Anti-creeping testing device for numerical control machine tool research and development

A testing device and numerically controlled machine tool technology, which is applied to measuring devices, short-circuit testing, components of electrical measuring instruments, etc., can solve problems affecting the comprehensiveness and accuracy of testing, and achieve strong practicability and improve comprehensiveness and accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

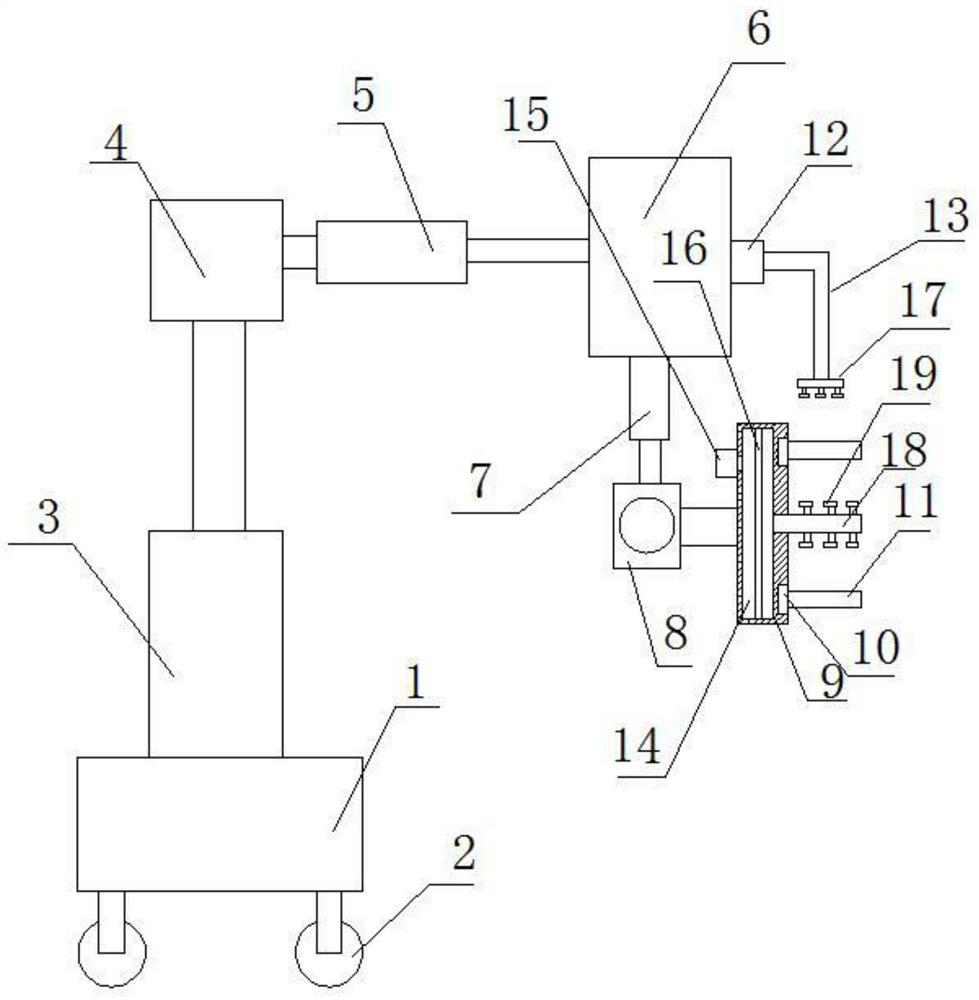

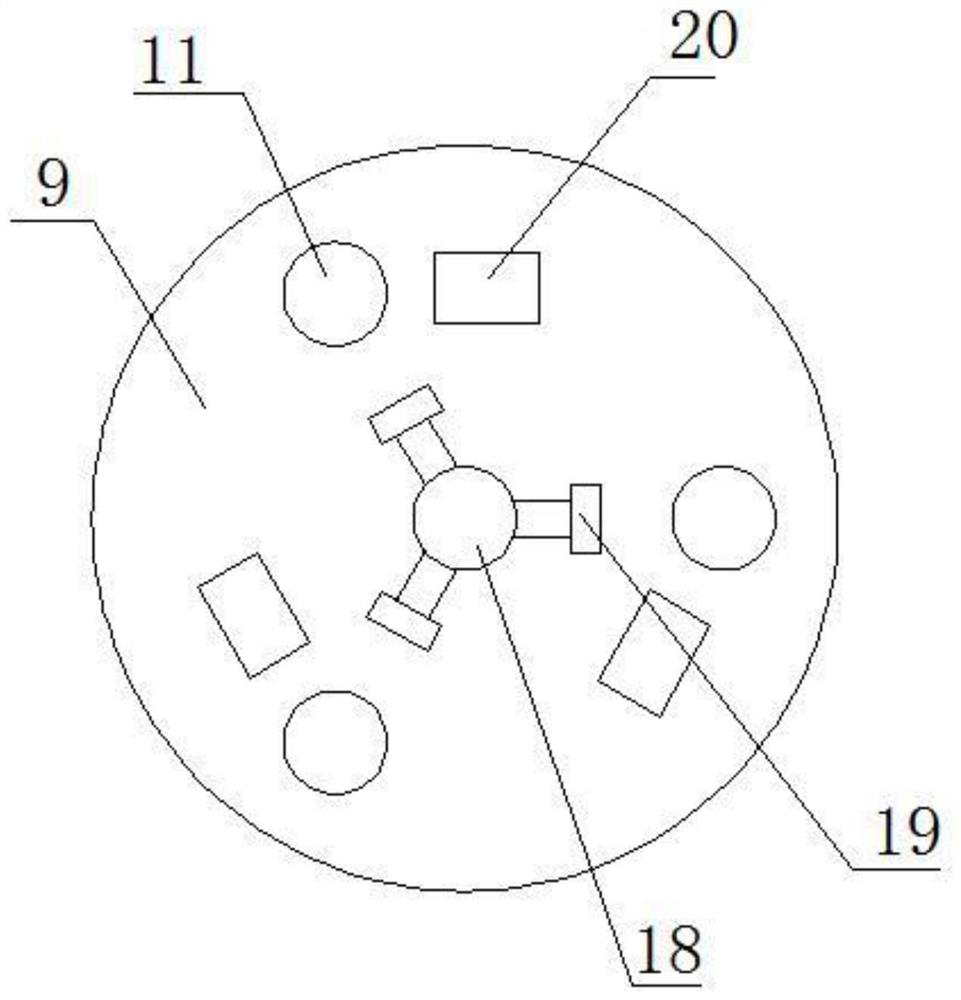

[0023] see Figure 1-5 , in an embodiment of the present invention, a leakage prevention test device for research and development of a numerically controlled machine tool, comprising a base 1, universal wheels 2 are provided at the four corners of the lower side of the base 1, and a first electric telescopic mechanism 3 is provided on the upper side of the base 1 , the upper end of the first electric telescopic mechanism 3 is provided with a first motor 4, the output end of the first motor 4 is provided with a second electric telescopic mechanism 5, and the right end of the second electric telescopic mechanism 5 is provided with a water tank 6 , the lower end of the water