An improved design method for error-prone riveting of server sheet metal parts

A technology of sheet metal parts and design methods, which is applied in the field of sheet metal riveting processing, can solve problems such as easy riveting of hardware parts, low cost, and wrong riveting of hardware parts, and achieve the goal of improving product yield and good intangible benefits Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

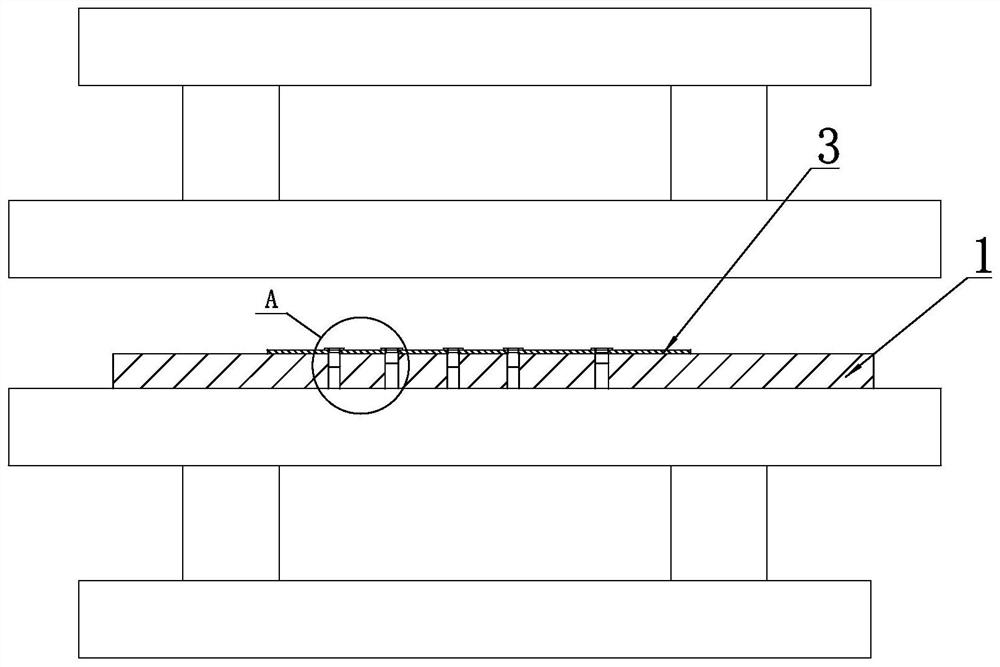

[0036] Through the analysis of the technical problems in the background technology, it can be known, such as Figure 5 As shown, the wrong riveting situation is mainly caused by misplacement of the small hardware 4 into the hole of the large hardware, because the large hardware 4 cannot be put into the small hole.

