Method of measuring micro thrust eccentricity of solid rocket engine without constraint condition

A solid rocket and engine technology, which is applied to rocket engine devices, machines/engines, mechanical equipment, etc., can solve problems such as large test errors, increased test workload and cost, and large impact on measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

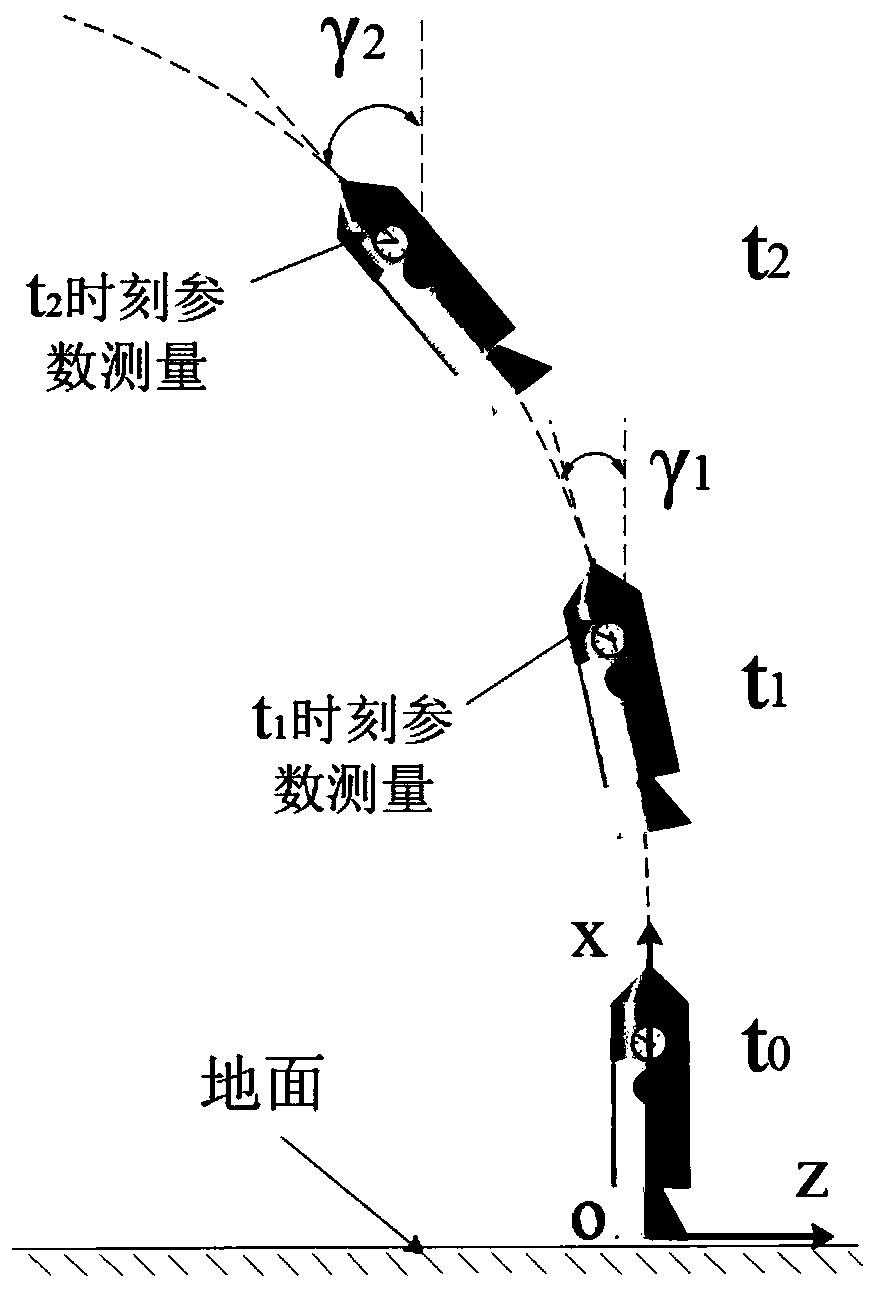

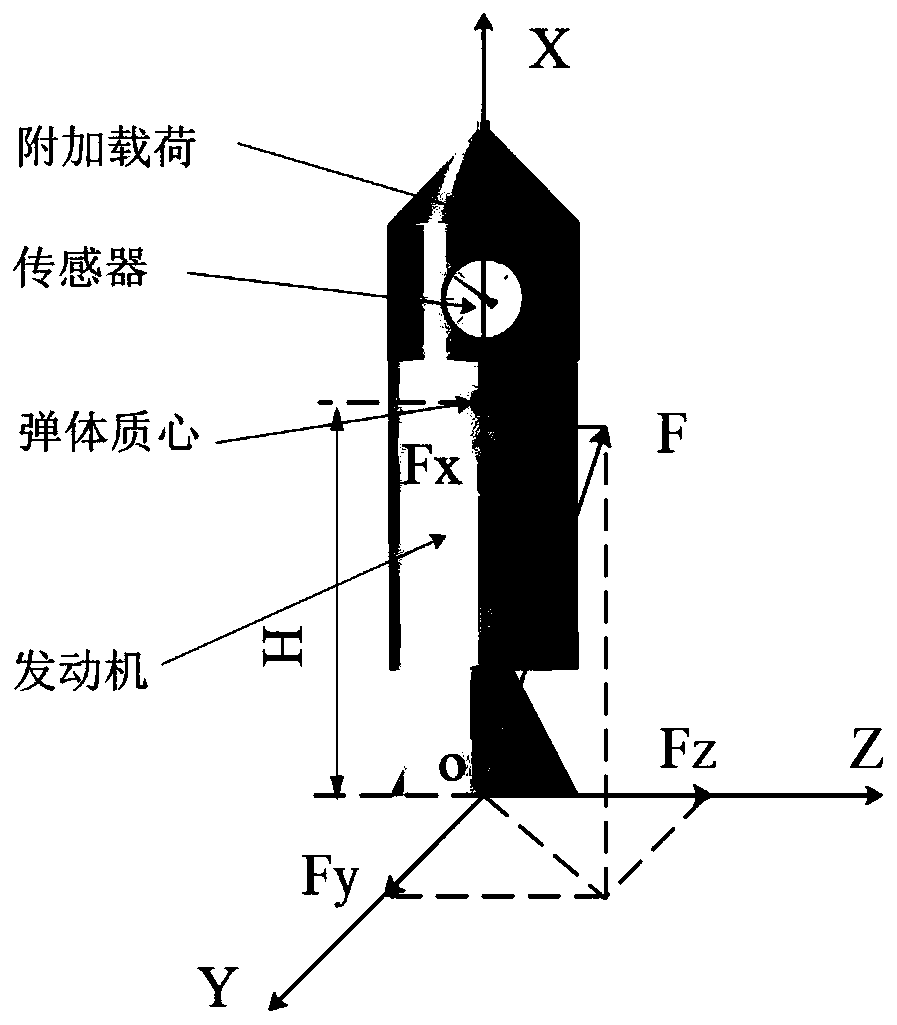

[0060] refer to Figure 1 to Figure 7 , this embodiment is based on the calculation of thrust eccentricity through flight test data under free-state flight. The following is an analysis of the recorded data of a certain rocket engine under unconstrained conditions. The specific steps are as follows:

