Special clamp for milling head of numerically controlled machine tool

A special fixture and CNC machine tool technology, which is applied in milling cutters, manufacturing tools, milling machine equipment, etc., can solve the problems of inaccurate processing, reduce the clamping force of fixtures, and easy sliding of milling cutters, so as to achieve high quality of processed workpieces and ensure accuracy , Good processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

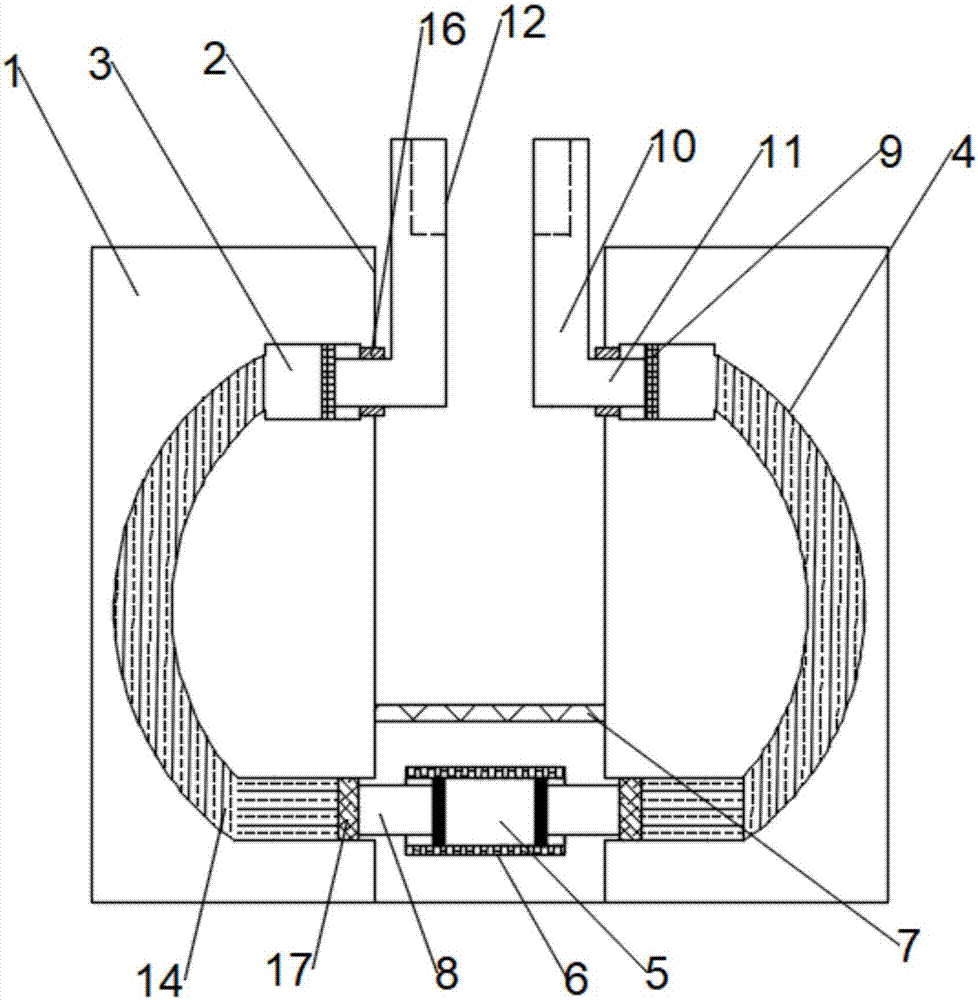

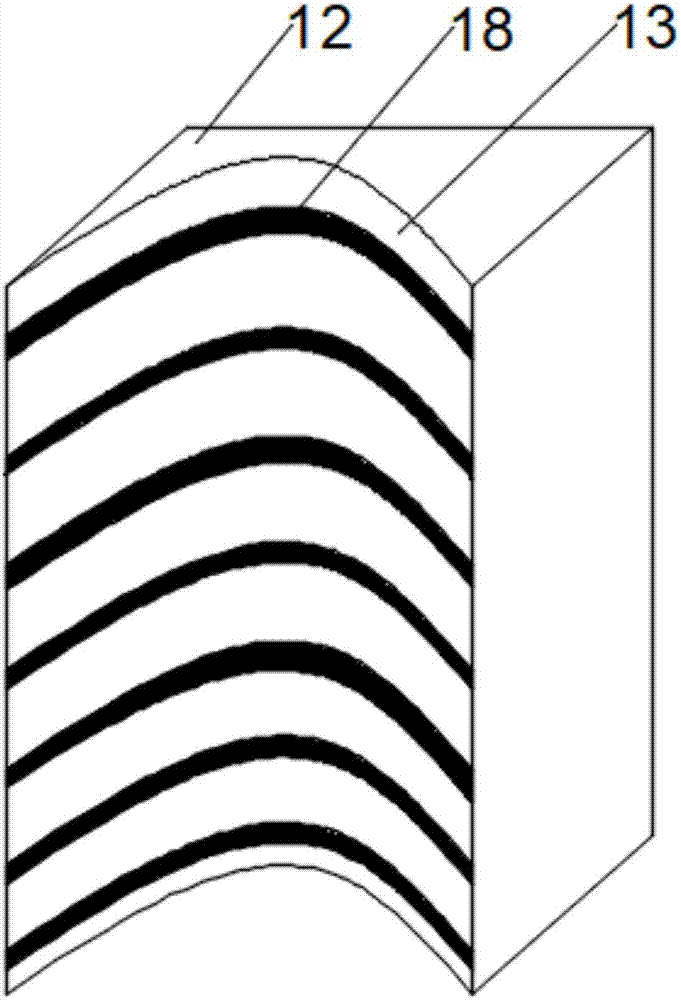

[0022] Such as figure 1 and figure 2 As shown, a special fixture for a milling head of a CNC machine tool includes a milling head 1. The milling head 1 is a cylindrical structure. The milling head 1 is dug with a cylindrical hole 2 along the axial direction. The top surface of the milling head 1 Connected to the control arm of the CNC machine tool, the control end can control the milling head 1 to rotate, rise or fall in the vertical three-dimensional space around the axis, so as to process different parts and part shapes. There are two square holes 3 and two oil holes 4 between the walls. Both the square holes 3 and the oil holes 4 communicate with the cylindrical hole 2. The square holes 3 and the oil holes 4 do not pass through the cylindrical outer wall of the milling head, ensuring that the square holes 3 and the tightness of the inner space of the oil hole, the bottom of the cylindrical hole 2 is fixedly installed with a hydraulic cylinder 5, and the hydraulic cylinder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com