Worm wheel polishing machine and polishing system

A polishing machine and worm gear technology, applied in surface polishing machine tools, grinding/polishing equipment, grinding racks, etc., can solve the problems of manual loading and unloading, low efficiency, etc., and achieve the effect of improving work efficiency and good processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] In order to make the technical means, creative features, goals and functions achieved by the present invention clearer and easier to understand, the present invention will be further elaborated below in conjunction with the accompanying drawings and specific embodiments:

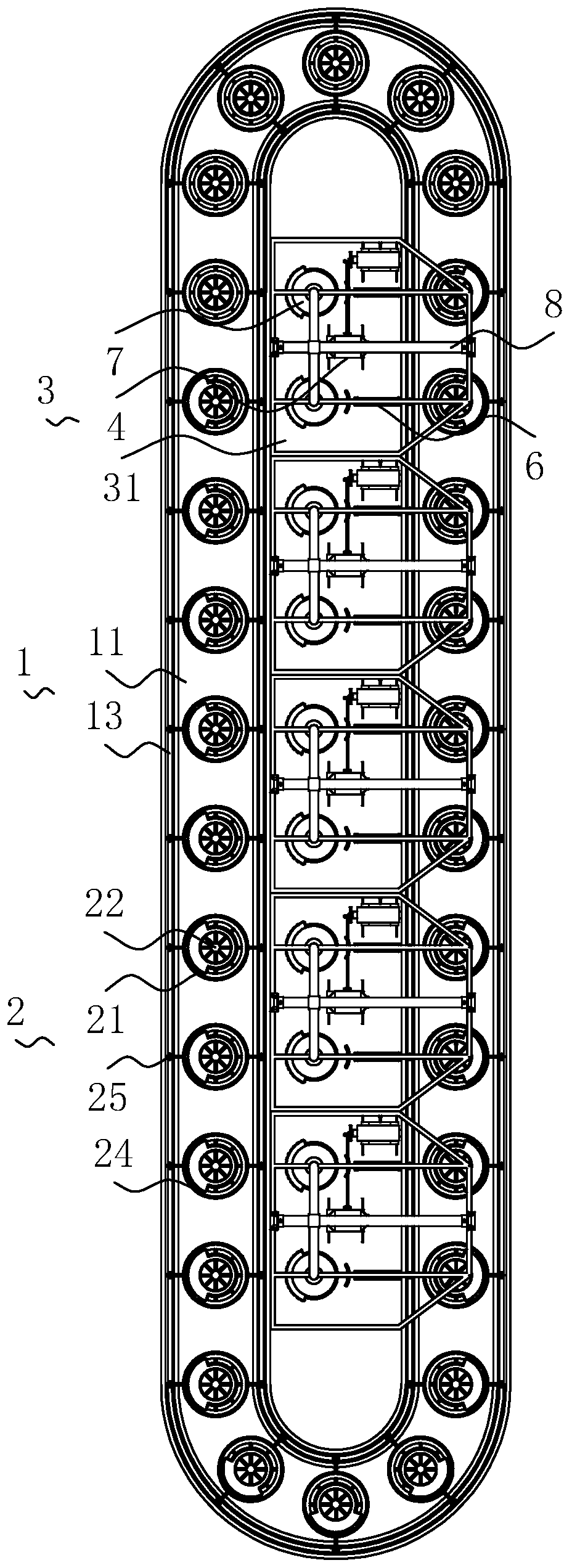

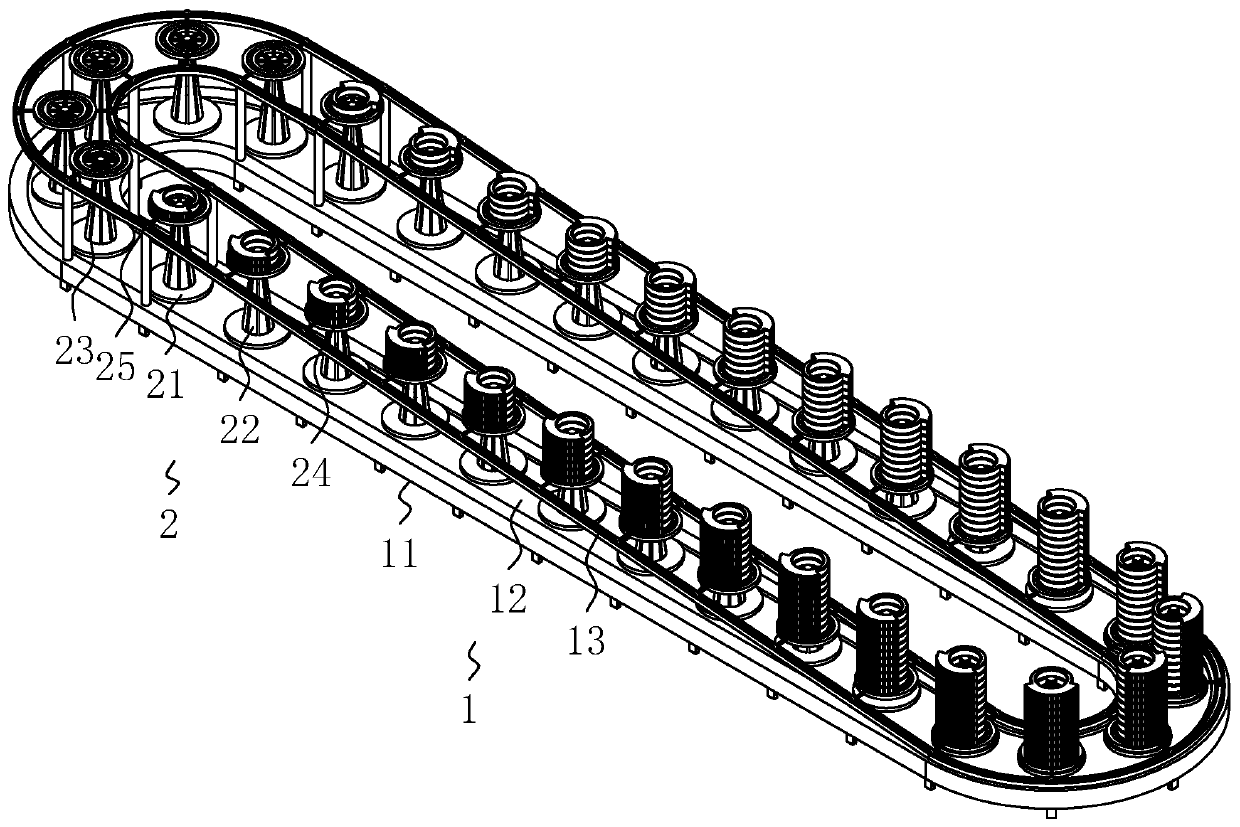

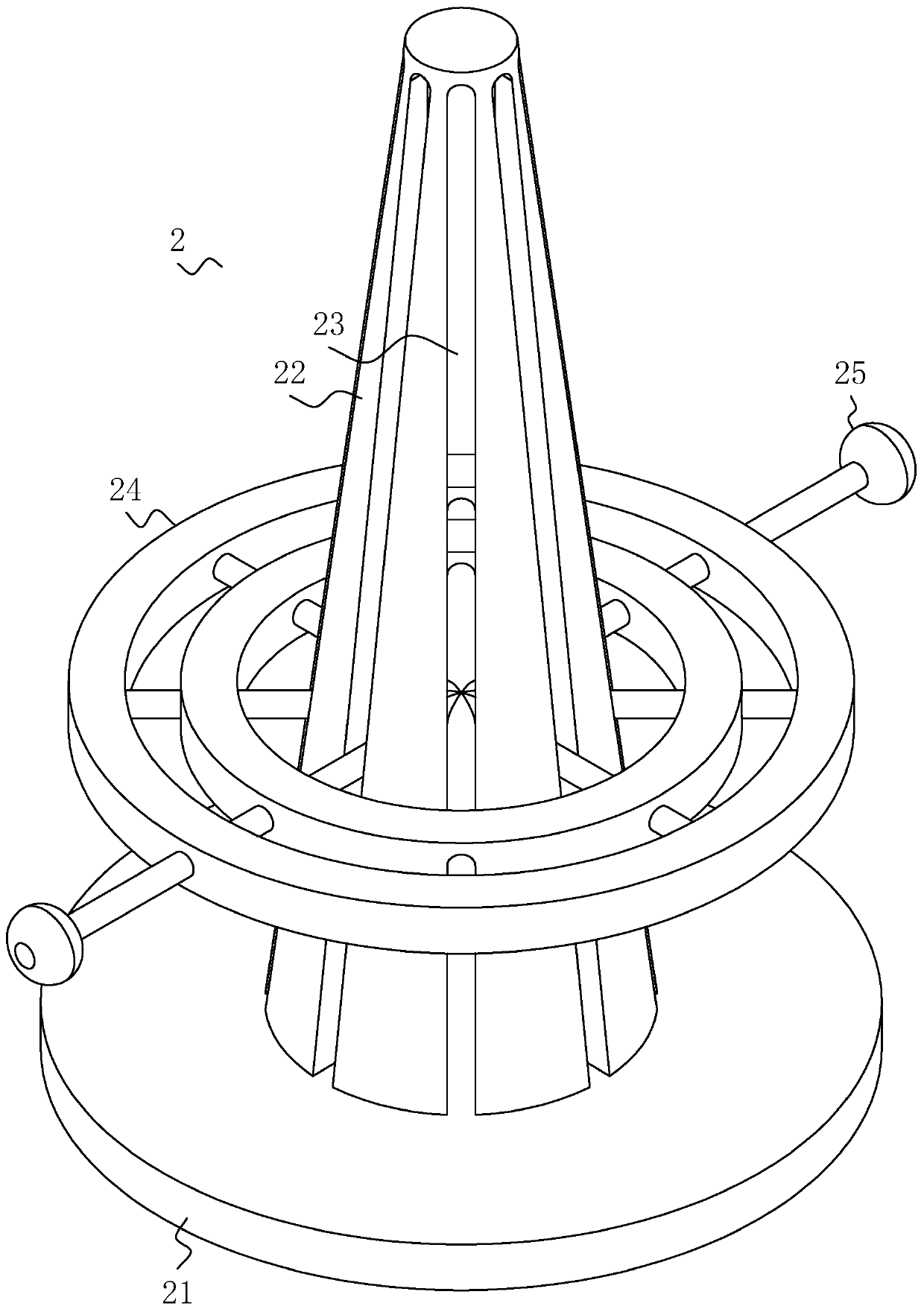

[0045] refer to figure 1 , is a kind of polishing system disclosed by the present invention, including five worm wheel polishers 3 arranged in an inline shape, circulation conveyors 1 around these worm wheel polishers 3, and conveying conveyors evenly distributed on the circulation conveyors 1 Rack 2 on the path and used for stacking workpieces. Wherein, the uppermost workpiece on the material rack 2 passes through the feed points of these worm wheel polishers 3 successively, and then passes through the discharge points of these worm wheel polishers 3 successively, and the worm wheel polisher 3 is used to grab the workpiece at the corresponding feed point. After the workpiece is polished, it is trans...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com