Annular machining device of inductance detecting and packaging equipment

A processing device and packaging equipment technology, applied in packaging, packaging protection, transportation and packaging, etc., can solve the problems of error-prone inductance polarity detection, difficulty in distinguishing inductance polarity, positive and negative errors in installation, etc., and achieve clamping force. control, switching speed is high, and the effect of avoiding missing measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

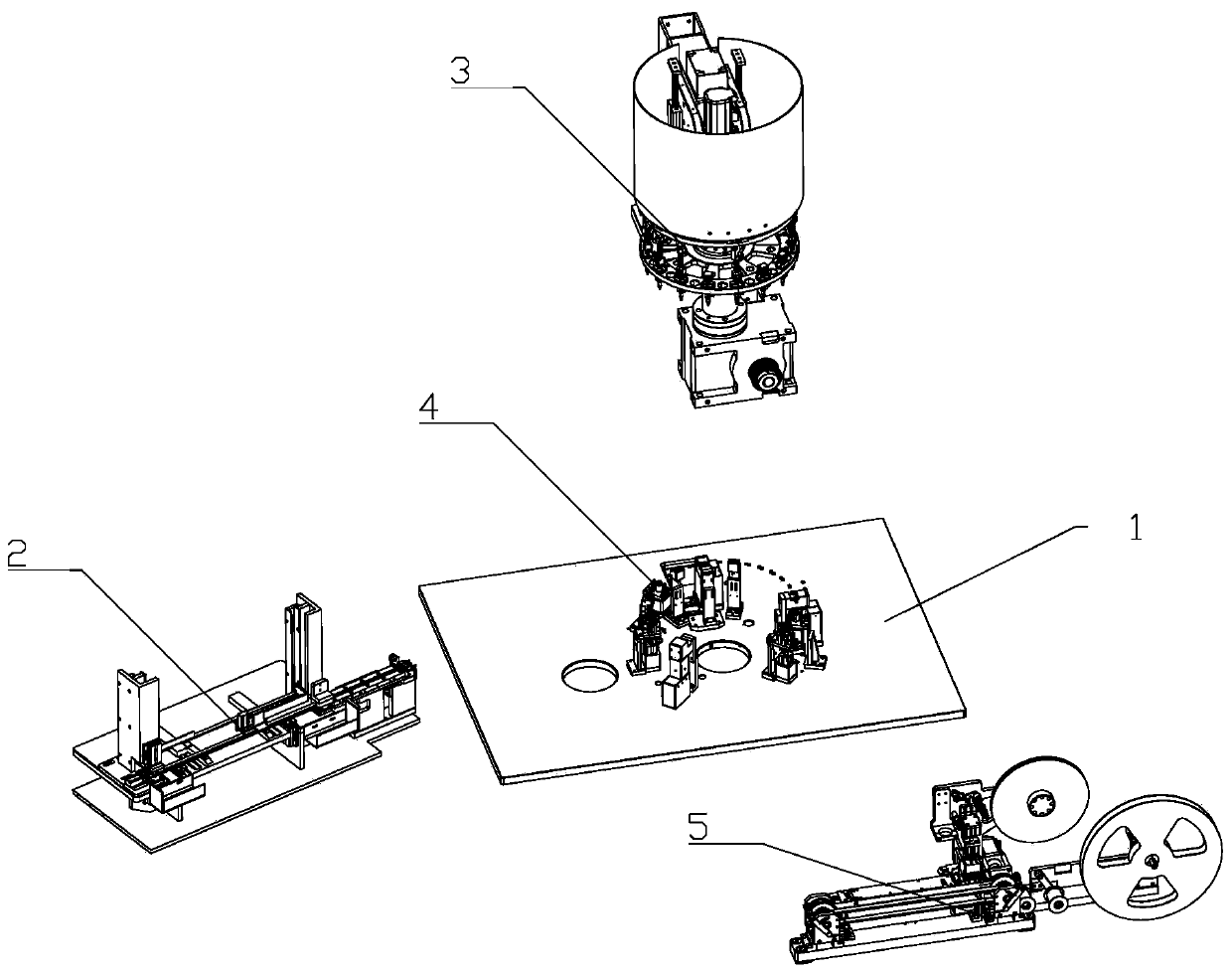

