Semiconductor laser device bar cleavage epitaxial wafer adhering device and semiconductor laser device bar cleavage epitaxial wafer adhering method

A chip device and laser technology, applied in the structural details of semiconductor lasers and other directions, can solve the problems of insufficient contact between the blue film and the epitaxial wafer, affecting the cleavage effect of the epitaxial wafer, and insufficient expansion of the blue film, etc., to achieve operation and inspection. Convenient and reliable, good patch effect, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

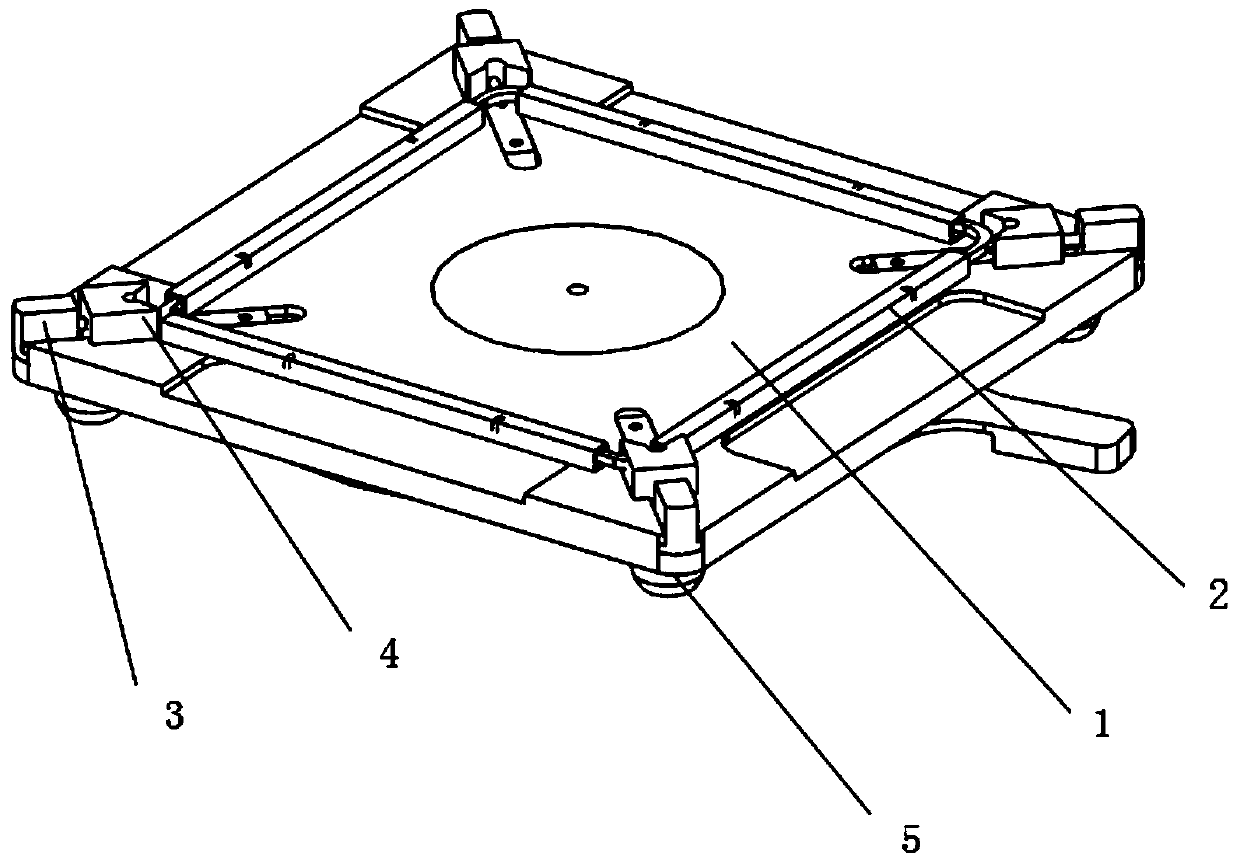

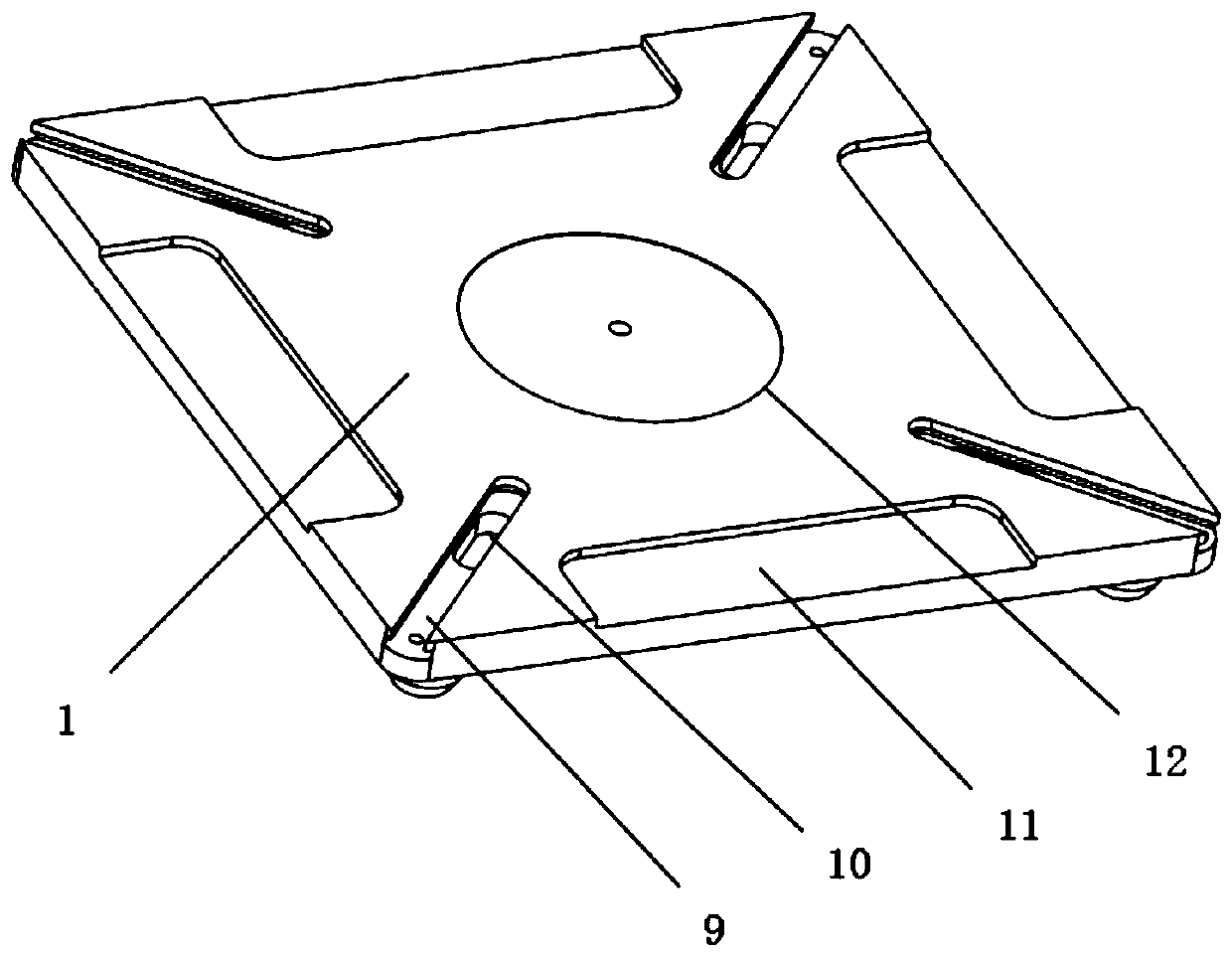

[0046] Such as Figure 1-11 As shown, a semiconductor laser bar cleavage epitaxial wafer placement device includes a main body 1, a square frame 2, a round cake 6, a positioning block 3 and a sliding block, the square frame 2 is located on the upper part of the main body 1, and the round cake 6 is located on the main body 1 In the lower part, the main body 1 has a square structure, and the four corners of the main body 1 are provided with chutes 9 towards the center. The four chutes 9 have the same structural size. The positioning blocks 3 are fixed on the four corners of the main body 1. Located at the upper end of the chute 9, the sliding block is located in the chute 9 and can slide along the chute 9;

