hole is formed in the side face of the box cover, a fixing hole is correspondingly formed in the box body, and the fixing hole and the positioning hole are connected through a pin. Heat dissipation holes are formed in the side surface of the box body; a handle is arranged above the box cover; the leakage current testing device provided by the invention can perform electric leakage detection on the equipment, the equipment is directly connected with the wiring terminal, and a power supply is connected through the socket; in the using process, operation isconvenient, safety and reliability are achieved, performance is good, and maintenance is convenient.

Owner:SHANGHAI INST OF MEASUREMENT & TESTING TECH

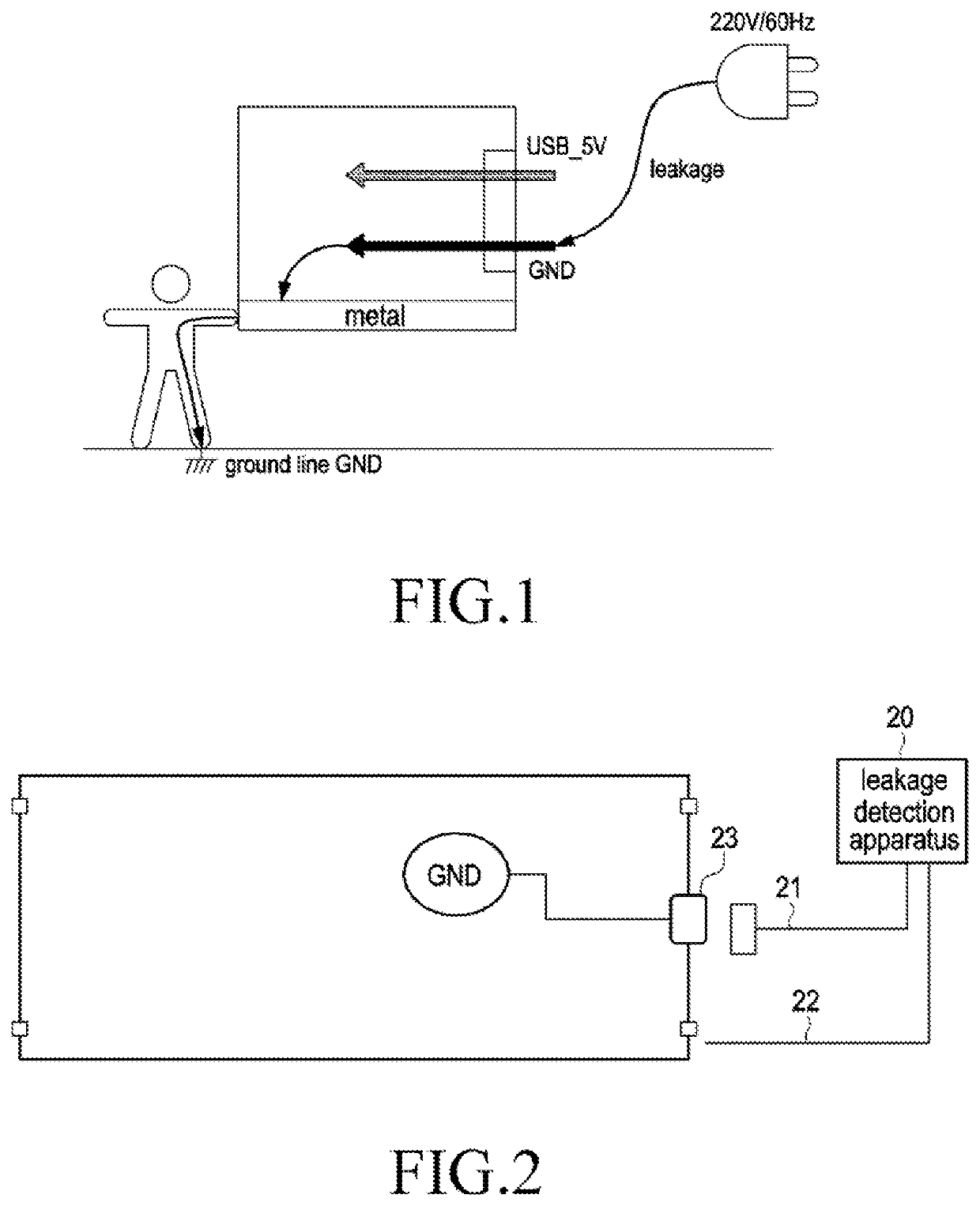

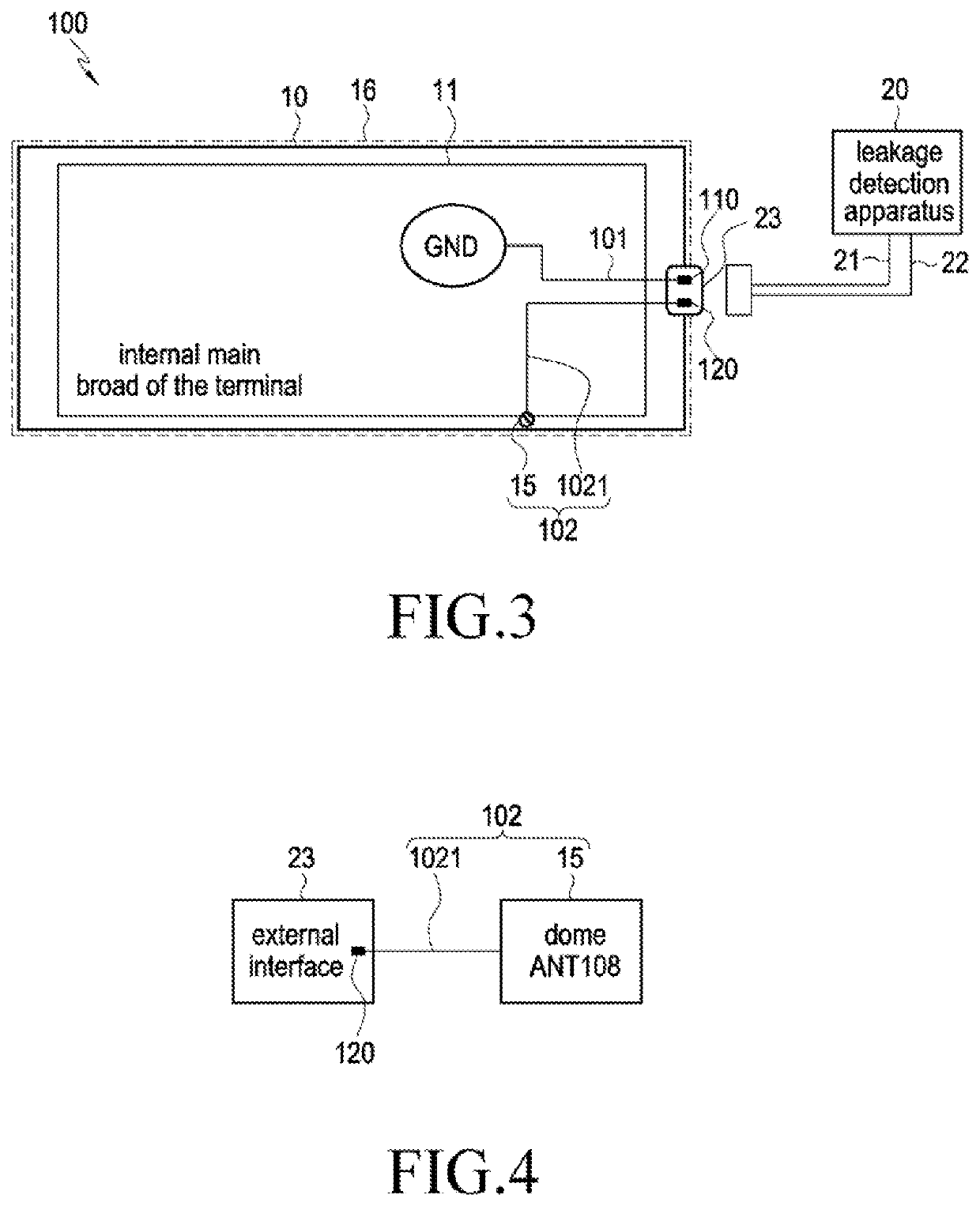

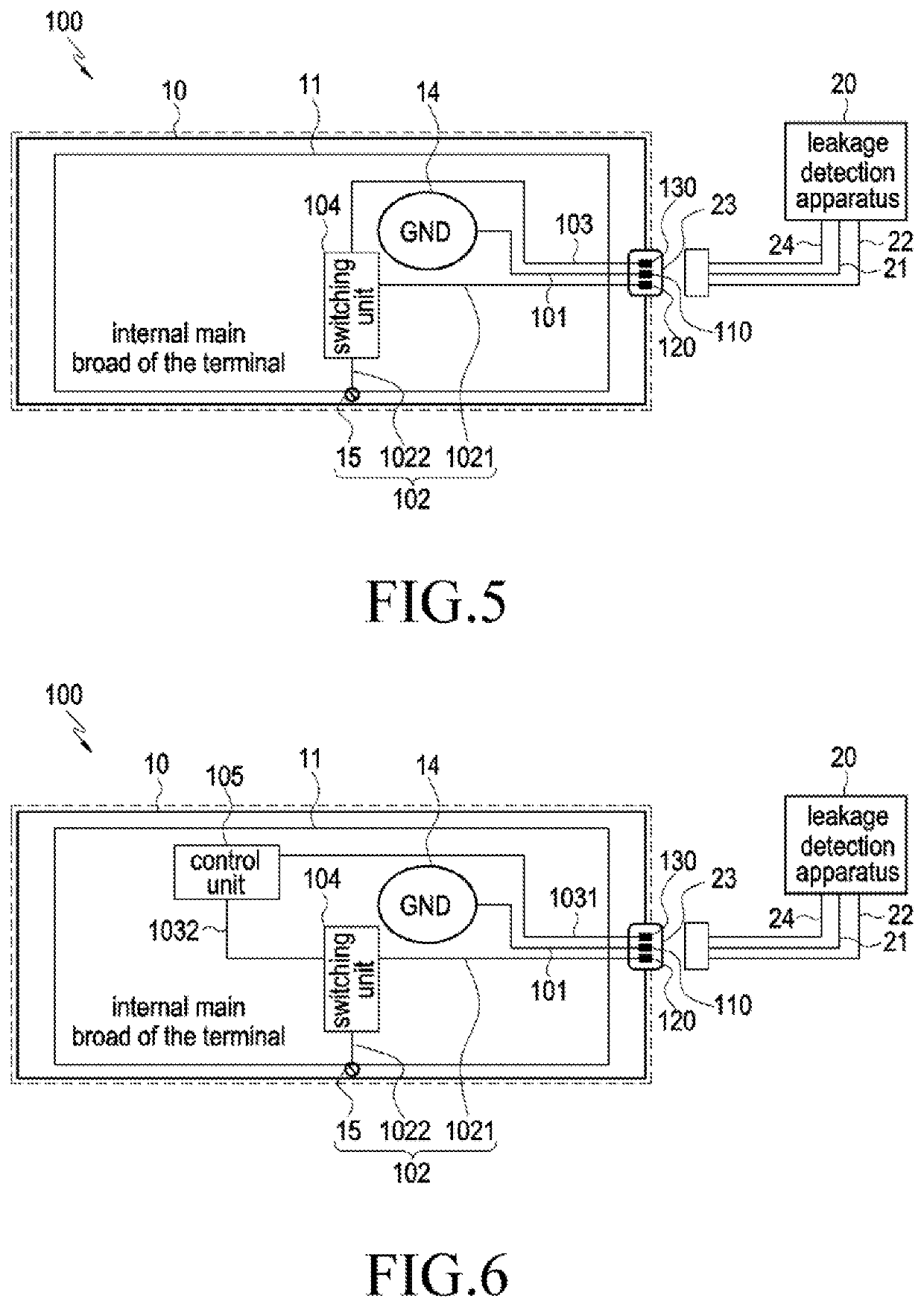

Terminal of supporting leakage detection, and method for performing leakage detection for the terminal

A terminal supporting leakage detection and a detection method for performing leakage detection for the terminal is provided, the terminal may include: a first conductive unit, a second conductive unit, a first access end, and a second access end, wherein the first access end is configured to be connected to a ground line of a main board of the terminal through the first conductive unit and used to access a ground line of an external leakage detection apparatus, and the second access end is configured to be connected inside the terminal to a metal portion of a outer casing of the terminal through the second conductive unit and used to access a leakage test line of the leakage detection apparatus.

