A plywood edge repairing machine and its automatic edge repairing process

A technology for plywood and board edge, which is applied to other plywood/plywood utensils, manufacturing tools, wood processing utensils, etc., and can solve problems such as moisture infiltration, missing corners, and fried edges

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

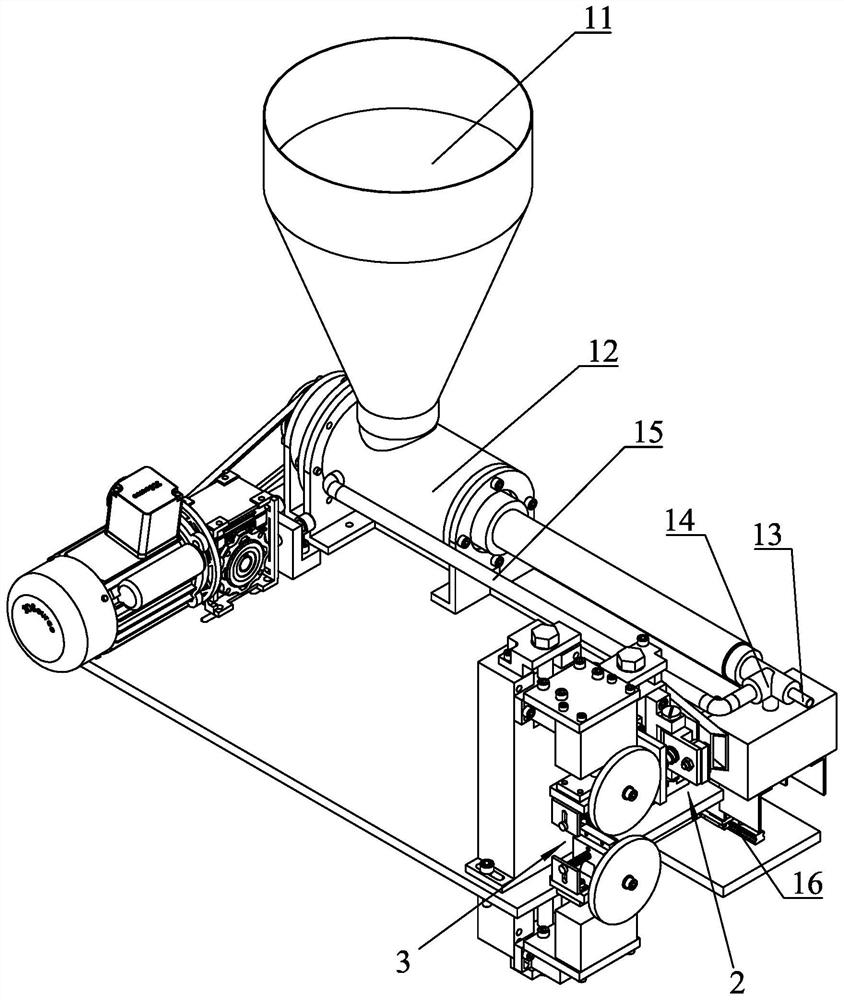

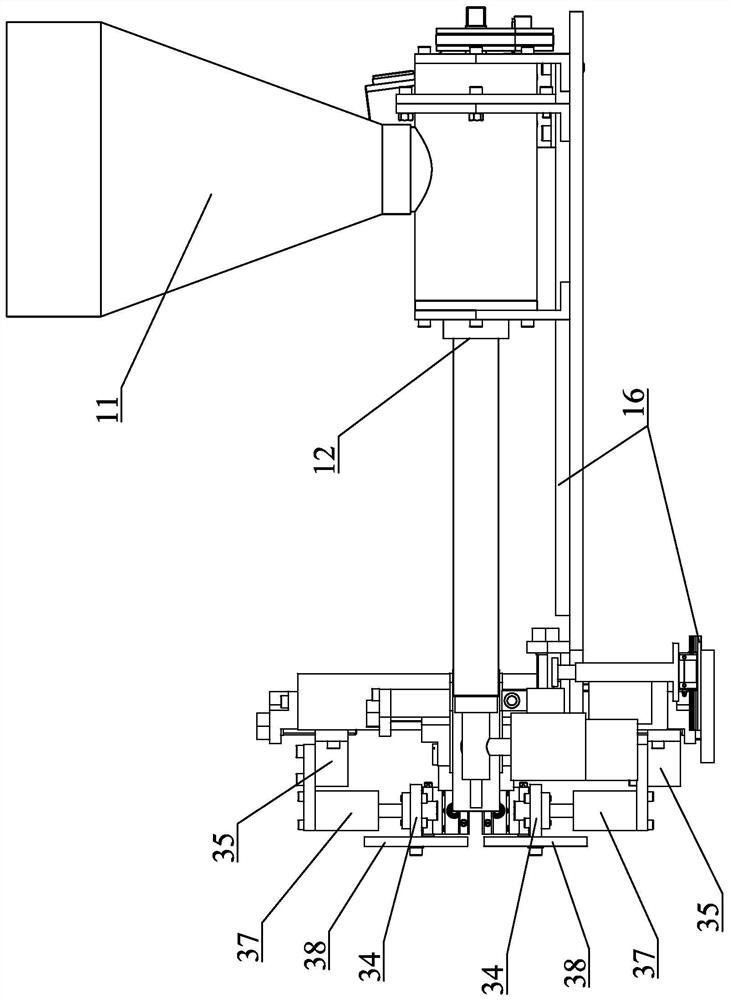

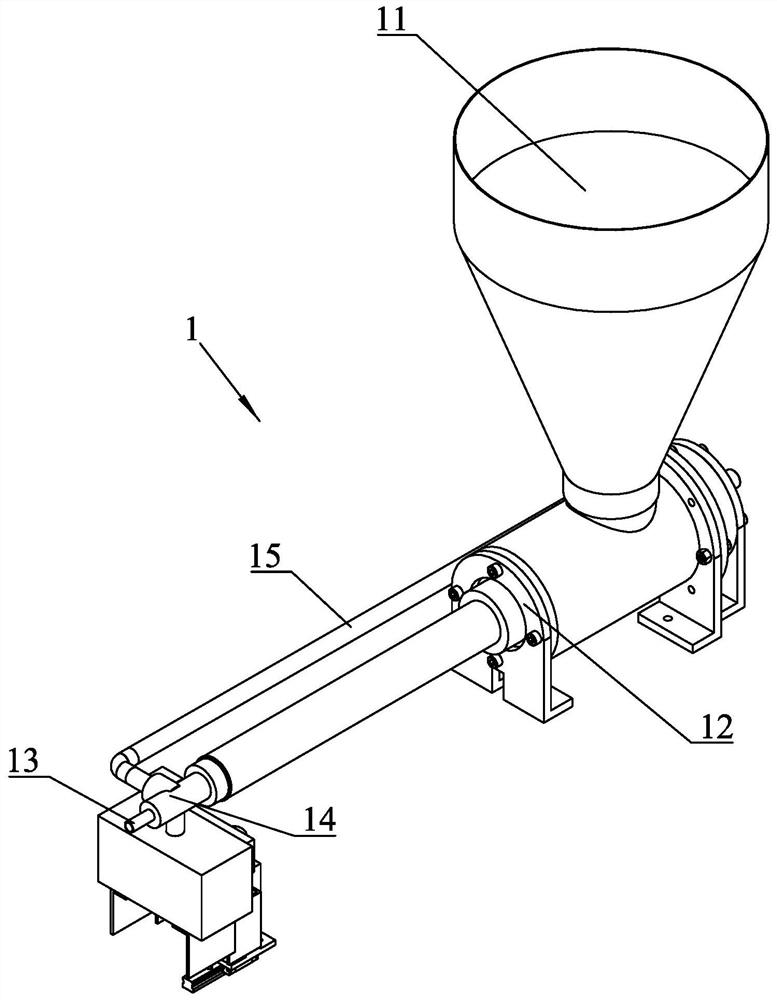

[0050] like Figure 1 to Figure 12 As shown, it is a kind of plywood edge repairing machine related to the present invention, comprising a putty extrusion mechanism 1, a board edge scraping putty mechanism 2 and a board surface putty removal mechanism 3, the putty extrusion mechanism 1, a board edge scraping mechanism 2 and the board surface putty removal mechanism 3 are arranged sequentially from upstream to downstream along the plywood conveying direction.

[0051] Like this, a kind of plywood edge mending machine that the present invention relates to, during use, plywood is transported on the conveyer belt, and putty extruding mechanism 1 extrudes the putty in the hopper 11 to the plywood edge in conveying through putty outlet 13; Along with the movement of the plywood, the putty scraping mechanism 2 on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com