New online integrated equipment system for egg-beancurd production

A technology of egg tofu and line type, which is applied in the field of new online integrated equipment system for egg tofu production, which can solve the problems of uninterrupted continuous production of raw liquid, long waiting time, and insufficient efficiency of continuous canning, etc., so as to reduce invalid waiting time , to achieve the effect of no waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

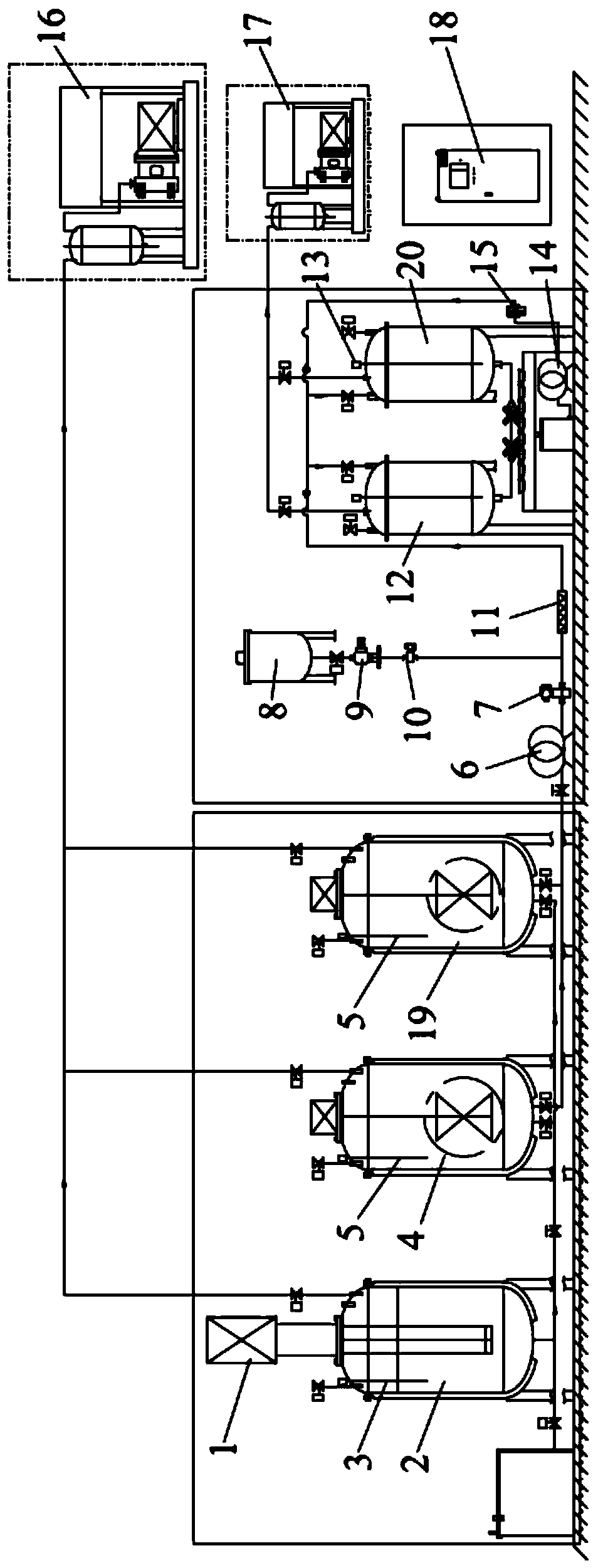

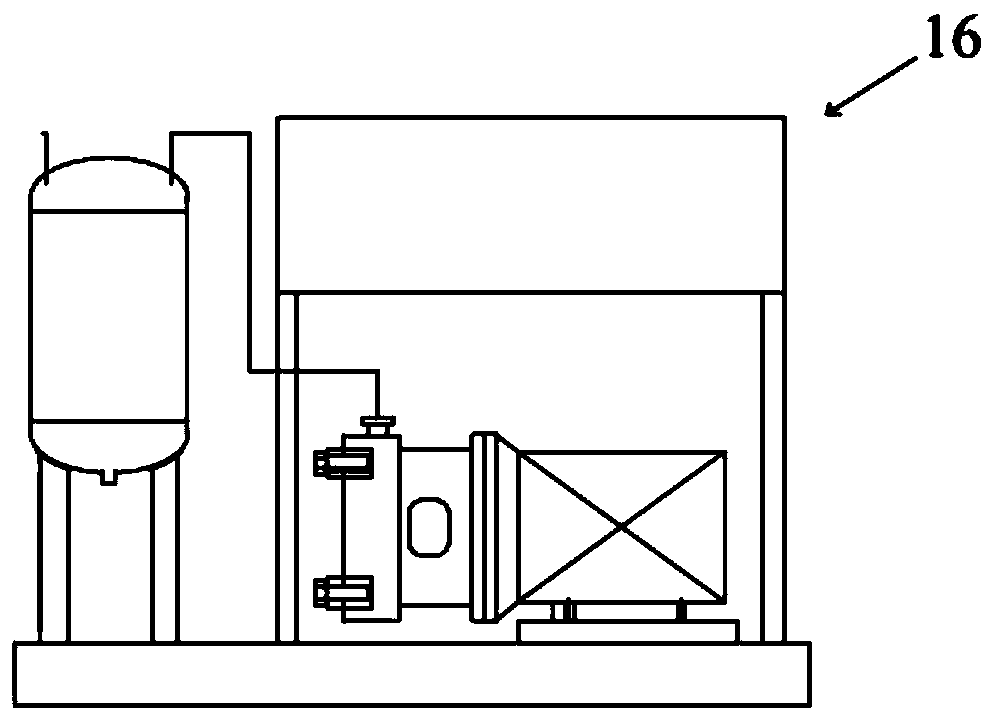

[0025] see Figure 1-Figure 4 As shown, the technical scheme adopted in this specific embodiment is that it includes an emulsification head 1, an online degassing emulsification tank 2, a first liquid level gauge 3, a first online degassing buffer tank 4, a second liquid level gauge 5, a first Rotor pump 6, flow meter 7, coagulant tank 8, micro metering pump 9, high-precision flow meter 10, static mixer 11, A buffer tank 12, third liquid level gauge 13, second rotor pump 14, pipeline type Filter 15, water ring vacuum pump assembly one 16, water ring vacuum pump assembly two 17, control cabinet 18, second online degassing buffer tank 19, B buffer tank 20, the upper end of the online degassing emulsification tank 2 is set There is an emulsification head 1, the lower end of the first liquid level gauge 3 is inserted into the interior of the online degassing emulsification tank 2 and fixed on the online degassing emulsification tank 2, and the lower end of the second liquid level ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com