Owner:SAMSUNG ELECTRONICS CO LTD

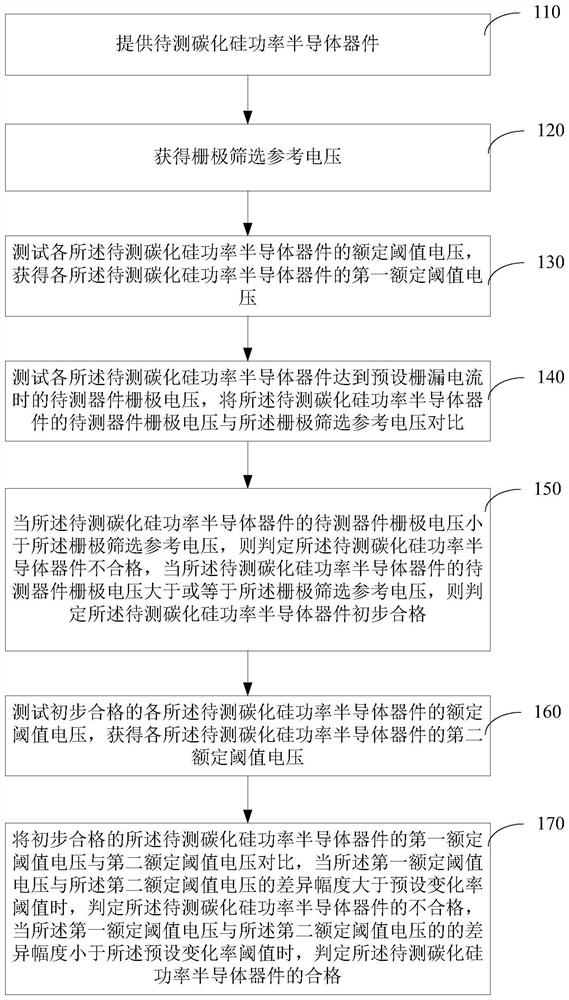

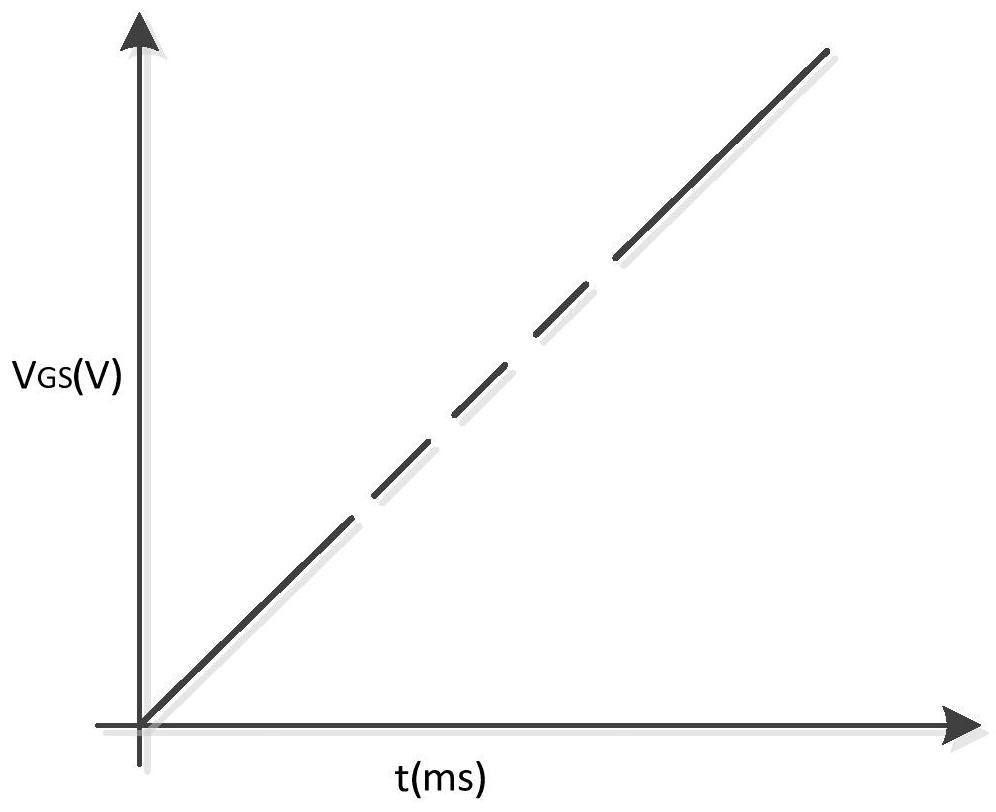

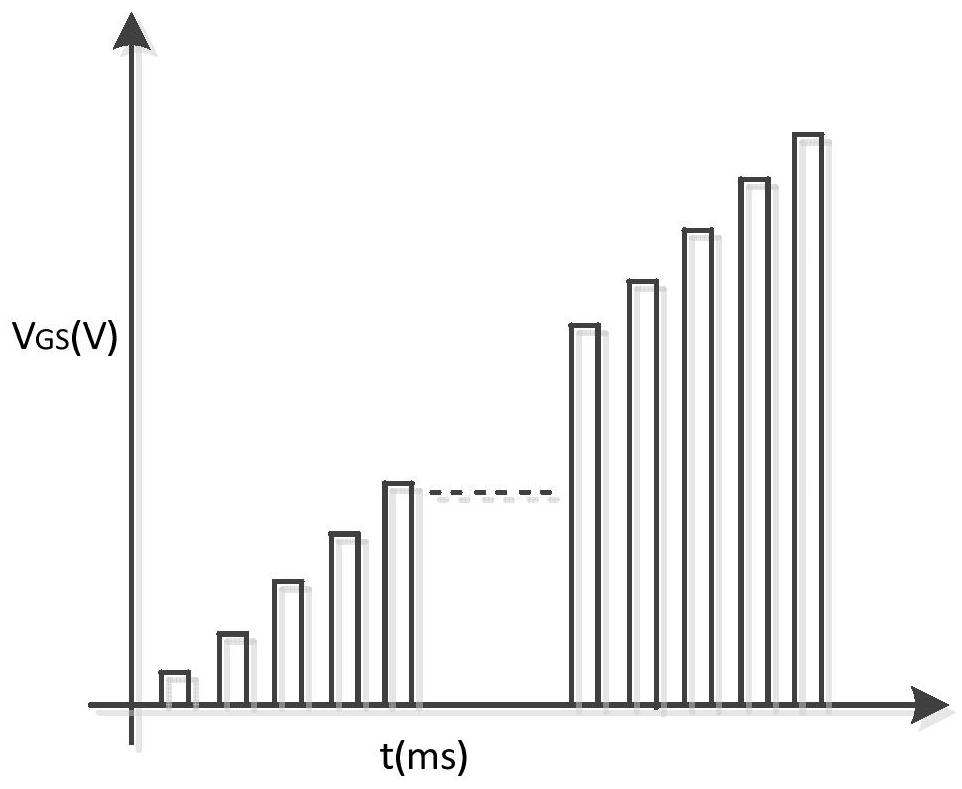

Silicon carbide power semiconductor device testing method

ActiveCN114210605AImprove factory yieldEfficient screeningEfficient power electronics conversionSortingPower semiconductor deviceCurrent Leakage Testing

The invention provides a silicon carbide power semiconductor device testing method. The method comprises the following steps: acquiring grid screening reference voltage; testing to obtain a first rated threshold voltage of each silicon carbide power semiconductor device to be tested; the to-be-tested device grid voltage of each to-be-tested silicon carbide power semiconductor device is tested; when the grid voltage of the to-be-tested device is greater than or equal to the grid screening reference voltage, judging preliminary qualification; testing to obtain a preliminarily qualified second rated threshold voltage of each silicon carbide power semiconductor device to be tested; and when the difference amplitude between the first rated threshold voltage and the second rated threshold voltage is greater than a preset change rate threshold, determining that the silicon carbide power semiconductor device is unqualified, otherwise, determining that the silicon carbide power semiconductor device to be detected is qualified. According to the technical scheme, screening is carried out through the grid leakage current test, the threshold voltage test, the grid voltage comparison and the threshold voltage comparison, damaged chips in the grid leakage current test can be effectively screened out, the screening efficiency is ensured, and the screening precision is improved.

Owner:ZHUZHOU CRRC TIMES SEMICON CO LTD

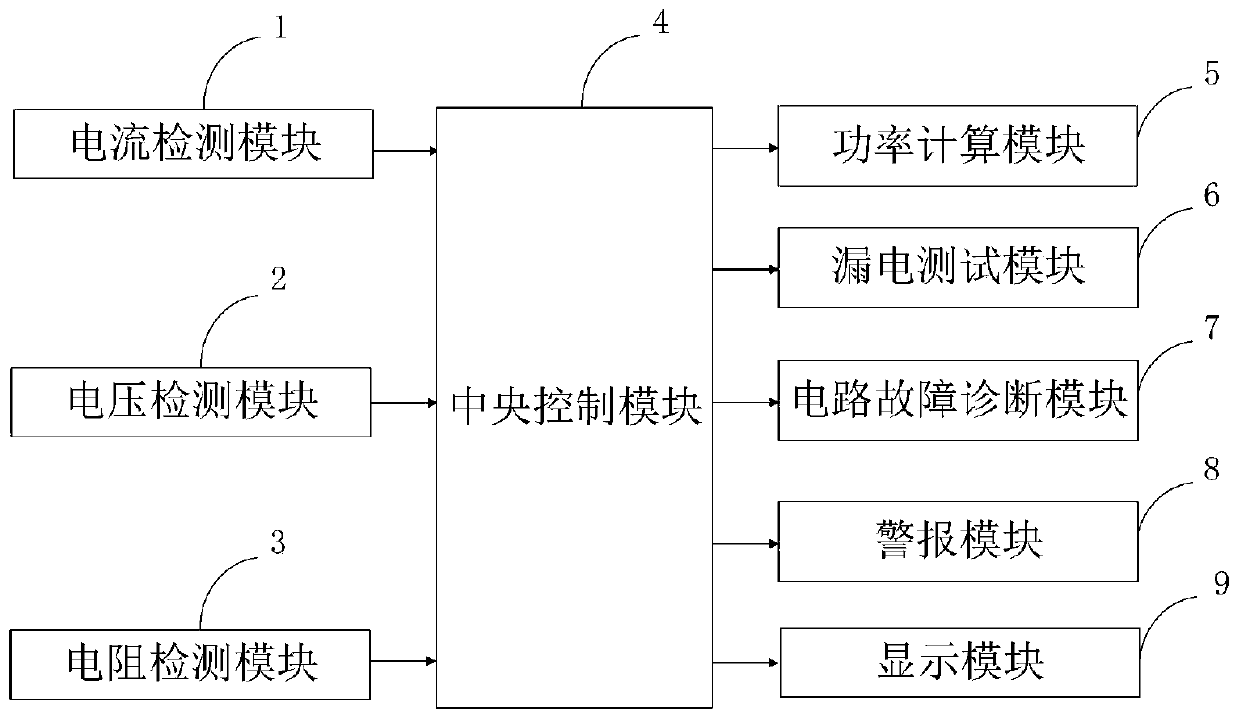

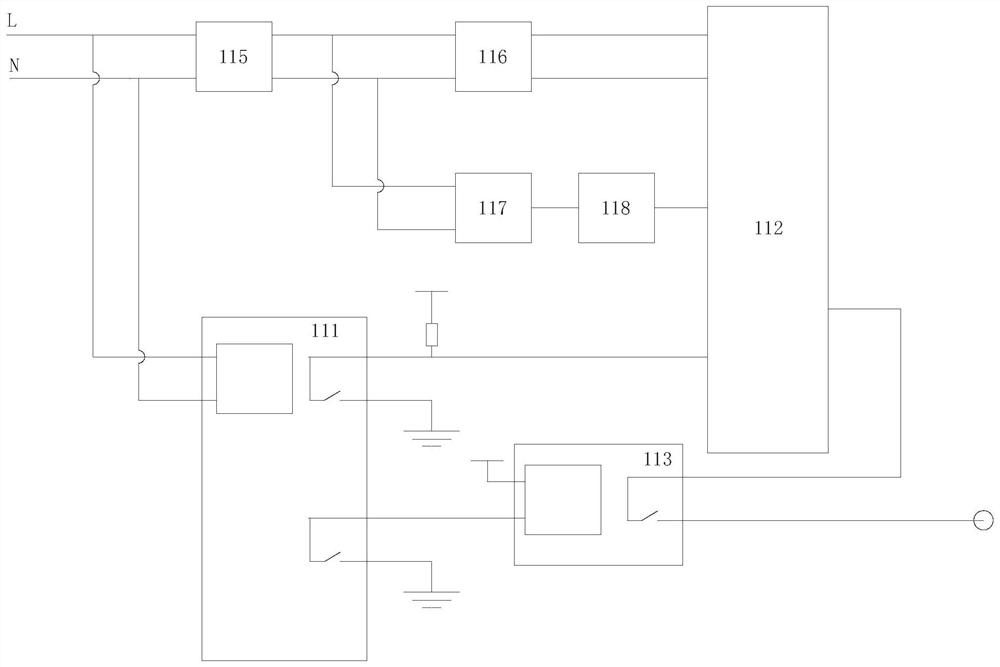

Control system based on circuit physical parameter detection

InactiveCN111190094APrecise positioningEasy maintenanceElectric devicesElectronic circuit testingControl systemCurrent Leakage Testing

The invention belongs to the technical field of circuit physical parameter detection. The invention discloses a control system based on circuit physical parameter detection. The control system based on circuit physical parameter detection comprises: a current detection module, a voltage detection module, a resistance detection module, a central control module, a power calculation module, an electric leakage test module, a circuit fault diagnosis module, an alarm module and a display module. According to the invention, the electric leakage test module is used for measuring the current of a second signal pin in signal pins of a to-be-tested element and judging whether the to-be-tested element has leakage current or not according to the current, so that the test accuracy is high; meanwhile, the circuit fault diagnosis module utilizes a projection mode to project defect points on a circuit board, so that maintenance personnel can conveniently position and maintain defects of the circuit board, the system is suitable for products of various sizes and models, and the technical problem that in the prior art, the circuit fault detection result display effect is not visual, and consequentlythe maintenance process of the maintenance personnel is complex is solved.

