Thin wall tyre case for cast-in-place concrete filling and method of manufacturing the same

A technology of concrete and production methods, which is applied in the direction of building structures, building components, molds, etc., can solve the problems of large differences in physical and chemical properties, reducing the sound insulation effect of thin-walled carcass for filling, and the inability of the wall surface to blend with the surrounding side walls. Integral and other problems, to achieve the effect of not easy to fall off and to achieve tight combination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

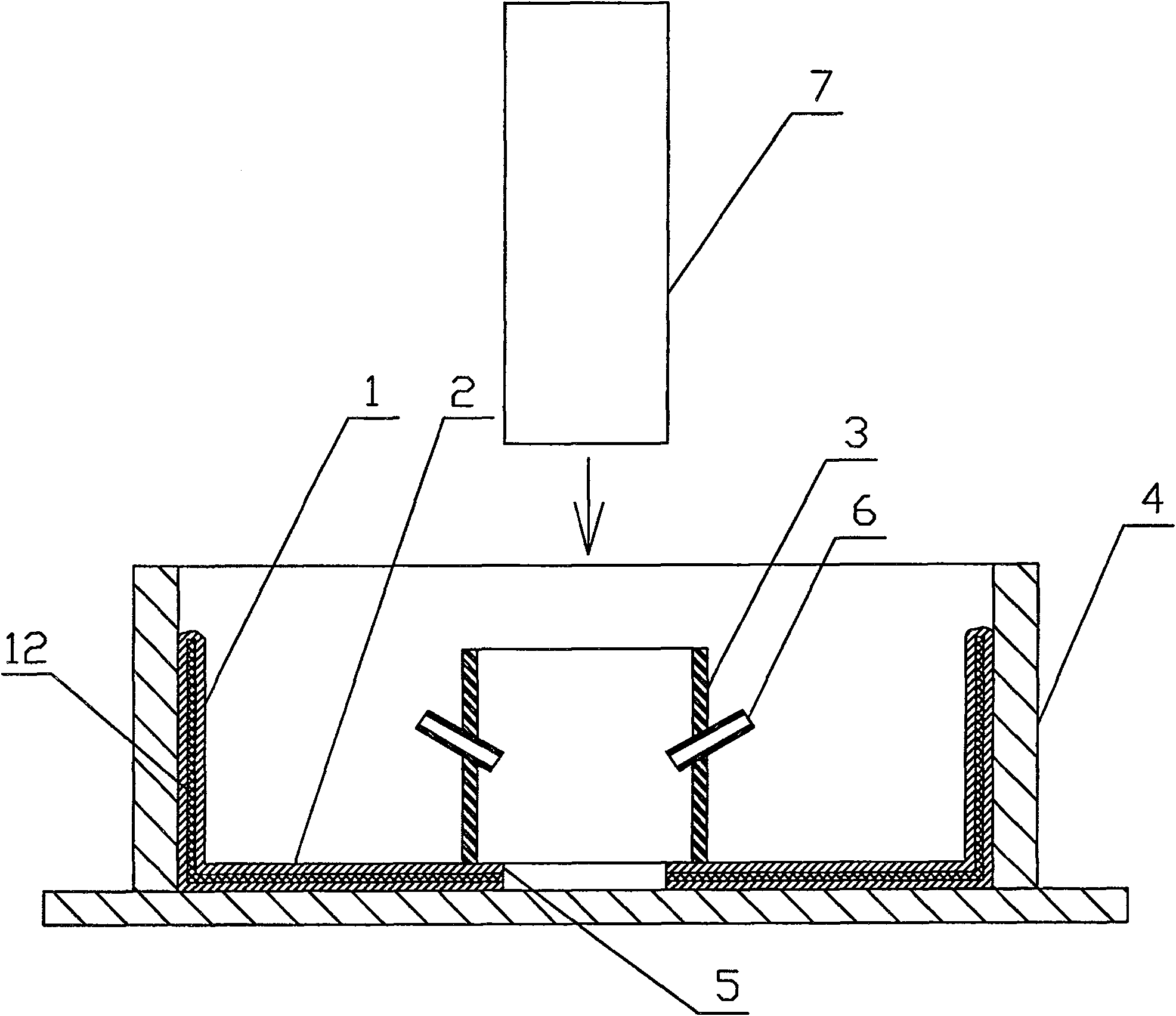

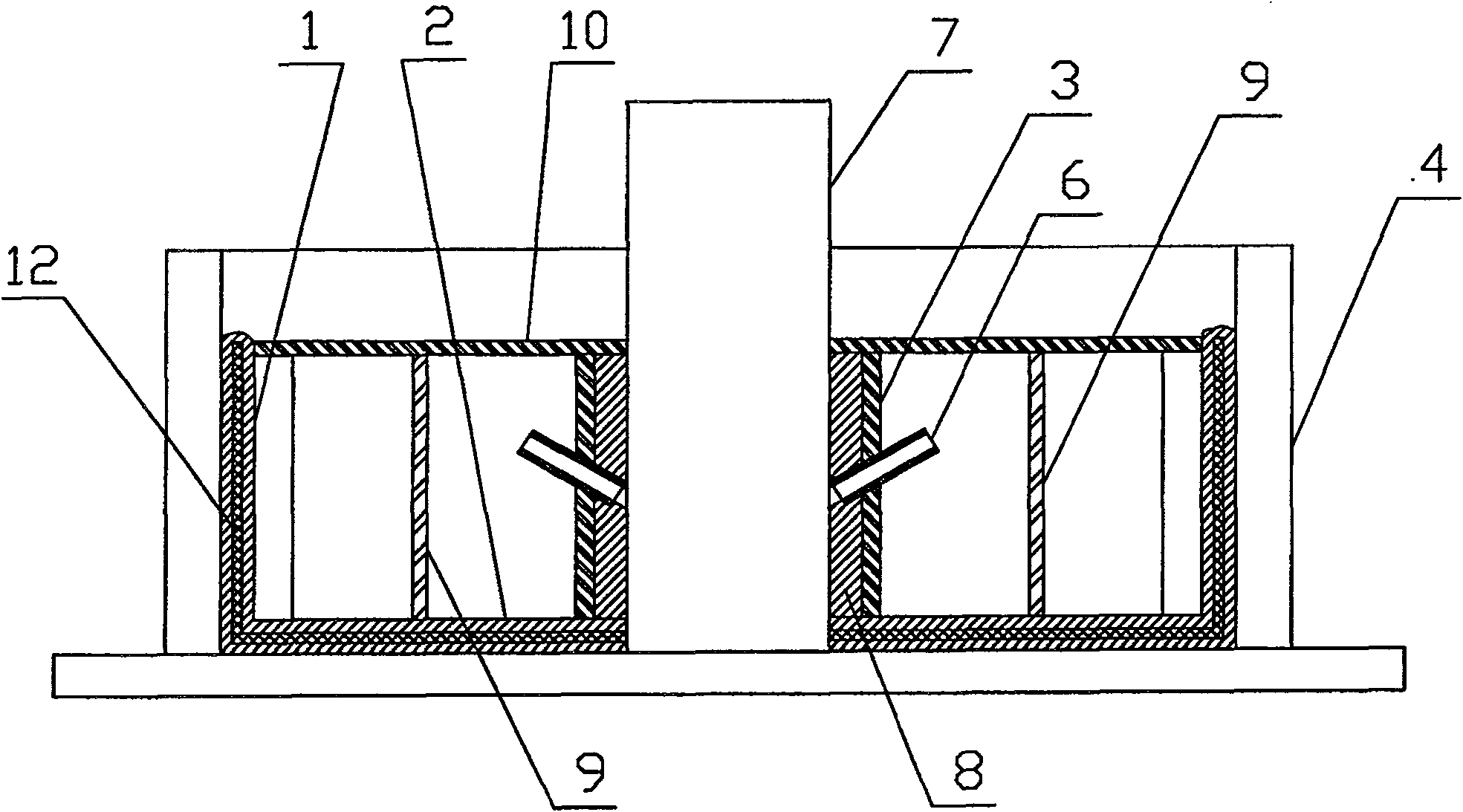

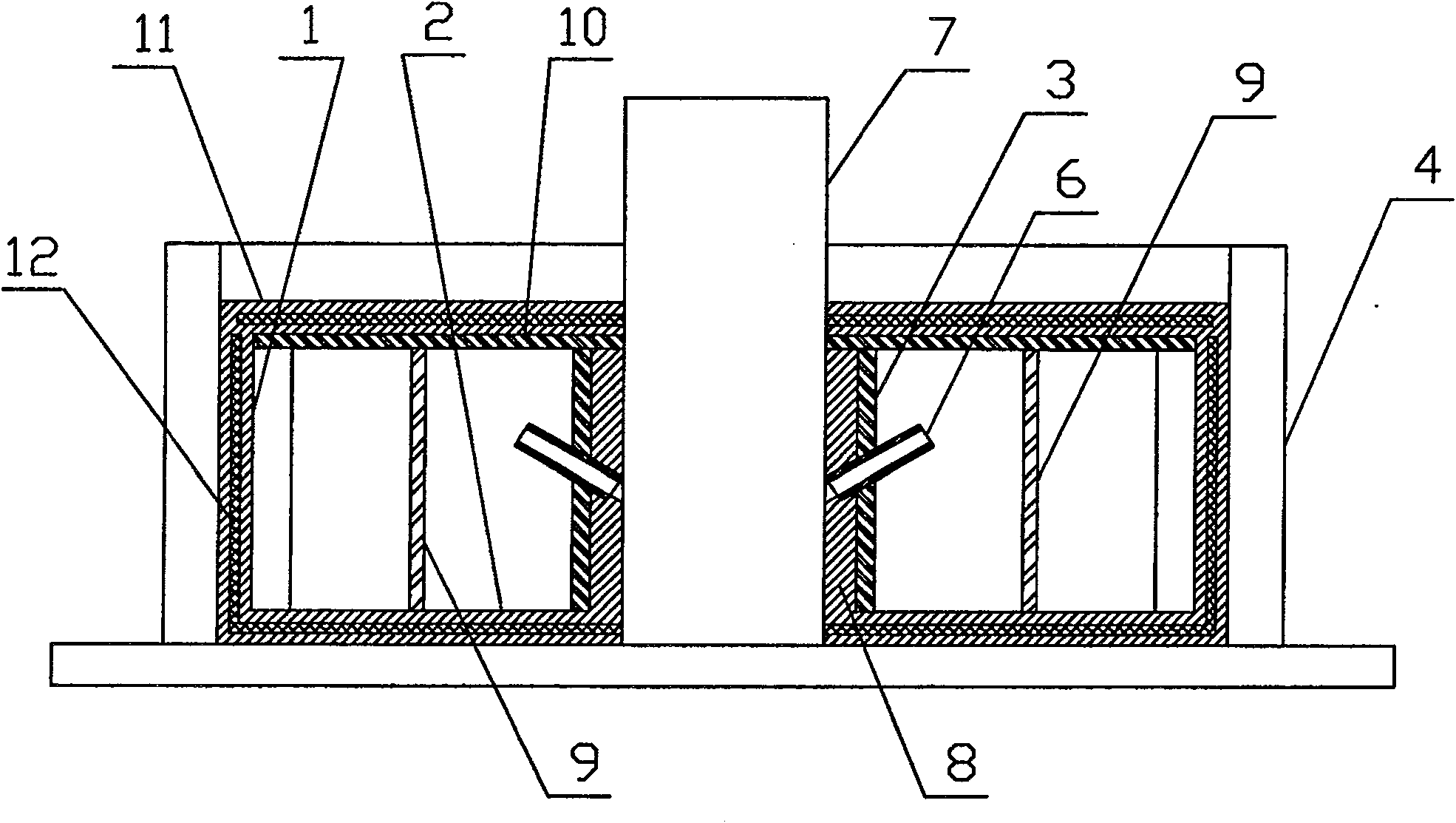

[0023] The structure of the cast-in-place concrete filling thin-walled carcass of the present invention is as follows: Figure 4 As shown, there is a cavity in the carcass, and there is a pouring hole tube 8 in the cavity. The top plate 11, the bottom plate 2, and the side walls 1 around the carcass are integrally formed as a whole. The top plate 11, the bottom plate 2, and the side walls around the carcass In 1, glass fiber mesh 12 is added as a reinforcement layer, the top plate 11 and the bottom plate 2 are provided with through holes corresponding to the inner holes of the pouring hole tube 8, and the carcass bottom plate 2 is provided with a vertical through hole tube 3, the through hole The tube 3 is set on the pouring hole tube 8, and the pouring hole tube 8 is attached to the inner wall of the through hole tube 3, and the through hole tube 3 and the tube wall of the pouring hole tube 8 are inserted with oblique holes to connect the inside of the pouring hole tube 8 with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com