Resistance spot welding spatter inhibition method with piezoelectric driving active pressure application

A resistance spot welding and piezoelectric drive technology, applied in resistance welding equipment, welding equipment, manufacturing tools, etc., can solve the problems of poor solder joint forming effect, increase welding pressure, spatter solder joint strength, etc., and reduce subsequent inspections. process, improve accuracy, reduce the effect of spatter defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

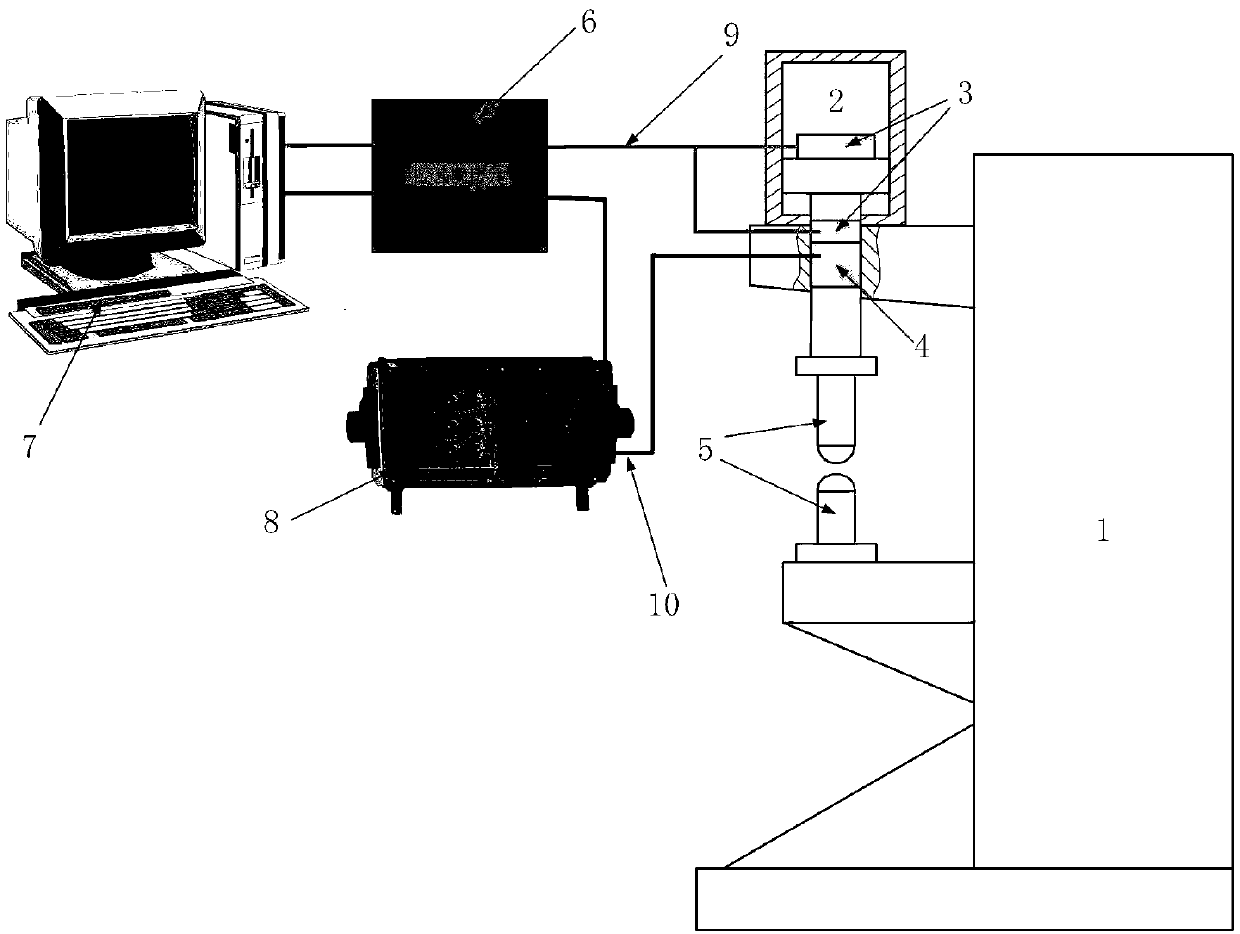

[0021] Embodiments of the present invention will be specifically described below with reference to the drawings.

[0022] First, the pressure sensor 3 is installed in the cylinder 2 or the electrode arm to measure the electrode pressure, and the output data of the pressure sensor is connected to the port of the control unit 6 through the pressure sensor connection line 9, and the control unit 6 is connected to the industrial computer 7. The piezoelectric actuator control signal output by the software system is connected to the piezoelectric actuator driver 8 through the control power supply 6 , and connected to the piezoelectric actuator 4 through the connecting line 10 . The piezoelectric actuator 4, including but not limited to, is installed in the electrode pressure output shaft through upper and lower bolts.

[0023] Then, turn on the resistance spot welding spatter defect monitoring system in the industrial computer 7, set corresponding parameters and run the system. Aft...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap