Discharging method and device of capacity fall-off tester

A capacitance leakage and tester technology, which is applied to the components of electrical measuring instruments, measuring devices, instruments, etc., can solve problems such as arcing, mechanical vibration, high voltage and high current, and digital control system interference, so as to prevent mechanical vibration and high voltage The effect of high current arcing phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

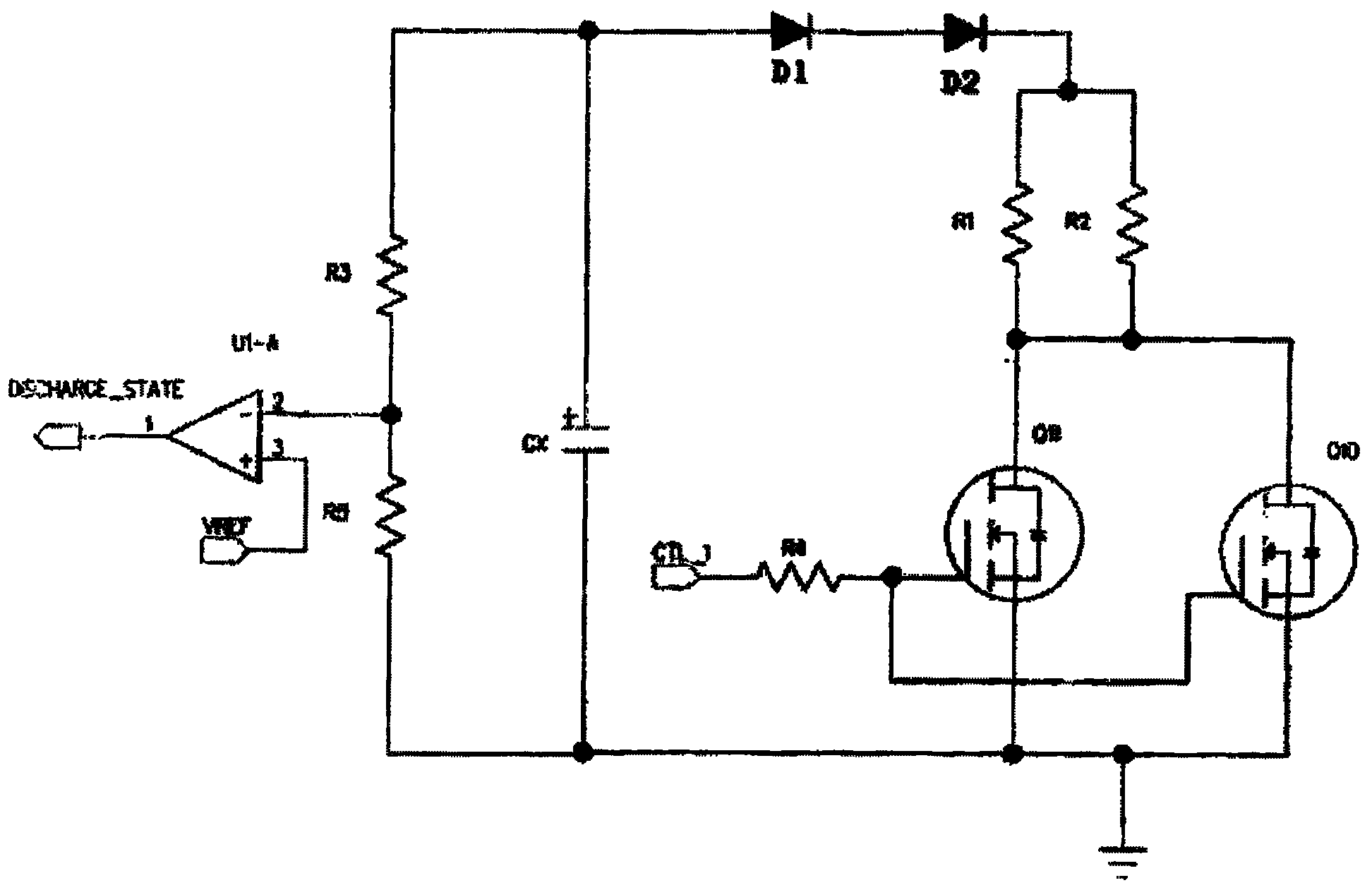