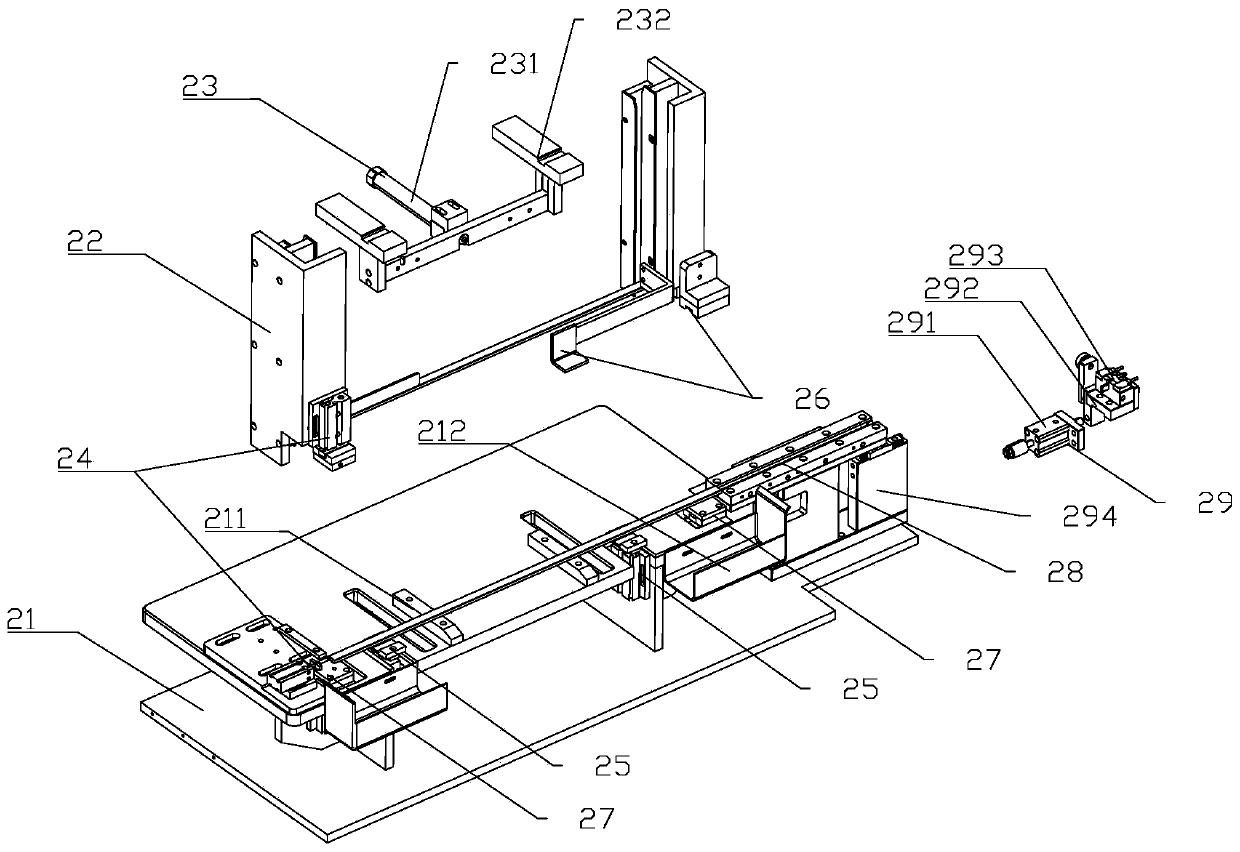

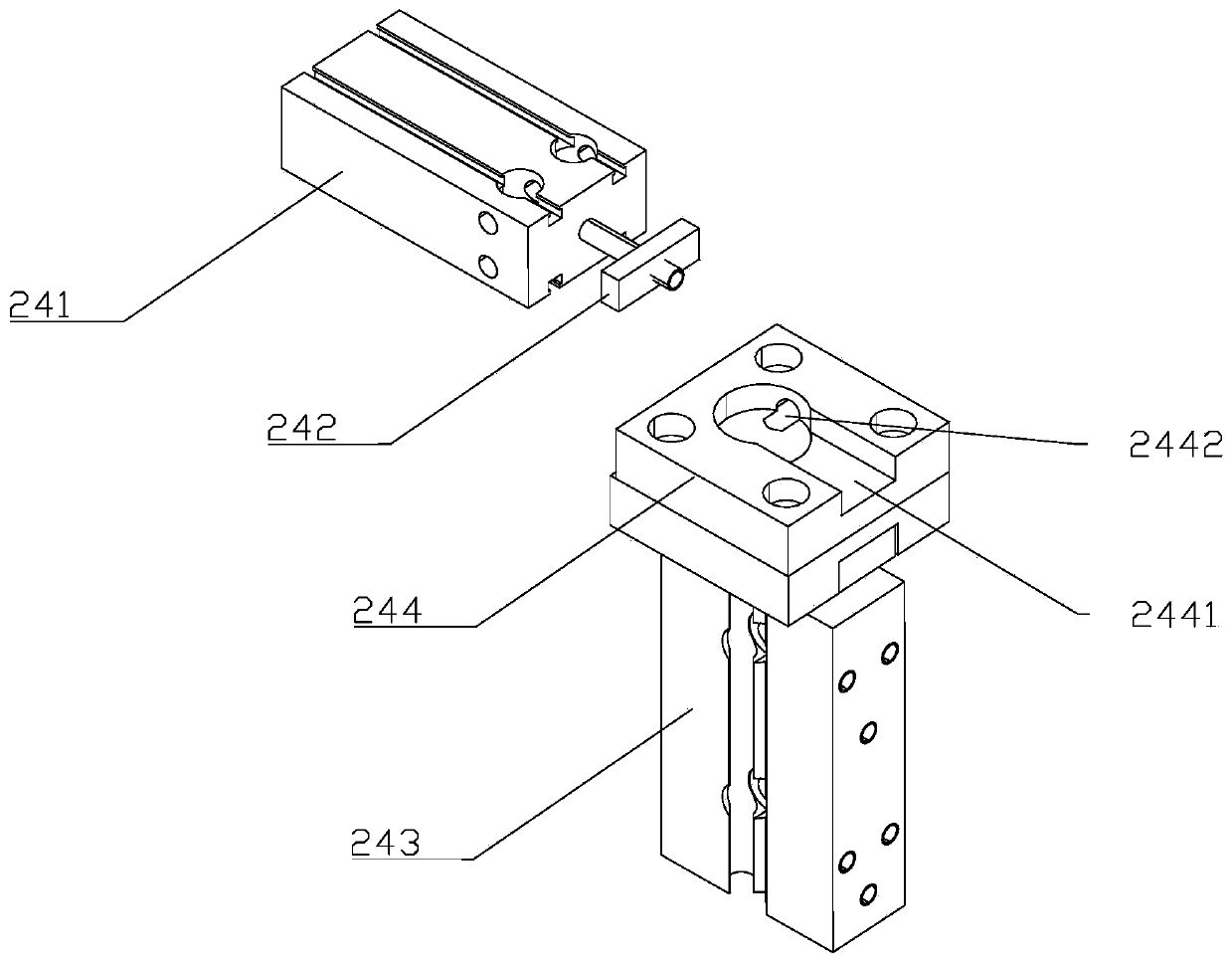

[0027] Such as figure 1 As shown, a kind of inductance detection packaging equipment comprises frame 1 and inductance feeding device 2 installed on frame 1, inductance handling device 3, ring processing device 4 and inductance packaging device 5; described inductance handling device 3 It is arranged in the middle of the frame 1 , the ring processing device 4 is located below the inductive conveying device 3 , and the inductive feeding device 2 and the inductive packaging device 5 correspond to the sides of the inductive conveying device 3 .

[0028] The inductance feeding device 2 is used to realize the feeding of the inductance elements arranged in the magazine; the inductance handling device 3 is used to carry the inductance, and the ring processing device 4 is used to process the inductance accordingly. The inductance packaging device 5 is used for unloading the detected and sorted inductance. The aforementioned ring processing device 4 is a ring processing device for indu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com