A Fatigue Life Prediction Method for CFRP-Metal Hybrid Bolted Connections

A technology for fatigue life prediction and connecting structures, applied in geometric CAD, instruments, design optimization/simulation, etc., can solve problems such as competitive fatigue failure, and achieve the effect of reducing test costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

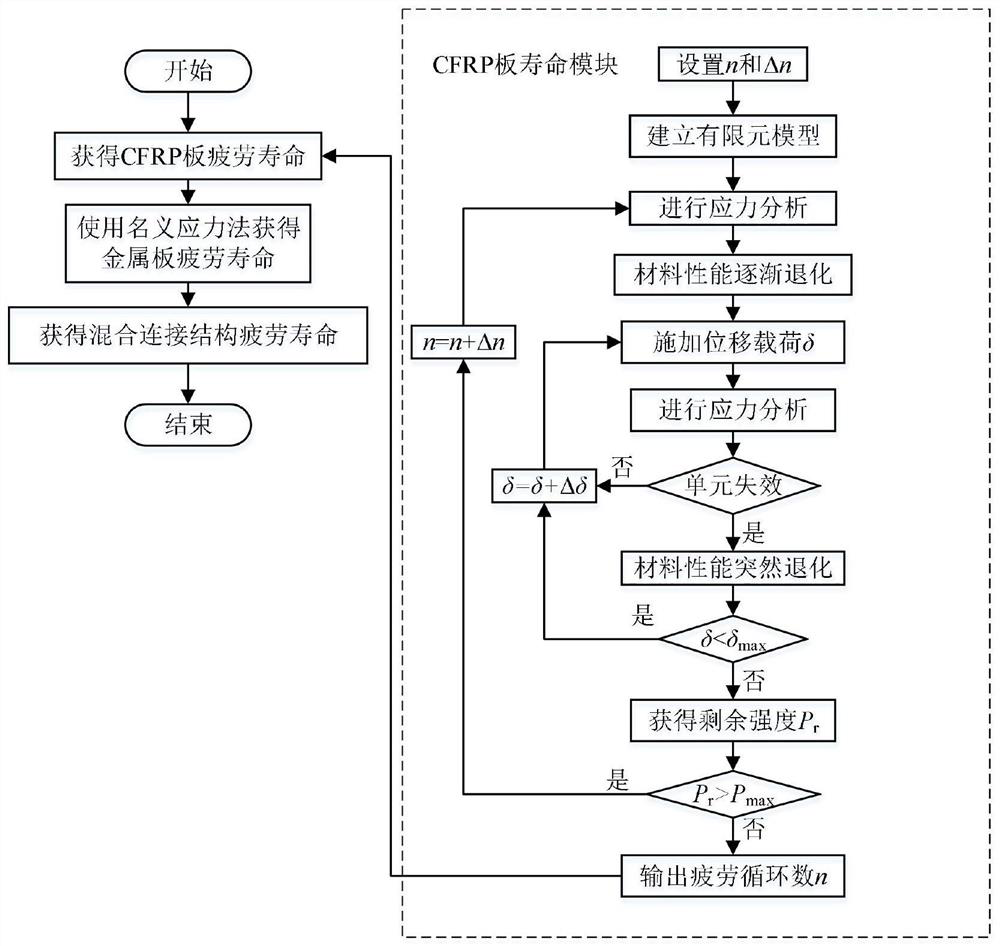

Method used

Image

Examples

Embodiment 1

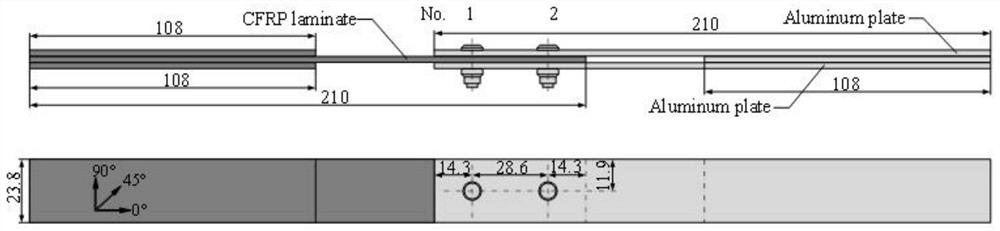

[0064] Example 1: Prediction of fatigue life of CFRP-aluminum alloy two-nail and double-shear connection structure

[0065] CFRP-aluminum alloy two-nail double-shear bolt connection structure such as figure 2 As shown, the middle plate is a CFRP laminate, the two sides are aluminum alloy plates, the fastener bolts are made of Ti-6Al-4V titanium alloy, and a tightening torque of 5.0 N m is applied to the two fasteners respectively. The steps to achieve fatigue life prediction are as follows:

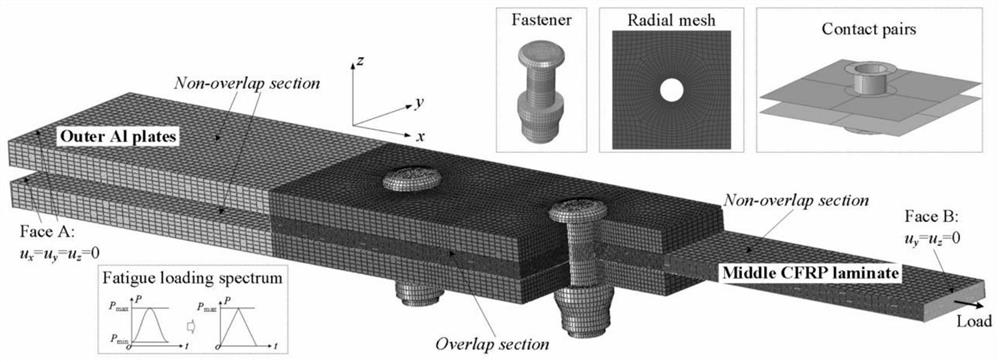

[0066] 1. According to the structural parameters of the CFRP-aluminum alloy two-nail and double-shear connection, a three-dimensional finite element model of the structure is established in the finite element software ABAQUS, and the free ends of the aluminum plates on both sides are completely constrained. In the 3D finite element model, contact pairs are defined on the contact surfaces of CFRP plate and aluminum plate, CFRP plate and fastener, and aluminum plate and fastener. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com