Method for machining lip of hypersonic-speed low-noise wind tunnel nozzle

A technology of hypersonic speed and processing method, applied in metal processing equipment, manufacturing tools, turning equipment, etc., can solve the problems of high rejection rate of lip workpieces, insufficient rigidity of workpieces, deformation of lip workpieces, etc., so as to improve processing efficiency and improve Processing efficiency, the effect of increasing rigidity

Active Publication Date: 2020-07-03

中国空气动力研究与发展中心超高速空气动力研究所

View PDF7 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] However, the small cutting amount machining method has the following fatal disadvantages for the machining of the nozzle lip of the hypersonic low-noise wind tunnel: (1) Due to the thin wall thickness of the lip and insufficient rigidity of the workpiece, when semi-finishing the inner and outer curved surfaces, the cutting force Under the action of the lip workpiece, it will cause deformation of the lip workpiece, which will affect the precision of the lip, so that the rejection rate of the lip workpiece is very high; (2) Low production efficiency

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

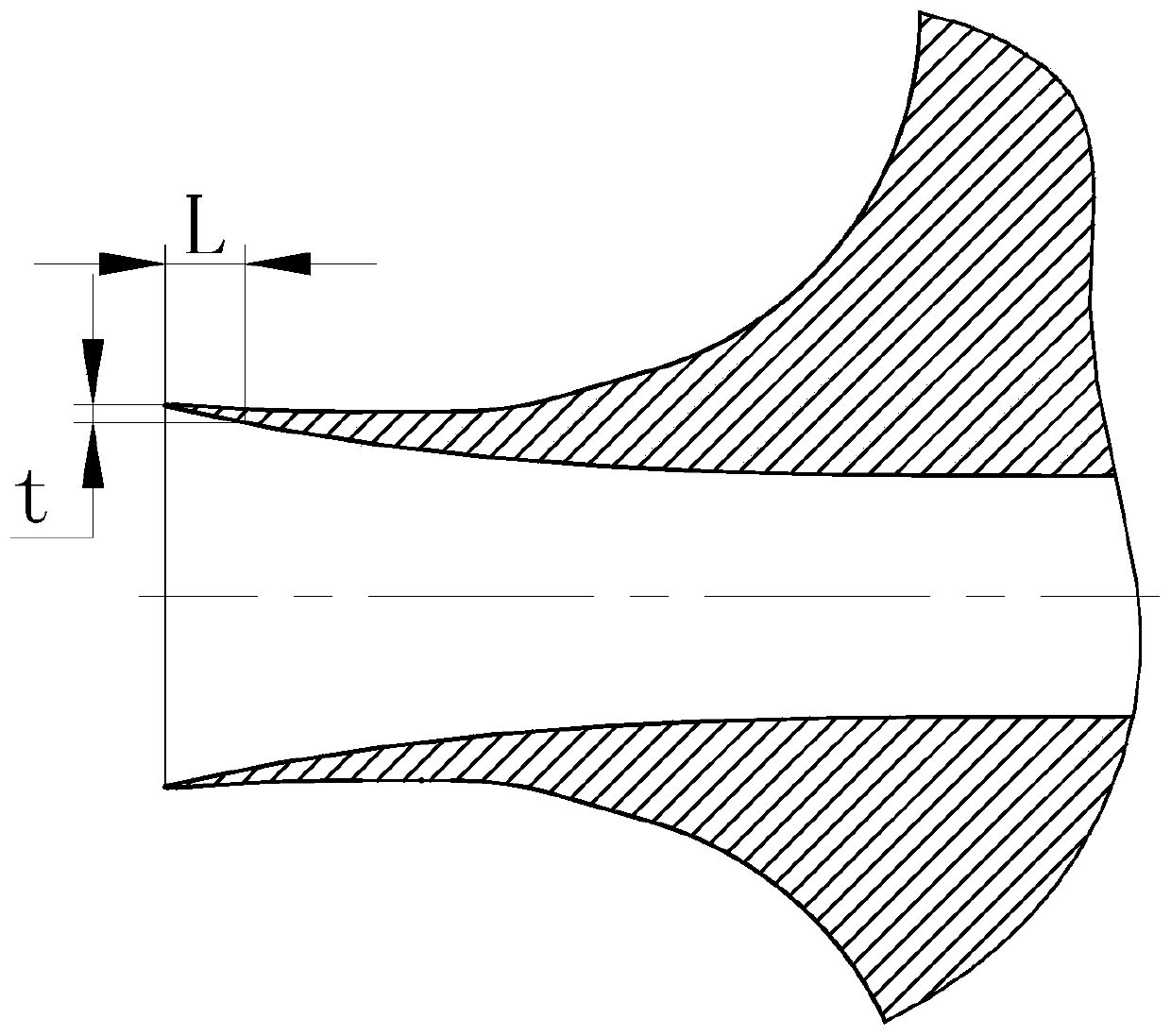