Owner:SHANDONG BUSINESS INST

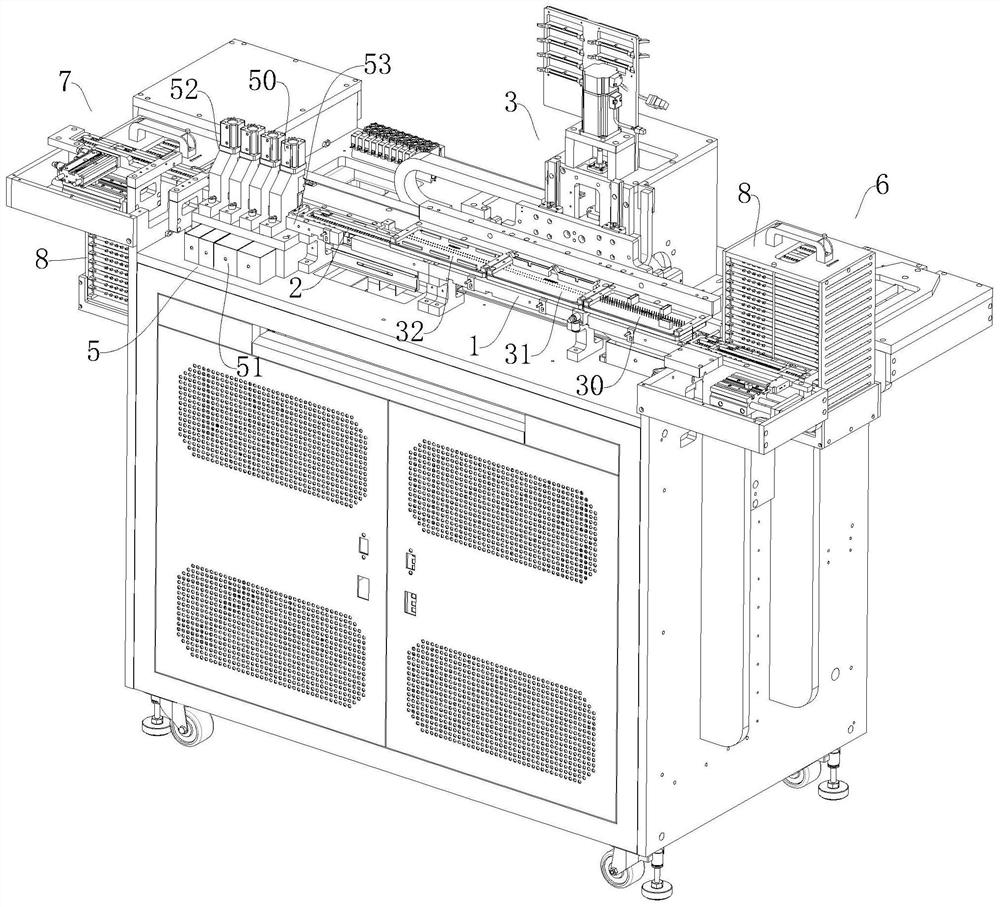

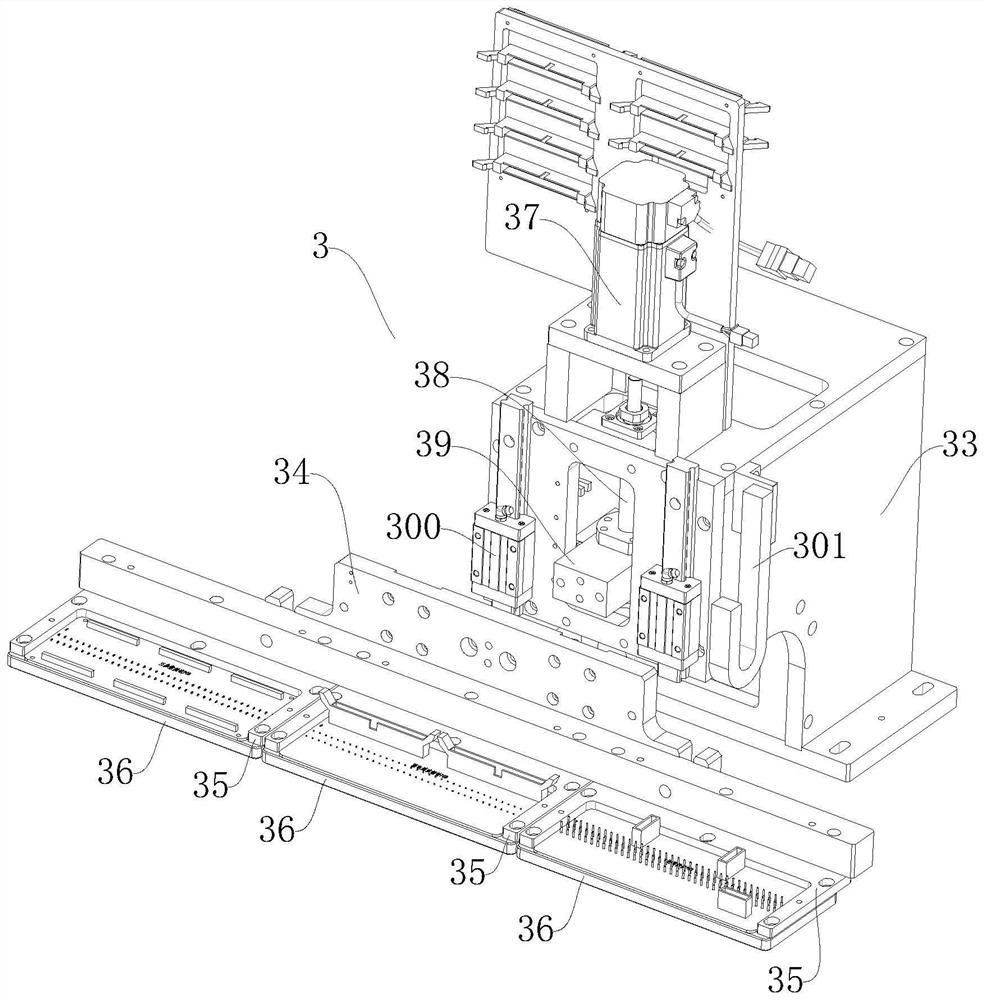

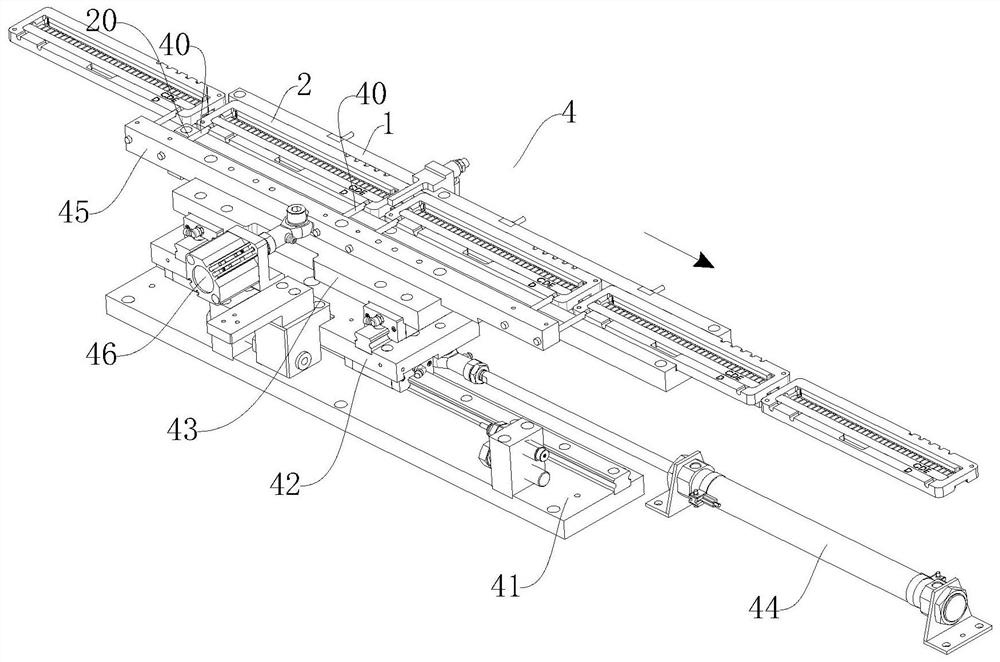

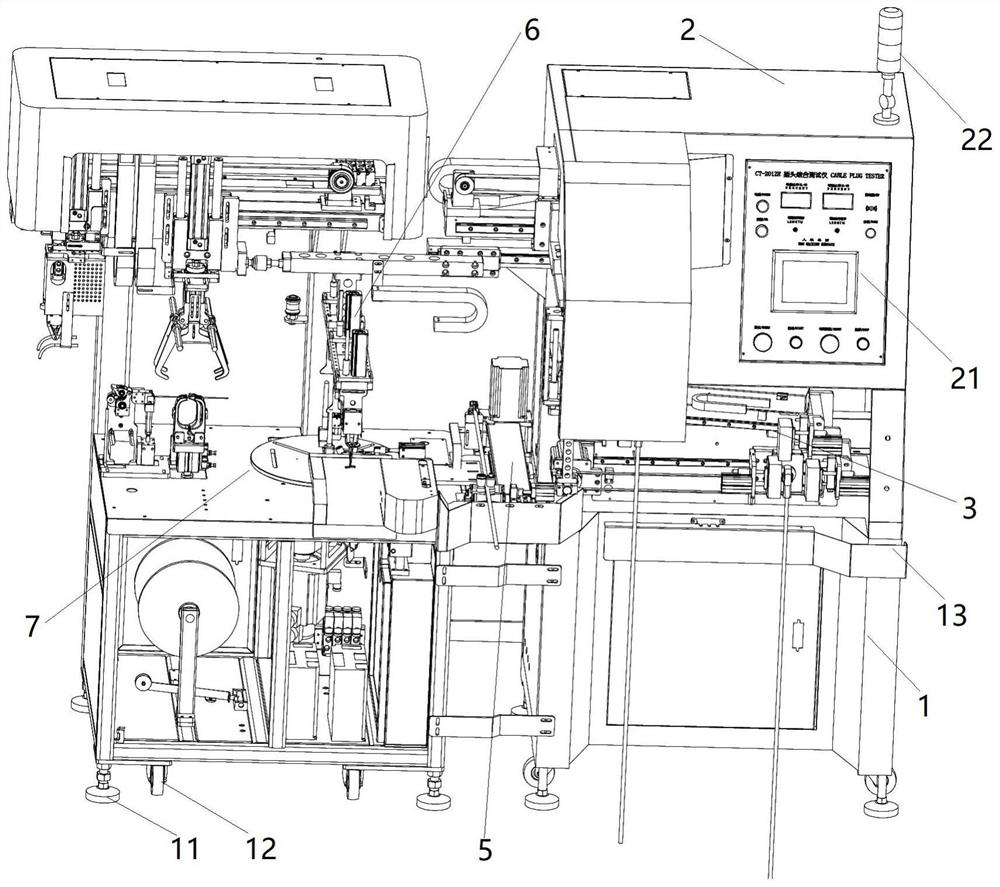

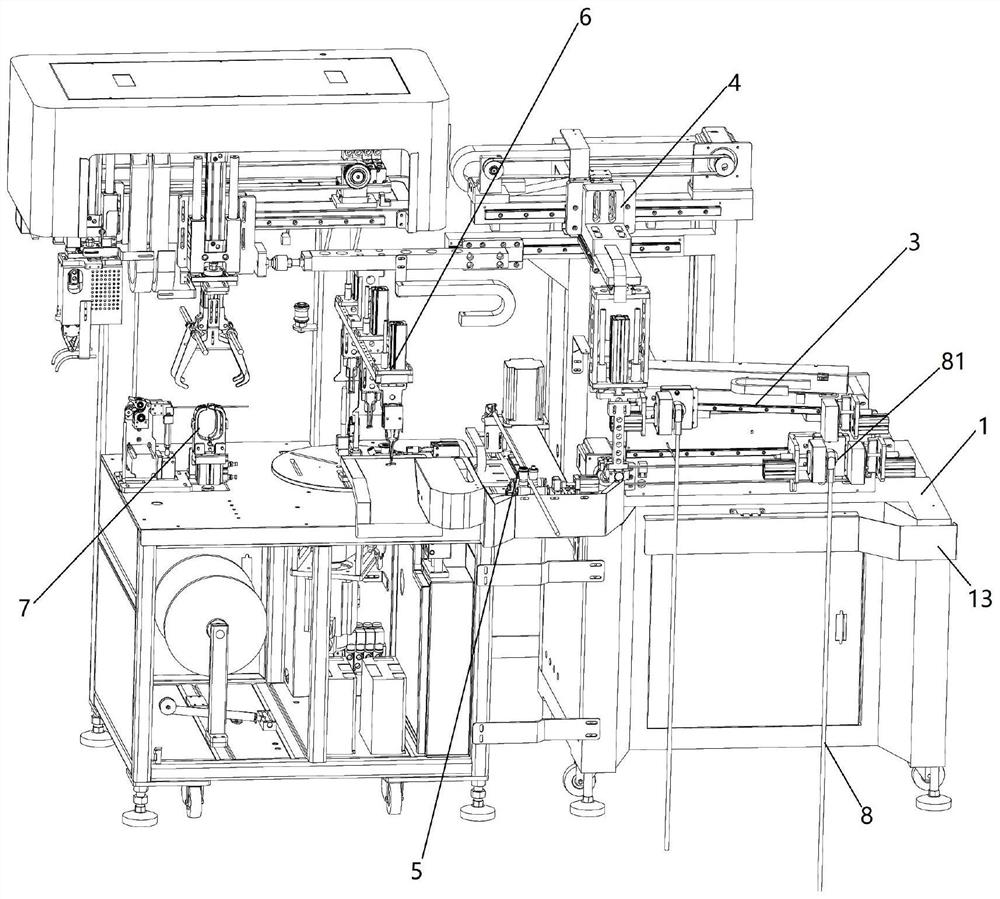

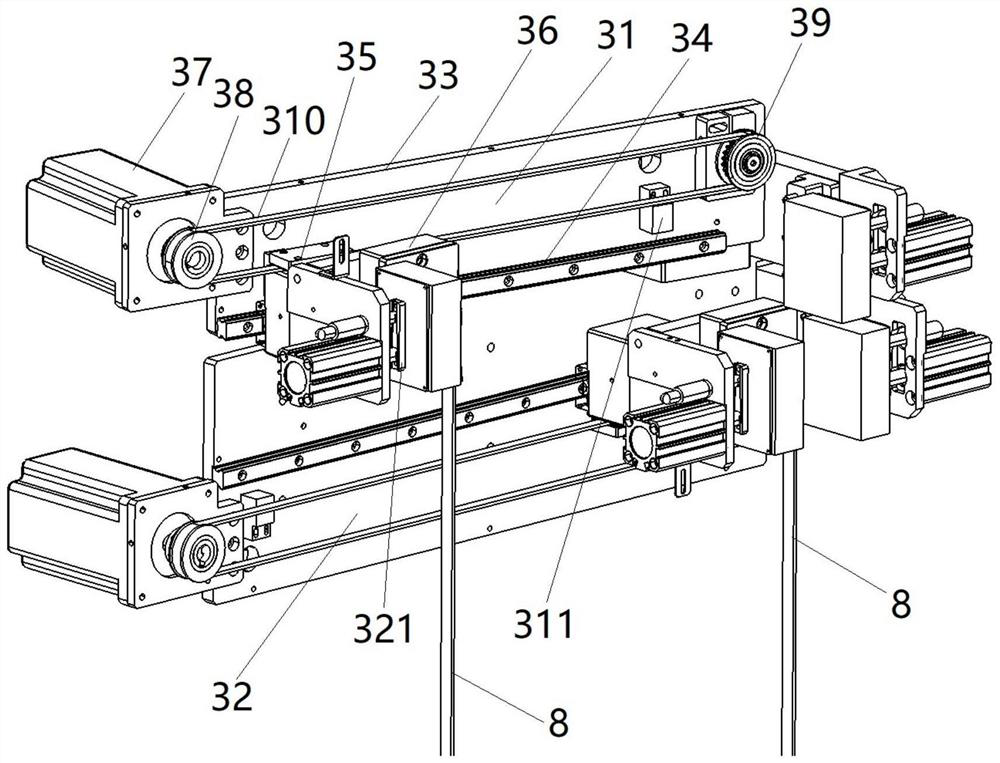

Automatic testing and winding all-in-one machine

PendingCN113092909AReduce manufacturing costIncrease the level of automationFilament handlingElectrical testingWinding machineWire rod

The invention discloses an automatic testing and winding all-in-one machine. The machine comprises a controller and a machine table, wherein the machine table is provided with a double-station testing mechanism, a wire conveying mechanism and a winding mechanism which are connected with the controller, the double-station testing mechanism is used for conducting a conduction test and an electric leakage test on wires, and the winding mechanism is used for arranging and packaging wires which are tested to be qualified; the wire conveying mechanism is used for conveying the wire from the double-station testing mechanism to the wire winding mechanism; the wire conveying mechanism comprises a wire pulling and conveying mechanism, a wire arranging mechanism and a wire taking hand mechanism, the wire pulling and conveying mechanism is used for conveying qualified wires on the double-station testing mechanism to the wire arranging mechanism, and the wire arranging mechanism is used for arranging the wires conveyed by the wire pulling and conveying mechanism in order; the wire taking hand mechanism is used for conveying the wires which are arranged in order on the wire arranging mechanism to the wire winding mechanism. According to the device, integrated operation of wire testing and winding storage is achieved, one device achieves two functions, the automation level of the device is improved, and a large amount of labor cost is saved.

Owner:SHENZHEN LIANCHENGZHI TECH CO LTD

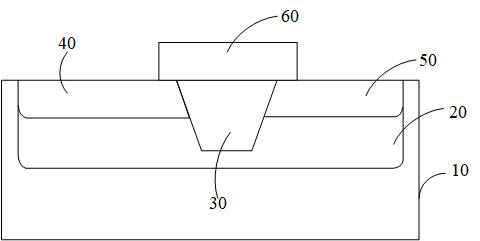

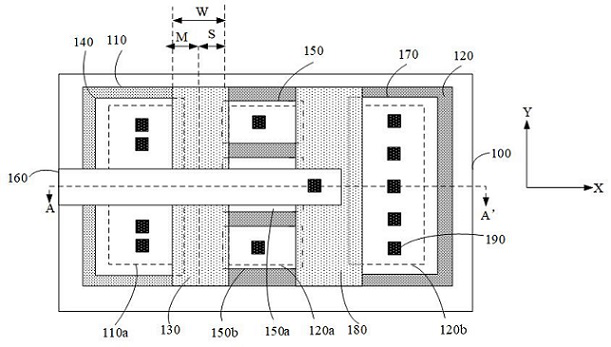

Electric leakage test structure and electric leakage test method

ActiveCN113257790AReflect problems such as parasitic leakageSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsDevice materialCurrent Leakage Testing

The invention provides an electric leakage test structure and an electric leakage test method. the electric leakage test structure comprises a substrate, and a first well region and a second well region are formed in the substrate; and the electric leakage test structure further comprises a first shallow trench isolation structure formed between the second well region and the first well region, a first source and drain region formed in the first well region, a plurality of second source and drain regions formed in the second well region and a test grid electrode formed on the substrate. In the electric leakage test method, the design sizes of the plurality of electric leakage test structures are different, and each electric leakage test structure is tested, so that the leakage current in each electric leakage test structure can be obtained; and the corresponding relation between the design size and the leakage current in the electric leakage test structure is obtained according to the leakage current in each electric leakage test structure, so that the problems of parasitic electric leakage and the like caused by the internal design of the semiconductor device can be reflected.

Owner:GUANGZHOU CANSEMI TECH INC

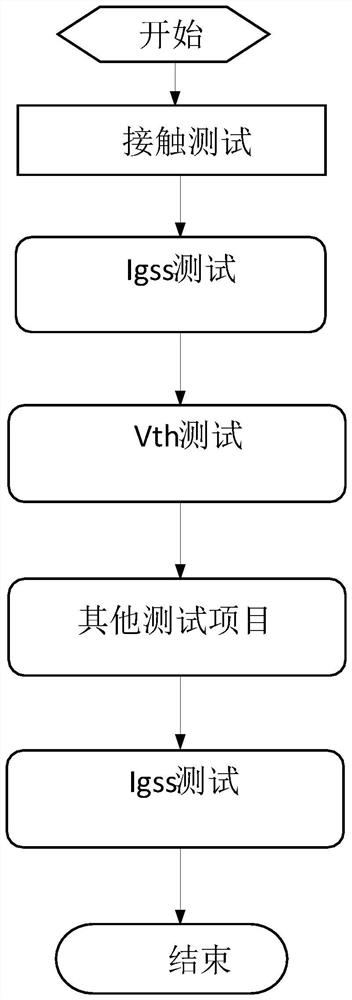

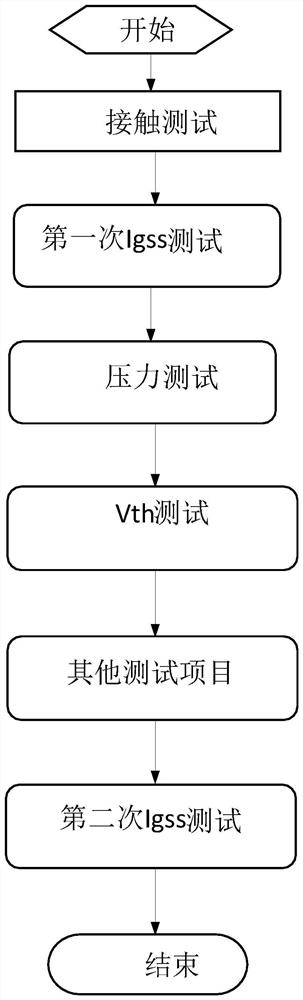

Discrete device testing method

PendingCN114582746AStable DC parameter resultsReliable DC parameter resultsSemiconductor/solid-state device testing/measurementContact testCurrent Leakage Testing

The invention discloses a discrete device testing method. The discrete device testing method comprises the following steps: step 1, contact testing; step 2, carrying out a first gate-source electric leakage test; step 3, pressure testing; 4, testing a threshold value; step 5, other test items; and step 6, carrying out a second gate-source electric leakage test. According to the invention, a stable and reliable DC parameter result can be well obtained, the test is convenient, and the test precision and the chip quality are improved.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

