A method of manufacturing a permanent magnet motor rotor

A technology for permanent magnet motors and manufacturing methods, which is applied in the manufacture of motor generators, stator/rotor bodies, electromechanical devices, etc., and can solve the problem that epoxy potting adhesives cannot meet the requirements of high temperature resistance, mass production of motors, Affect the reliability of the motor rotor and other issues to achieve the effect of avoiding air bubbles and holes, improving potting efficiency, and reducing the possibility

Active Publication Date: 2022-05-31

襄阳中车电机技术有限公司 +1

View PDF8 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0010] This process uses epoxy potting glue to fill the gap between the rotor permanent magnet and the iron core. This traditional method of impregnating epoxy impregnating paint is complicated and cannot meet the requirements of mass manufacturing of motors. In the special application environment of rail transit permanent magnet motors, epoxy potting adhesives cannot meet the high temperature resistance requirements above 200°C, and the shock resistance after potting and curing is not good, and it is easily affected by vibration and shock, resulting in failure of the filling part; at the same time, the traditional potting The core part of the sealing process is prone to loss of potting glue, resulting in air bubbles or cavities in the filling part, which affects the reliability of the motor rotor

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

preparation example Construction

[0051] In the step S3, the curing conditions are: the workpiece is kept at 110-120° C. for 1.5-2 h.

Embodiment 1

[0054]

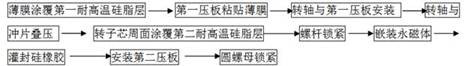

[0060] S4: the potting glue 15 adopted is an addition type silicone rubber. The potting process of the potting compound 15 is as follows: adding silicone rubber

Embodiment 2

[0068] At the same time, Teflon has unique and excellent heat resistance, low temperature resistance and dielectric properties. It has the highest operating temperature

