Lug plate machining clamp

A lug and fixture technology, applied in the direction of manufacturing tools, metal processing equipment, metal processing mechanical parts, etc., can solve the problems of large errors in the drilled holes, easy to move, affecting the use effect, etc., and achieves good limit effect and operation. Simple and convenient, good processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

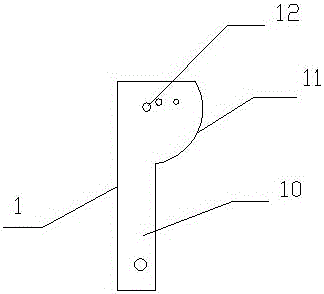

Embodiment 1

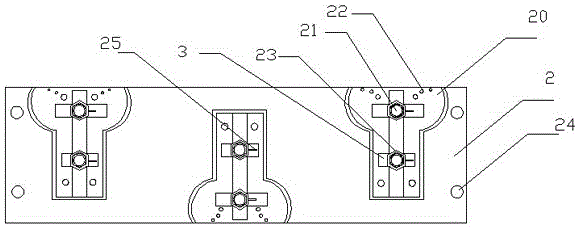

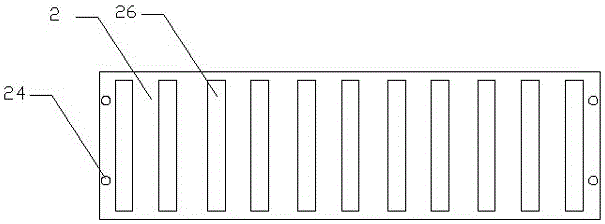

[0028] This embodiment includes a base plate 2 and a limiting plate 3. A groove 20 adapted to the shape of the ear plate 11 is arranged on the base plate 2. A plurality of blind holes 22 are also arranged in the groove 20. The blind holes 22 The size and position are the same as the size and position of the through hole on the lug plate 1. A limit post 21 is arranged on one side of the groove 20. The limit post 21 is perpendicular to the base plate. The limit post 21 is provided with threads, and the limit plate is set There is a hole, the diameter of which is larger than the diameter of the limiting post 21 , the limiting post 21 is equipped with a limiting nut 23 , and the limiting plate is limited on the limiting post 21 by the limiting nut 23 . Through the cooperation of the groove 20 and the limit plate, the ear plate 1 can be firmly limited on the base plate, and the ear plate 1 will not move when processing the through holes on the ear plate 1, and there will be no proce...

Embodiment 2

[0030] This embodiment includes a base plate 2 and a limiting plate 3. Two grooves 20 adapted to the shape of the ear plate 11 are arranged on the base plate 2, and a plurality of blind holes 22 are also arranged in the grooves 20. The blind holes 22 The size and position of the hole are the same as the size and position of the through hole on the ear plate 1. On one side of the groove 20, a limit column 21 is arranged. The limit column 21 is perpendicular to the base plate. The limit column 21 is provided with threads, and the limit plate A hole is provided, and the diameter of the hole is larger than the diameter of the limit post 21. The limit post 21 is equipped with a limit nut 23, and the limit plate is limited on the limit post 21 by the limit nut 23. Through the cooperation of the groove 20 and the limit plate, the ear plate 1 can be firmly limited on the base plate, and the ear plate 1 will not move when processing the through holes on the ear plate 1, and there will b...

Embodiment 3

[0033] This embodiment includes a base plate 2 and a limiting plate 3. Four grooves 20 adapted to the shape of the lug plate 11 are arranged on the base plate 2, and a plurality of blind holes 22 are also arranged in the grooves 20. The blind holes 22 The size and position of the hole are the same as the size and position of the through hole on the ear plate 1. On one side of the groove 20, a limit column 21 is arranged. The limit column 21 is perpendicular to the base plate. The limit column 21 is provided with threads, and the limit plate A hole is provided, and the diameter of the hole is larger than the diameter of the limit post 21. The limit post 21 is equipped with a limit nut 23, and the limit plate is limited on the limit post 21 by the limit nut 23. Through the cooperation of the groove 20 and the limit plate, the ear plate 1 can be firmly limited on the base plate, and the ear plate 1 will not move when processing the through holes on the ear plate 1, and there will ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com