Apparatus for collecting and removing gases from aluminium reduction tanks

A gas collection and gas technology, applied in the field of non-ferrous metallurgy, can solve problems such as inability to ensure the removal of electrolytic gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

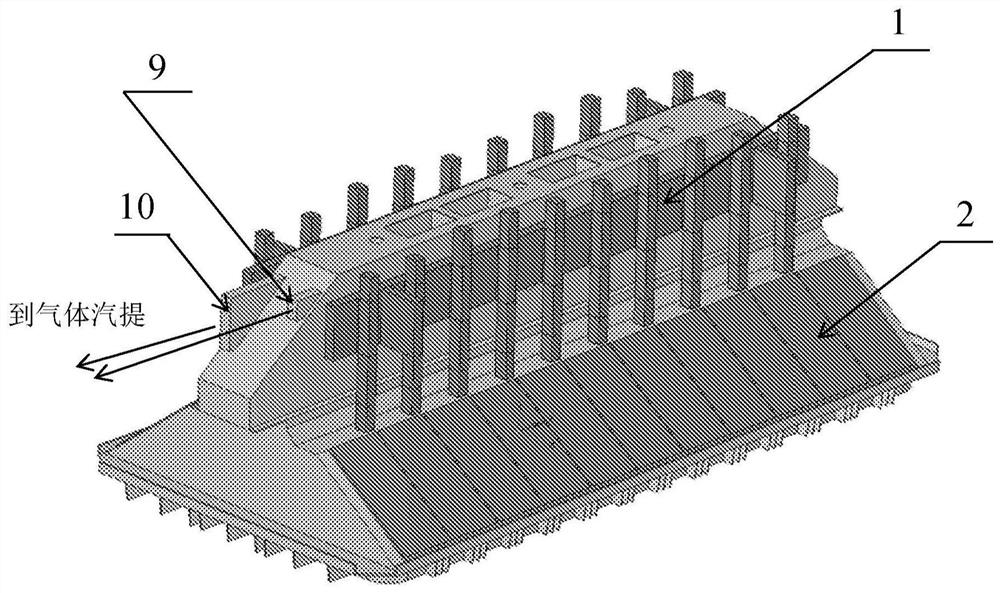

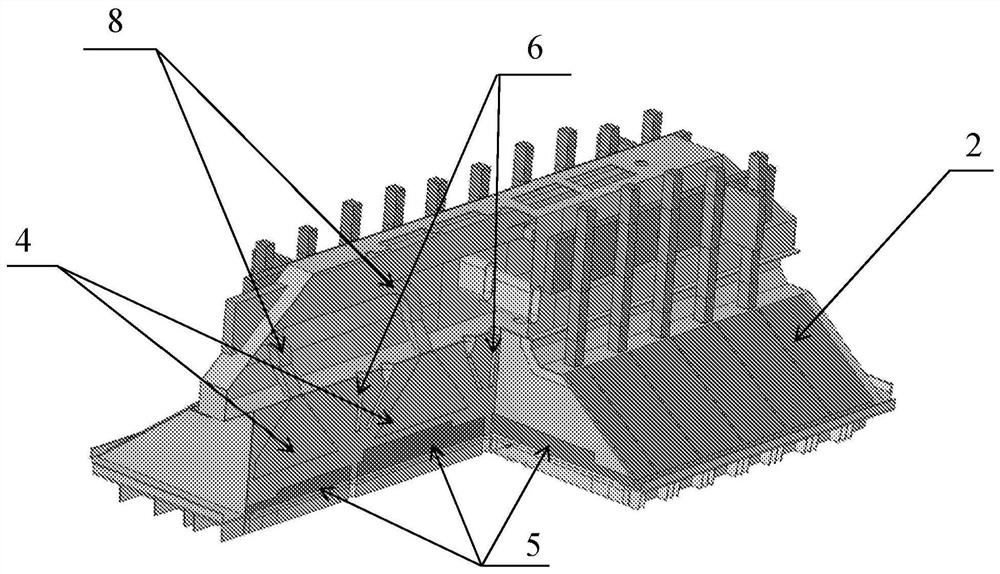

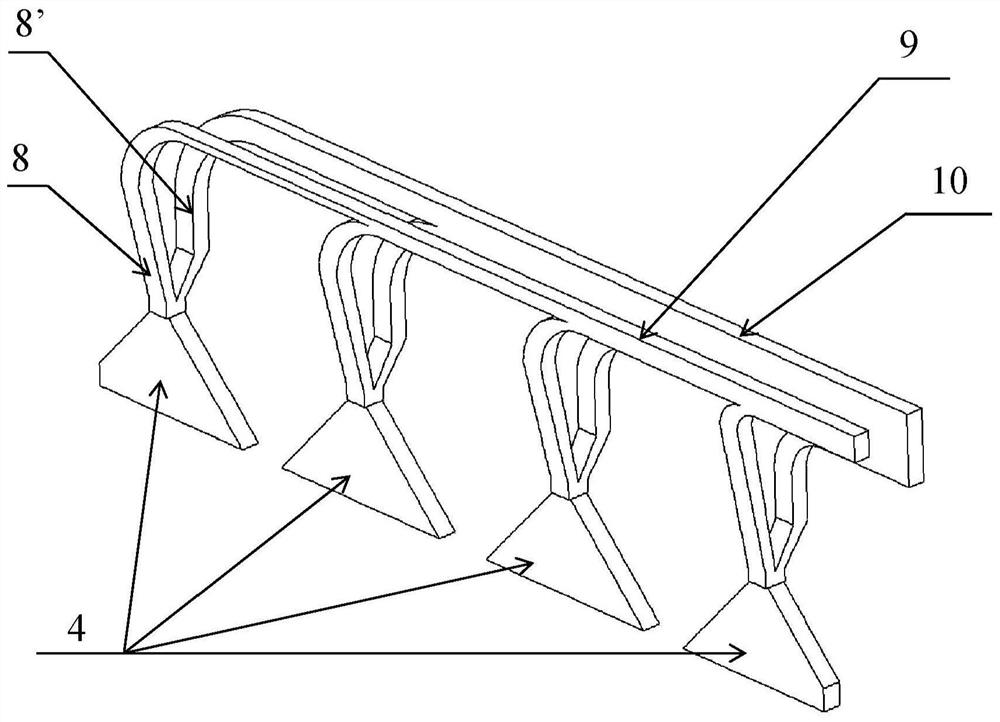

[0040] A device for collecting and removing gas is installed in the reduction tank. A reduction tank is a device that produces aluminum by reducing the melt, and typically includes an anode, a point alumina feeder with a crusher, a collector beam with gas conduits and gas caps, and a hood. All structural elements of the claimed device are fastened to the collector beam 1 . The cover of the reduction tank 2 is made of a separate cover, inside which the guide element 3 is mounted firmly horizontally with respect to the electrolyte housing of the melt. The guide elements can be structured in plates or protrusions ( Figure 4 and Figure 5 ), the plate or protrusion is made of the material used to make the cover, such as aluminium. The number of guide elements is determined by the velocity of the flow between the guides and needs to be ensured that the gas flow velocity is higher than 2m / s and lower than 7m / s in order to exclude the gas escaping from the reduction tank and carr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com