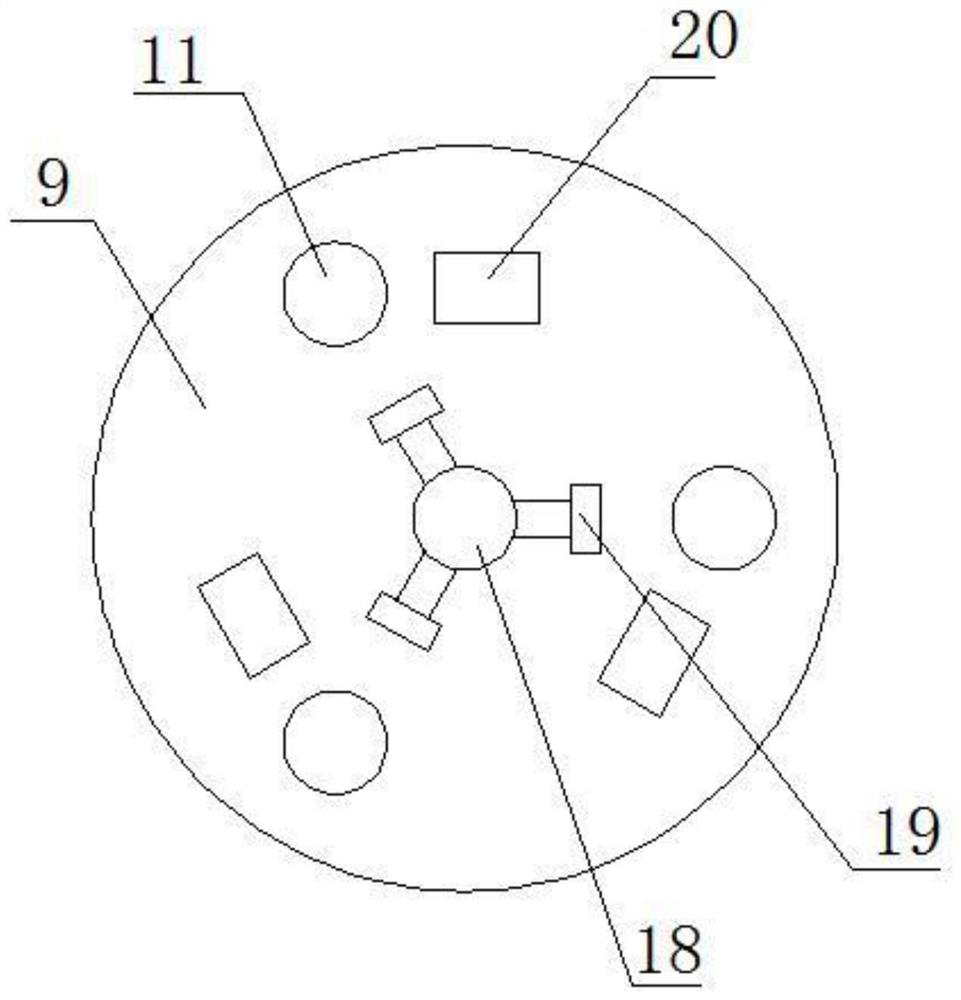

Anti-creeping testing device for numerical control machine tool research and development

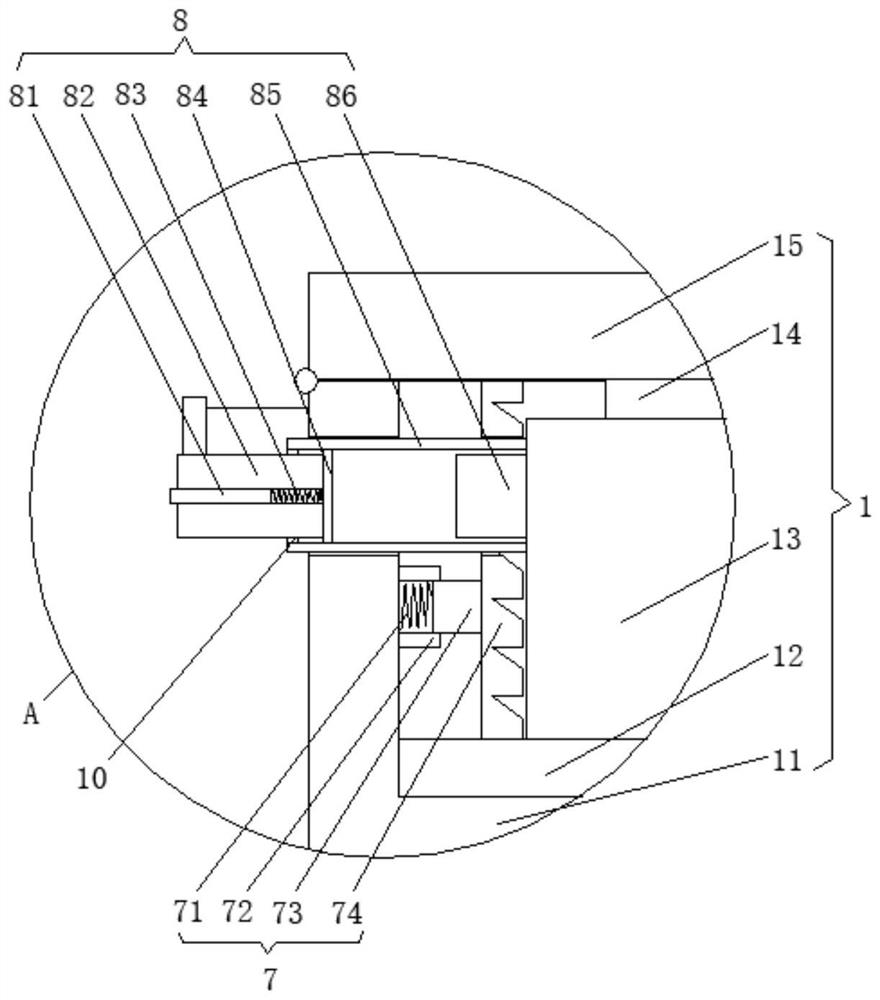

PendingCN112098896ARealize leakage testIncrease diversityElectrical measurement instrument detailsShort-circuit testingNumerical controlElectric machine

The invention relates to the field of numerical control machine tool research and development, in particular to an anti-creeping testing device for numerical control machine tool research and development. A water tank is arranged at the right end of a second electric telescopic mechanism, a third electric telescopic mechanism is arranged at the lower end of the water tank, and a driving mechanismis arranged at the lower end of the third electric telescopic mechanism. The driving mechanism comprises a first mounting base, a mounting groove is formed in the first mounting base, a second motor is arranged on the outer side of the first mounting base, a second mounting base is connected to the interior of the mounting groove through a first rotating shaft, the output end of the second motor is connected with the first rotating shaft, and a third motor is arranged in the second mounting base; and a second rotating shaft is arranged at the output end of the third motor, a rotating seat is arranged at the outer end of the second rotating shaft, and an electric leakage test main body is arranged in the right side of the rotating seat. The structure can achieve the omnibearing anti-electric leakage test of the machine tool, the comprehensiveness and accuracy of the test are improved, and the practicability is high.

Owner:CHINA NORTH STANDARDIZATION CENT

Intelligent earth leakage protection switch

ActiveCN114079261AEmergency protective arrangements for automatic disconnectionElectric power equipmentCurrent Leakage Testing

The invention relates to the field of power equipment, in particular to an intelligent earth leakage protection switch. The switch comprises an earth leakage protection switch body, an instruction receiving module, a test triggering module and a judgment indication module. The instruction receiving module receives a test instruction periodically sent by the superior controller, and controls the test trigger module to trigger an electric leakage test function after receiving the test instruction; and when the judgment indication module does not detect the leakage protection action, the alarm prompt information is sent. In the invention, the control equipment at the upper level can send out or generate a signal which can be identified by the electric leakage protection switch and can be uniquely identified, and when the electric leakage protection switch identifies the signal, the electric leakage protection test function is executed, so the normal function of the electric leakage protection switch can be ensured. According to the invention, the leakage protection function of the leakage protection switch can be periodically and automatically tested.

Owner:ZOUPING POWER SUPPLY CO

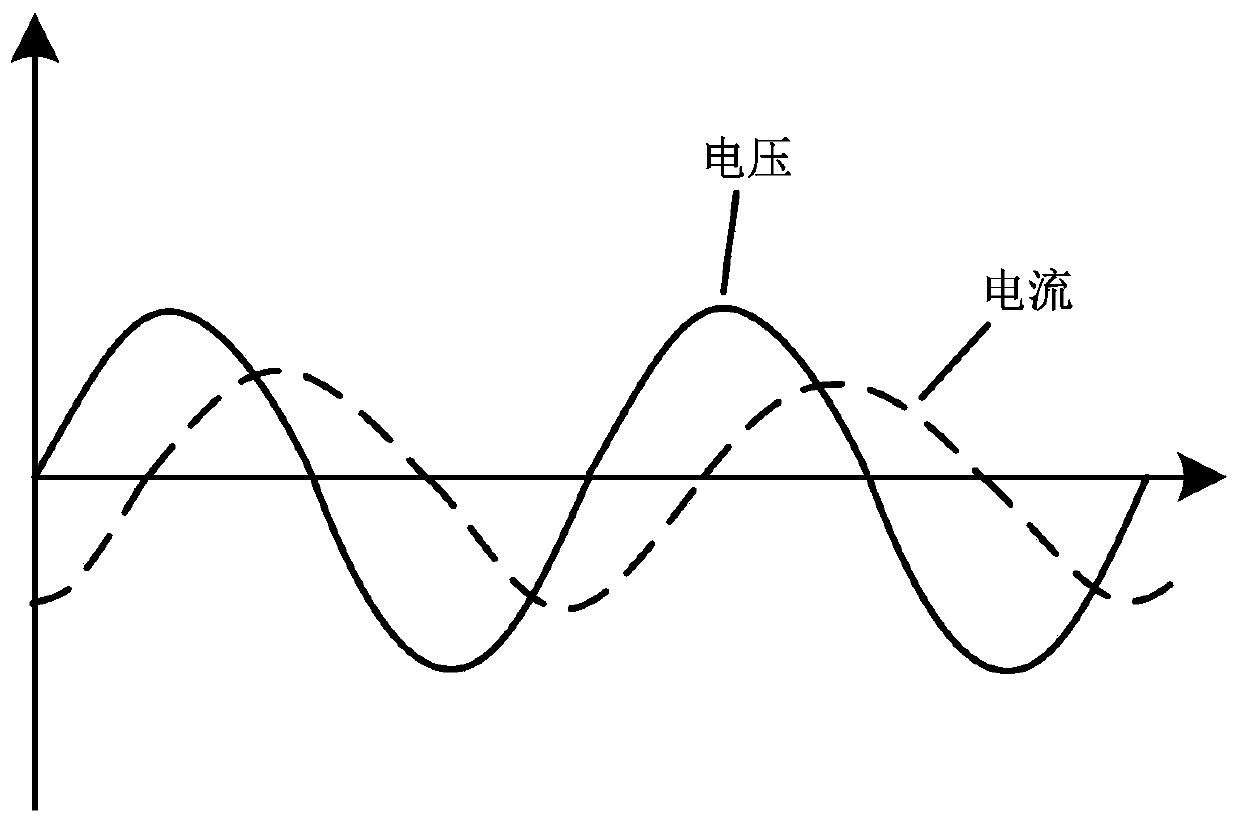

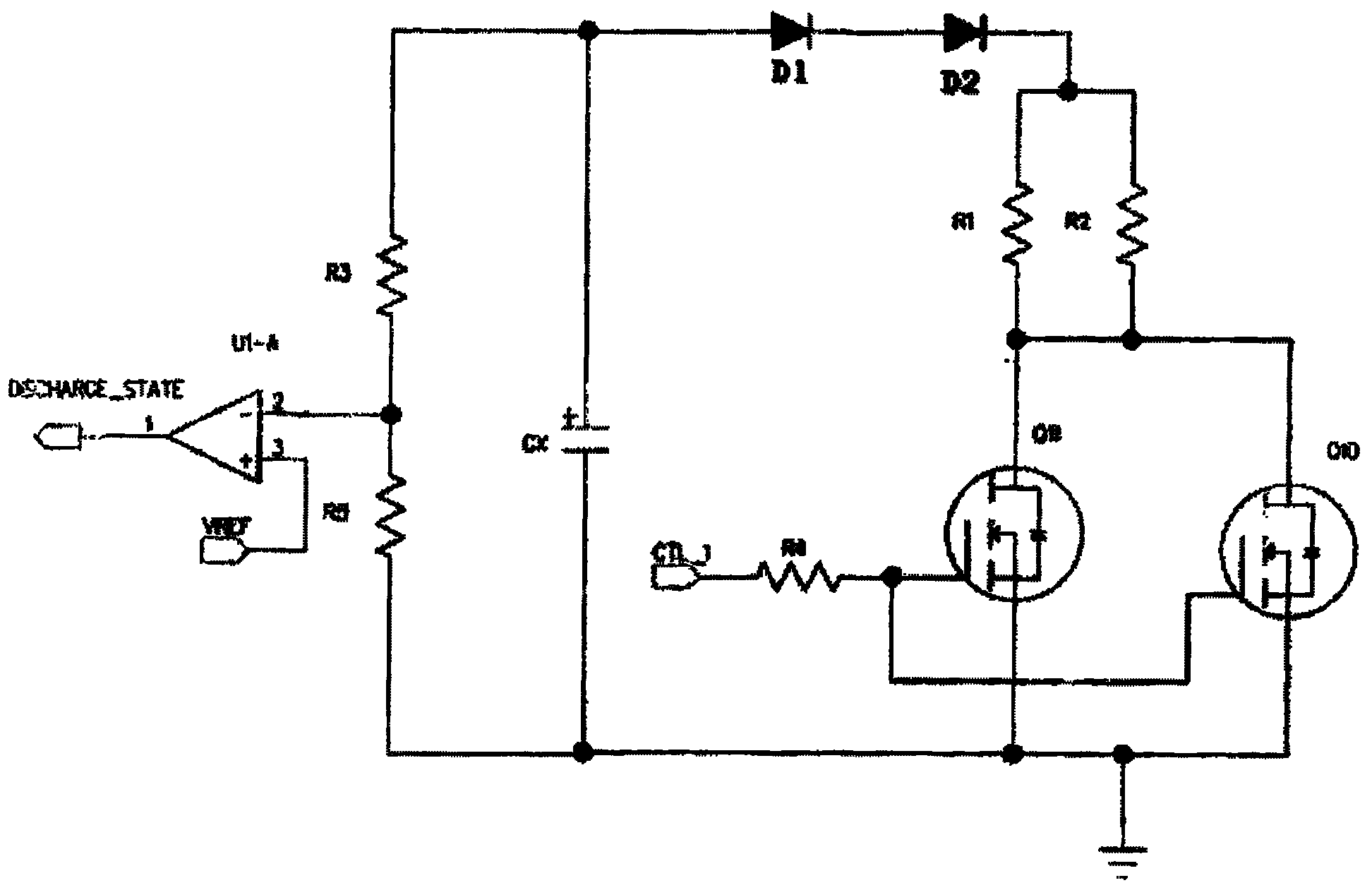

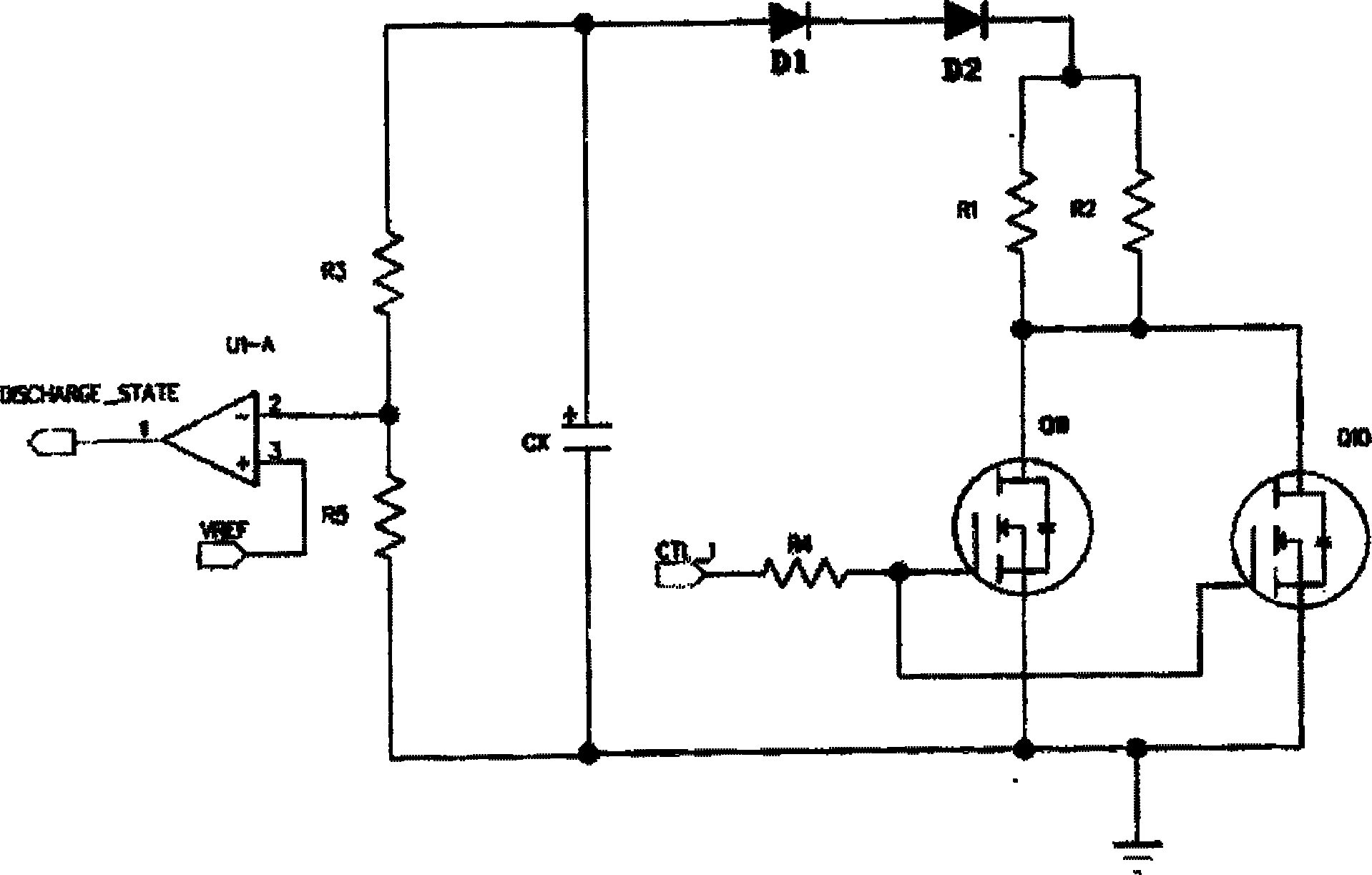

A Test Circuit for Residual Current Protection

ActiveCN103399236BImprove reliabilityReduce power consumptionElectrical testingCircuit reliabilityLow voltage

