Outer knife groove cutting machine of vibrissa trimmer

A trimmer and cutting machine technology, which is applied to metal processing machinery parts, manufacturing tools, driving devices, etc., can solve the problems of inconvenient equalization and low processing efficiency, and achieve the effect of good processing quality and high production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

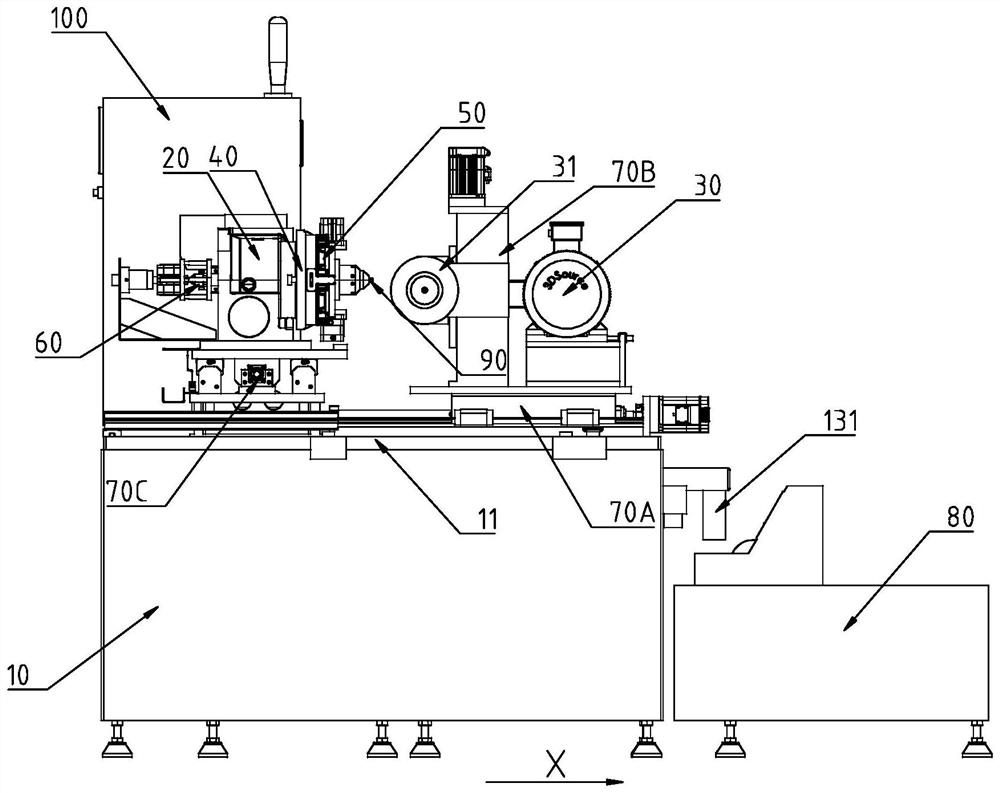

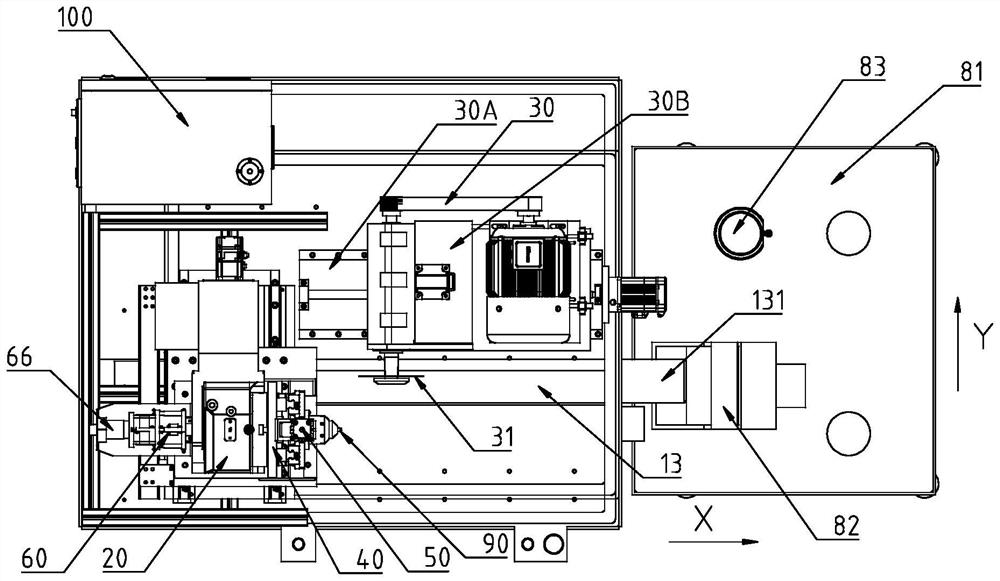

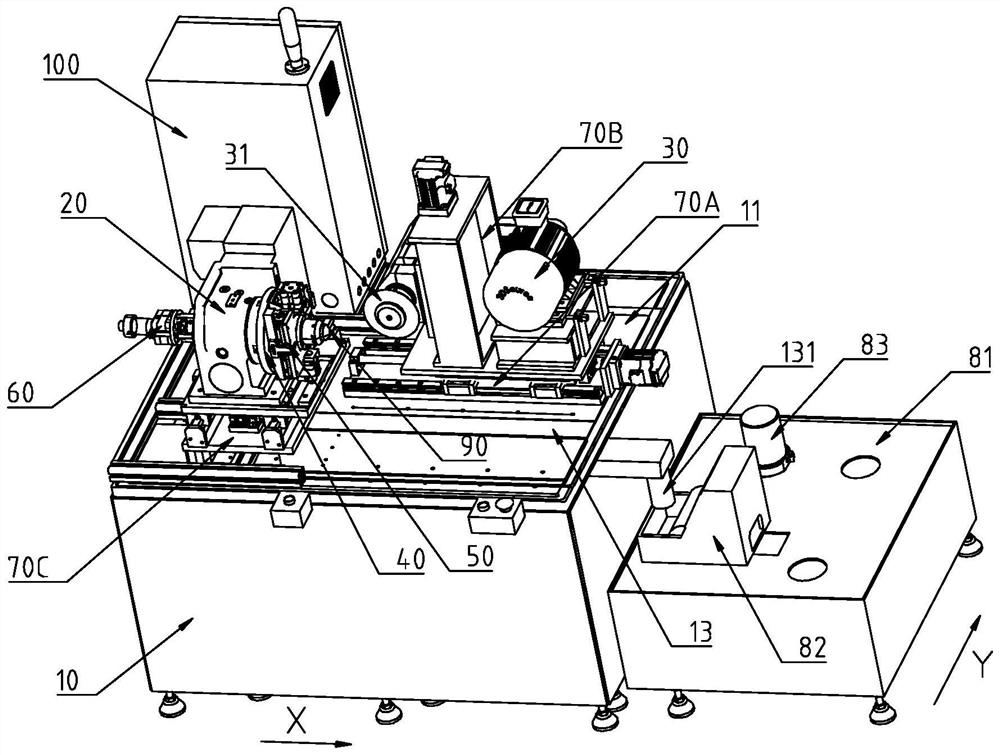

[0037] The structure of the outer knife groove cutter of the hair trimmer in the embodiment of the present invention is as follows: Figure 1 to Figure 19As shown, it includes a stand 10 as a frame, a numerically controlled dividing head 20, a pneumatic clamp, a disc milling cutter 31, a tool rotating mechanism 30, a feed mechanism, a cooling water circulation mechanism 80 and a control circuit. The control circuit includes an electric control box 100, a controller is housed in the electric control box 100, and a platen 11 is arranged on the top of the stand 10.

[0038] The feed mechanism includes an X-direction feed mechanism, a Y-direction feed mechanism and a Z-direction feed mechanism. The structures of the three feeding mechanisms are similar, and each includes a linear motion module 70 .

[0039] Now take the second linear motion module 70B of the Z-direction feeding mechanism as an example to illustrate the structures of the three linear motion modules 70 .

[0040] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com