A method for locating the upper part of the special processing of the valve body

A positioning method and valve body technology, applied in metal processing, chucks, etc., can solve the problems of low processing accuracy of the connection end, and achieve the effects of facilitating accurate processing, stabilizing the connection end, and improving processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

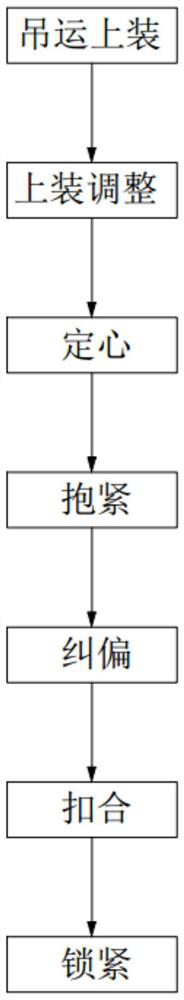

[0045] Such as figure 1 As shown, a method for positioning the upper part of the special processing of the valve body includes the following steps:

[0046] Step 1: hoisting and loading, hoisting the valve body 1 to be processed to the adjacent side of the installation vertical plate 3, the first port 13 at one end of the main body 11 on the valve body 1 is sleeved to the fixed mounting plate 3 Heart grasping component 41;

[0047] Step 2, top-loading adjustment, after the valve body 1 is sleeved on the centering and grasping assembly 41, by rotating the valve body 1, the interface ends 12 on both sides of the main body 11 of the valve body 1 are placed on the installation On the corresponding clamping claw 511 on the clamping component 51 on the front side of the vertical plate 3;

[0048] Step 3, centering, the driving assembly 43 on the installation vertical plate 3 starts, drives the three-jaw chuck 411 on the centering and grasping assembly 41 to run, and makes the posi...