The invention relates to a circuit, in particular to a residual current protection testing circuit in a device with residual current protection. The residual current protection testing circuit is characterized in that the residual current protection testing circuit comprises a testing button S1, an operational amplifier U1, a Wien bridge circuit, an output circuit and a current transformer CT, and the Wien bridge circuit comprises a resistor R7, a resistor R8, a capacitor C2 and a capacitor C3. By adopting the scheme, the novel residual current protection testing circuit provided by the invention has the advantages that the problems existing in the prior art are overcome; since a sine wave oscillating circuit is used for simulating output current leakage testing signals, the circuit reliability is high and the circuit is not influenced by open phase and under-voltage of a three-phase power supply; and since a low-voltage power supply is used for supplying power, the power consumption is low, and the problems that heat is produced and power resistors are apt to damage due to a reason that a high-power resistor is used for decreasing voltage are avoided.

Owner:DELIXI ELECTRIC

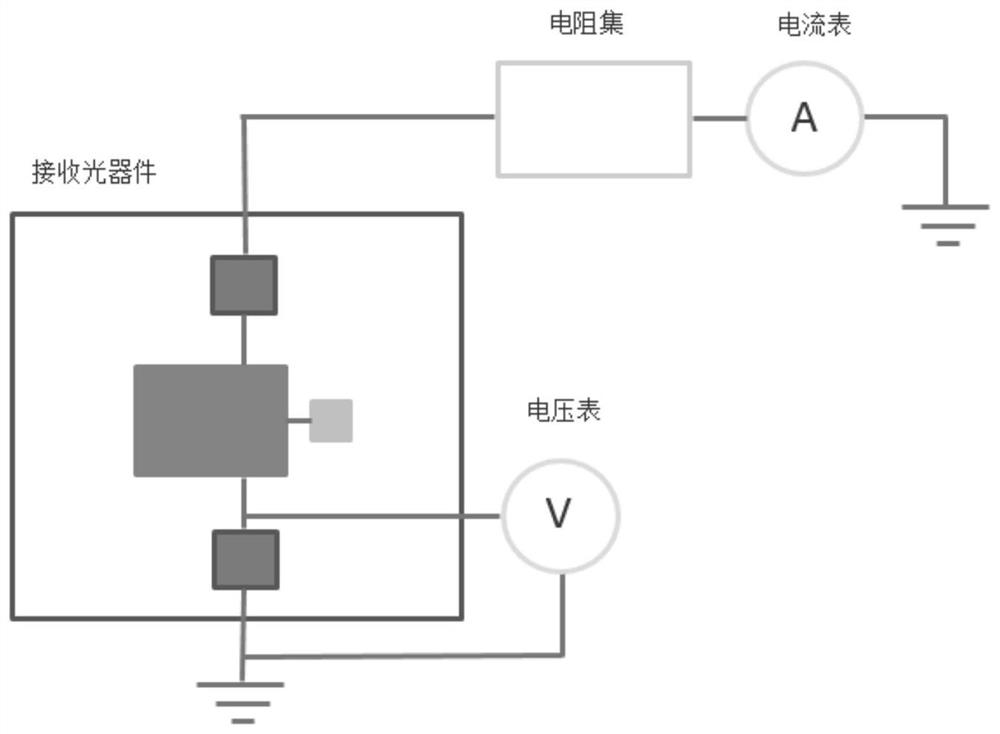

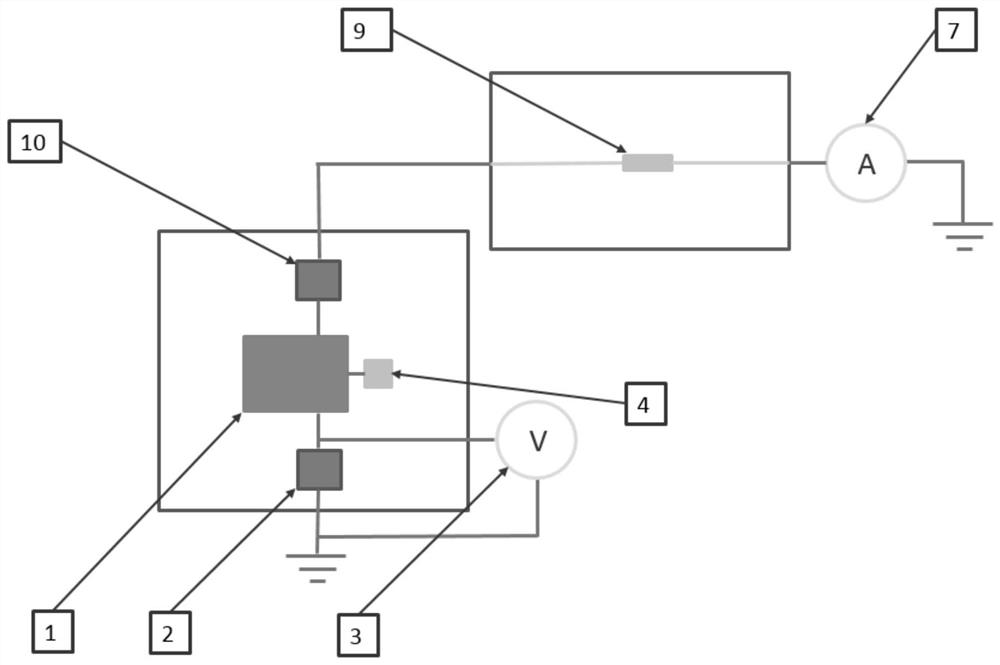

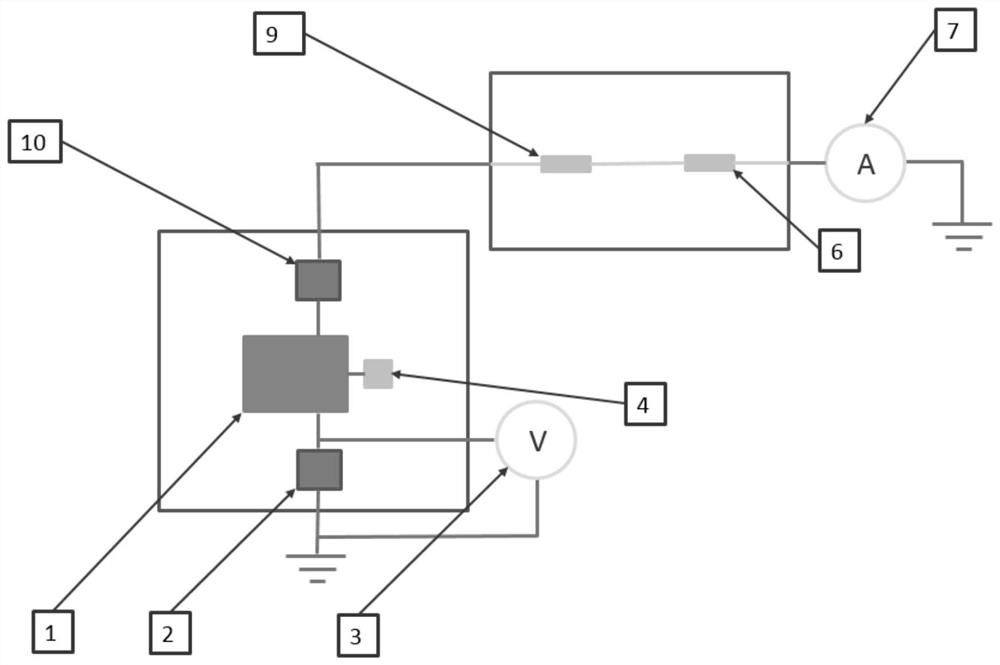

A leakage test system and test method for defective optical device capacitor elements based on the device side

ActiveCN112710941BPrevent stay untilLow costShort-circuit testingIndividual semiconductor device testingCapacitanceCurrent Leakage Testing

The invention provides a leakage test system for defective optical device capacitive elements based on the device end, including: a voltmeter (3), an ammeter (7), a variable resistance set and an optical receiving device, wherein both the ammeter and the voltmeter are grounded, and the ammeter The other end is connected to the variable resistance set, and the other end of the variable resistance set is connected to the optical receiving device. The optical receiving device includes a VCC capacitor (2), a transimpedance amplifier (1), an RSSI capacitor (10) and a detector ( 4), one end of the RSSI capacitor is connected to the variable resistance set, one end of the VCC capacitor is grounded, the other end is respectively connected to the transimpedance amplifier and the voltmeter, and one end of the detector is connected to the transimpedance amplifier; the variable resistance set is a series or parallel connection formed by resistors In the circuit, the resistance of the variable resistor set can be adjusted. Different products have different requirements for matching resistors. By adjusting the voltage value and current value, it is judged whether there is a capacitor failure in the receiving optical device. Corresponding testing methods are also disclosed.