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

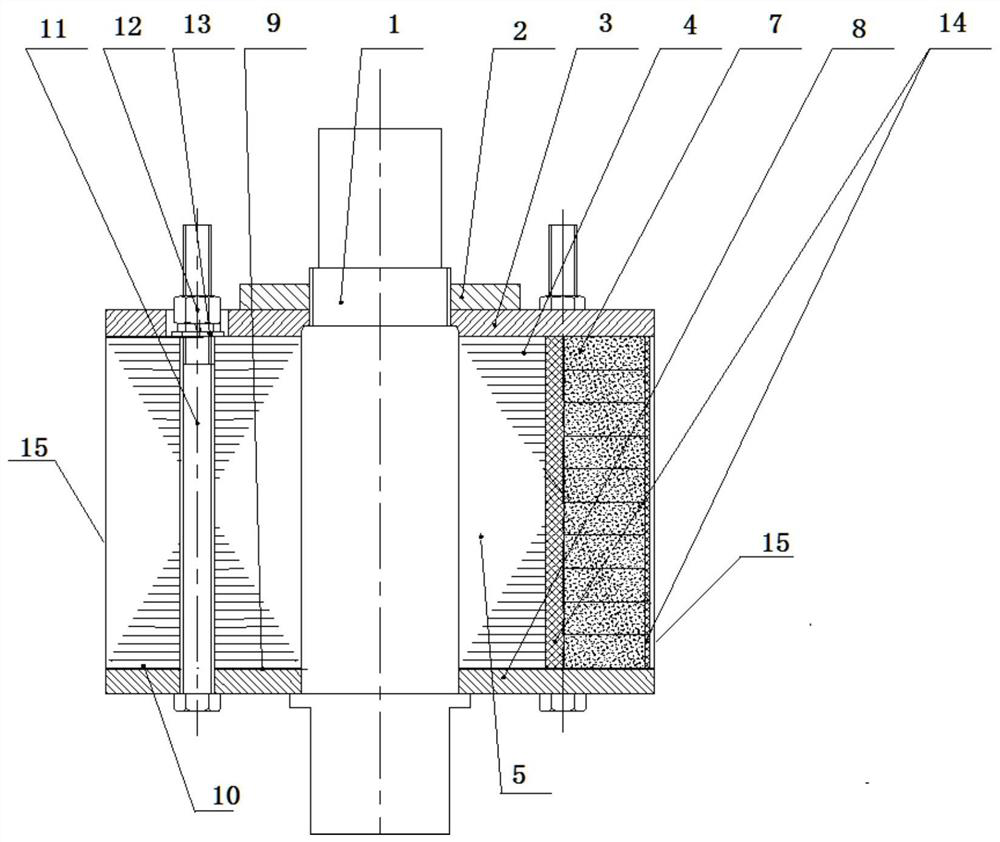

The invention discloses a method for manufacturing a rotor of a permanent magnet motor, comprising: coating a first high-temperature-resistant silicone grease layer on the first surface of a polyimide film, and pasting the second surface of the polyimide film on the first surface of the polyimide film. The surface of a pressing plate forms the first component, or directly coats the surface of the first pressing plate with Teflon coating to form the first component; the first component and the rotor stamping are sequentially placed on the shaft, and then the first component and the rotor stamping Compress the rotor punches to form a rotor core, and then lock the rotor core and the first component; assemble the permanent magnet in the rotor core to obtain a semi-finished product, and then fill the gap between the permanent magnet and the rotor punch with glue. The sealant is cured to obtain a workpiece; a second pressing plate is installed on the obtained workpiece, and the workpiece and the second pressing plate are locked to obtain a permanent magnet motor rotor. The method has a simple technological process, is easy to realize, and has low cost, and can effectively prevent the loss of potting glue while ensuring high reliability of the rotor.

Description

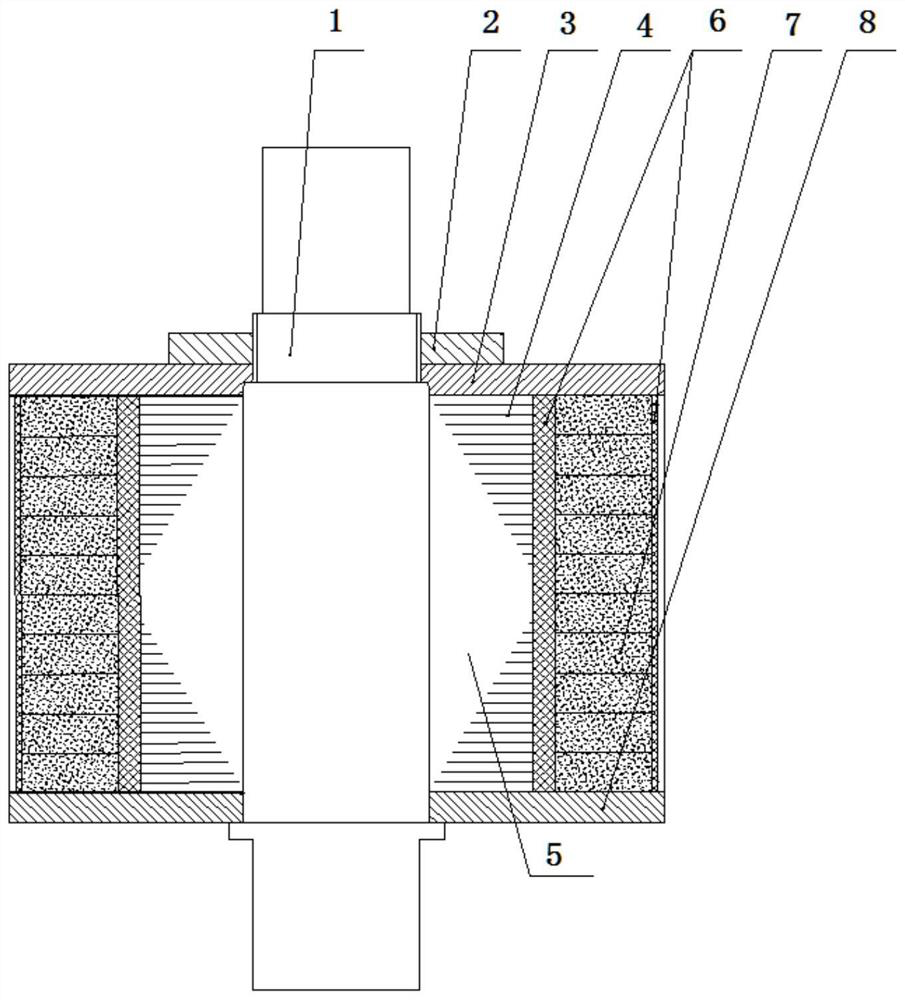

A kind of manufacturing method of permanent magnet motor rotor technical field [0001] The present invention relates to the field of motor rotors, in particular to a method for manufacturing a permanent magnet motor rotor. Background technique Existing rail transit permanent magnet motor rotor is usually composed of rotor core 5, permanent magnet 7, The front pressure plate 3 , the rear pressure plate 8 , the round nut 2 , and the rotor slot wedge constitute 6 , as shown in FIG. 1 . [0003] Theoretically, the smaller the gap between the rotor permanent magnet and the rotor core and the rotor slot wedge, the better its tightening effect, but In fact, due to the dimensional tolerance of the permanent magnet itself, and the permanent magnet assembly must have a certain process gap to To ensure its installation efficiency, the gap between the permanent magnet of the permanent magnet rotor and the iron core and slot wedge cannot be avoided. The gap between the magnet and ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): H02K15/03

CPCH02K15/03H02K2213/03

Inventor 谭林王新剑黄谷香雷军黄德聪尹琨罗祥程包华羽殷茜

Owner 襄阳中车电机技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com