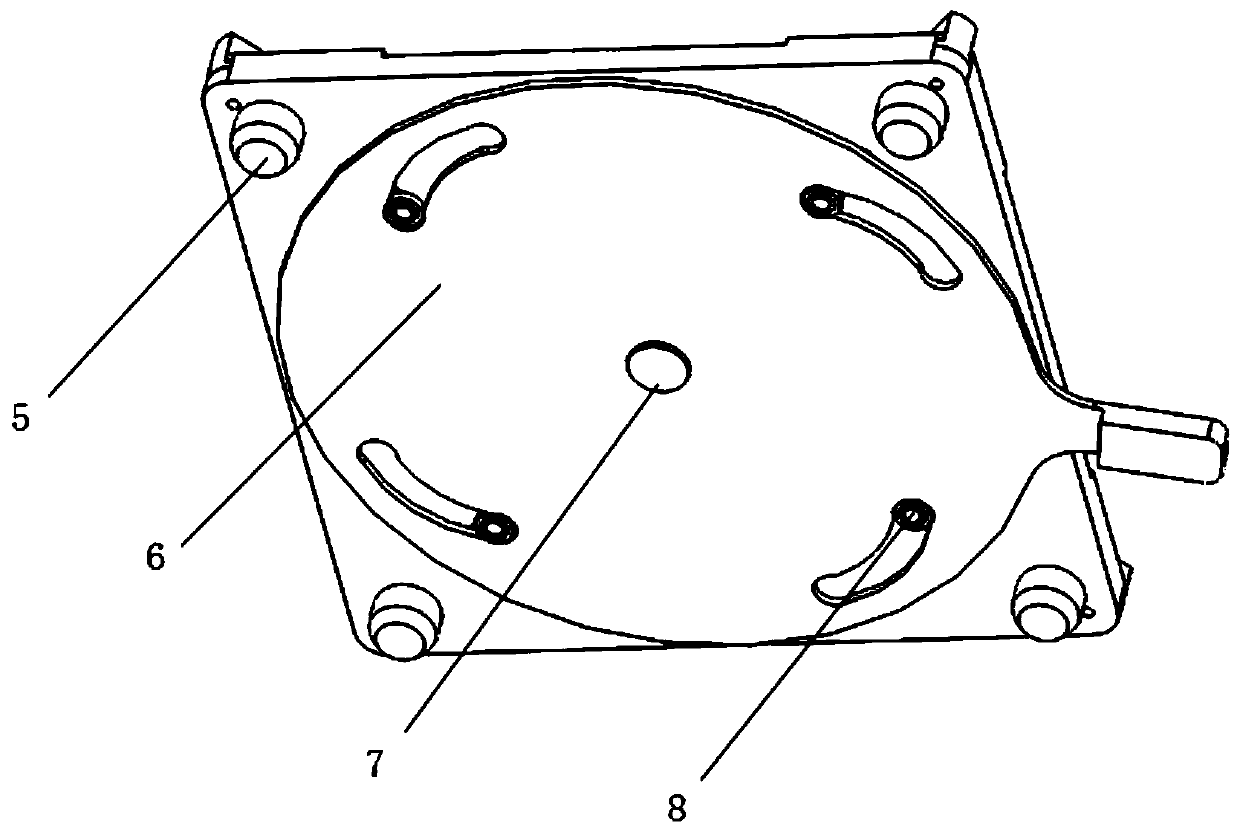

[0047] The middle part of the round cake 6 is provided with a fixing hole 20, and the pin shaft 7 passes through the fixing hole 20 to connect the round cake 6 and the main body 1. The round cake 6 can rotate relative to the main body 1 through the pin shaft 7, and the round...

Embodiment 2

[0050] A semiconductor laser bar cleavage epitaxial chip placement device, the structure is as shown in Embodiment 1, the difference is that the bottom of the positioning block 3 is provided with a slide rail II18, and the middle position of the bottom of the slide rail II18 is provided with a screw hole 17, and the screw The hole 17 is used to fix the position of the positioning block 3 on the main body 1, and one end of the positioning block 3 is provided with a positioning rod 16, and the positioning rod 16 is used for positioning the sliding block.

Embodiment 3

[0052] A semiconductor laser bar cleavage epitaxial chip placement device, the structure is as shown in Embodiment 1, the difference is that the guide groove 21 is a long arc-shaped hole, and the two ends of the long arc-shaped hole are provided with a first arc 31 and the second arc 32, as Image 6 As shown, the direction of the arrow is counterclockwise, and the distance from the first arc 31 to the center of the round cake 6 is smaller than the distance from the second arc 32 to the center of the round cake 6 .

[0053] The slider includes a slider main body 4 and a slide rail I14 located at the lower part of the slider main body 4. The slide rail I14 is integrated with the slider main body 4. The size of the slide rail I14 is adapted to the size of the chute 9. The size of the slider main body 4 One end is provided with the positioning hole 13 that cooperates with positioning rod 16, and the other end is provided with V-shaped groove 15; The positioning rod 16 cooperates ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com