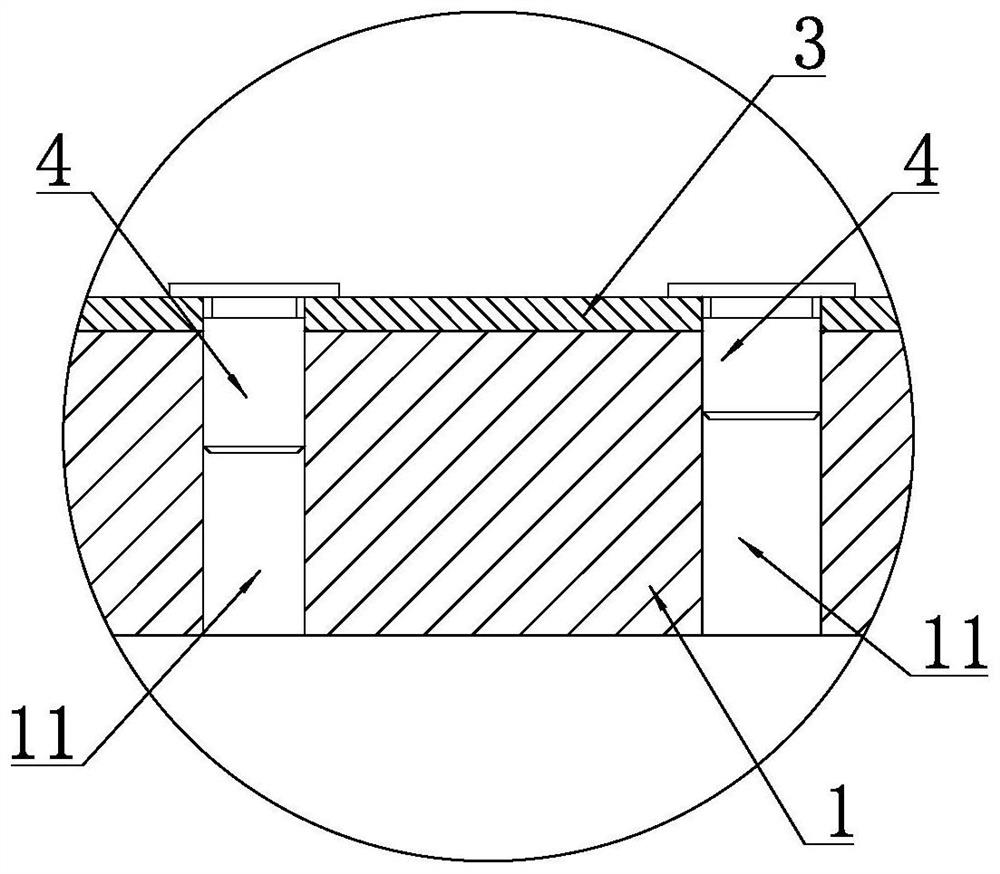

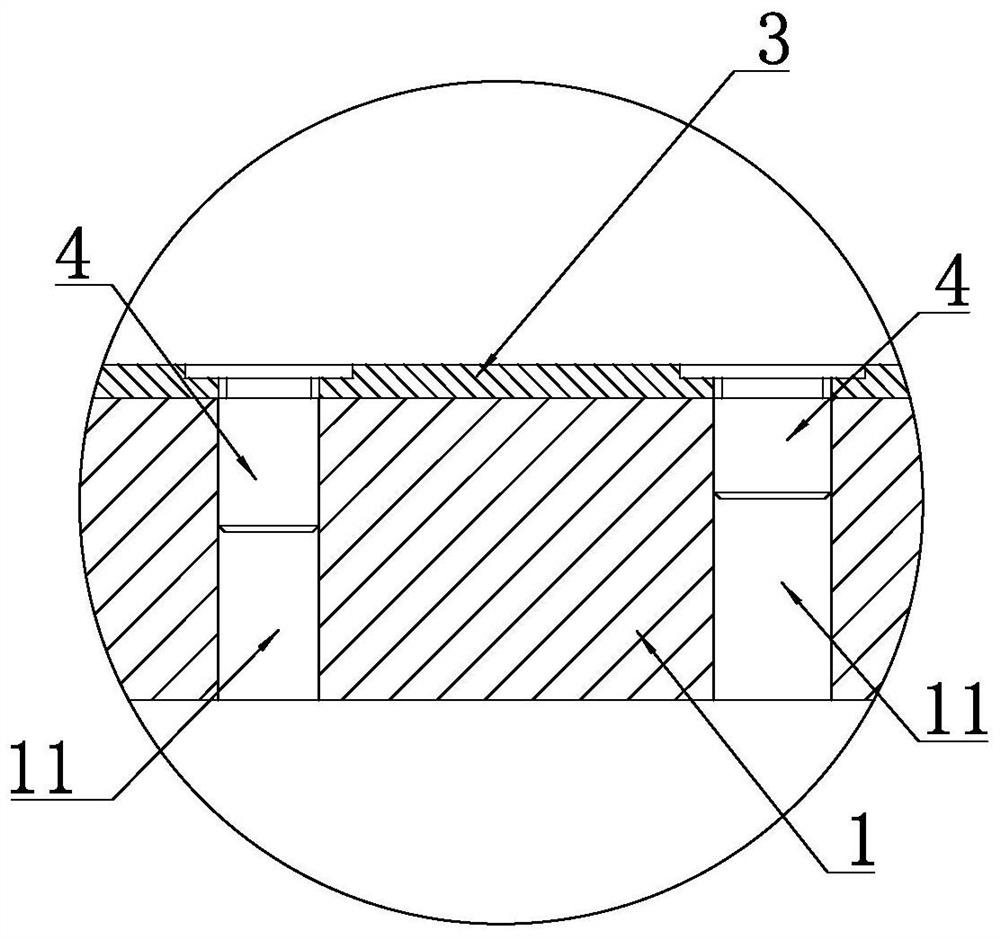

[0037] For this, as Figure 6 and Figure 7 As shown, the lower template 1 of the stamping equipment is provided with a height-limiting block 2 matching with the installation hardware 4 (that is, the type of the height-limiting block 2 corresponds to the type of the hardware 4 one by one), preferably, The height limiting block 2 is cylindrical, and the lower template 1 is provided with a cylindrical groove for accommodating the height limiting block 2, and when the height limiting block 2 is placed in the groove When inside, the upper end surface of the height limiting block 2 is flush with the upper side of the lower formwork 1 . An insertion hole 21 extending ...

Embodiment 2

[0047] Generally speaking, the function of the hardware 4 is the thread and height. The thread is related to the inner diameter of the hardware 4, and the outer diameter of the hardware 4 generally has little effect on the function of the product 3 and can be adjusted. Therefore, it can be adjusted according to the actual situation in the design. If it is necessary to adjust the outer diameter of the hardware, the outer diameter of the short hardware 4 is designed to be large.

[0048] Product 3 Structural optimization Although the outer diameter of hardware 4 can be realized in most cases, there are also special cases, such as when the outer diameter and height of hardware 4 have functions at the same time, the outer diameter cannot be adjusted casually.

[0049] According to the stamping experience of iron parts, the opening size of the lower die hole of the metal riveting die is determined by the root diameter of the hardware, and if the outer diameter of the hardware 4 in p...

Embodiment 3

[0054] The hardware 4 installed on the lower formwork 1 is named as the first type of hardware, the second type of hardware . . .

[0055] As a specific implementation, there are three types of hardware on the lower formwork 1 described in this embodiment, and they are the first type of hardware and the second type of hardware according to the order of the diameter of the end portion 42 from small to large. and the third category of hardware.

[0056] The lower template 1 is provided with through holes 11 corresponding to the first type of hardware and height limiting blocks 2 respectively corresponding to the second type of hardware and the third type of hardware.

[0057] All the other structures are the same as in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com