Electric hydraulic forklift for logistics transportation

A forklift and electric technology, applied in the direction of lifting devices, etc., can solve problems such as package slipping, cargo falling, package shaking, etc., to achieve the effect of increasing the contact area, avoiding forward dumping, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

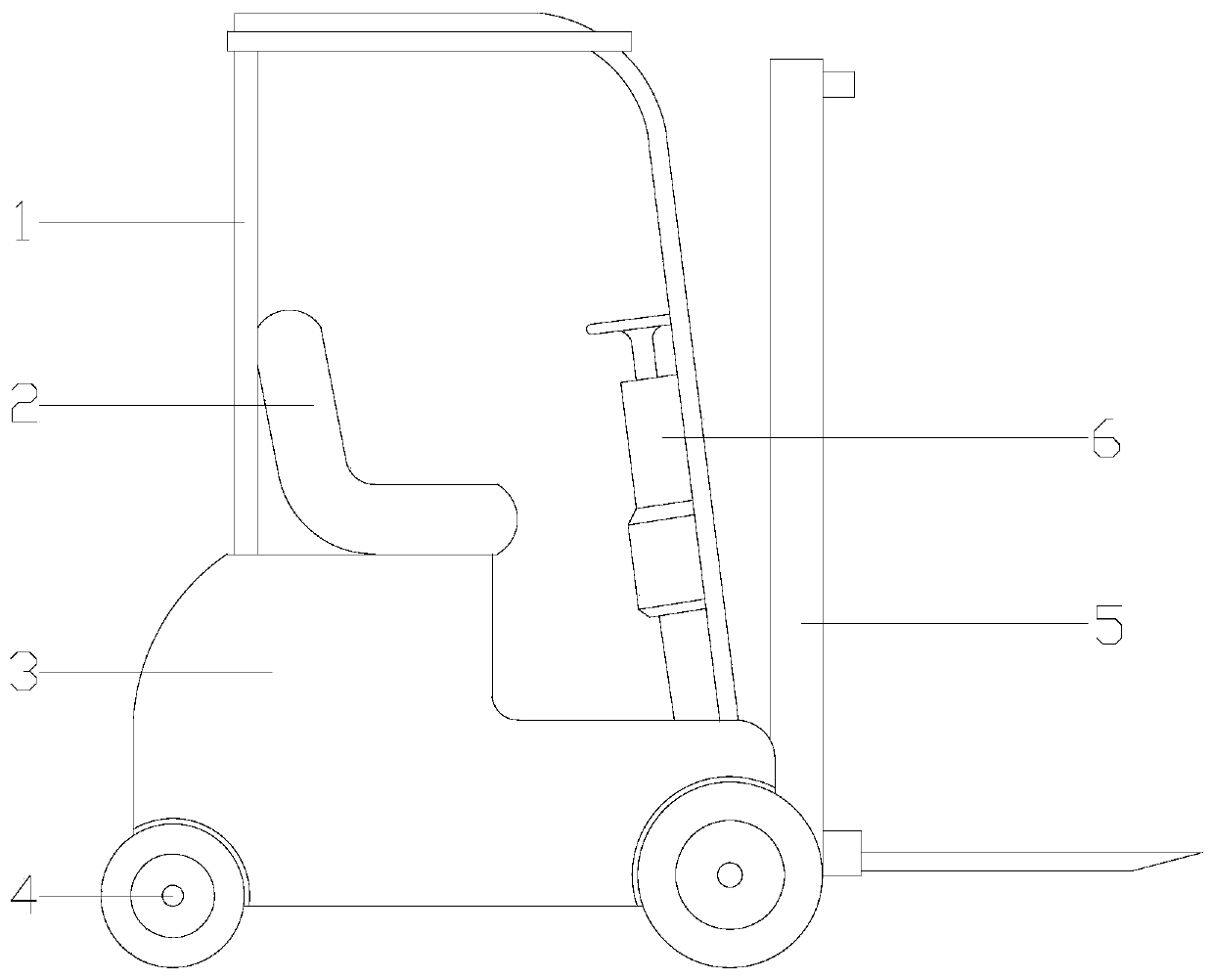

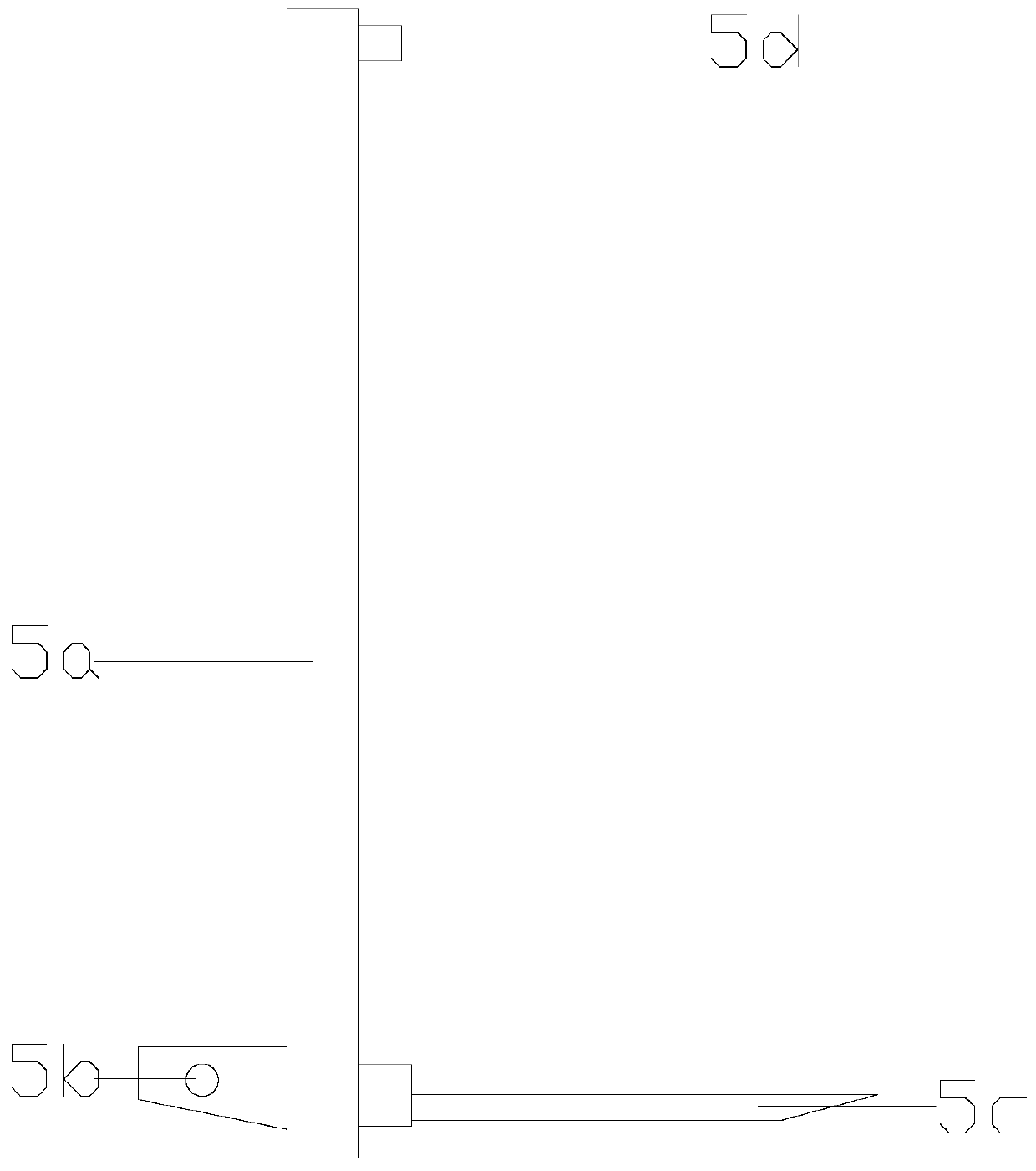

[0024] see Figure 1-Figure 5, the present invention provides an electro-hydraulic forklift for logistics transportation, its structure includes a cockpit protective frame 1, a driver's seat 2, a forklift body 3, driving wheels 4, a forklift gantry 5, a forklift steering wheel 6, the forklift body 3 is an L-shaped structure, the driving wheel 4 is nested on the left and right sides of the bottom of the forklift body 3, the cockpit protective frame 1 is located above the forklift body 3 and is fixed together with the forklift body 3 by bolts, the driver seat The chair 2 is located on the left side of the top of the forklift body 3, the forklift steering wheel 6 is nested in the right end of the cockpit protective frame 1, the forklift gantry 5 is installed on the right side of the forklift body 3 and fixed together by bolts, the forklift gantry The frame 5 is made up of a fork lift slide rail 5a, a gantry connector 5b, a cargo support fork 5c, and a cargo limit block 5d. The ga...