Owner:GUILIN OPTOSEAL TECH CO LTD

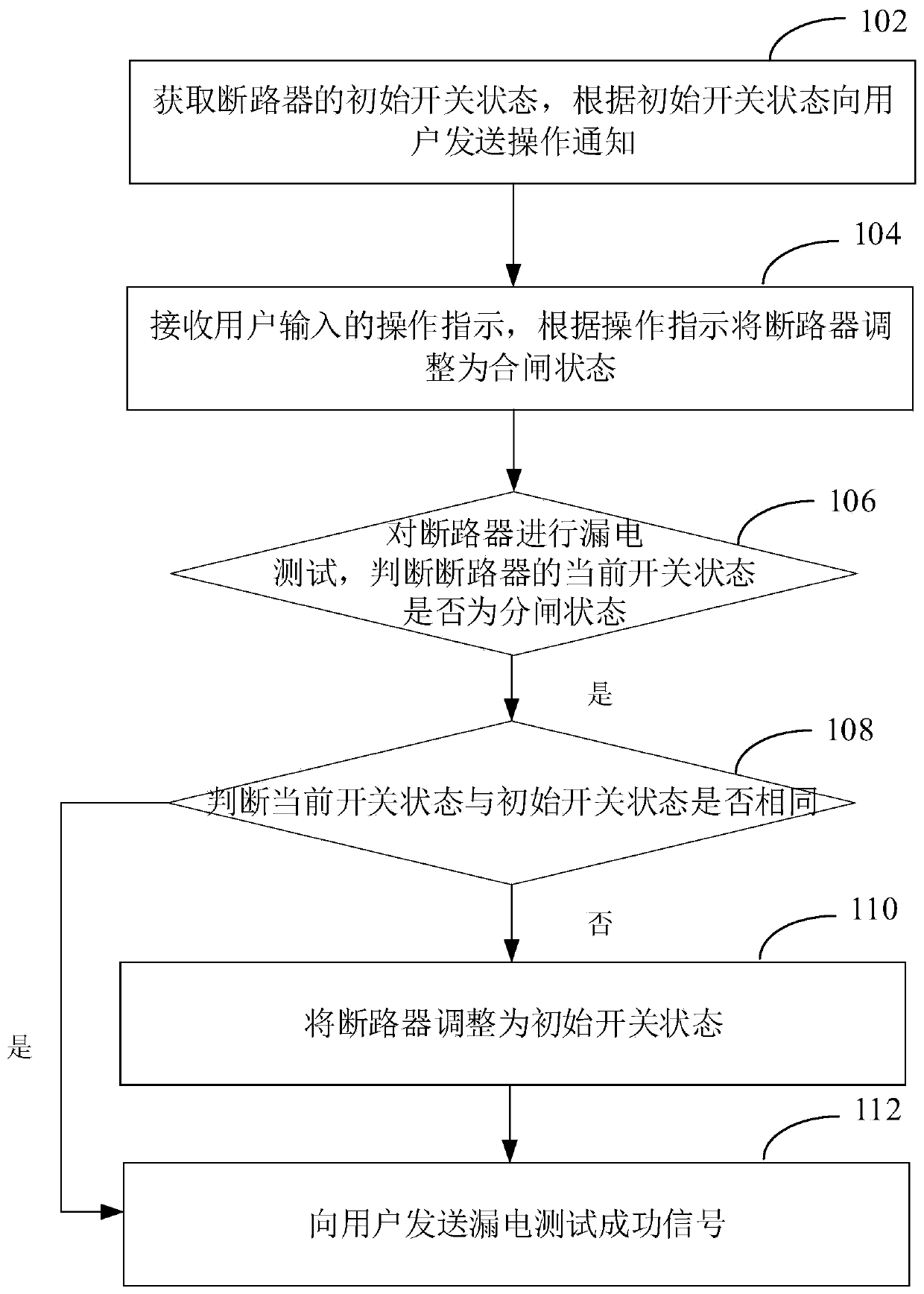

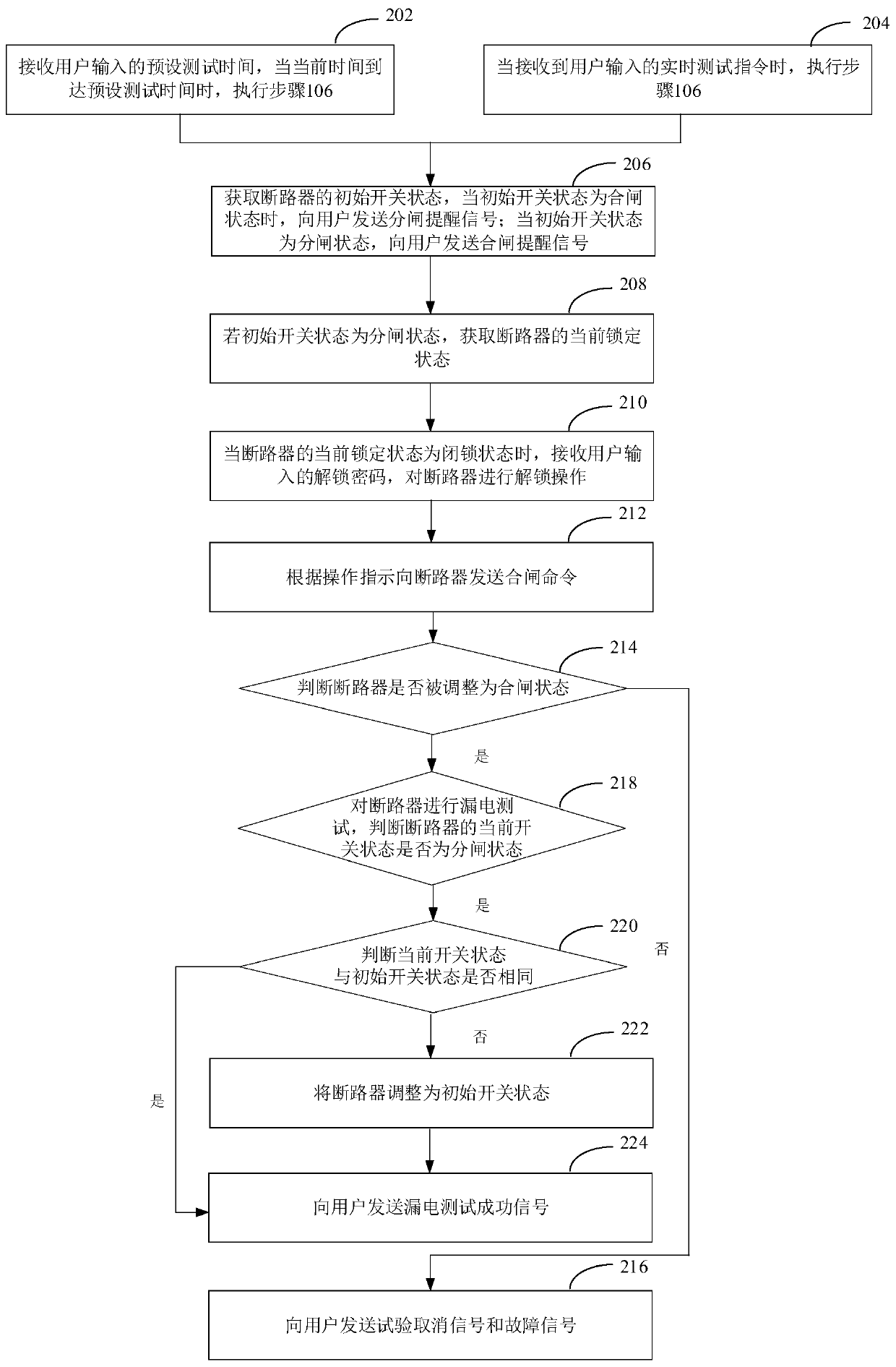

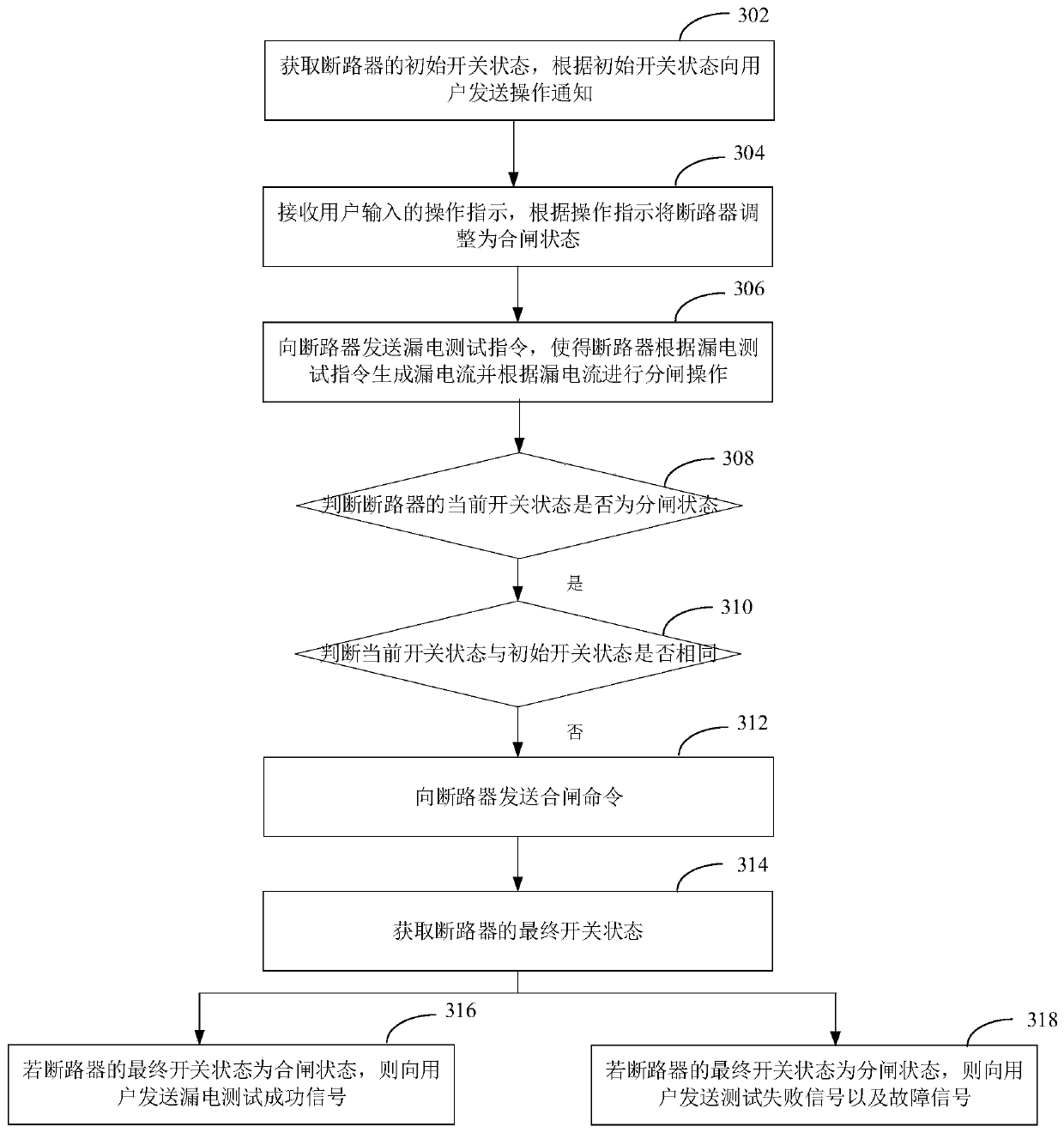

Circuit breaker electric leakage test method and system, equipment and medium

InactiveCN111537870ALeakage test went wellIncrease success rateShort-circuit testingCircuit interrupters testingCurrent Leakage TestingLeakage test

The invention discloses a circuit breaker electric leakage test method, which comprises the following steps: obtaining an initial switch state of a circuit breaker, and sending an operation notification to a user according to the initial switch state; receiving an operation instruction input by the user, and adjusting the circuit breaker to be in a closing state according to the operation instruction; performing an electric leakage test on the circuit breaker, and judging whether the current switch state of the circuit breaker is an opening state; if the current switch state of the circuit breaker is an opening state, judging whether the current switch state is the same as the initial switch state; and if the current switch state is different from the initial switch state, adjusting the circuit breaker to be in the initial switch state, and sending an electric leakage test success signal to the user. According to the invention, the success rate of the electric leakage test can be effectively improved, and the adverse effect of the electric leakage test is also effectively reduced. The invention also provides a circuit breaker electric leakage test device, computer equipment and a storage medium.

