Cast-in-situ concrete filling thin-walled matrix and method for making same

A production method and concrete technology, which can be used in molds, ceramic forming cores, ceramic forming mandrels, etc., can solve problems such as great differences in physical and chemical properties, inability to achieve integrated integration, and inability to integrate wall surfaces and surrounding sidewalls into one. , to achieve the effect of saving construction time, reliable structure, and not easy to fall off and dump

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

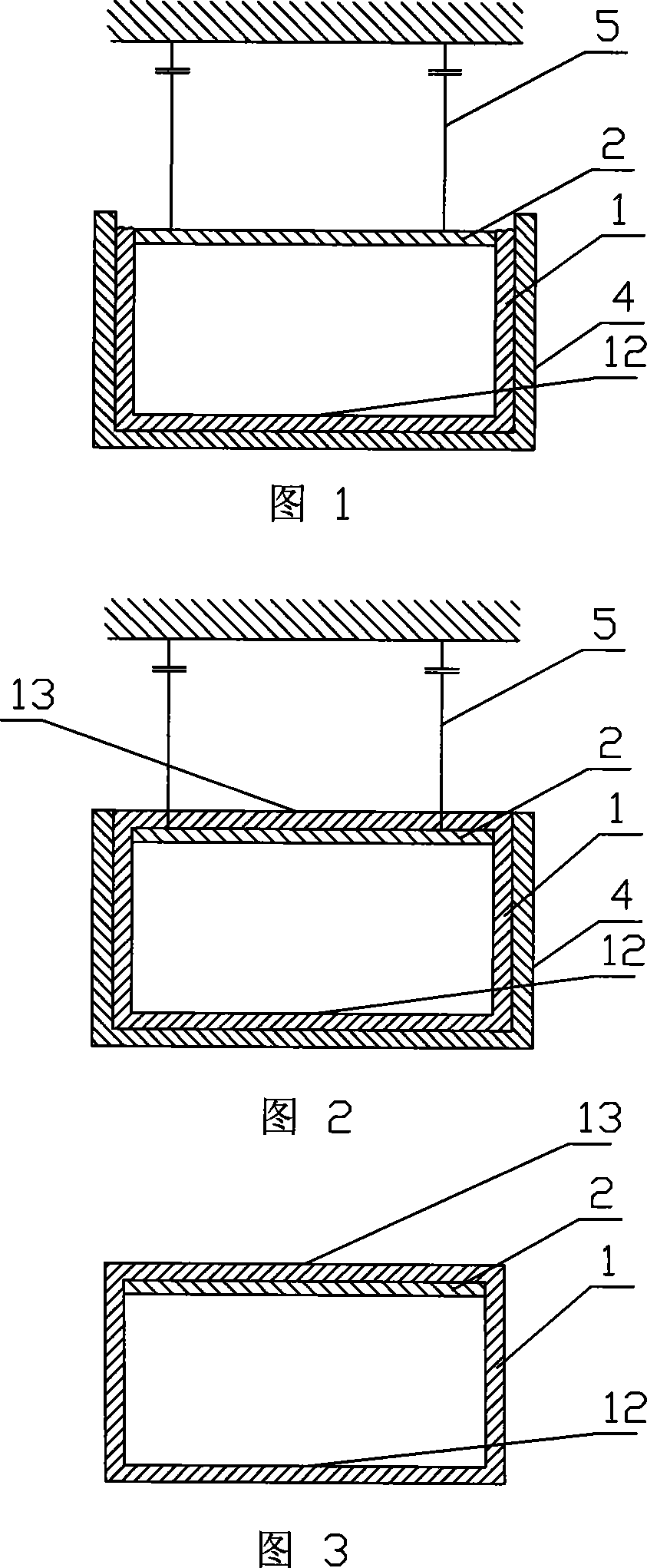

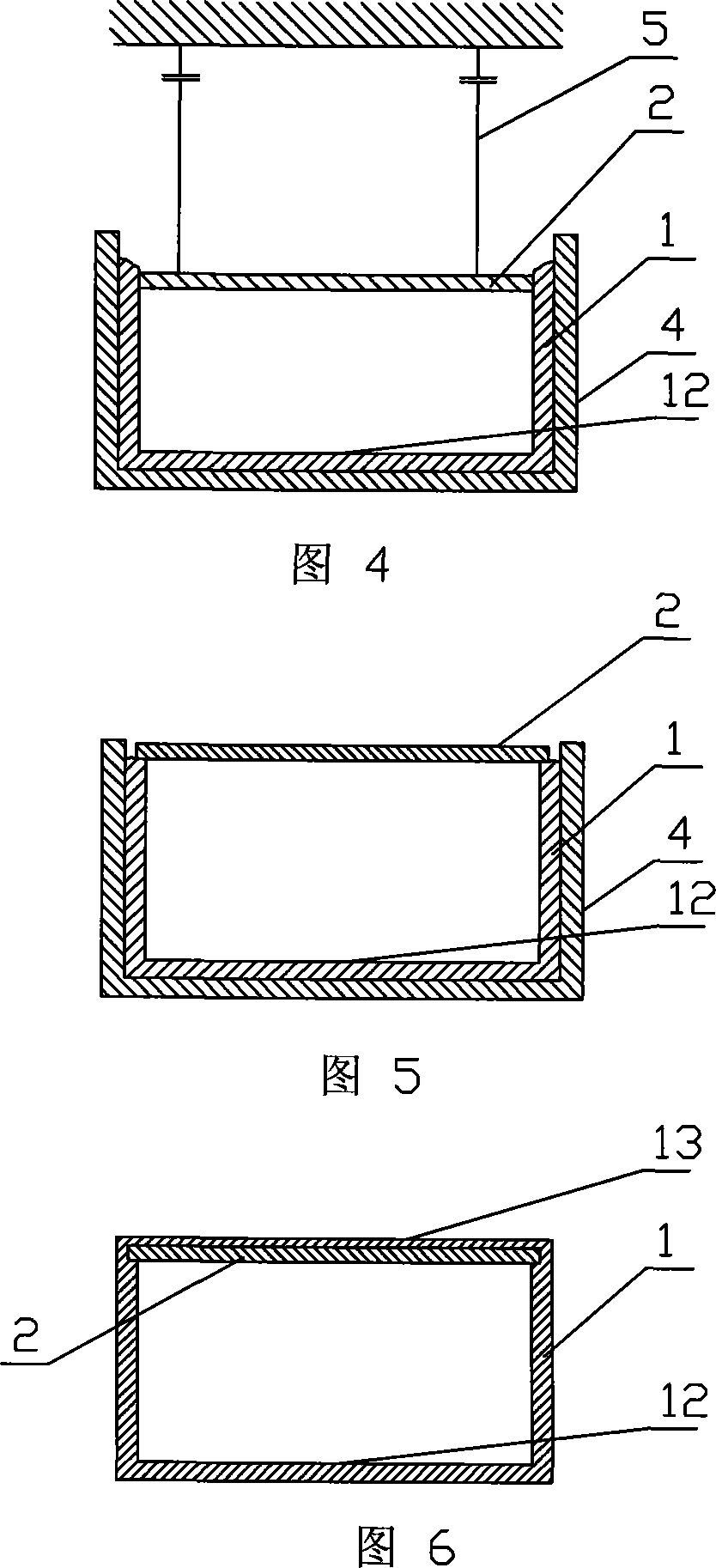

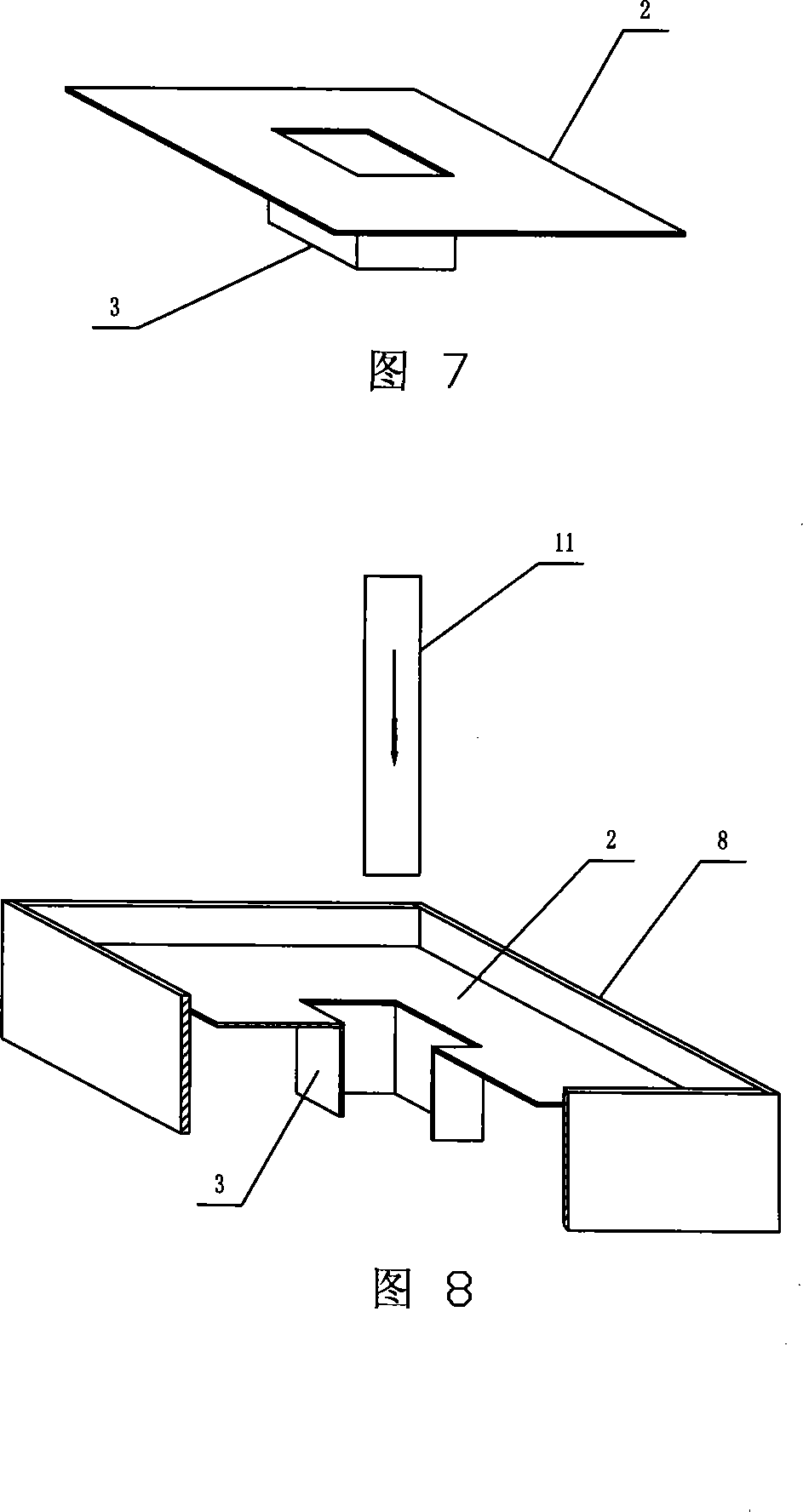

[0036]As shown in Fig. 1, Fig. 2 and Fig. 3, in embodiment 1 of the manufacturing method of the present invention, the used matrix material is cement mortar, and the surrounding side walls 1 and the bottom plate of one body are first coated with wet loose cement mortar in the outer mold 4 12. Then hoist the inner mold supporting plate 2 in the opening of the surrounding side wall 1 with the rope 5, the top surface of the inner mold supporting plate 2 is flush with the mouth edge of the surrounding side wall 1, and the mouth edge of the outer mold 4 is higher than the surrounding The opening of the side wall 1 is along the height of the top plate of the carcass, and then cement mortar is spread on the top surface of the inner mold support plate 2, and the cement mortar is smeared with a tool to form a carcass combined with the cement mortar on the upper end of the surrounding side wall 1 opening For the top plate 13, since the cement mortar of the surrounding side walls 1 has no...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com