tank 6 is provided with a third electric telescopic mechanism 7, and the lower end of the third electric telescopic mechanism 7 is provided with a driving mechanism 8, and the driving mechanism 8 includes a first mounting seat 29, and the first mounting seat The inside of 29 is provided with mounting groove 3...

Embodiment 2

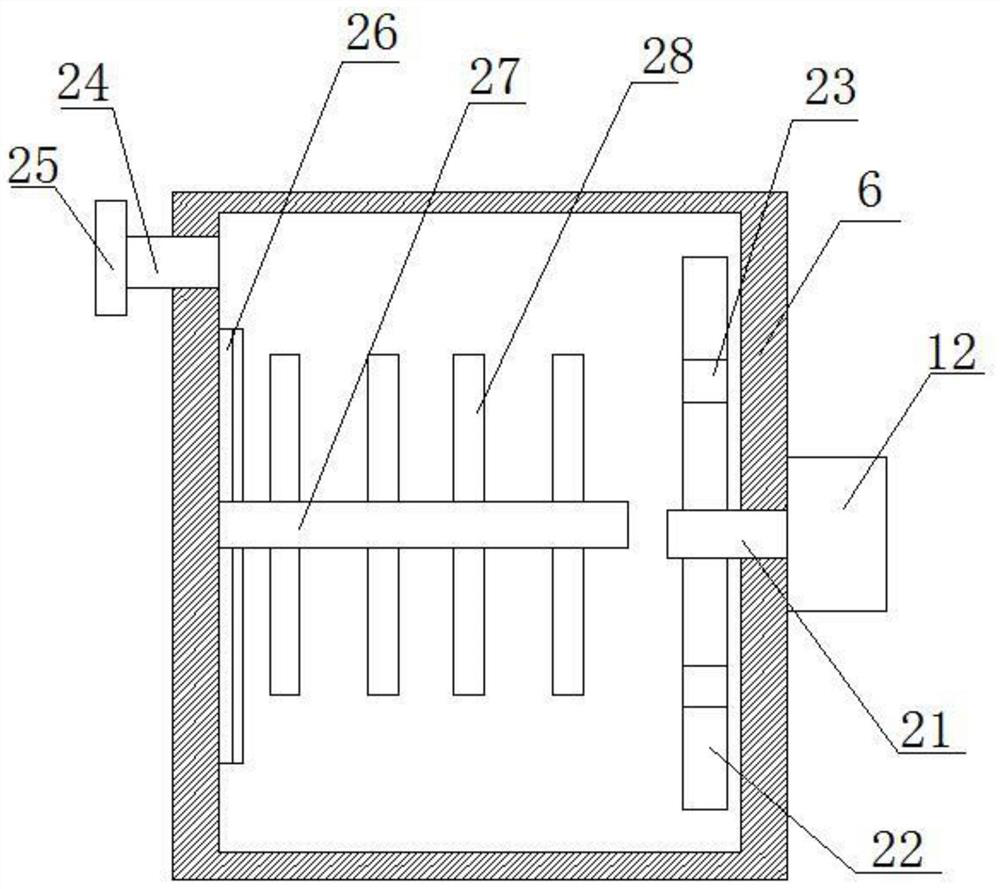

[0028]On the basis of Embodiment 1, a water supply pipe 24 is provided on the left side of the water tank 6, a sealing cover 25 is provided on the water supply pipe 24, a T-shaped slide rail 26 is provided on the left side of the water tank 6, and the inside of the water tank 6 A floating board 27 is provided, and the floating board 27 is connected with the T-shaped slide rail 26 through a T-shaped chute 36. The upper and lower sides of the floating board 27 are symmetrically provided with wave-blocking boards 28, and the floating board 27 is provided with several passageways. Water hole 37. The setting of this structure can reduce the shaking of water when the device is moving, reduce the impact force on the water tank 6, prolong the service life of the water tank 6, and ensure the stability of the device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com