A kind of hpb300 steel material and the production method for improving the surface scarring of hpb300 steel material

A production method and steel technology, applied in the direction of manufacturing tools, metal rolling, metal rolling, etc., can solve the problems of steel surface quality impact, inability to completely eliminate, high spinning temperature, etc., to achieve inhibition that is easy to aggravate or be enlarged, avoid The probability of cracks and the effect of reducing cracks in the middle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

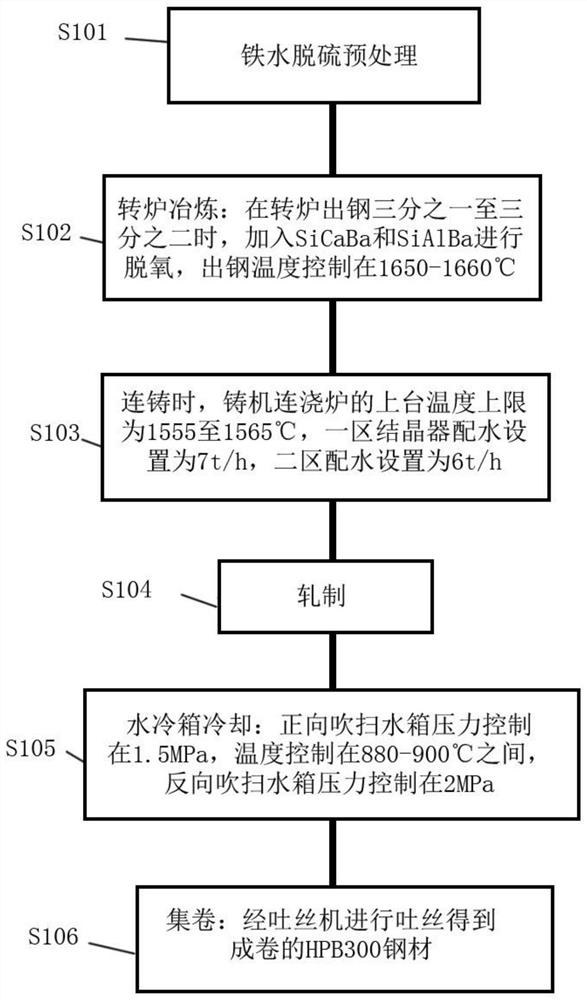

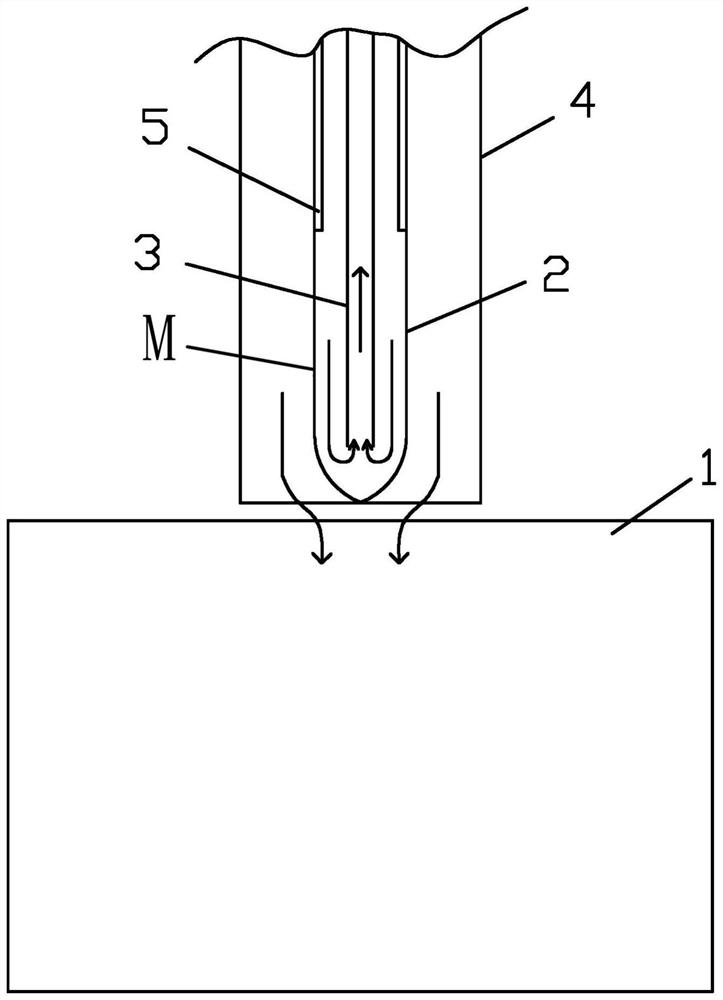

[0015] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

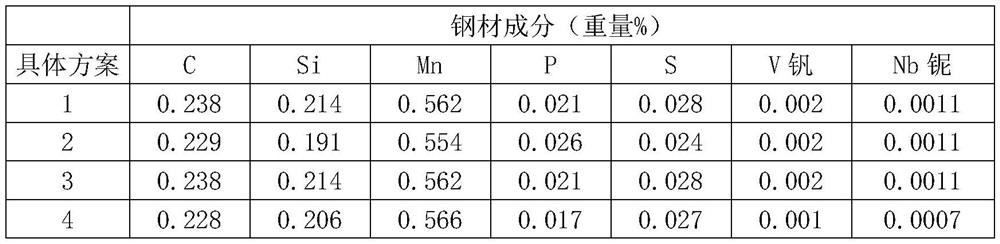

[0016] In view of the defects and deficiencies in the prior art, the composition ratio of the HPB300 steel of the present invention is scientific and reasonable, so that the scars on the steel surface are effectively improved, the probability of scarring on the steel surface is greatly reduced, and the quality of the steel surface is effectively improved. At the same time, the production method for improving the scarring on the surface of HPB300 steel of the present invention can effectively inhibit the development of columnar crystals, improve the internal defects of the billet, further reduce the probability of scarring on the steel surface, and improve the quality of the steel surface.

[0017] In the preferred embodiment of a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com