Combination method and combination structure of pocket spring bed net

A pocket spring and combination method technology is applied in the production of spring mattresses, mattresses, furniture covers, etc., which can solve the problems of low degree of automation, low service life and high production cost, and achieve high degree of automation and service life. The effect of high and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Embodiment 1: A kind of combination method of pocket spring bed net.

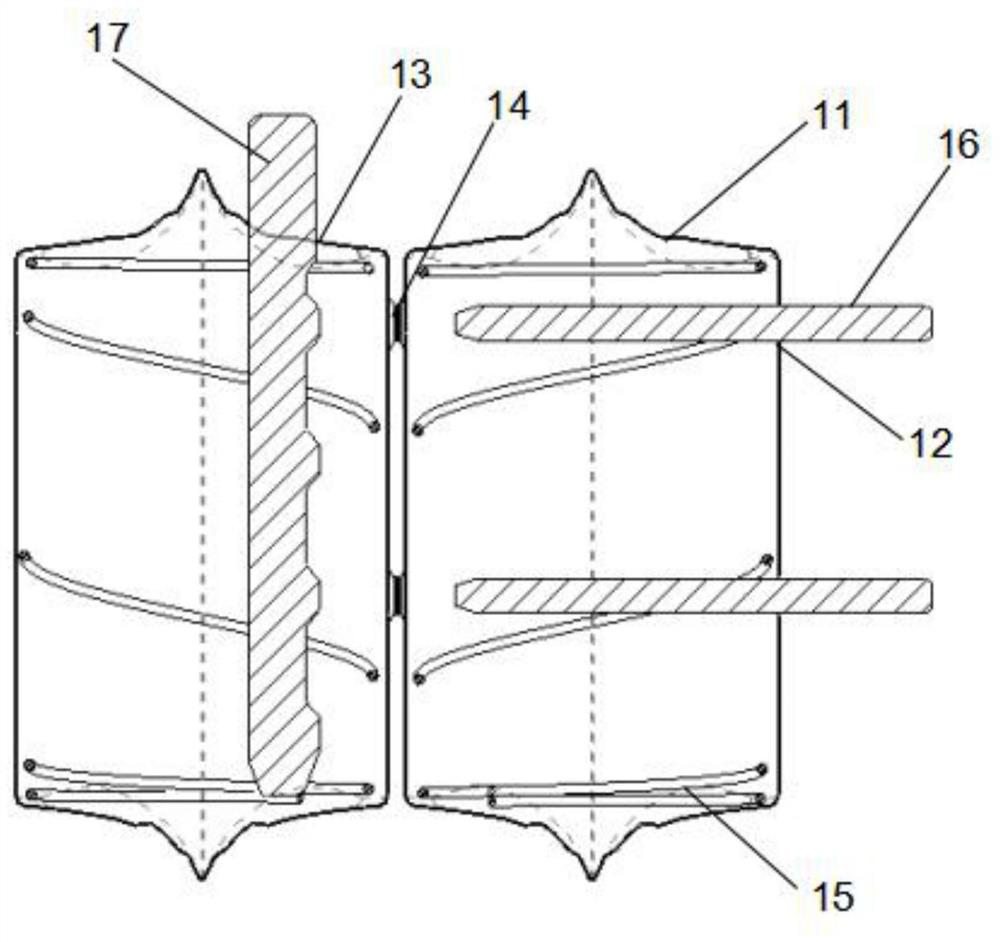

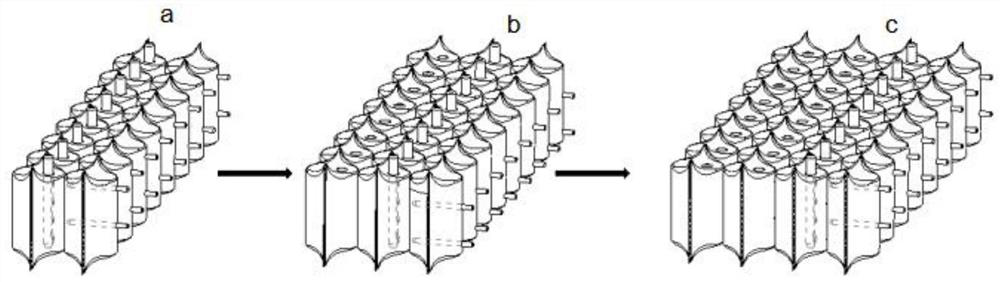

[0043] refer to Figure 1 to Figure 6 as well as Figure 11 As shown, a method for combining pocket spring bed nets is to weld the non-woven fabrics of several rows of pocket spring strings before and after by ultrasonic welding or heat welding, which specifically includes the following steps:

[0044] S1. Put the previous set of welding knives 17 from the top of the pocket spring string non-woven fabric bag through hot-melt opening or blowing high-temperature gas to melt the non-woven fabric and open the hole. A vertical through-hole 13 is provided on the top of the bag 11, and then the previous set of welding knives 17 penetrate the vertical through-hole 13 vertically downwards, and go deep into the inside of the individual pocket spring;

[0045]S2. The latter group of welding knives 16 are opened from the rear side arc surface of the rear row of pocket spring strings by hot melting or blowing h...

Embodiment 2

[0051] Embodiment 2: a kind of combination method of pocket spring bed net.

[0052] refer to Figure 7 to Figure 11 As shown, a method for combining pocket spring bed nets is to weld the non-woven fabrics of several rows of pocket spring strings before and after by ultrasonic welding or heat welding, which specifically includes the following steps:

[0053] S1. Put the previous set of welding knives 17 from the top of the pocket spring string non-woven fabric bag through hot-melt opening or blowing high-temperature gas to melt the non-woven fabric and open the hole. A vertical through-hole 13 is provided on the top of the bag 11, and then the previous set of welding knives 17 penetrate the vertical through-hole 13 vertically downwards, and go deep into the inside of the individual pocket spring;

[0054] S2. Connect the non-woven fabric at the connection between the adjacent two pocket spring individuals of the rear row of pocket spring strings to the non-woven fabric of the...

Embodiment 3

[0061] Embodiment 3: A kind of combined structure of pocket spring bed net.

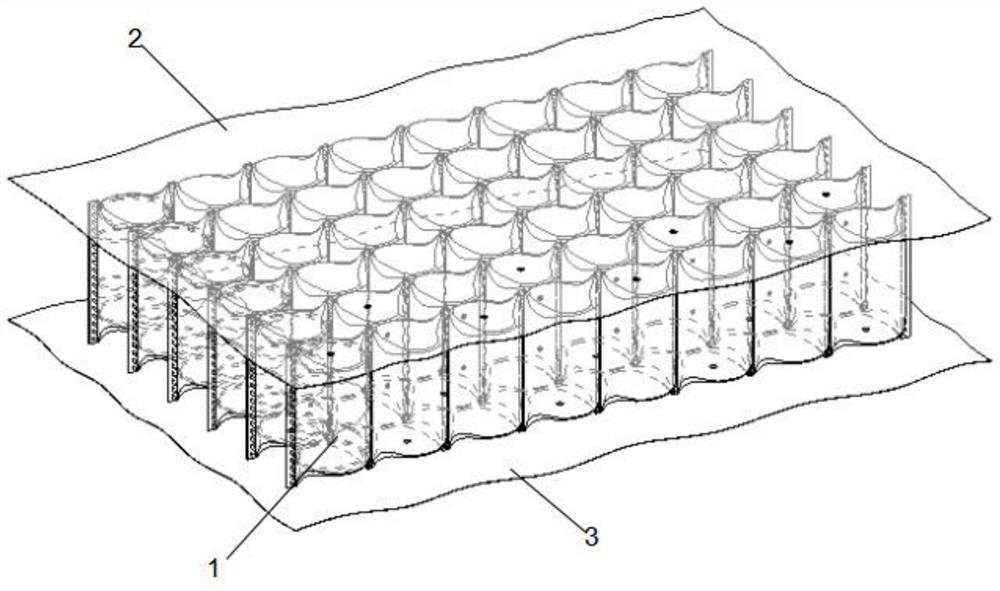

[0062] refer to Figure 1 to Figure 6 As shown, a combined structure of pocket spring bed nets includes several rows of pocket spring strings. Using the combination method provided in Example 1, the non-woven fabric contact points of several rows of neatly arranged parallel pocket spring strings are passed through Ultrasonic welding or heat welding together, wherein the non-woven fabric of the front cylindrical arc surface of the pocket spring string individual of the rear row is in contact with the non-woven fabric of the rear cylindrical arc surface of the pocket spring string individual of the previous row at least Two welding connection points 14, the tops of the welded rows of pocket spring strings are welded with the top cloth 2 by ultrasonic welding or thermal welding, and the bottoms of the welded rows of pocket spring strings are ultrasonically welded or thermally welded There is a bottom c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com