Owner:江苏能电科技有限公司

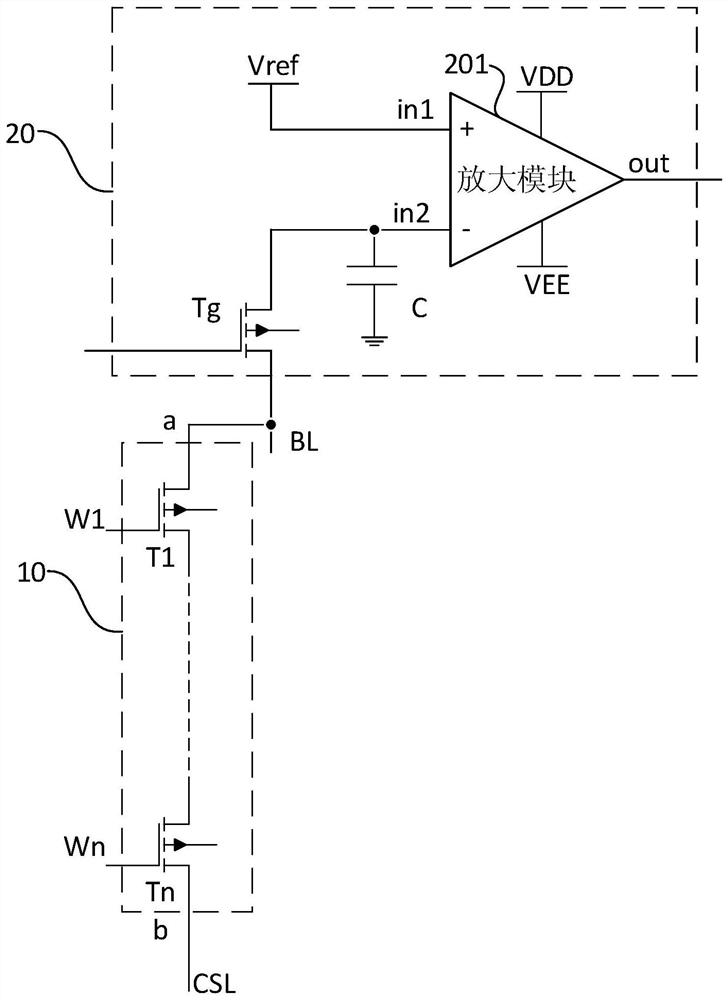

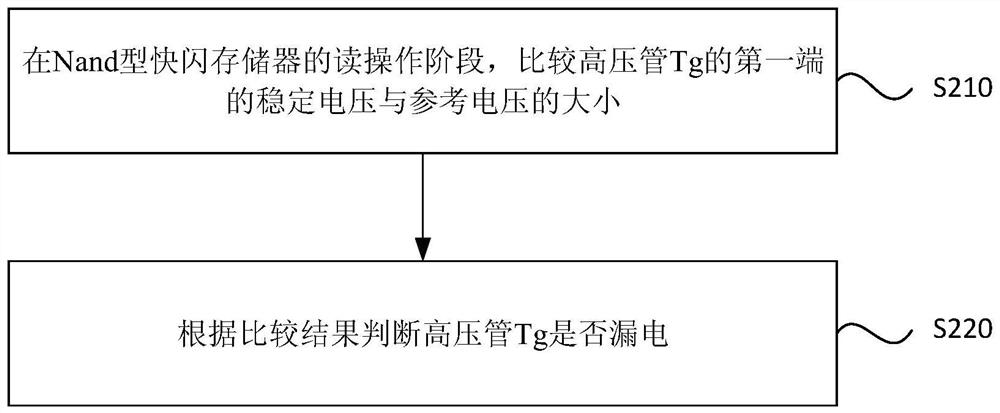

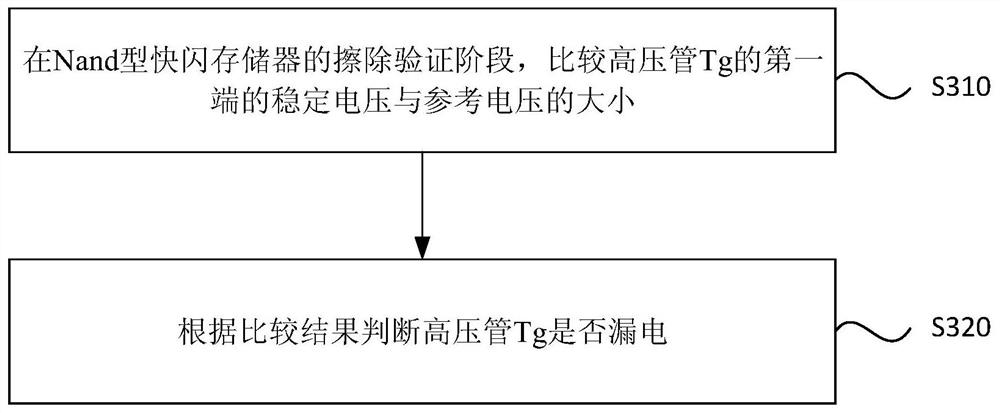

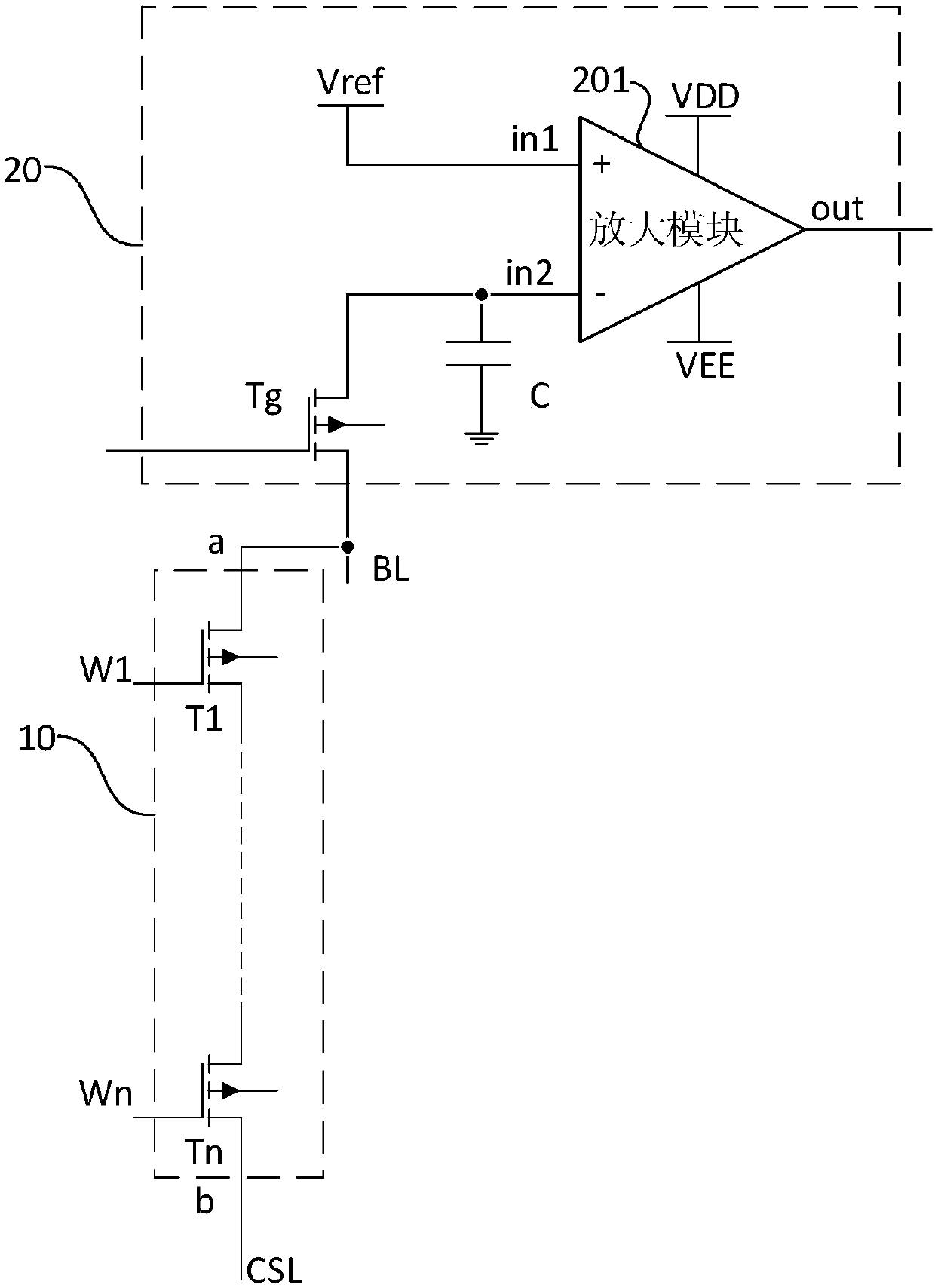

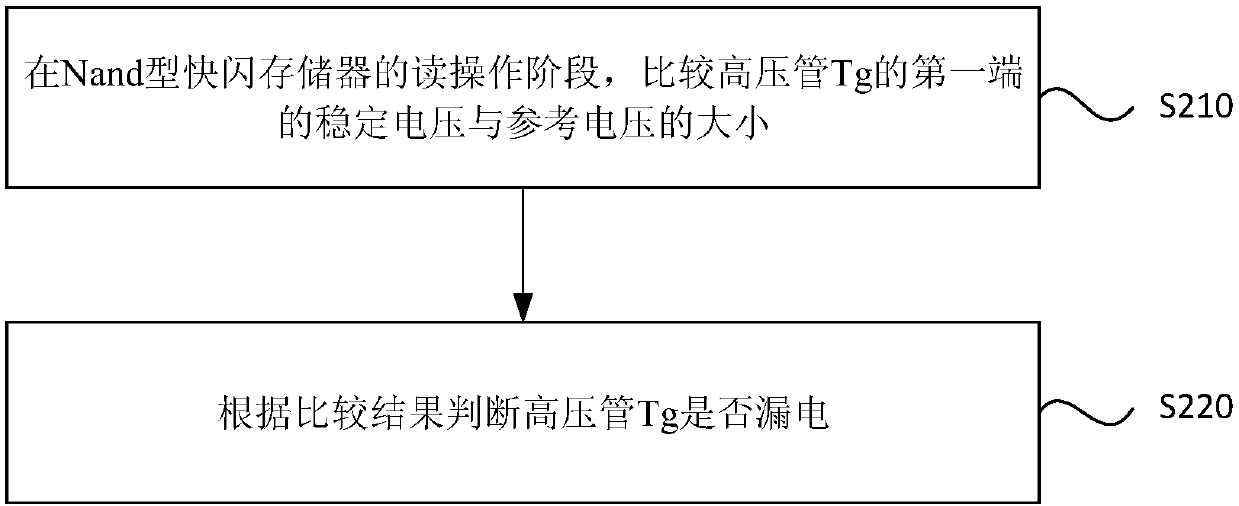

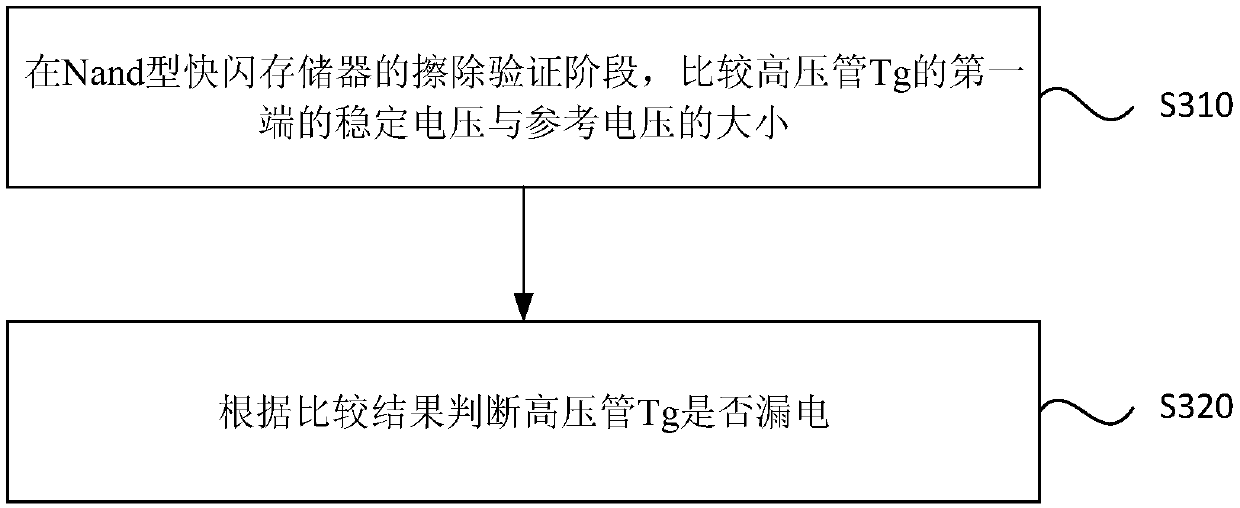

A kind of leakage test method of nand type flash memory

ActiveCN110838335BImprove reliabilityEfficiently detect leakage conditionsStatic storageCapacitanceCurrent Leakage Testing

The invention discloses a leakage test method of a Nand flash memory. The Nand type flash memory includes a storage unit and a sense amplifier, the first end of the high voltage tube of the sense amplifier is electrically connected to the first end of the precharge capacitor, the second end of the high voltage tube and the first end of the storage unit are connected to the bit The second end of the precharge capacitor is connected to the ground, and the second end of the storage unit is electrically connected to the source line. The leakage test method of the Nand flash memory includes: comparing the stable voltage of the first end of the high voltage tube with the reference voltage in the erasing verification stage of the Nand type flash memory; judging whether the high voltage tube leaks electricity according to the comparison result. The invention carries out the leakage test of the high-voltage tube through the multiplexing erasure verification process, so that the voltage difference loaded at both ends of the high-voltage tube is relatively large, and the leakage of the high-voltage tube in the sense amplifier can be effectively detected, thereby improving the performance of the Nand type flash memory reliability.

Owner:GIGADEVICE SEMICON (BEIJING) INC +1

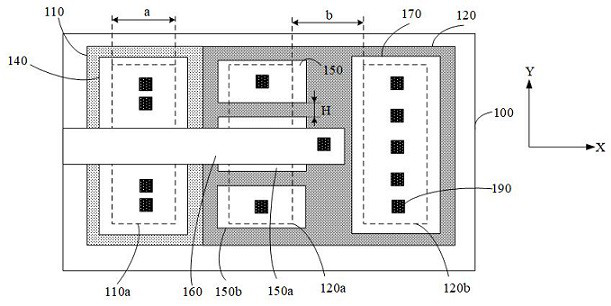

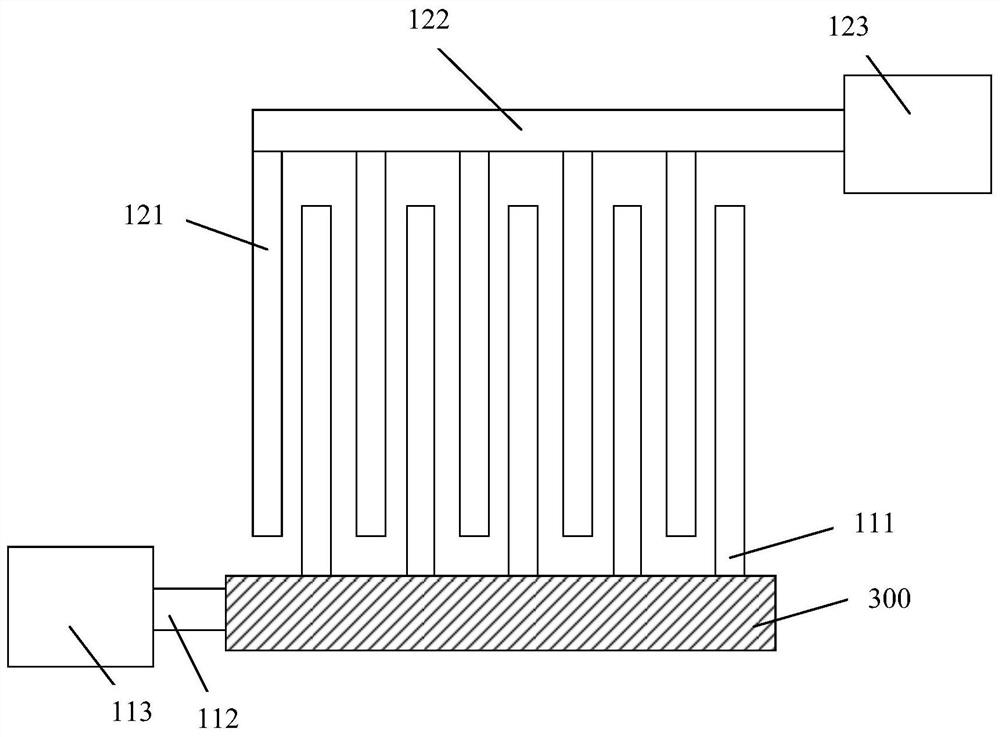

A low leakage connector

ActiveCN108037325BReliable electrical connectionImprove test efficiencyPrinted circuit testingMeasurement instrument housingElectrical connectionCurrent Leakage Testing

The embodiment of the invention provides a low-electric leakage connector. The low-electric leakage connector comprises multiple telescopic connection mechanisms; one end of each telescopic connectionmechanism is correspondingly connected with a first signal electrode of a first test substrate and a first equipotential electrode respectively, and the other end of the telescopic connection mechanism is correspondingly connected with a second signal electrode of a second test substrate and a second equipotential electrode respectively; a ground shield mechanism is arranged on the ground electrode of the first test substrate or the ground electrode of the second test substrate; and a ground connection part is connected between the ground electrode of the first test substrate and the ground electrode of the second test substrate. Thus, according to the low-electric leakage connector, pins of the first test substrate and the second test substrate can be electrically connected while the low-electric leakage performance is kept, the number of low-electric leakage connectors can be determined according to the number of to-be-connected pins, the multiple low-electric leakage connectors canfurther be used to connect and test a low-electric leakage test substrate with multiple pins, and the test efficiency is improved.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

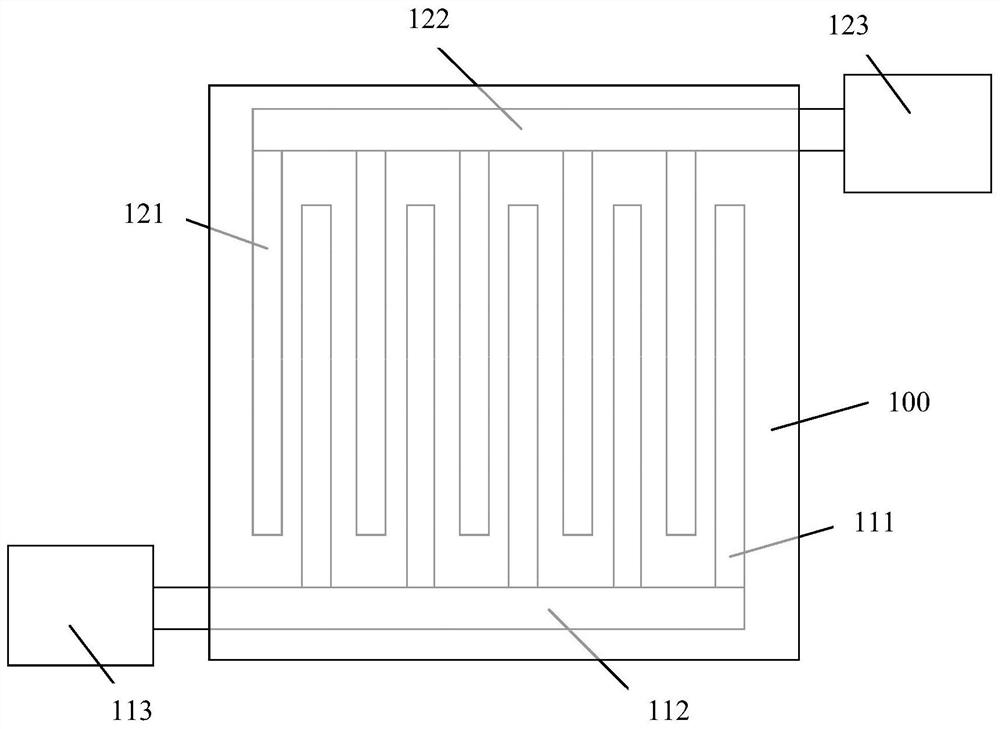

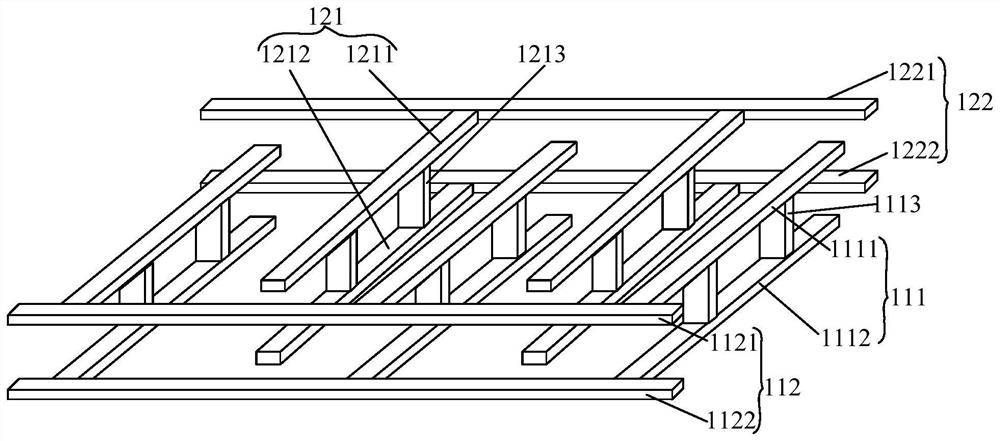

Leakage test method

ActiveCN108831843BLocation determinationSemiconductor/solid-state device testing/measurementTest sampleCurrent Leakage Testing

The invention relates to an electric leakage test method, which comprises the steps of providing a test sample, wherein the test sample includes an insulating layer, the insulating layer is internallyprovided with an electric leakage test structure, the electric leakage test structure includes a first comb-shaped metal wire and a second comb-shaped metal wire, the first comb-shaped metal wire includes a plurality of first comb tooth metal wires which are arranged in parallel, the second comb-shaped metal wire includes a plurality of second comb tooth metal wires which are arranged in parallel, and the first comb tooth metal wires and the second comb tooth metal wires are arranged in a mutually parallel manner at intervals; etching the test sample, and forming a groove in the test sample,wherein the side wall at one side of the groove at least exposes end parts of the plurality of first comb tooth metal wires; and positioning failure location through observing the voltage contrast atthe end parts of the plurality of first comb tooth metal wires exposed by the side wall of the groove. The failure location can be positioned without destroying the surface of the test sample according to the method.

