Thin-wall box for cast-in-situ concrete filling and its manufacturing method and die for manufacturing the same

A concrete and thin-walled box technology, which is applied in the field preparation of building components, formwork/formwork/work frame, construction, etc., can solve the problems of hollow boxes that are easy to be damaged, easy to fall off or fall, easy to be damaged, etc., to achieve The effect of firm structure, easy forming and not easy to damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

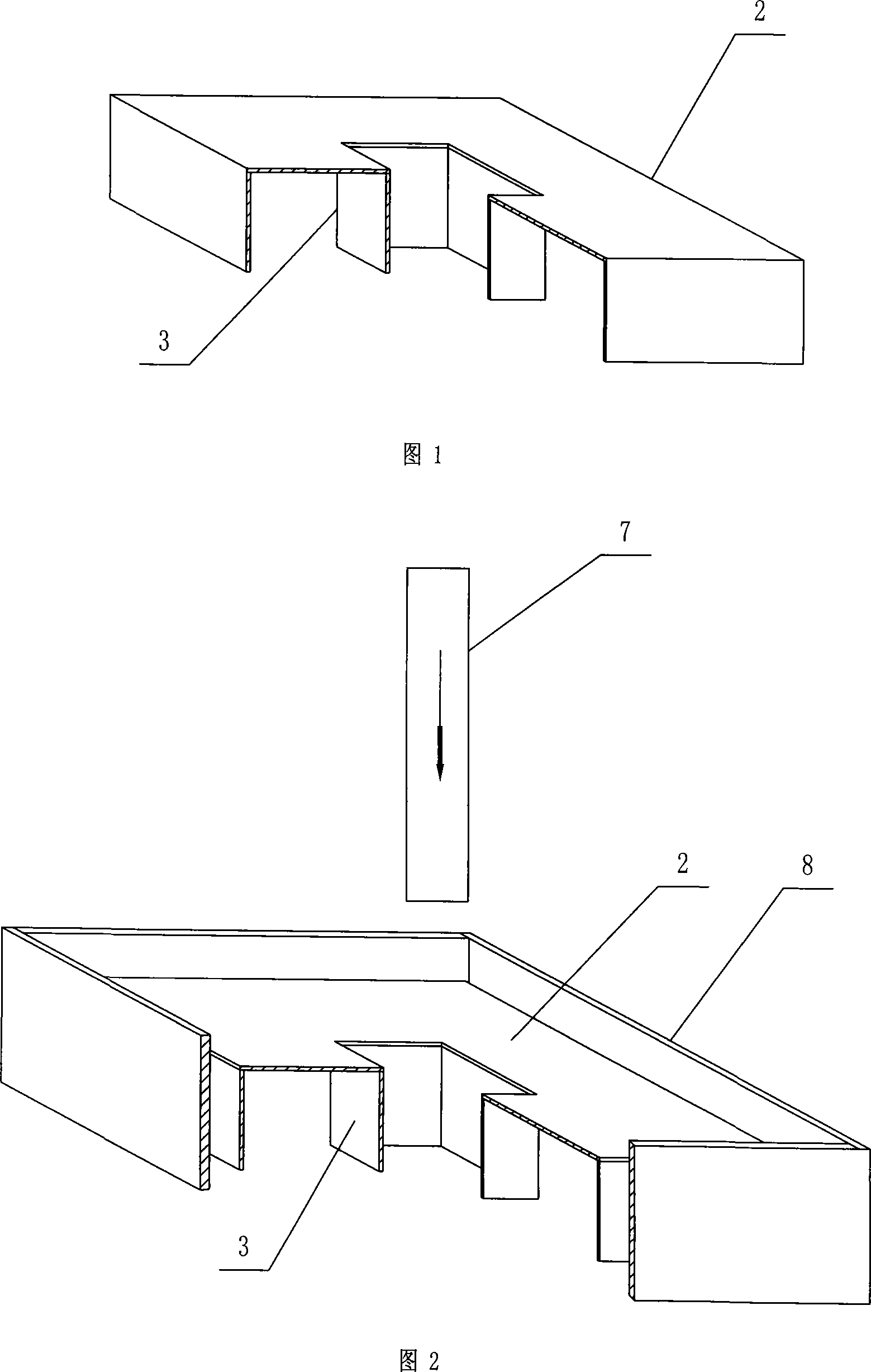

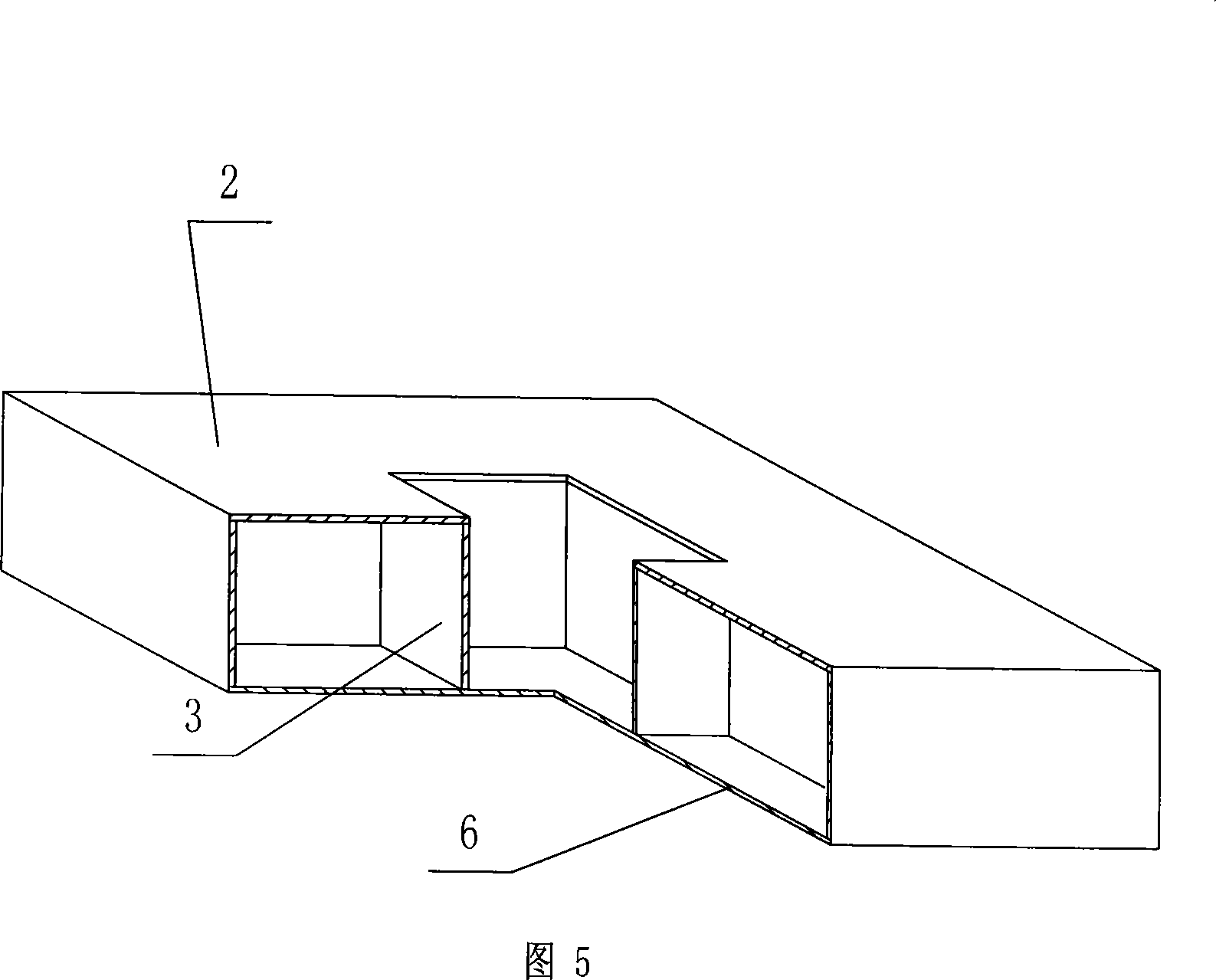

[0020] As shown in Figure 1, in embodiment 1 of the mold of the present invention, the mold body is a hollow five-sided skeleton inner mold 2 with an open bottom surface, and a through-hole pipe 3 is arranged in the inner cavity of the skeleton inner mold 2, and the through-hole pipe 3 The upper end is connected with the opening on the top surface of the skeleton inner mold 2, and the top surface of the skeleton inner mold 2 is the surface with the largest area.

