Plywood edge filling machine and automatic edge filling process thereof

A plywood and board edge technology, which is applied to other plywood/plywood appliances, manufacturing tools, wood processing appliances, etc., can solve problems such as damage, affecting the appearance of the board, and low work efficiency, so as to reduce the number of starts and stops and ensure the edge filling effect , the effect of reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

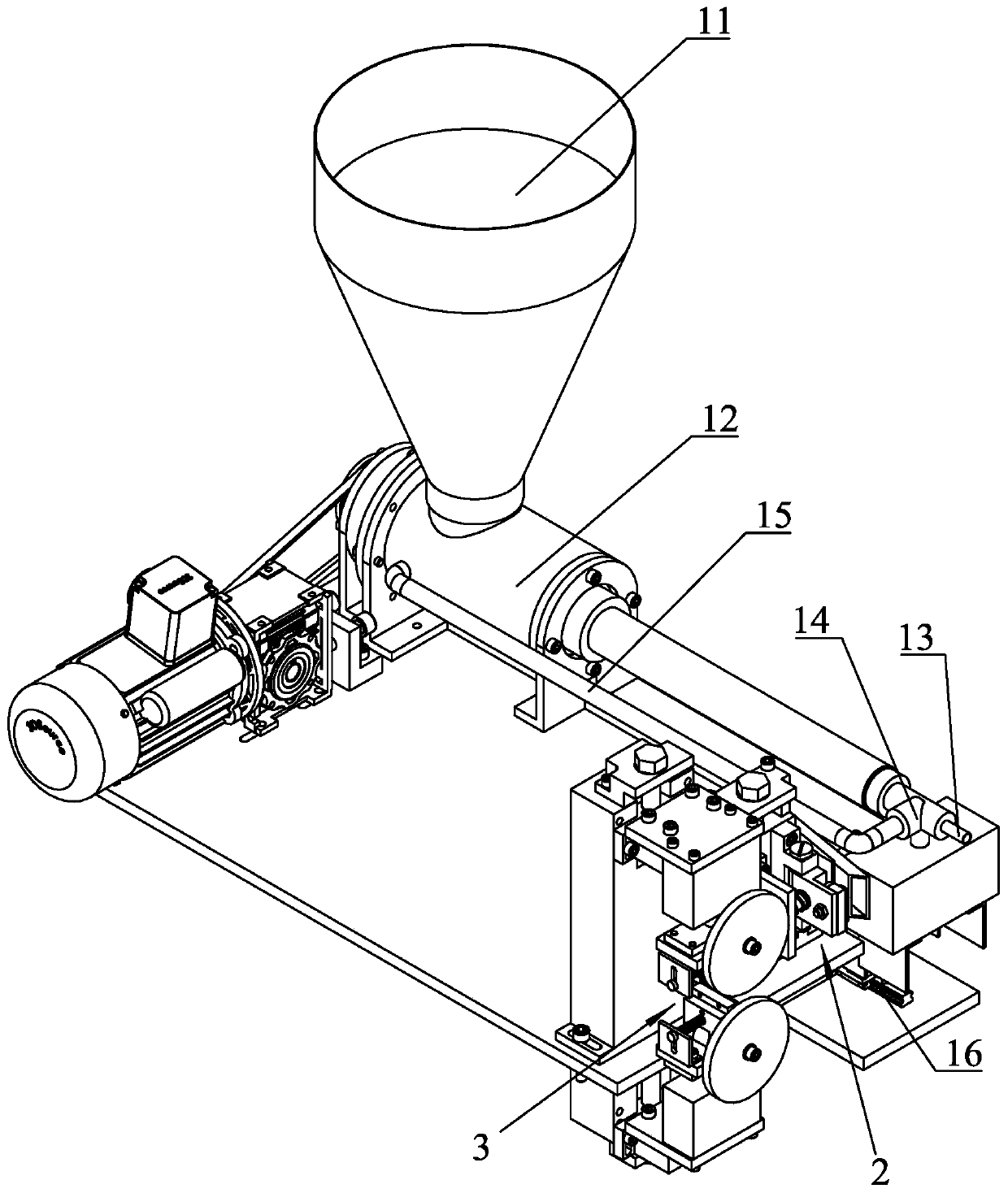

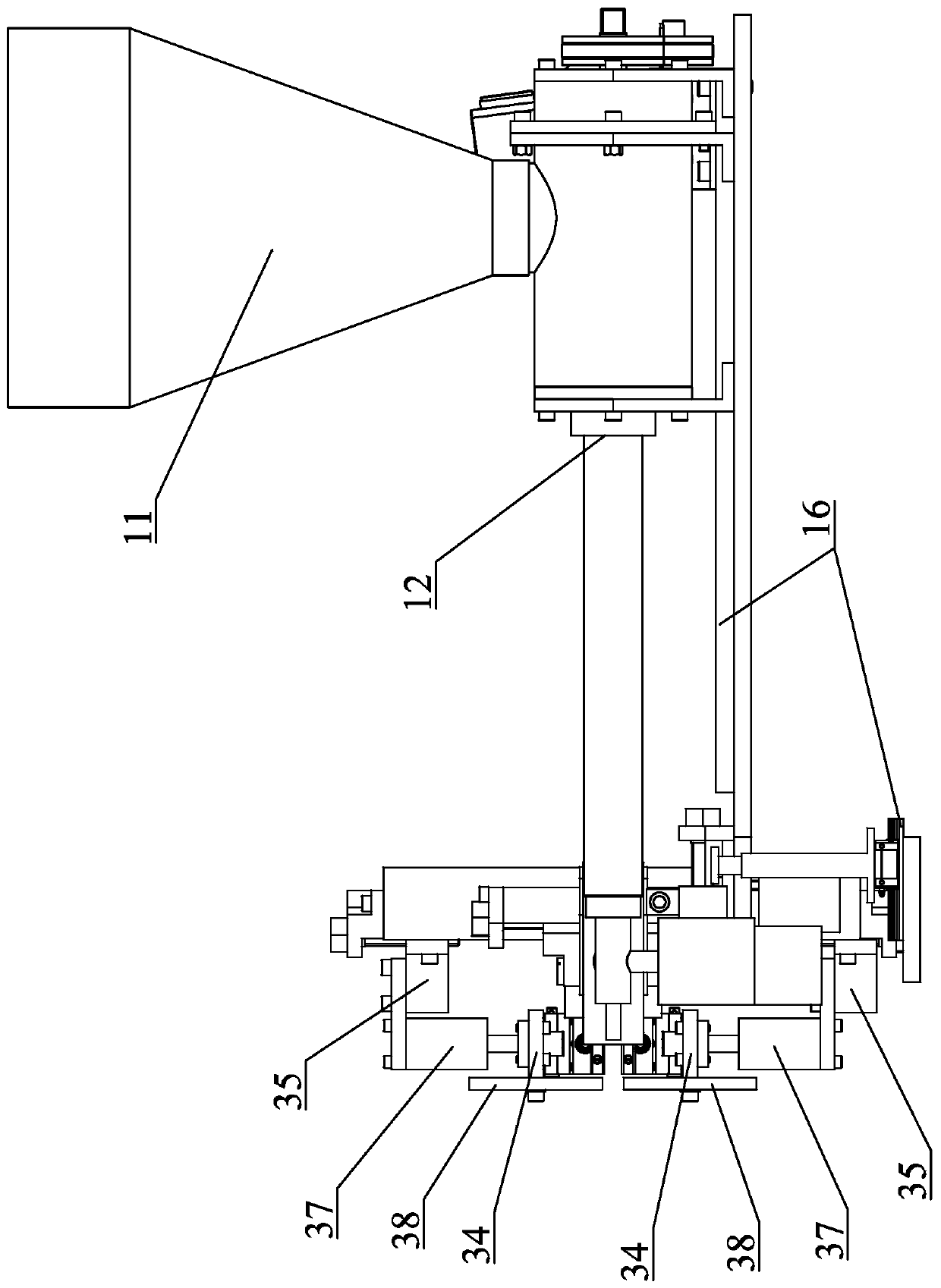

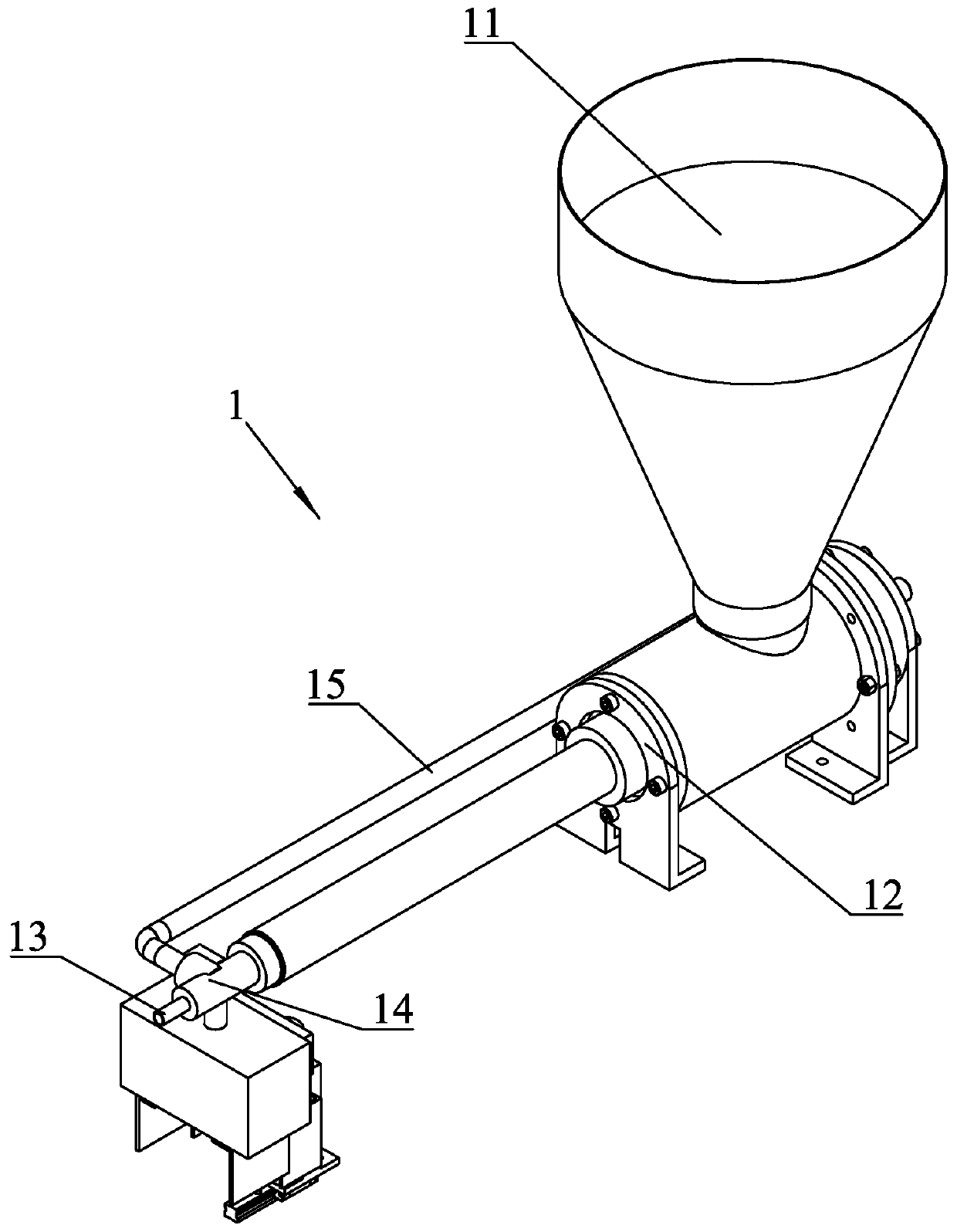

[0050] Such as Figure 1 to Figure 12 As shown, it is a kind of plywood edge repairing machine related to the present invention, comprising a putty extrusion mechanism 1, a board edge scraping putty mechanism 2 and a board surface putty removal mechanism 3, the putty extrusion mechanism 1, a board edge scraping mechanism 2 and the board surface putty removal mechanism 3 are arranged sequentially from upstream to downstream along the plywood conveying direction.

[0051] Like this, a kind of plywood edge mending machine that the present invention relates to, during use, plywood is transported on the conveyer belt, and putty extruding mechanism 1 extrudes the putty in the hopper 11 to the plywood edge in conveying through putty outlet 13; Along with the movement of the plywood, the putty scraping mechanism 2 on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com