Briquetting machine

A dough making machine and transmission device technology, applied in the field of dough making machines, can solve the problems of unsatisfactory small bread dough making, inconvenient maintenance, complicated structure, etc., and achieve the effect of low noise, good safety in use and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

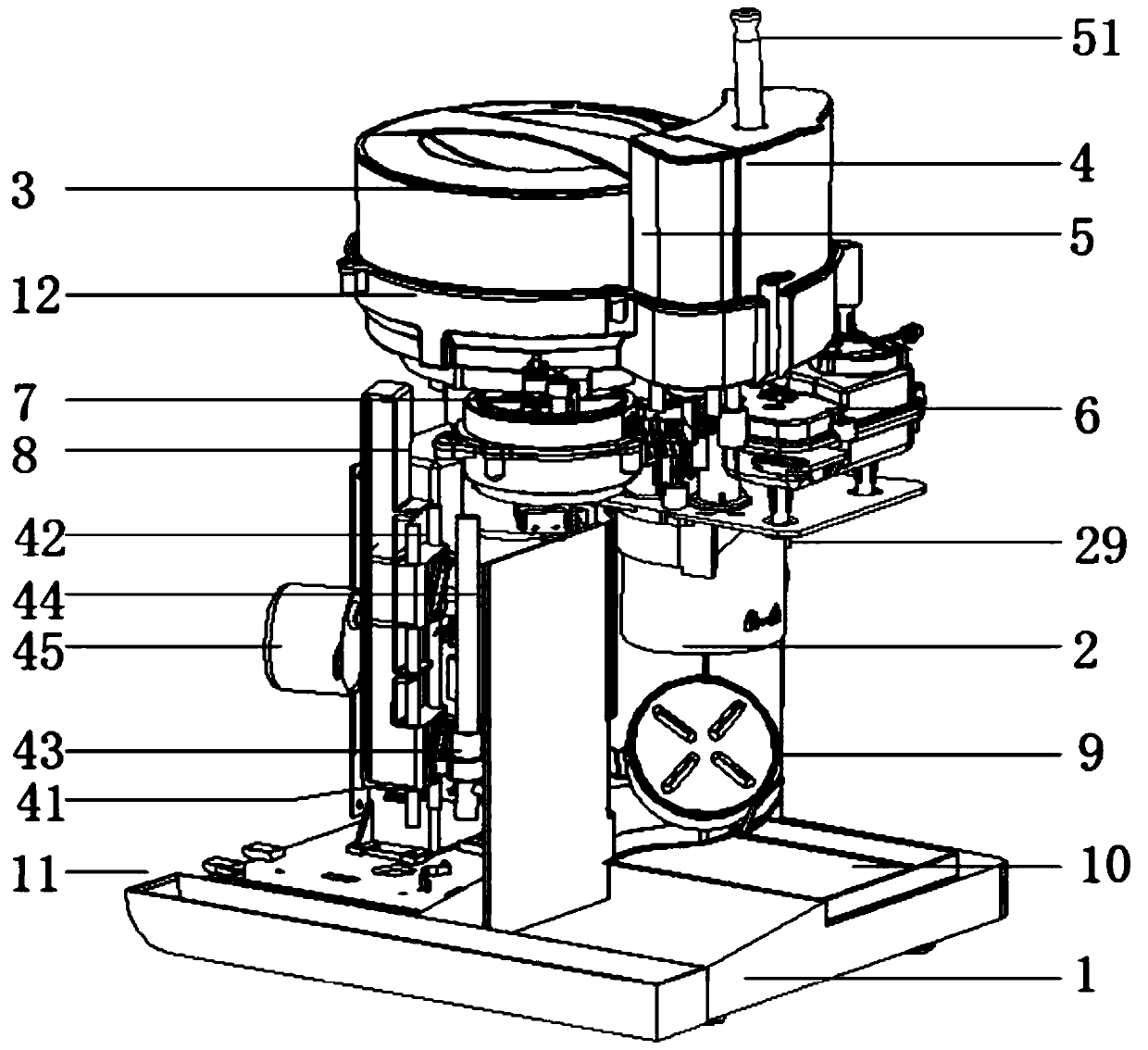

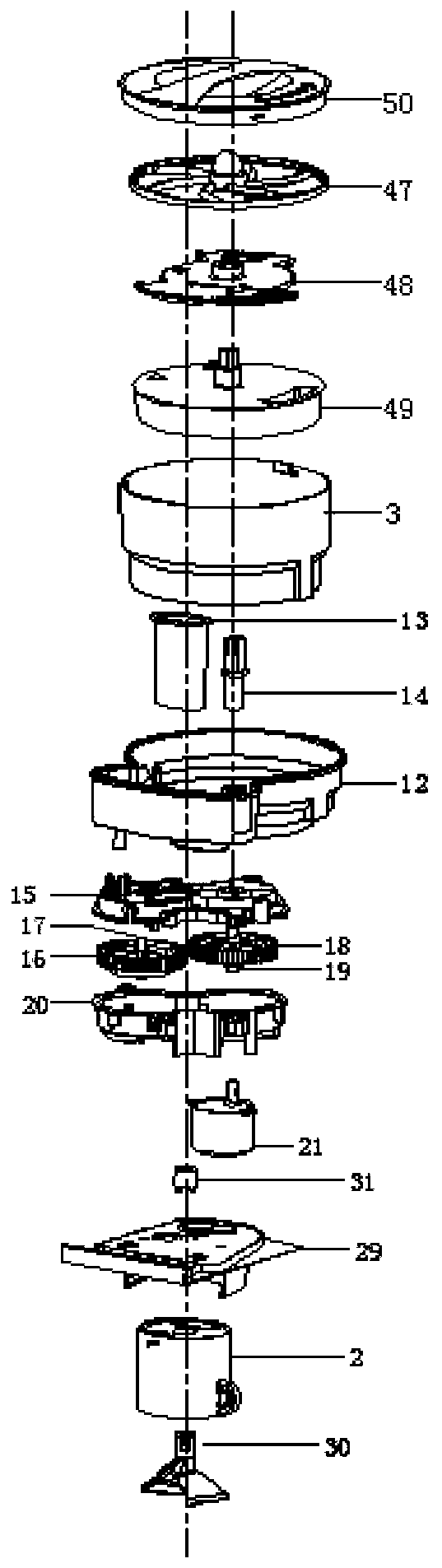

[0031] Embodiment one, such as Figure 1-8As shown, a dough making machine according to an embodiment of the present invention includes a base 1, a mixing container 2, a powder storage container 3, a water storage container 4, an oil storage container 5, a first transmission device 6, a second transmission device 7, The third transmission device 8 and the tray 9, the powder receiving box 10 is fixed on one side of the top surface of the base 1, and the powder receiving box 10 is located below the mixing container 2, and the other side of the top surface of the base 1 is fixed There is a dough box 11, the powder storage container 3 is fixed on the upper side of the base 1, and the water storage container 4 and the oil storage container 5 are connected to one side of the powder storage container 3, the The bottom ends of the powder storage container 3, the water storage container 4 and the oil storage container 5 are fixed with a second container seat 12, and the bottom ends of ...

Embodiment 2

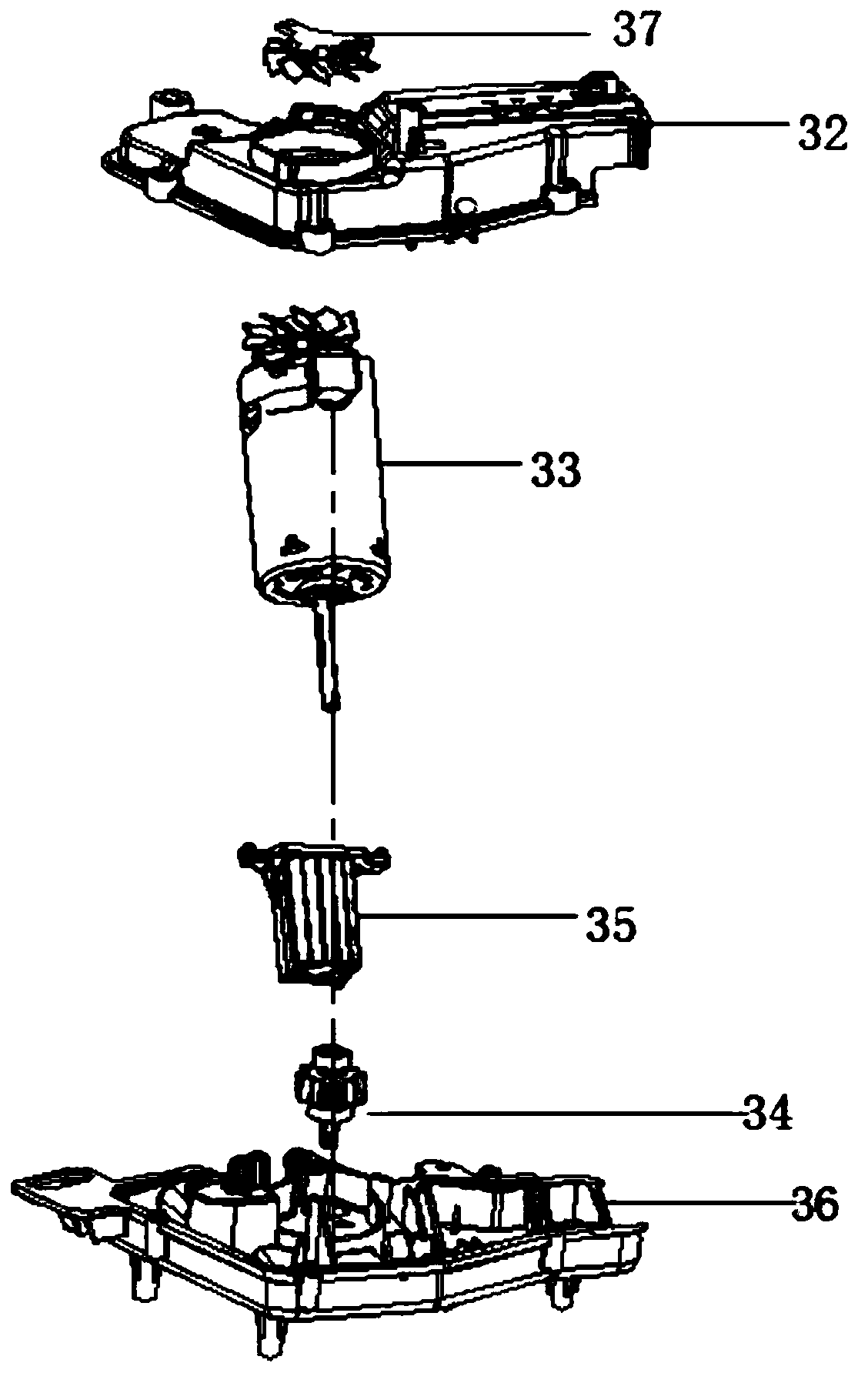

[0032] Embodiment two, such as figure 2 As shown, the first transmission 6 includes a first transmission cover 32, a first transmission motor 33, an output gear 34, a power output shaft 35 and a first transmission box 36; the first transmission cover 32 is installed The first transmission box 36 is closely connected with the first transmission box 36, and the first transmission motor 33, the power output shaft 35, and the output gear 34 are installed in the first transmission box 36 respectively. Inside, the first transmission motor 33 is connected to the power output shaft 35, the power output shaft 35 is connected to the output gear 34, and the bottom movable shaft of the output gear 34 runs through the first transmission device The box 36 is connected to the stirring drive head 31 .

Embodiment 3

[0033] Embodiment three, such as figure 2 As shown, the top of the first transmission cover 32 is fixed with a cooling fan 37 at the position corresponding to the first transmission motor 33; the cooling fan 37 can accelerate the heat dissipation of the device, which is more conducive to the safety and use of the device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com