Cloth printing machine

A technology for printing machines and fabrics, used in printing machines, rotary printing machines, general parts of printing machinery, etc., can solve the problem of no ink processing, and achieve the effect of ensuring health, increasing coverage, and good purification effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to enable those in the technical field to better understand the solutions of the present invention, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

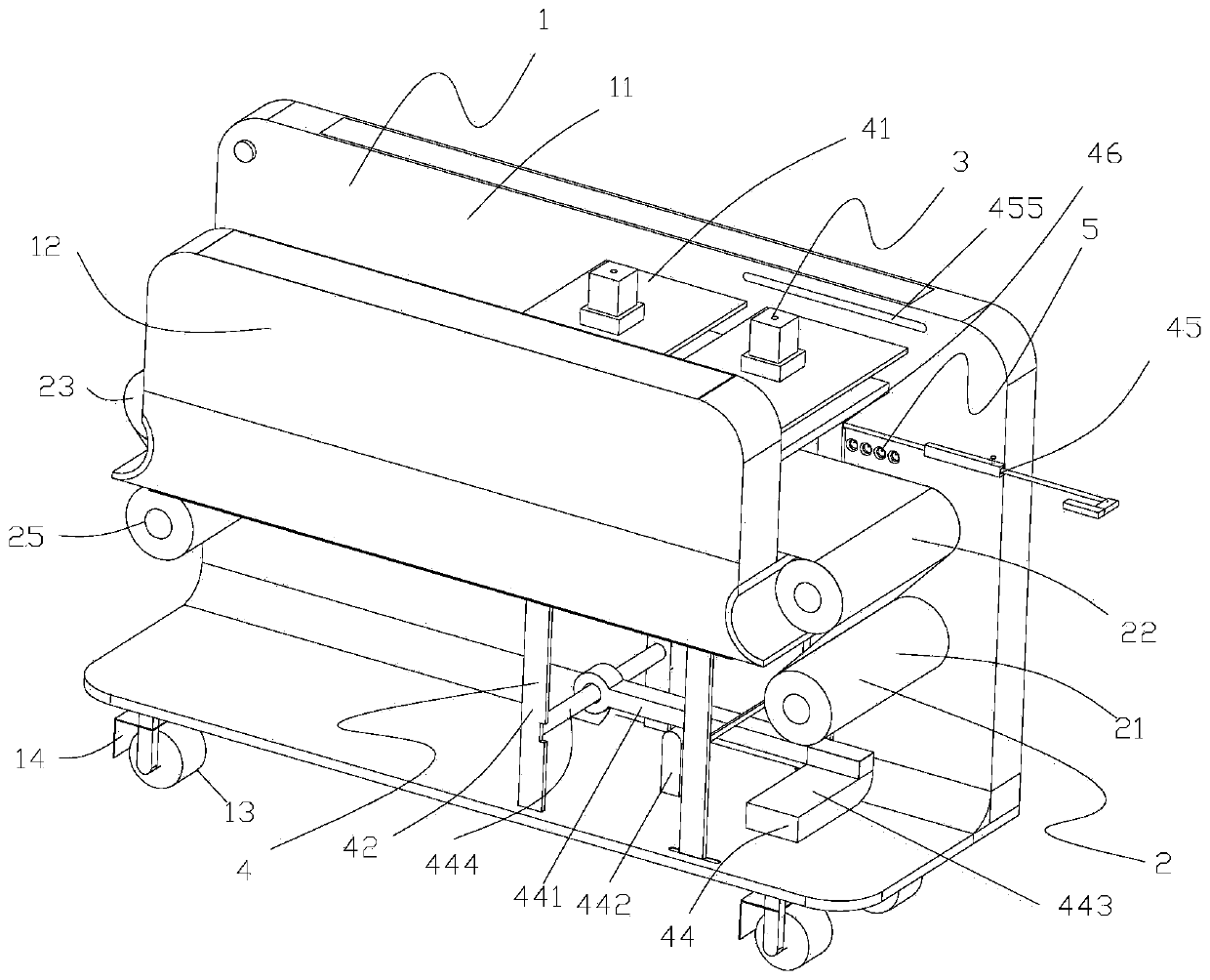

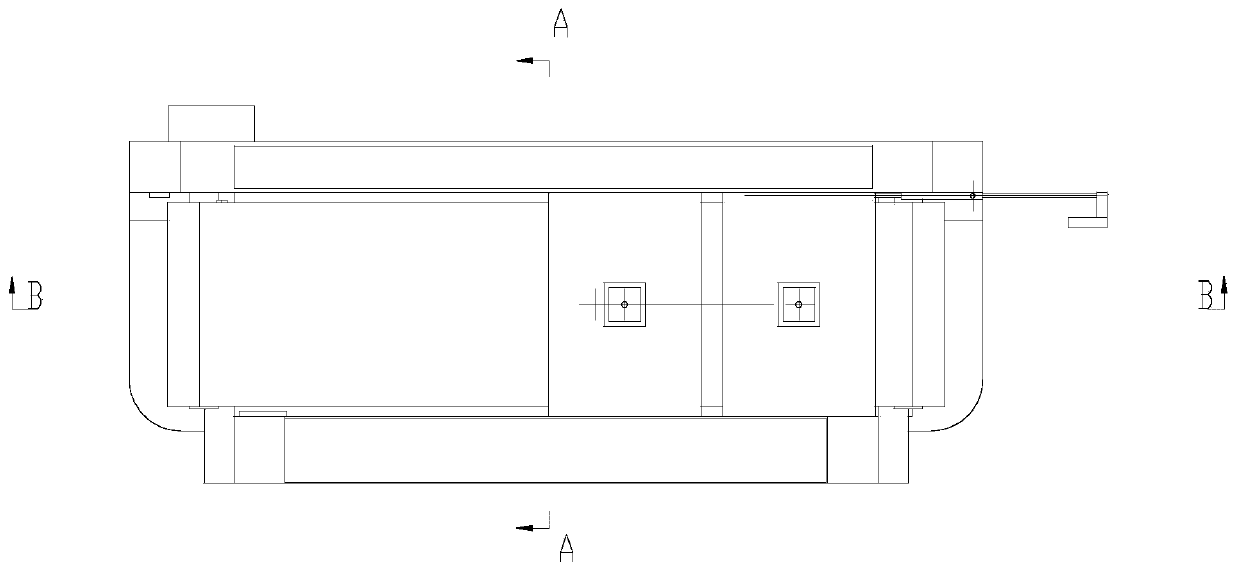

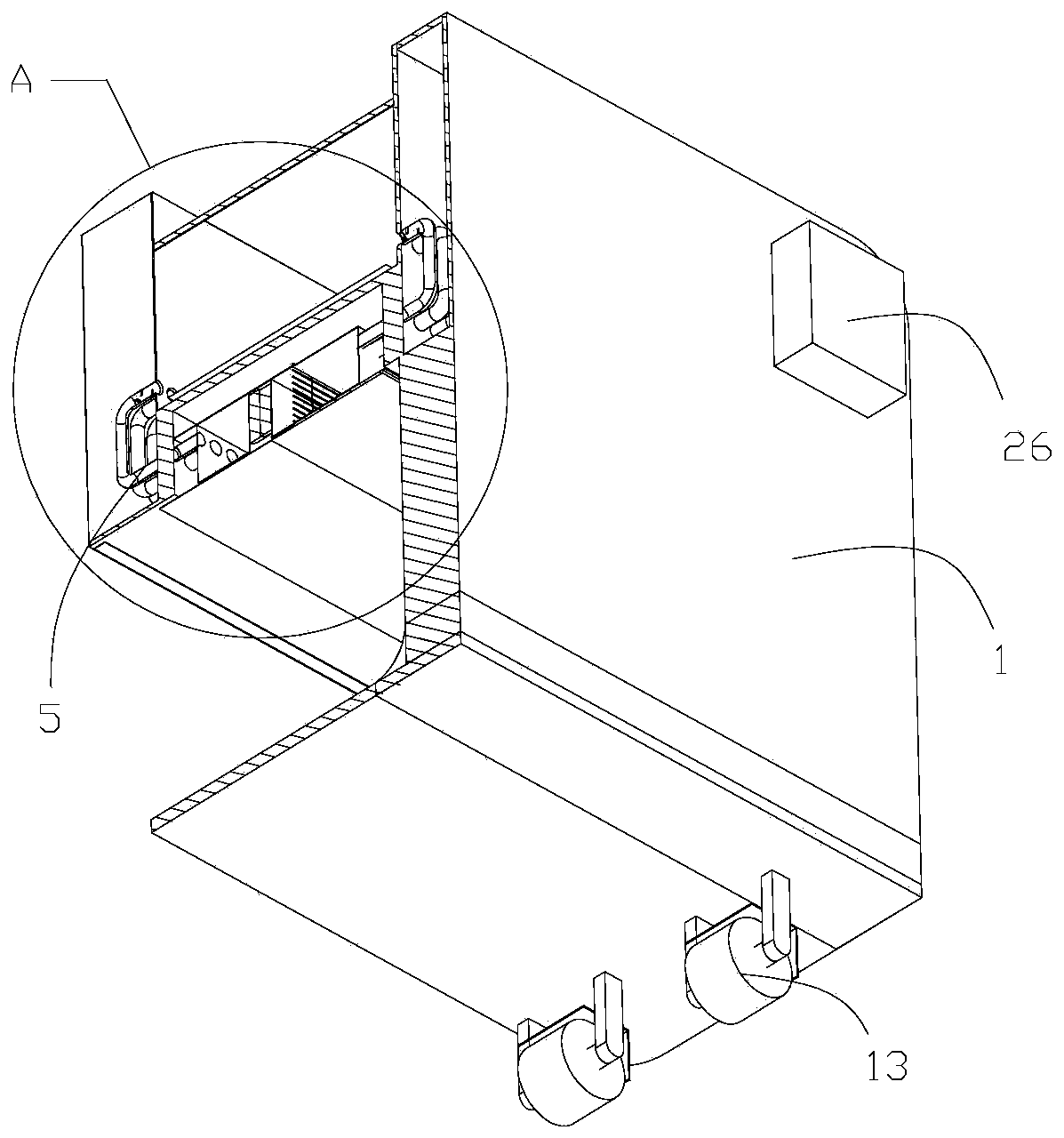

[0035] Such as Figure 1-9 As shown, a cloth printing machine includes a frame 1, a feeding mechanism 2, a printing mechanism 3, a support frame 4 and an ink processing device 5; the feeding mechanism 2 is arranged on the frame 1; the printing mechanism 3 It is arranged on the feeding mechanism 2 and is arranged in two groups; the support frame 4 is sleeved outside the printing mechanism 3 ; the ink processing device 5 is arranged inside the frame 1 .

[0036]The frame 1 includes a frame body 11, a transparent baffle 12, wheels 13 and brake pads 14; the transparent baffle 12 is located in front of the printing mechanism 3, and the transparent baffle 12 is fixedly connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com