Air monitoring device for spraying workshop

A monitoring device and workshop air technology, which is applied in spraying devices, liquid spraying devices, spray booths, etc., can solve the problems of paint quality decline, high cost, danger, etc., and achieve the effect of long service life and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

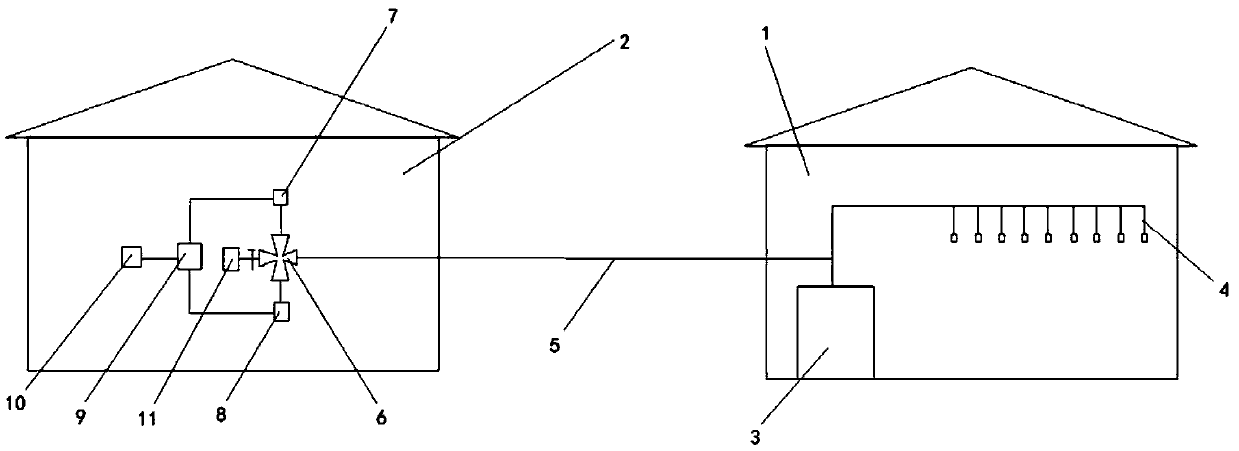

[0020] An air monitoring device for a spraying workshop. The spraying workshop 1 is provided with an air compressor 3 and a plurality of paint nozzles 4. The paint nozzles 4 are connected to the air compressor 3. The outlet of the air compressor 3 is provided with a bypass pipe 5. The bypass pipe The end of 5 is connected with four-way valve 6, one port in the four-way valve 6 is connected with electronic pressure gauge 7, one port is connected with air quality detector 8, and the last one is connected with air blower 11 openably and closably. The electronic pressure gauge 7, the air quality detector 8, and the air blower 11 are all located in the control center 2. The air blower 11 is provided to avoid the long-term use of the bypass pipe 5, and a part of dust is deposited therein. On the one hand, it will increase the bypass pipe. The air resistance of the road pipe 5 causes the pressure at the end of the bypass pipe 5 to change, and on the other hand, it also affects the mon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com