Rotary pairing spot welding equipment

A spot welding equipment and rotary technology, which is applied in the direction of welding equipment, welding equipment, resistance welding equipment, etc., can solve the problems of high labor intensity, increased production cost, and low precision of the staff, and achieve good fastening effect and convenient operation , The effect of high installation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

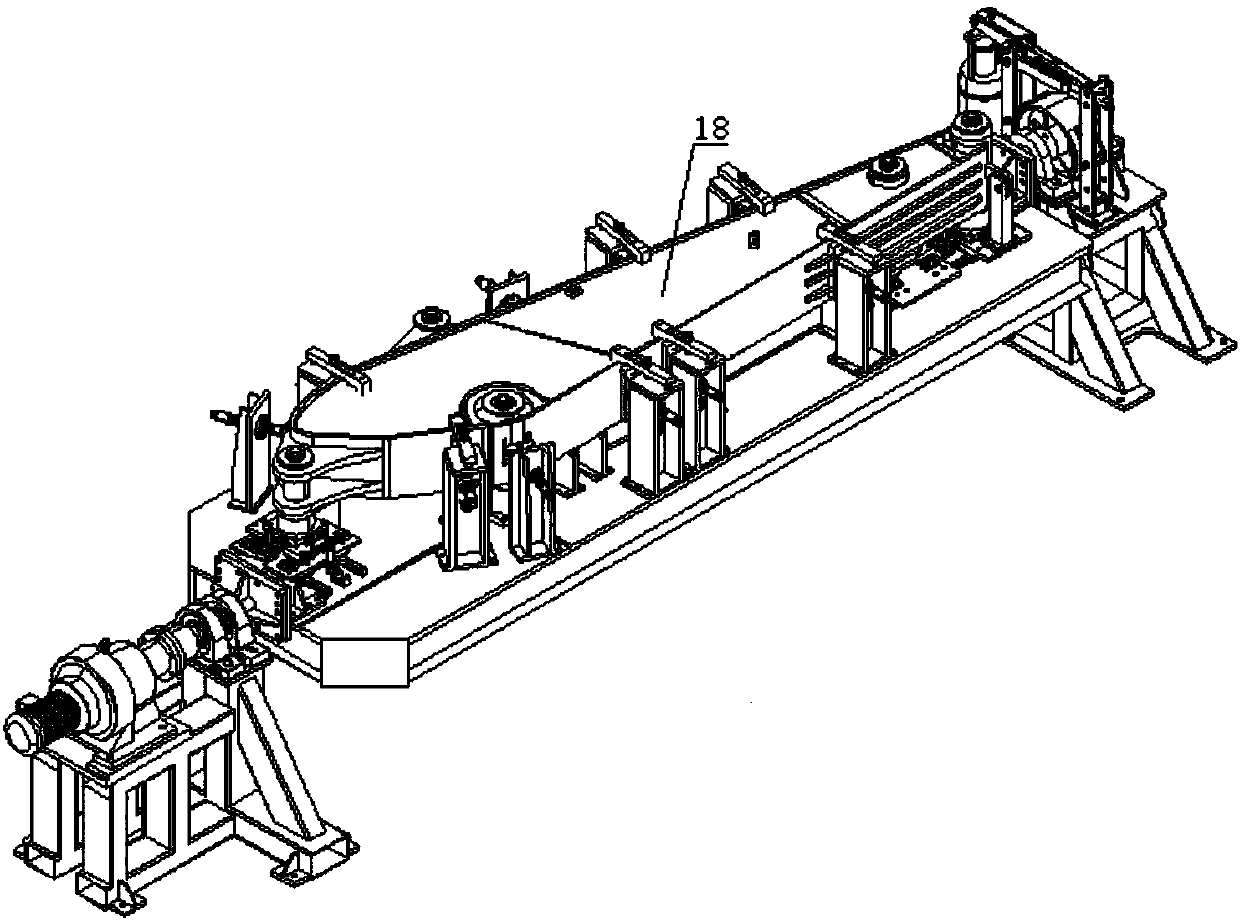

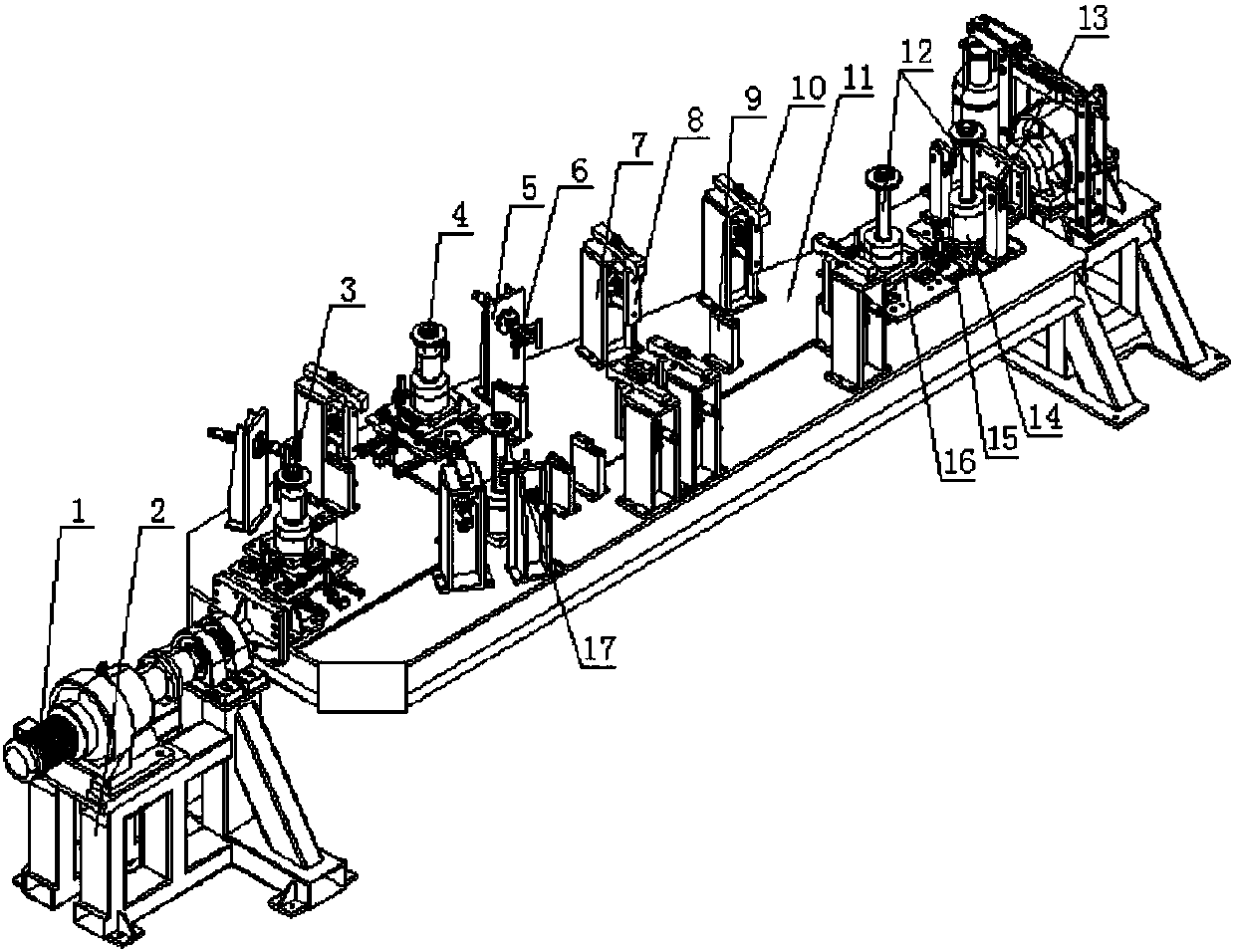

[0022] The embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings; it should be noted that the embodiments are illustrative, not restrictive, and cannot limit the protection scope of the present invention.

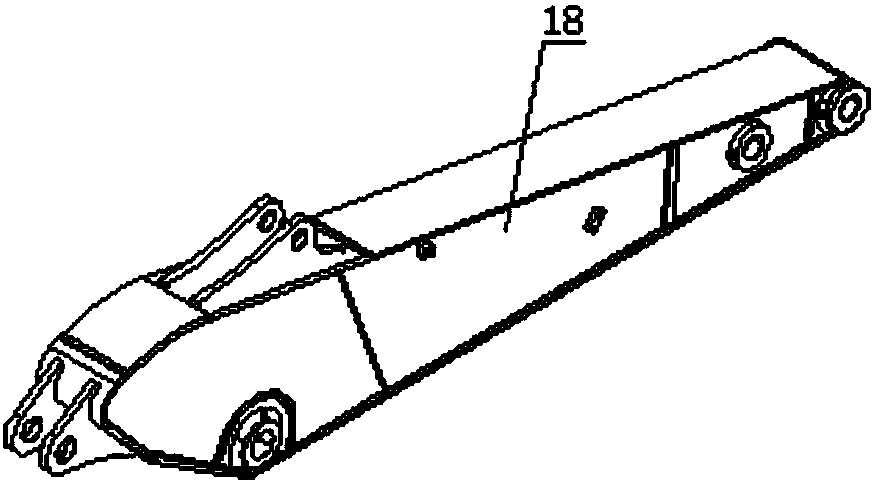

[0023] A rotary pair spot welding equipment, including a workbench 11, a driving device 1, a bottom plate pad 9, a head double-hole positioning shaft 12, a straight lug plate positioning shaft 4, a bent lug plate positioning shaft 3, and a sector piece positioning shaft 17 and the side top device, a mounting frame 2 is arranged on the left and right sides of the workbench, and a driving device is installed on one of the mounting frames. The driving device can be driven by hydraulic pressure or electric motor. On one side of the workbench, another installation frame is connected to the workbench through a rotating shaft and a bearing structure. The base plate spacer, the head double-hole positioning shaft, the st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com