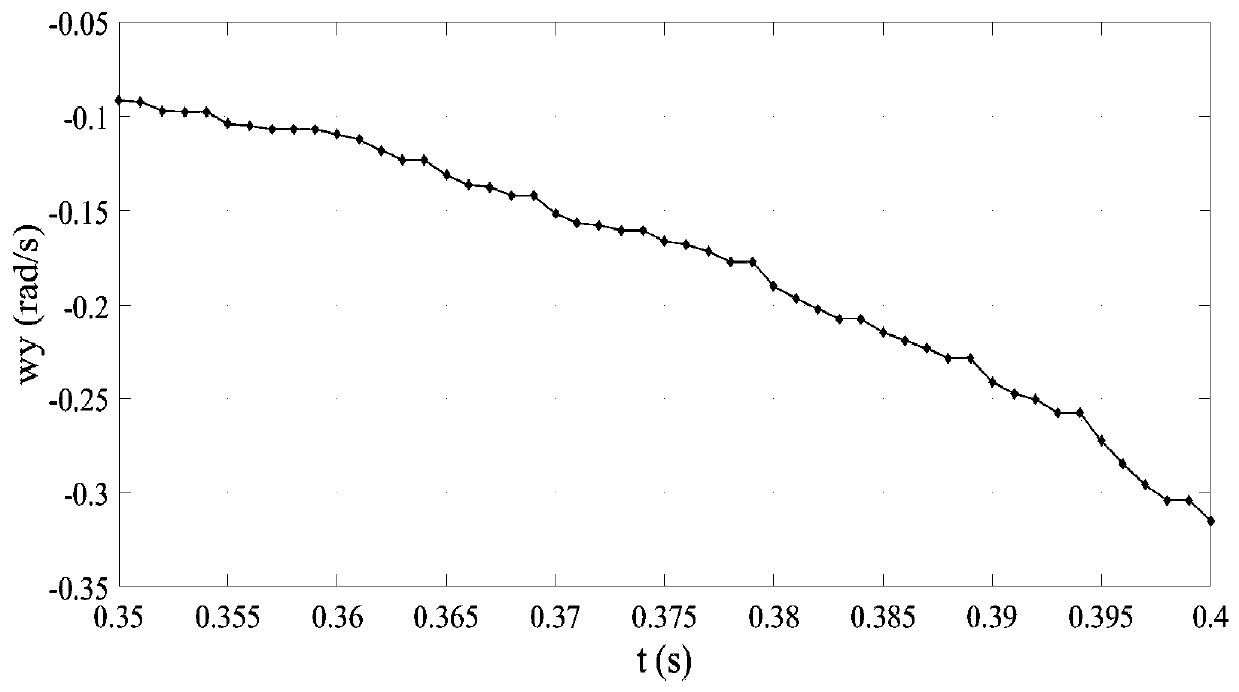

[0061] Step 1: Calculate the upper limit of flight speed according to the magnitude of aerodynamic resistance. In the example, the engine weighs 1.2Kg, the thrust is about 320N, the working time is 0.8s, and the aerodynamic resistance is less than 0.1% of the engine thrust. The upper limit of flight speed calculated by the formula in step 1 is about 60m / s. Calculate the additional load mass according to the upper limit of the flight speed to control the flight speed and height of the aircraft, improve the measurement accuracy, and facilitate the recovery of equipment. Calculated from the upper limit of the speed of the entire working section, the attached mass is about 2.8Kg. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com