Embodiment 2

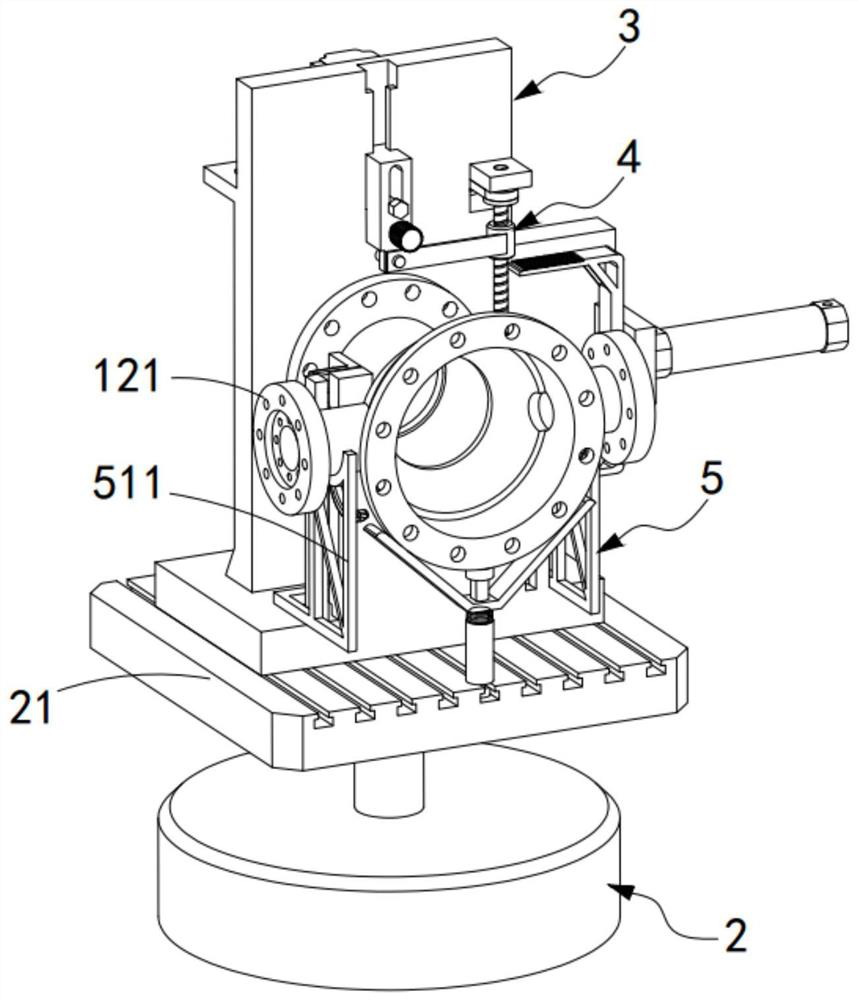

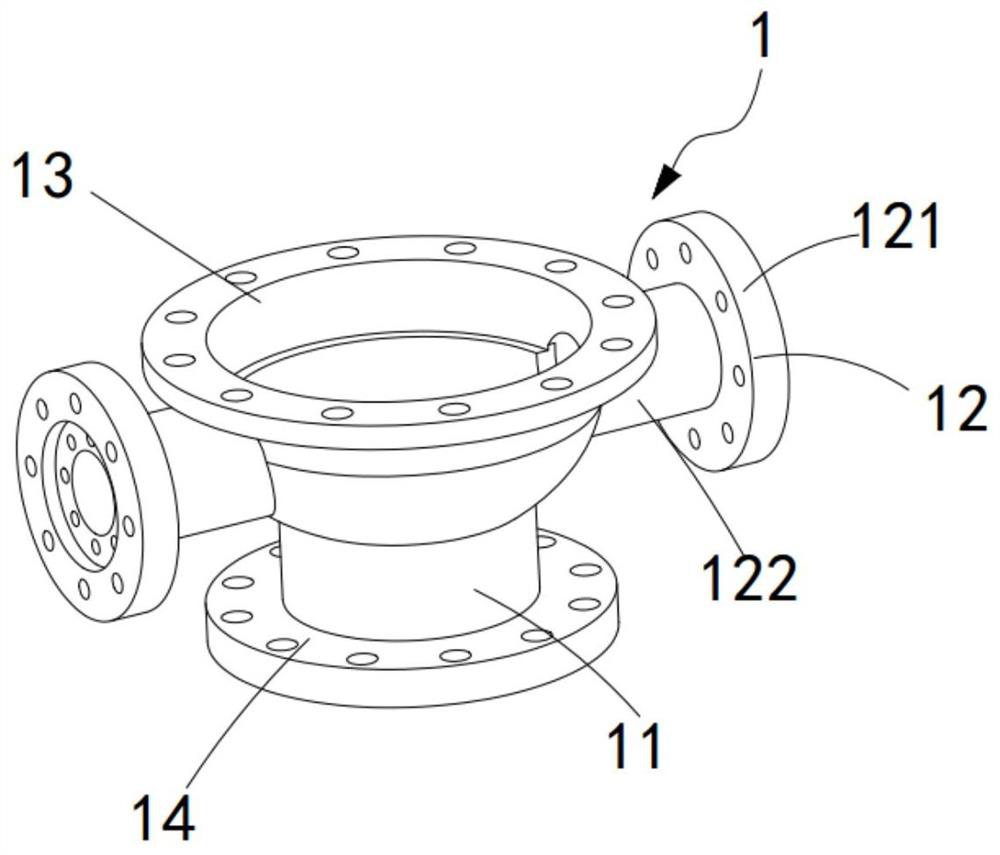

[0063] Such as Figure 2 to Figure 4 As shown in the figure, a valve body special machining and positioning method is used to fix the valve body 1 to be processed. The valve body 1 includes a main body 11 and an interface end 12 arranged perpendicularly to the main body 11. The interface end 12 is separately arranged on the main body. 11, the two ends of the main body 11 are respectively the first port 13 and the second port 14, including:

[0064] A rotating electrical machine 2, a mounting base 21 is installed on the rotating shaft of the rotating electrical machine 2;

[0065] Install the vertical board 3, the installation vertical board 3 is vertically installed on the installation base 21, the first port 13 of the valve body 1 is attached to the installation vertical board 3;

[0066] Clamping mechanism 4, the clamping mechanism 4 is installed on the described installation vertical plate 3, it is used for clamping and fixing the valve body 1 on the described installation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com