Impurity removing device for tea beverage processing

A technology for tea beverages and barrels, which is applied in the field of impurity removal devices for tea beverage processing. It can solve the problems of poor filtration effect, slow filtration speed, and many impurities, and achieve good filtration effects, easy handling, and rapid filtration and impurity removal. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

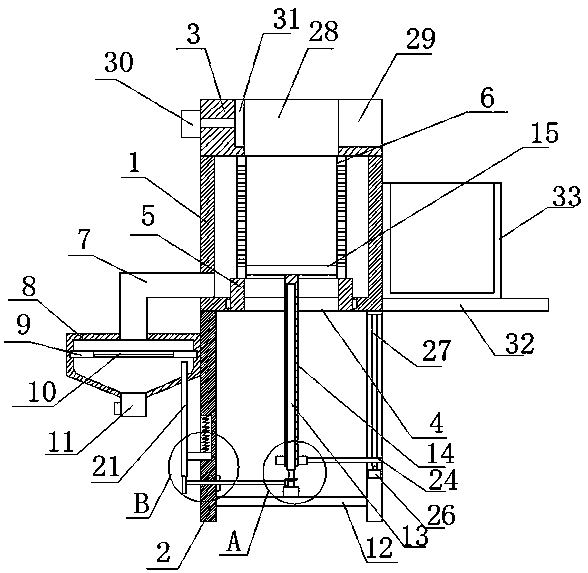

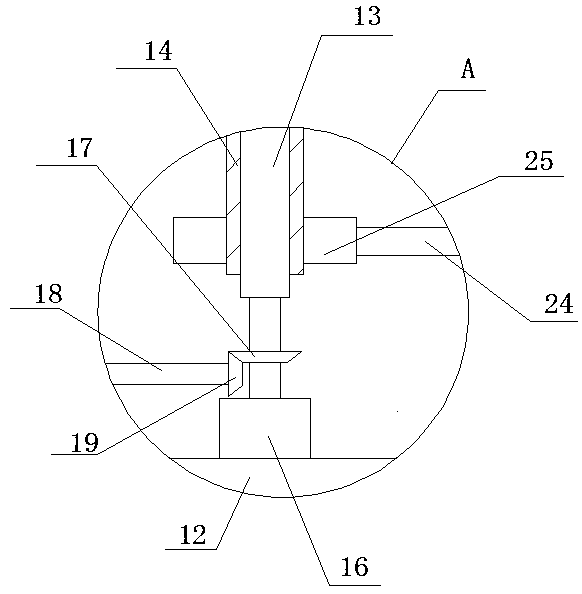

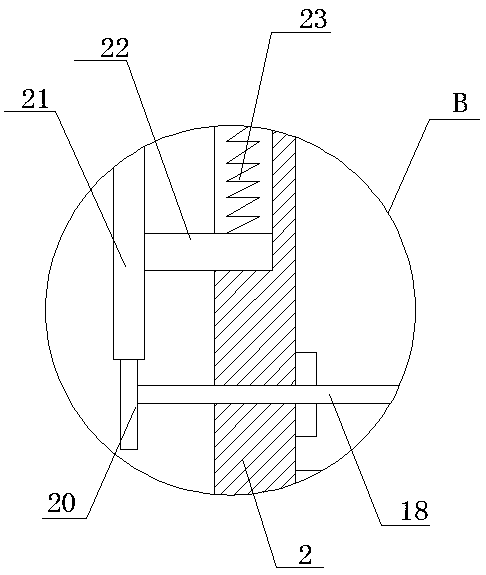

[0029] refer to Figure 1-5 , a kind of impurity removal device for tea beverage processing, comprising a barrel body 1, a rectangular box 6 with top and bottom openings is arranged in the barrel body 1, a plurality of small holes are opened on the outside of the rectangular box 6, and a rectangular box 6 is provided inside the rectangular box 6. Push plate 15 is arranged, and the bottom of push plate 15 is fixedly connected with push rod 14, is provided with first motor 16 below push rod 14, and is fixedly connected with rectangular rod 13 on the output shaft of first motor 16, and the bottom of push plate 15 is provided with There is a rectangular groove, the outer side of the rectangular rod 13 is slidingly connected with the inner wall of the rectangular groove, one end of the delivery pipe 7 is fixedly connected to the outer side of the barrel body 1, and the other end of the delivery pipe 7 is fixedly connected to the filter housing 8, and the inside of the filter housing...

Embodiment 2

[0040] refer to Figure 1-5 , a kind of impurity removal device for tea beverage processing, comprising a barrel body 1, a rectangular box 6 with top and bottom openings is arranged in the barrel body 1, a plurality of small holes are opened on the outside of the rectangular box 6, and a rectangular box 6 is provided inside the rectangular box 6. Push plate 15 is arranged, and the bottom of push plate 15 is fixedly connected with push rod 14 by bolt, and the below of push rod 14 is provided with first motor 16, and the output shaft of first motor 16 is fixedly connected with rectangular bar 13 by bolt, and push plate The bottom of 15 is provided with a rectangular groove, and the outer side of the rectangular rod 13 is slidingly connected with the inner wall of the rectangular groove, and the outer side of the barrel body 1 is fixedly connected with one end of the delivery pipe 7, and the other end of the delivery pipe 7 is fixedly connected with the filter housing 8. A filter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com