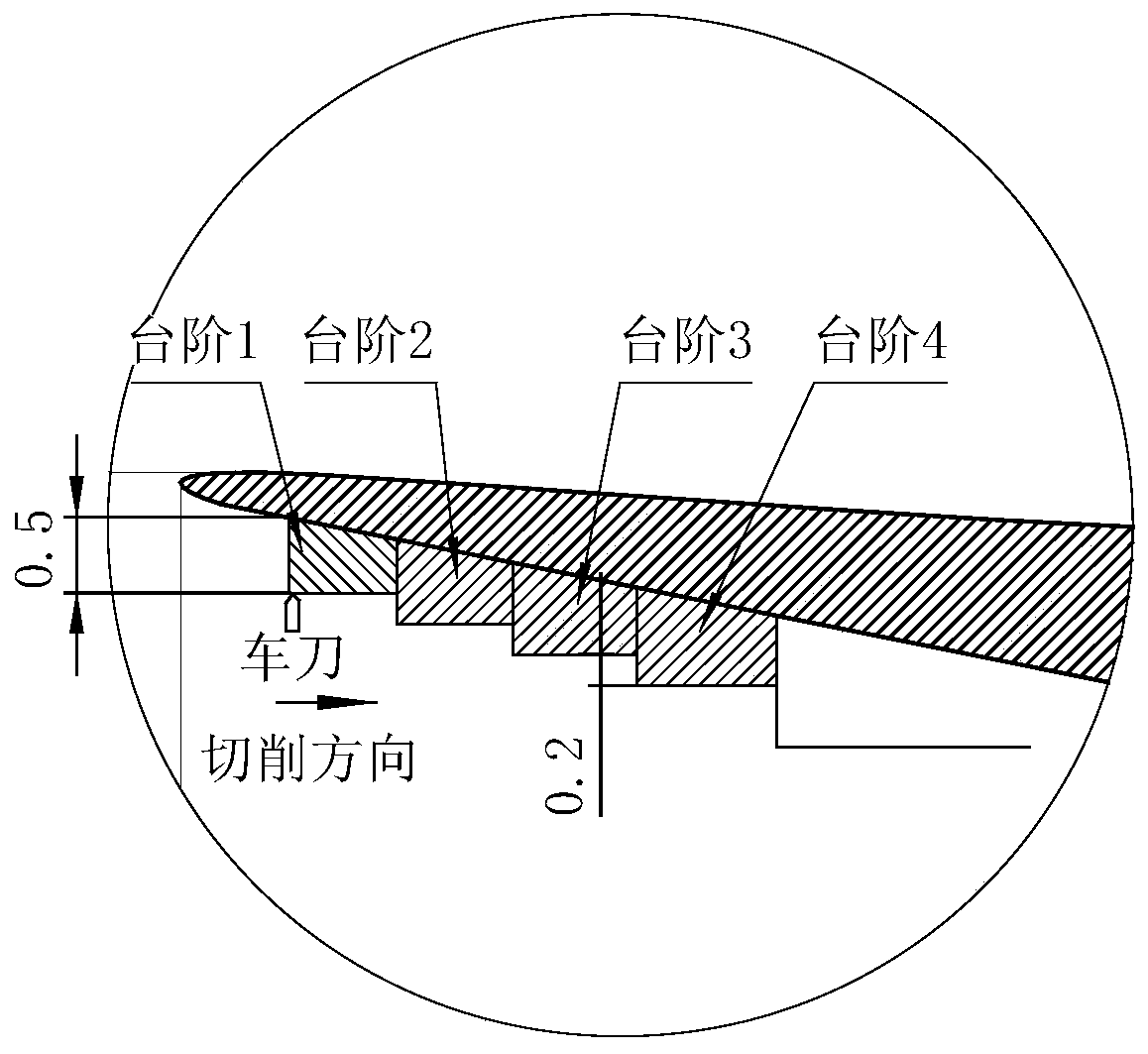

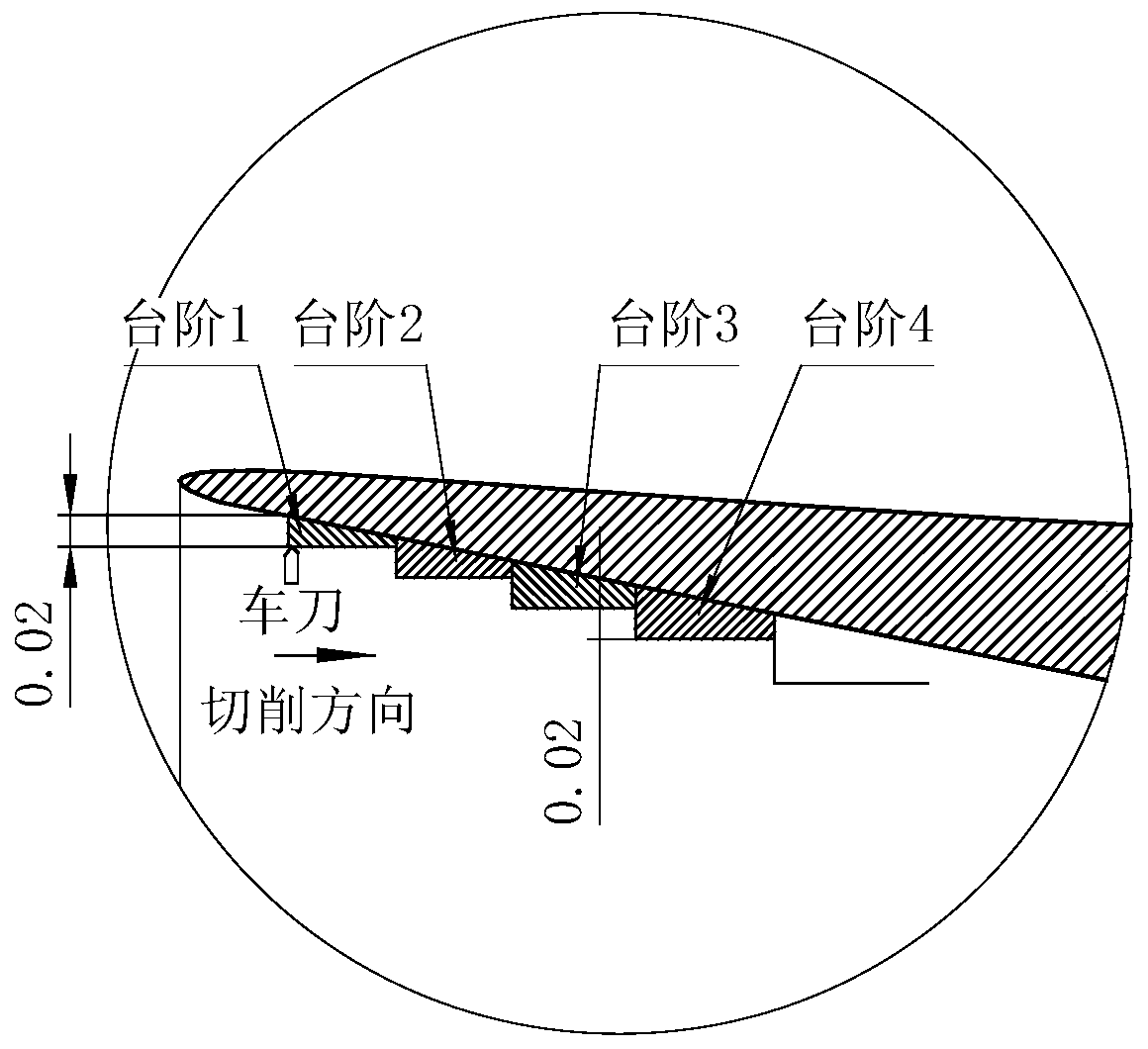

[0029] The characteristic size range of the hypersonic low-noise wind tunnel nozzle in this embodiment is 400mm to 700mm, the lip length L is 18.05mm, the thickness t=2.5mm, it is divided into 4 steps, and the lip processing time is 5h.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a method for machining a lip of a hypersonic-speed low-noise wind tunnel nozzle. The method includes the following steps that clamping is carried out, the thickness of the lipworkpiece is measured and the length L of the lip is determined, steps of the length L of the lip are roughly turned for the first time, the steps of the length L of the lip are roughly turned for thesecond time, the steps are removed after third-time rough turning, and fine turning is carried out. According to the method for machining the lip of the hypersonic-speed low-noise wind tunnel nozzle,the rigidity of the lip workpiece is improved through a step turning process, the problem that the lip workpiece easily deforms in the machining process is avoided, meanwhile, the machining efficiency is improved in the manner of increasing the bite, and the comprehensive machining efficiency is improved by 50%.

Description

technical field [0001] The invention belongs to the technical field of hypersonic wind tunnel tests, in particular to a method for processing a nozzle lip of a hypersonic low-noise wind tunnel. Background technique [0002] The low-noise flow field provided by the hypersonic low-noise wind tunnel is close to the real atmospheric environment at high altitude, and is an ideal facility for conducting boundary layer related research. The nozzle of the hypersonic low-noise wind tunnel is the core component of the hypersonic low-noise wind tunnel, and it is the key to obtain the low-noise flow field. In the hypersonic low-noise wind tunnel nozzle, a suction flow channel is arranged in front of the smallest throat of the nozzle to absorb the boundary layer of the upstream wall of the nozzle, which effectively reduces the noise of the flow field. According to the different diameters of the current hypersonic low-noise wind tunnel, the size of the nozzle of the hypersonic low-noise ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B23B1/00B23B25/06G01M9/04

CPCB23B1/00B23B25/06G01M9/04

Inventor 杨波范孝华孙启志孟祥润吴岸平张傲张健朱涛许晓斌

Owner 中国空气动力研究与发展中心超高速空气动力研究所

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com