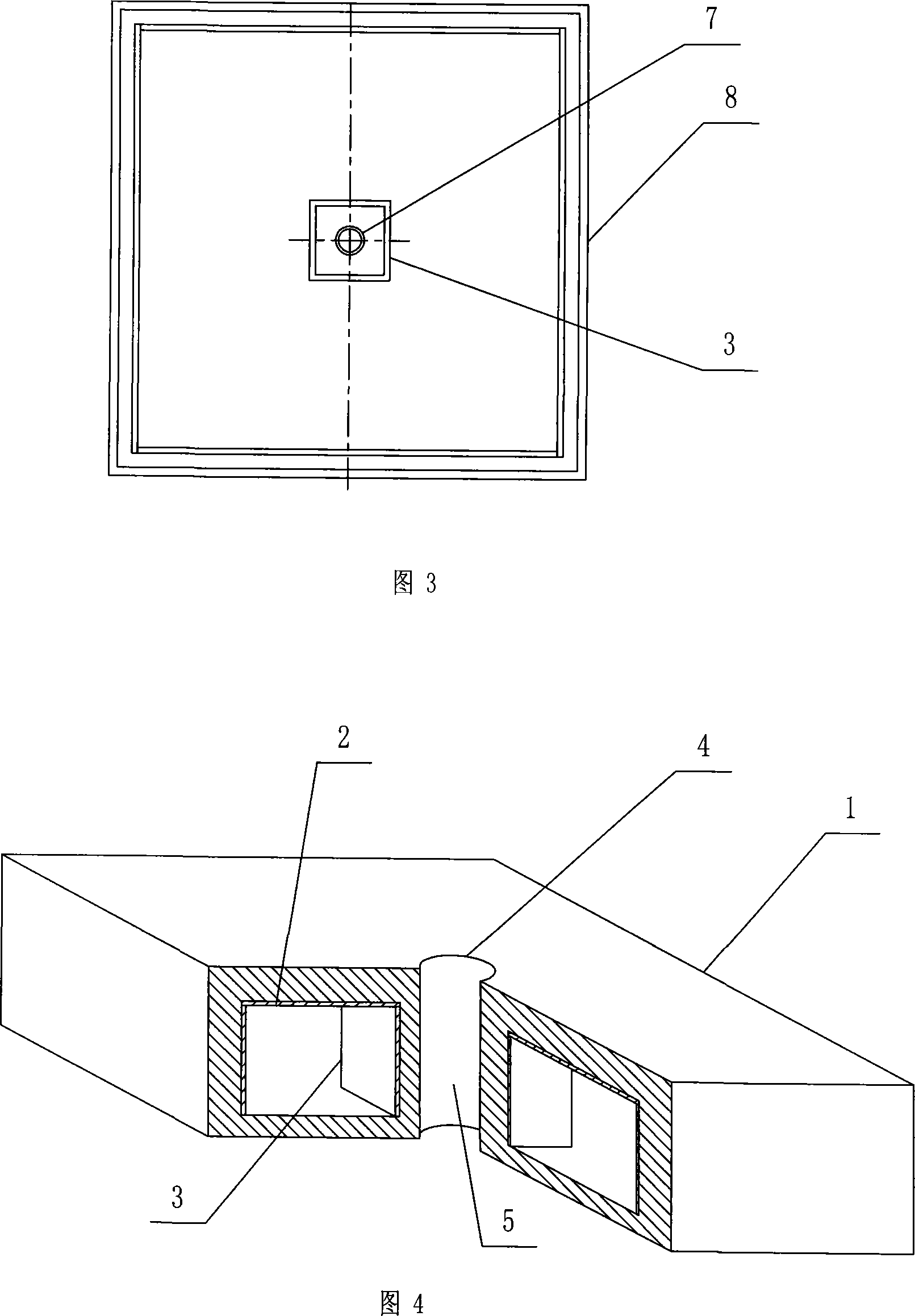

[0021] Use the embodiment 1 of mold of the present invention to make thin-walled box as shown in Fig. 2, Fig. 3, surround and be set up as hollow rectangular frame earlier with four wall panels 8, and a stem 7 is inserted and arranged in the frame, Then pour the bottom plate of the thin-walled box with concrete in the frame 8, place the five-sided hollow frame inner mold 2 on the bottom plate when the concrete is not dry, and place the core column in the center of the through-hole pipe 3 of the five-sided hollow skele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com