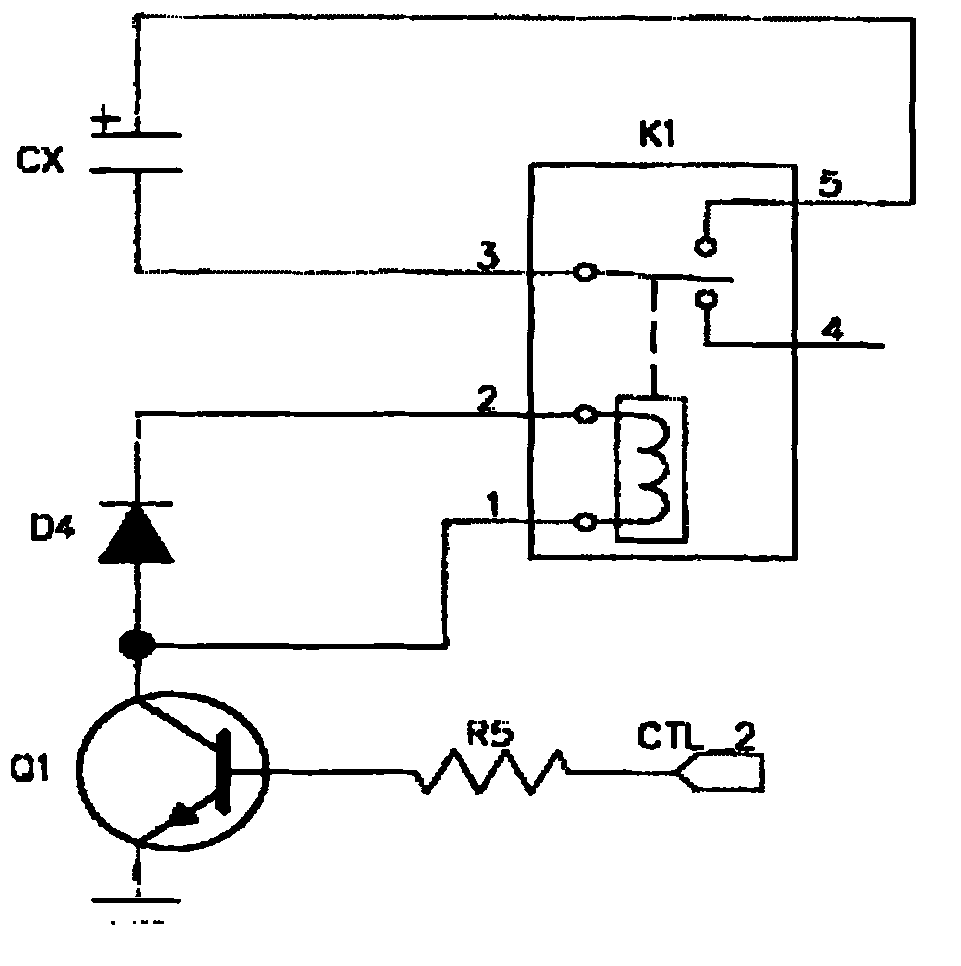

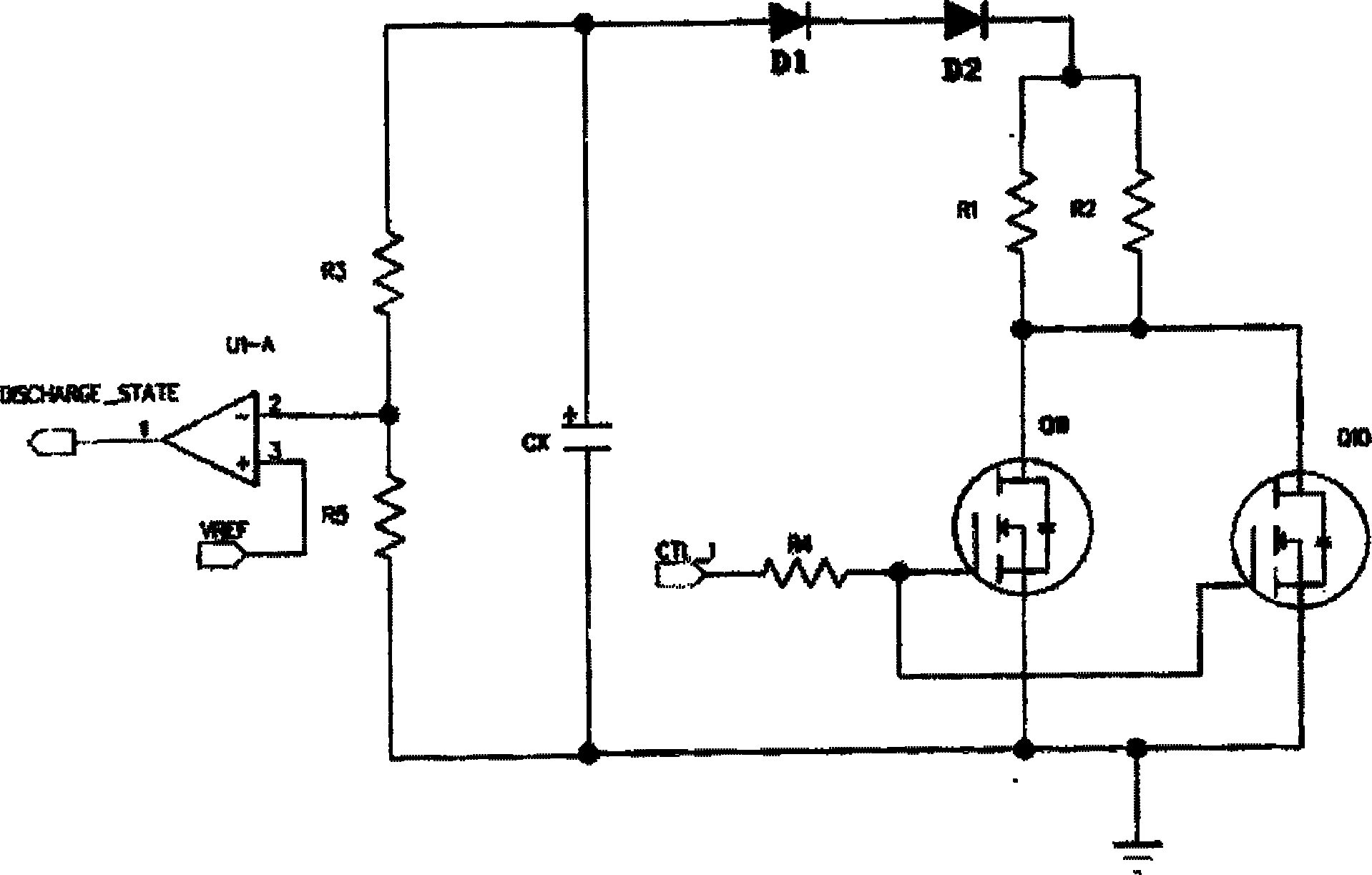

[0019] see figure 1 and figure 2 , the discharging method of a kind of capacitance leakage tester of the present invention, it comprises the steps:

[0020] 1) a microprocessor-controlled discharge selection switch, electronic discharge circuit, mechanical discharge circuit and measured capacitance are set, and the discharge selection switch controlled by the microprocessor connects the measured capacitance to the electronic discharge circuit or the mechanical discharge circuit;

[0021] 2) judging the voltage of the measured capacitor Cx;

[0022] 3) When the voltage of the measured capacitor is higher than the reference value set by the VREF terminal of the comparator, the discharge selection switch terminals CTL_1 and CTL_2 controlled by the microprocessor switch the measured capacitor to the electronic discharge circuit for discharging;

[0023] 4) When the voltage of the measured capacitor is lower than or equal to the set reference value of the VREF terminal of the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com