A combined sealing device for vertical hydraulic generator bearing oil groove

A hydro-generator, bearing oil tank technology, applied in the direction of engine sealing, hydroelectric power generation, engine components, etc., can solve the problems of poor sealing effect, easy leakage of oil mist, etc., to prevent the leakage of oil mist and improve the sealing. effect, the effect of improving the sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

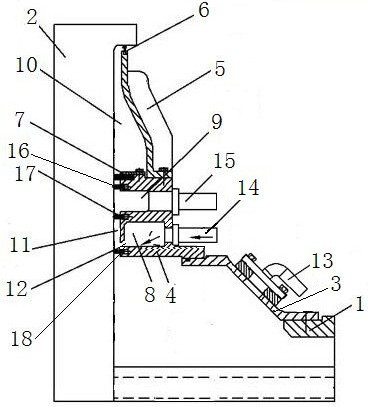

[0029] see figure 1 , a vertical water turbine generator bearing oil tank combined sealing device, including an oil tank 1, a rotating shaft 2 and a sealing end cover 3, and also includes a sealing seat ring 1 4 and a sealing seat ring 2 5, and one of the sealing end cover 3 One side is connected with the lower end of the sealing seat ring one 4, the other side of the sealing end cover 3 is fixedly connected with the oil tank 1, the upper end of the sealing seat ring one 4 is connected with the lower end of the sealing seat ring two 5, and the sealing seat ring two 5 The upper end is connected with a first sealing brush 6, and the sealing seat 4 is connected with a second sealing brush 7 and multi-layer sealing teeth, and the sealing seat 4 is provided with a cavity 8 and a cavity 2 9. The sealing seat ring 2 5, the sealing seat ring 1 4 and the rotating shaft 2 form a cavity 3 10, and the rotating shaft 2 and the sealing seat ring 1 4 form a cavity 4 11, and the cavity 8 pass...

Embodiment 2

[0032] see figure 1 , a vertical water turbine generator bearing oil tank combined sealing device, including an oil tank 1, a rotating shaft 2 and a sealing end cover 3, and also includes a sealing seat ring 1 4 and a sealing seat ring 2 5, and one of the sealing end cover 3 One side is connected with the lower end of the sealing seat ring one 4, the other side of the sealing end cover 3 is fixedly connected with the oil tank 1, the upper end of the sealing seat ring one 4 is connected with the lower end of the sealing seat ring two 5, and the sealing seat ring two 5 The upper end is connected with a first sealing brush 6, and the sealing seat 4 is connected with a second sealing brush 7 and multi-layer sealing teeth, and the sealing seat 4 is provided with a cavity 8 and a cavity 2 9. The sealing seat ring 2 5, the sealing seat ring 1 4 and the rotating shaft 2 form a cavity 3 10, and the rotating shaft 2 and the sealing seat ring 1 4 form a cavity 4 11, and the cavity 8 pass...

Embodiment 3

[0036] see figure 1 , a vertical water turbine generator bearing oil tank combined sealing device, including an oil tank 1, a rotating shaft 2 and a sealing end cover 3, and also includes a sealing seat ring 1 4 and a sealing seat ring 2 5, and one of the sealing end cover 3 One side is connected with the lower end of the sealing seat ring one 4, the other side of the sealing end cover 3 is fixedly connected with the oil tank 1, the upper end of the sealing seat ring one 4 is connected with the lower end of the sealing seat ring two 5, and the sealing seat ring two 5 The upper end is connected with a first sealing brush 6, and the sealing seat 4 is connected with a second sealing brush 7 and multi-layer sealing teeth, and the sealing seat 4 is provided with a cavity 8 and a cavity 2 9. The sealing seat ring 2 5, the sealing seat ring 1 4 and the rotating shaft 2 form a cavity 3 10, and the rotating shaft 2 and the sealing seat ring 1 4 form a cavity 4 11, and the cavity 8 pass...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Axial height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com