Owner:YANGTZE MEMORY TECH CO LTD

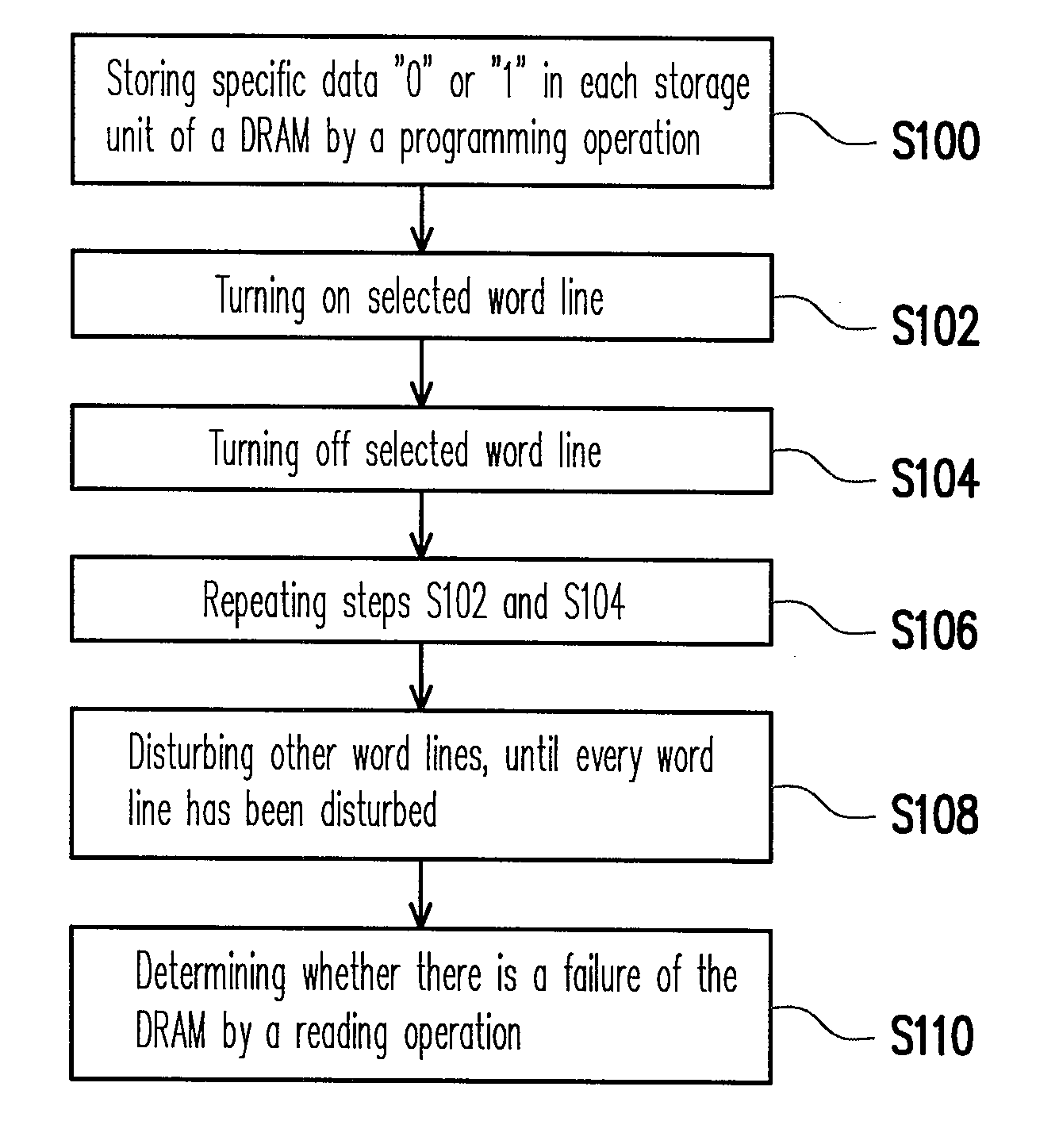

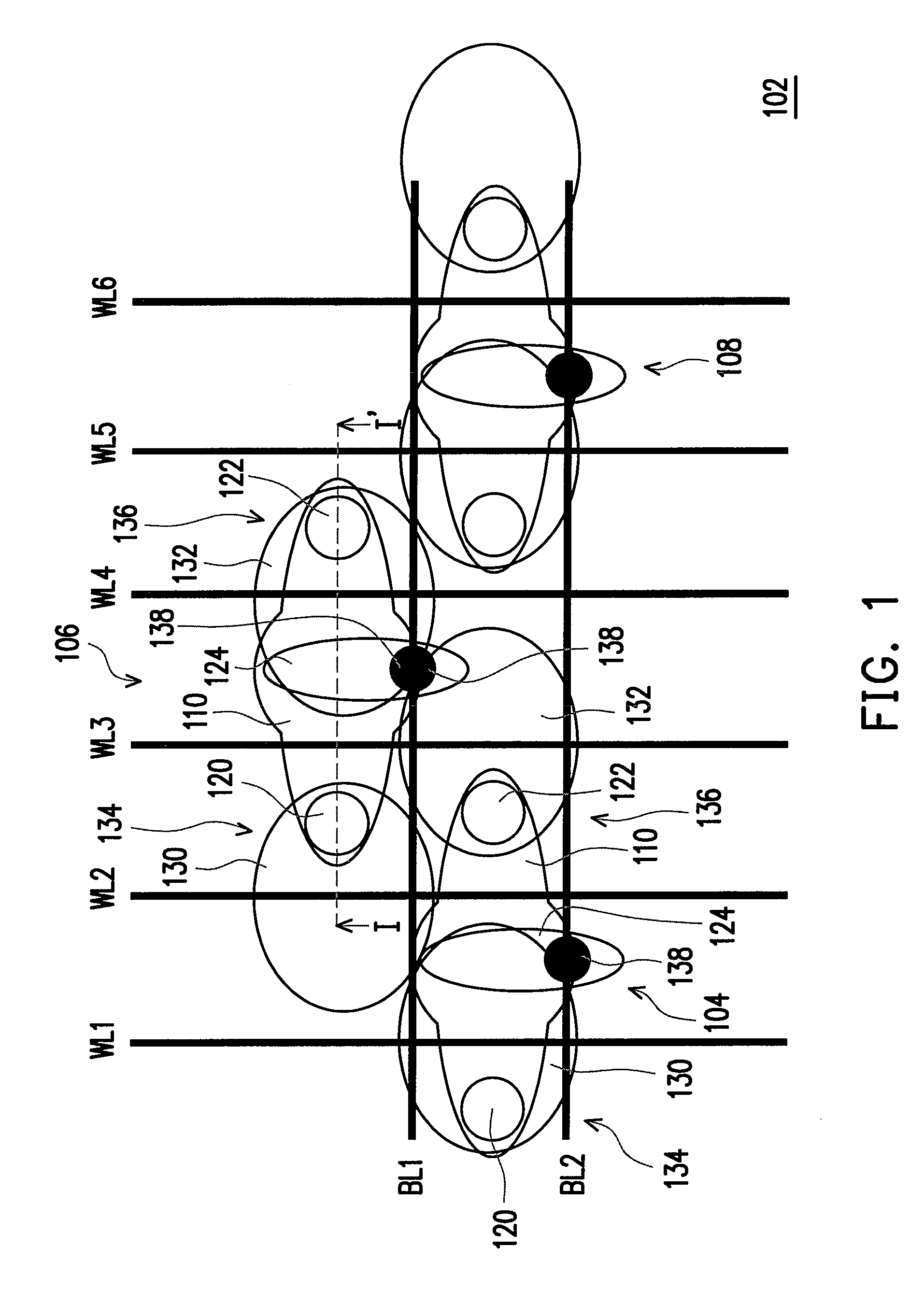

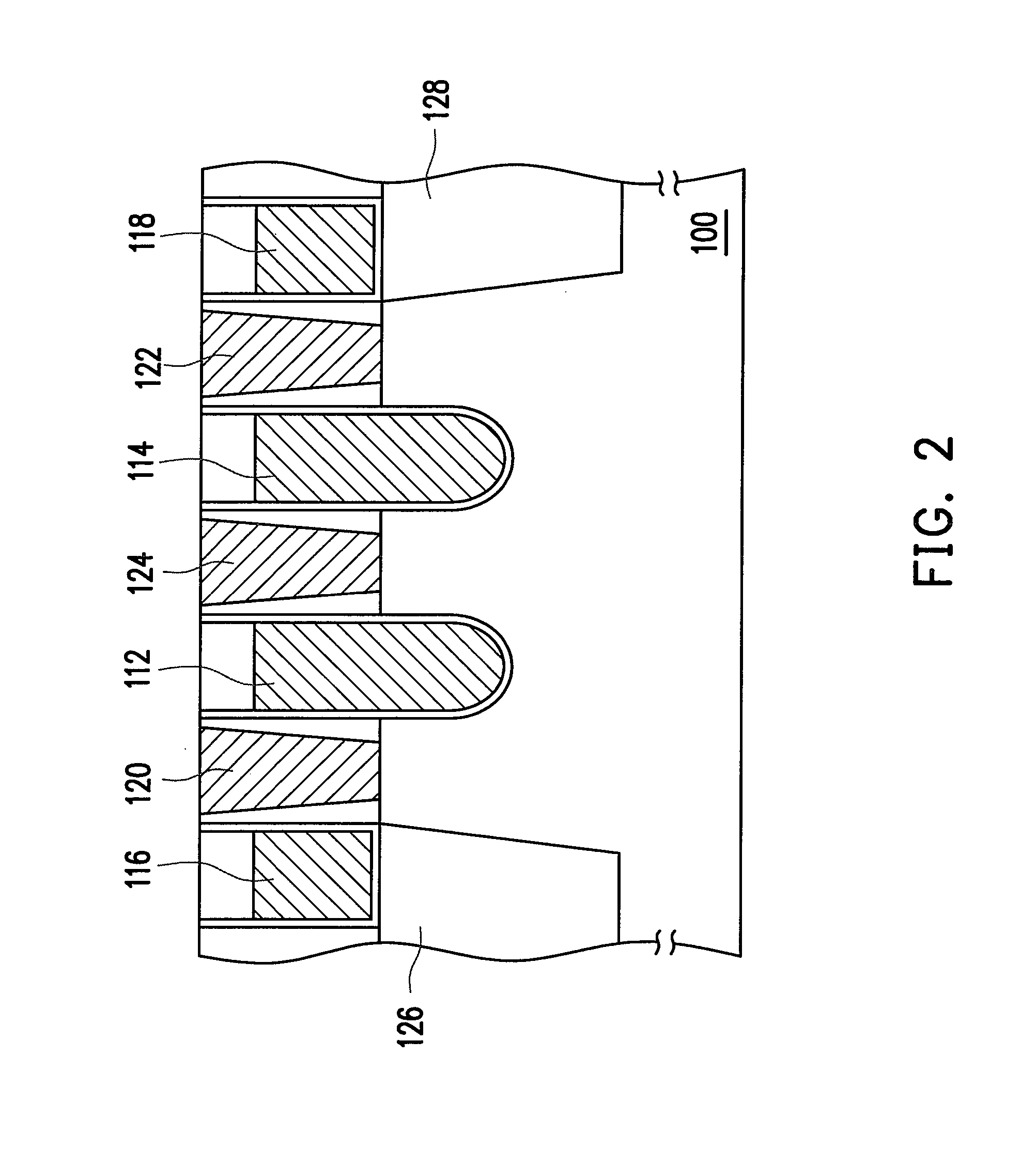

Leakage testing method for dynamic random access memory having a recess gate

A leakage testing method for a DRAM having a recess gate is provided. The method includes the steps of: programming to set the first storage unit and the second storage unit of a same memory cell with different storage statuses; and disturbing one of the word lines extending through the memory cells; then determining whether the DRAM is acceptable or not. When another one of the word lines extending through the memory cells is caused with a reading error by disturbing the one of the word lines extending through the memory cells, a failure is determined as occurred, and the failure is attributed to a leakage type of extended depletion region. When the another one of the word lines extending through the memory cells is not caused with a reading error by disturbing the one of the word lines extending through the memory cells, the DRAM is determined as acceptable.

Owner:PROMOS TECH INC

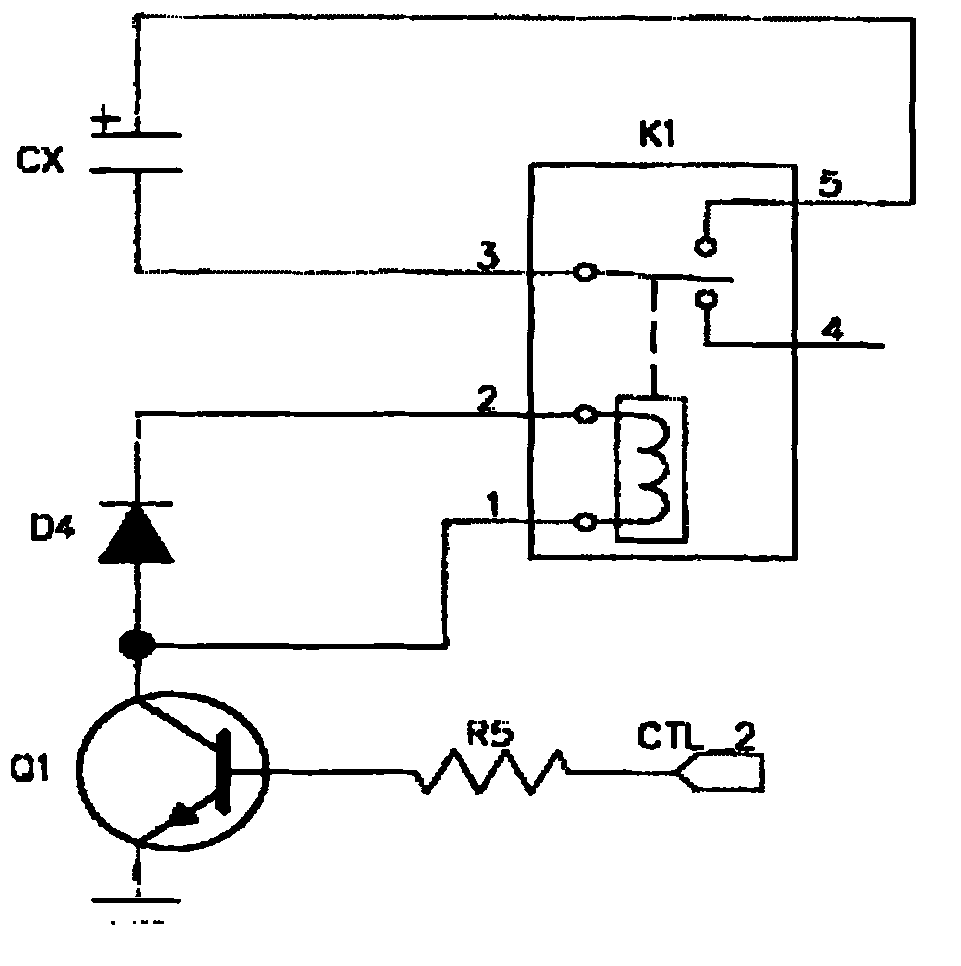

Discharging method and device of capacity fall-off tester

ActiveCN102169129APrevent mechanical vibration and arcing phenomenon of high voltage and high currentAvoid arcingElectrical measurement instrument detailsElectrical testingCapacitanceTester device

The invention provides a discharging method of a capacity fall-off tester. In the discharging method, mechanical discharging is adopted after electronic discharging, momentary large voltage and large current are not generated at the initial discharging stage, so that the arcing phenomena of mechanical dithering, large voltage and large current are avoided. The invention also provides a device forthe method. The device comprises a discharging selection switch, an electronic discharging circuit, a mechanical discharging circuit, a voltage comparator and a tested capacitor controlled by a microprocessor, wherein two ends of the tested capacitor are connected to the electronic discharging circuit and the mechanical discharging circuit. By adopting the device, the results such as machine halt, resetting and the like caused by the disturbance of various instruments on a digital control system during capacitor discharging can be avoided.

Owner:UNI TREND TECH (CHINA) CO LTD

Direct-current charging pile testing device

ActiveCN112162215AEasy to useImprove the protective effectNon-rotating vibration suppressionShort-circuit testingClassical mechanicsCurrent Leakage Testing

The invention discloses a direct-current charging pile testing device which comprises a damping mechanism, a clamping mechanism and an electric leakage testing mechanism. The damping mechanism comprises a shell, a lifting mechanism is arranged at the front side of the shell, and a moving mechanism is arranged at the bottom side of the shell; a supporting mechanism is arranged at the rear side of the shell, a first damping rubber is arranged at the bottom side in the shell, a testing machine is placed on the first damping rubber, and a sealing cover is hinged to the upper surface of the shell;second damping rubber is arranged at the bottom side in the sealing cover and is located on the upper surface of the testing machine, and a clamping mechanism is arranged at the front side of the shell and the front side of the sealing cover; and the clamping mechanism comprises eight first fixing sleeves. The direct-current charging pile testing device can carry out electric leakage testing on adirect-current charging pile, electric shock is avoided, dangers to workers are prevented; moreover, the testing device can be conveniently carried and damped, damage to the testing device is prevented, and the direct-current charging pile testing device can be conveniently used by a user.

Owner:SUZHOU TRACEABILITY STANDARD CERTIFICATION & INSPECTION CO LTD

Electric leakage test method of Nand type flash memory

ActiveCN110838335AImprove reliabilityEfficiently detect leakage conditionsStatic storageCapacitanceBit line

The invention discloses an electric leakage test method of a Nand type flash memory. The Nand type flash memory comprises a storage unit and a sense amplifier, the first end of a high-voltage tube ofthe sense amplifier is electrically connected with the first end of a pre-charging capacitor, the second end of the high-voltage tube and the first end of the storage unit are electrically connected with a bit line, the second end of the pre-charging capacitor is grounded, and the second end of the storage unit is electrically connected with a source line. The electric leakage test method of the Nand type flash memory comprises the following steps: in an erasure verification stage of the Nand type flash memory, comparing a stable voltage of a first end of a high-voltage tube with a reference voltage; and judging whether the high-voltage tube leaks electricity according to the comparison result. According to the invention, the electric leakage test of the high-voltage tube is carried out through the multiplexing erasure verification process, so that the voltage difference loaded at the two ends of the high-voltage tube is relatively large, the electric leakage condition of the high-voltage tube in the sense amplifier can be effectively detected, and the reliability of the Nand type flash memory is improved.

Owner:GIGADEVICE SEMICON (BEIJING) INC +1

Photovoltaic module wet electric leakage test device

InactiveCN112034308AGuaranteed uptimeTesting dielectric strengthCircuit arrangementsElectrolytic agentThermodynamics

The invention discloses a photovoltaic module wet electric leakage test device, which comprises an electrolytic cell used for containing an electrolyte, and a heating device whose input port and output port are respectively communicated with the electrolytic cell The heating device communicated with the electrolytic cell is arranged to heat the electrolyte in the electrolytic cell, the device canautomatically heat the electrolyte in the electrolytic cell, and normal operation of the photovoltaic module wet electric leakage test equipment in a low-temperature environment is guaranteed.

Owner:MIASOLE EQUIP INTEGRATIONFUJIANCO LTD

Manufacturing process of ultra-miniature semiconductor cooler

PendingCN113964264AImprove thermal shock resistanceReduce ultrasonic cleaning timeThermoelectric device with peltier/seeback effectThermoelectric device manufacture/treatmentCold sideWafering

The invention relates to a manufacturing process of an ultra-miniature semiconductor cooler, which comprises the following steps: crystal grain preparation: cutting a crystal bar into a wafer, electroplating the wafer, cutting the electroplated wafer, cleaning the crystal grain, and coating the crystal grain with a UV (ultraviolet) film to obtain standby crystal grains; printing the hot-side ceramic plate, fixing the standby crystal grains on the hot-side ceramic plate, printing the cold-side ceramic plate, carrying out die assembly welding on the hot-side ceramic plate with the fixed crystal grains and the printed cold-side ceramic plate, and carrying out resistance and infrared testing, grinding, wire welding, glue sealing, electric leakage testing and code spraying to obtain the ultra-miniature semiconductor cooler. According to the process, a multi-wire cutting machine is adopted for cutting the wafer, the ultrasonic cleaning time is shortened, the problems of cavities and product deformation are reduced through a die assembly welding method, and the ultra-miniature semiconductor cooler prepared through the method has good cold and hot impact resistance, is not prone to deformation in the wafer electroplating process and is uniform in product heat dissipation.

Owner:夏丽华

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com