Processing production system for elevator composite counterweight filler

A production system and counterweight technology, applied in the direction of manufacturing tools, supply devices, auxiliary molding equipment, etc., can solve the problems of easy accumulation, unevenness, and inability to accurately control the amount of feeding, etc., to achieve good processing quality, Diversified functions and good processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

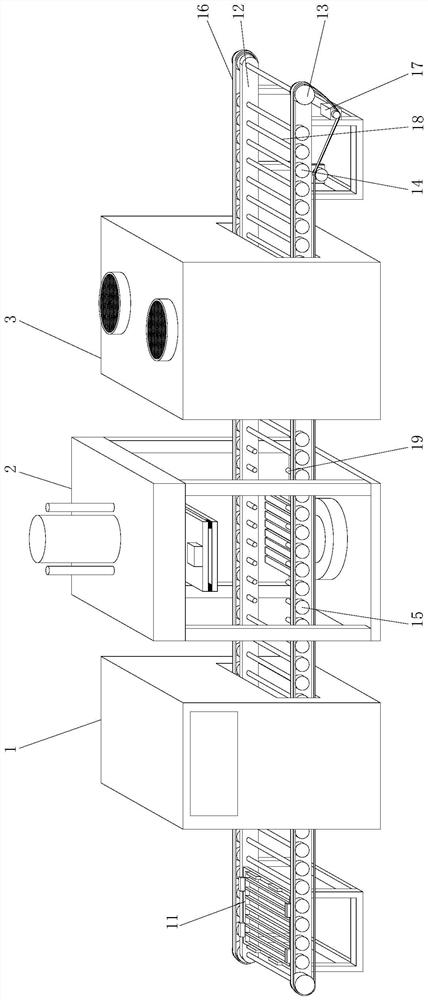

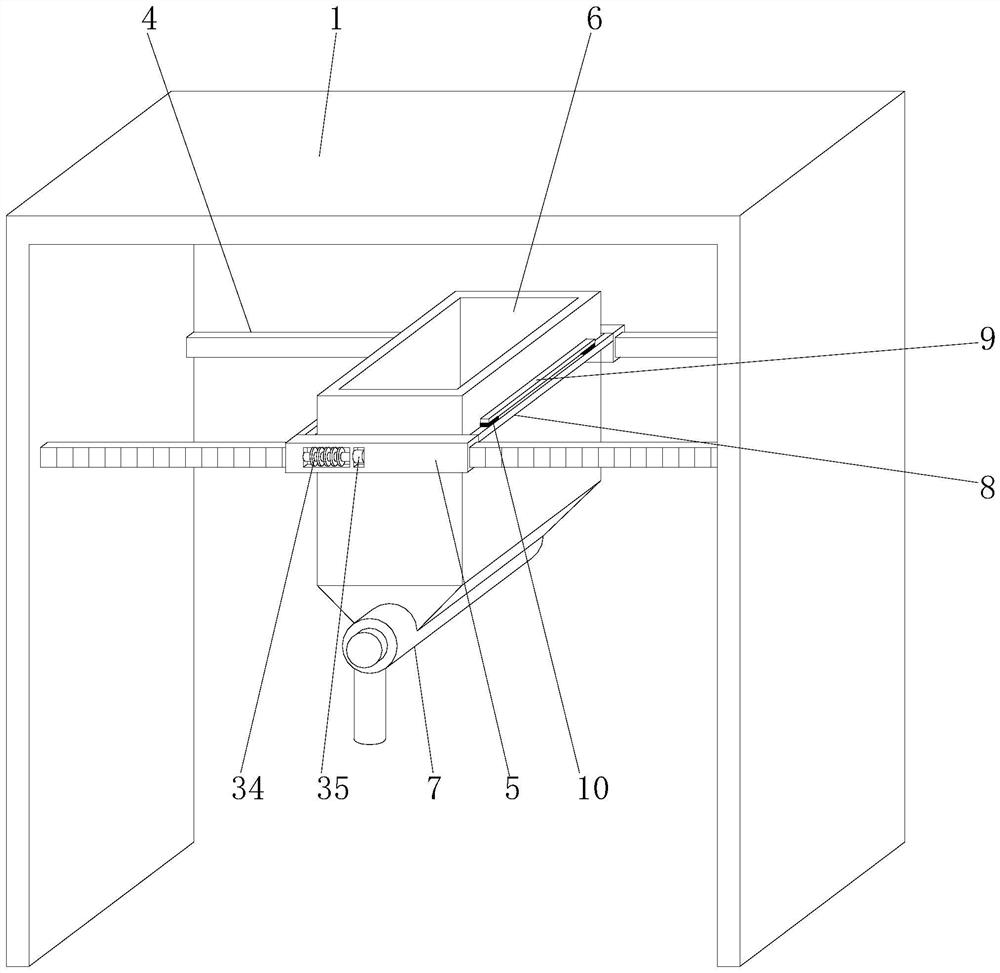

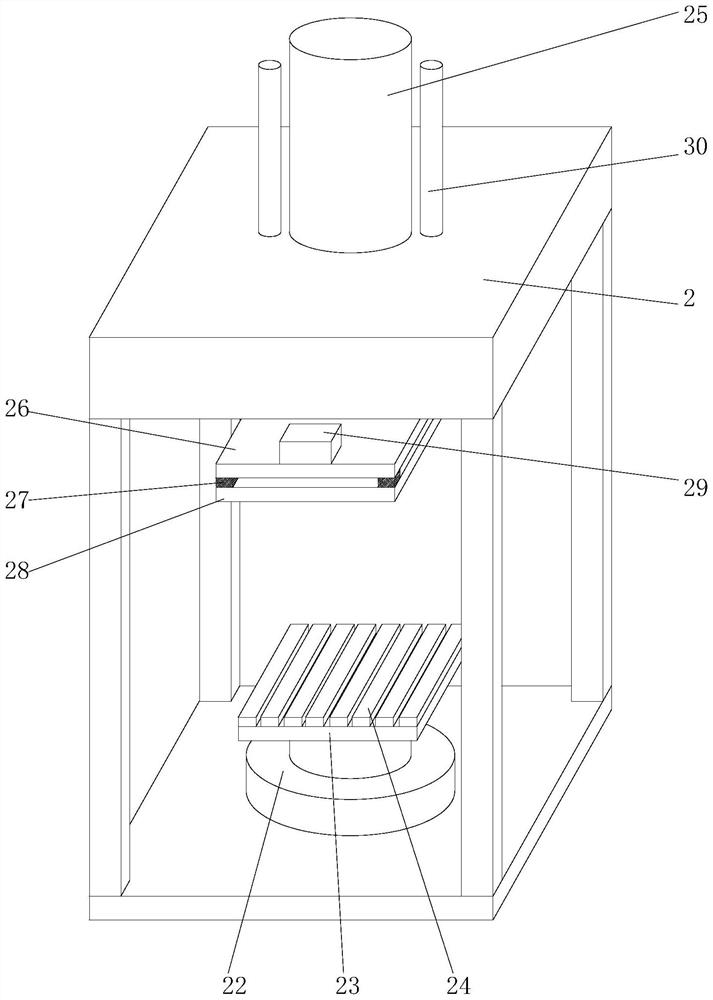

[0029] according to figure 1 , 2 , 3, 4, and 5, the present embodiment proposes a processing and production system for elevator composite counterweights, including a transfer unit, a filling bin 1, a compacting frame 2 and a drying bin 3, and the transfer unit passes through the filling The feed bin 1, the compacting frame 2 and the drying bin 3, and the inside of the filling bin 1, the compacting frame 2 and the drying bin 3 are respectively equipped with a filling assembly, a compacting assembly and a drying assembly, and the filling The assembly includes a guide rail 4, a sliding sleeve 5 and an aggregate hopper 6. The guide rail 4 is arranged in two groups, and the guide rails 4 of the two groups are respectively arranged at the two ends above the inside of the filling bin 1, and the guide rails 4 of the two groups are Sliding sleeves 5 are movably installed, and the aggregate hopper 6 is arranged between the two sets of sliding sleeves 5, and a discharge pipe 7 is connec...

Embodiment 2

[0036] according to figure 1 , 2 , 5, and 6, the present embodiment proposes a processing and production system for elevator composite counterweights, including a transfer unit, a filling bin 1, a compacting frame 2 and a drying bin 3, and the transfer unit passes through the filling bin 1. The compacting frame 2 and the drying bin 3, and the filling bin 1, the compacting frame 2 and the drying bin 3 are respectively equipped with a filling component, a compacting component and a drying component, and the filling component includes Guide rail 4, sliding sleeve 5 and aggregate hopper 6, the guide rail 4 is arranged in two groups, and the guide rails 4 of the two groups are respectively arranged at the two ends above the inside of the filling bin 1, and the guide rails 4 of the two groups are all movable A sliding sleeve 5 is installed, the aggregate hopper 6 is arranged between two sets of the sliding sleeves 5, and a discharge pipe 7 is communicated under the aggregate hopper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com