Embodiment 2

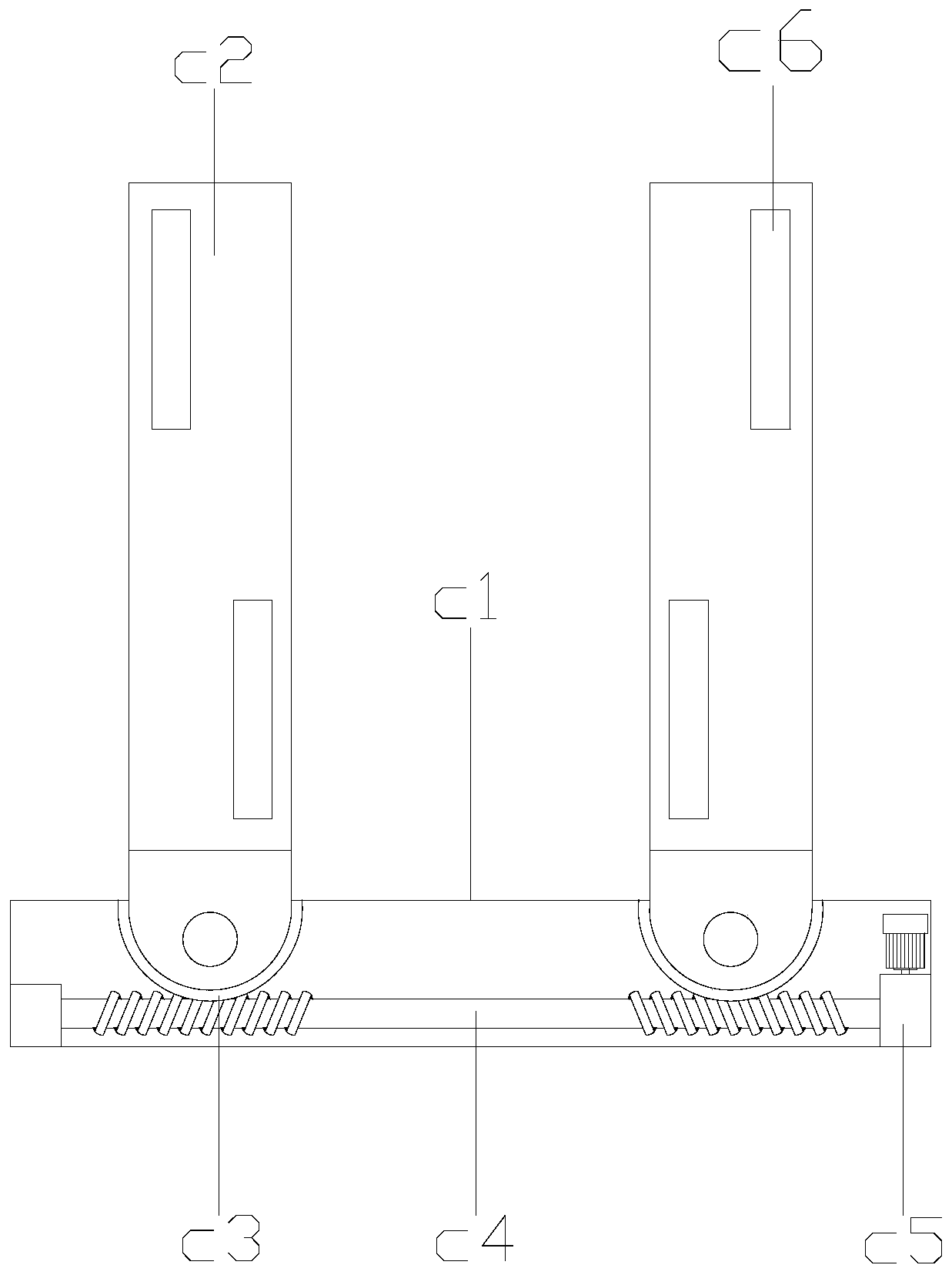

[0027] see Figure 6-Figure 7 , the anti-dumping structure c6 is composed of a cargo binder c61, a permanent magnet block c62, an inertia buffer slide bar c63, and a binder installation groove c64, and the binder installation groove c64 is a rectangular structure and is nested in a support plate At the left and right ends of c2, the inertial buffer slider c63 is horizontally installed in the middle of the adhesive device installation groove c64, the cargo adhesive c61 and the inertial buffer slider c63 adopt clearance fit, and the permanent magnets c62 are respectively installed on the cargo On the left and right sides of the binder c61 and the binder installation groove c64, the magnetic pole of the permanent magnet block c62 is N pole. The cargo bonder c61 is composed of a box bottom sealing plate 611, a sealing plate telescopic frame 612, a rotating exhaust pipe cover 613, a pipe cover fixing guide rail 614, and a bonder sliding block 615. The bonder sliding block 615 is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com