Automatic belt error polishing CNC single-axis equipment and its process method

An endless belt, automatic technology, used in grinding/polishing equipment, metal processing equipment, control of workpiece feed movement, etc. With precision machining and other issues, to achieve the effect of simplifying the process of uniform removal and smooth machining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be described in further detail below in conjunction with the accompanying drawings.

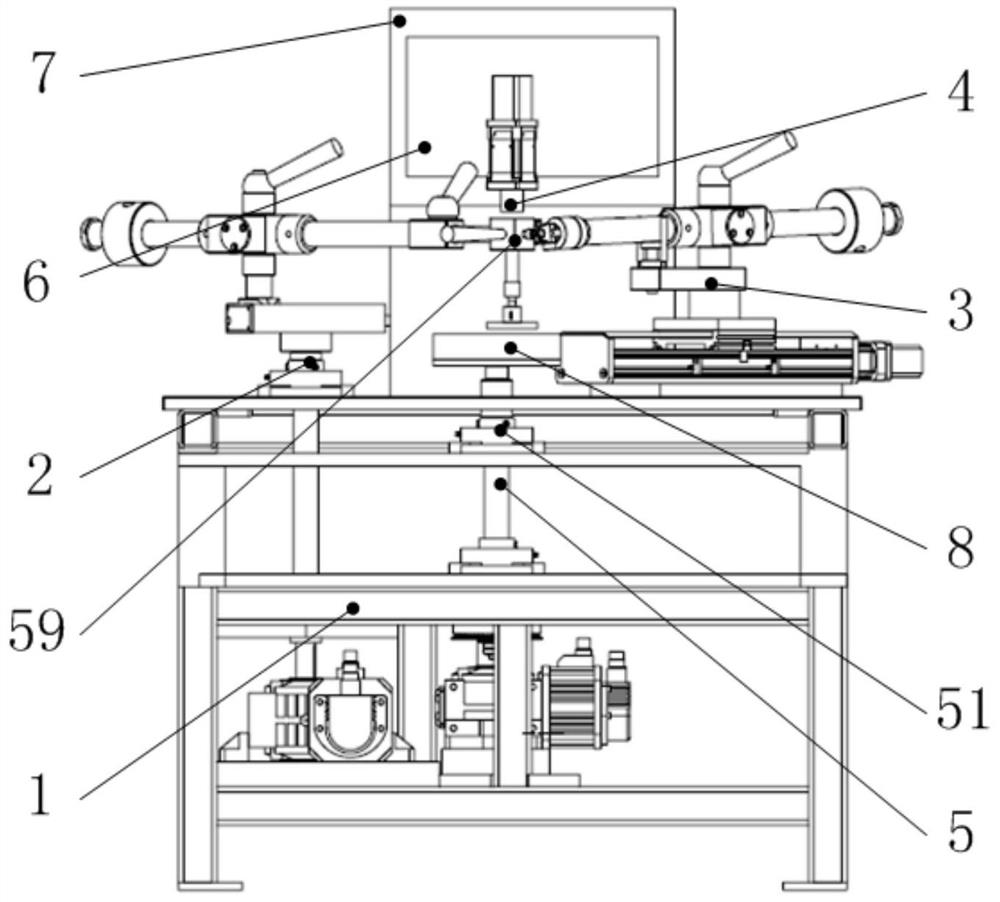

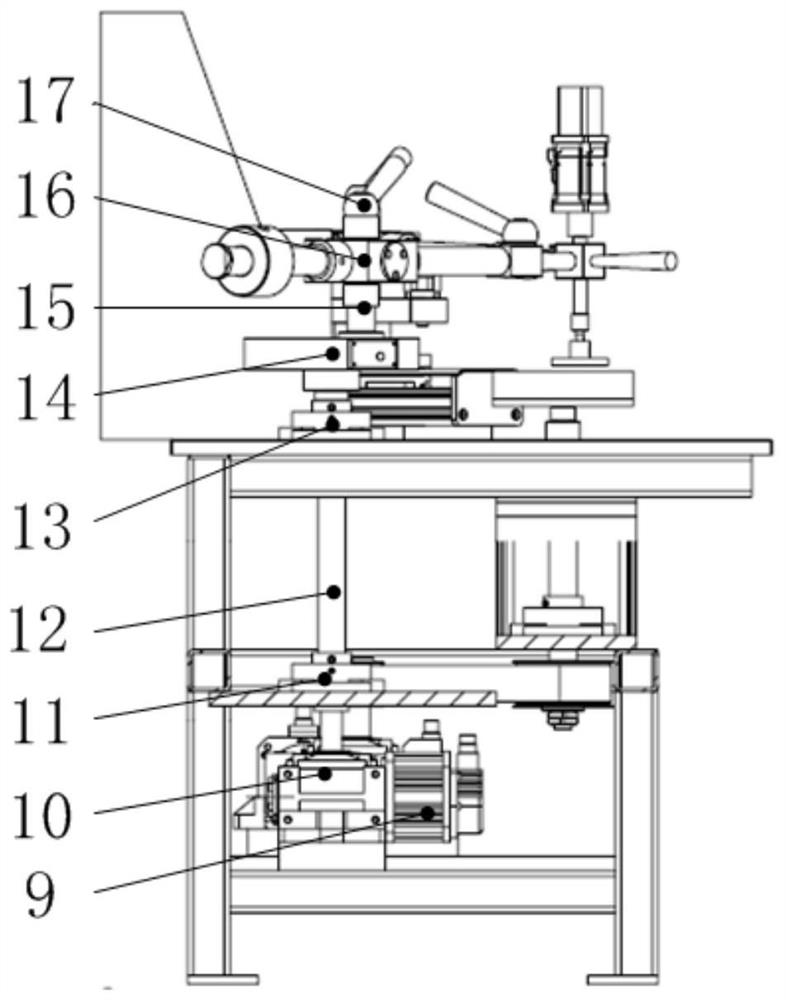

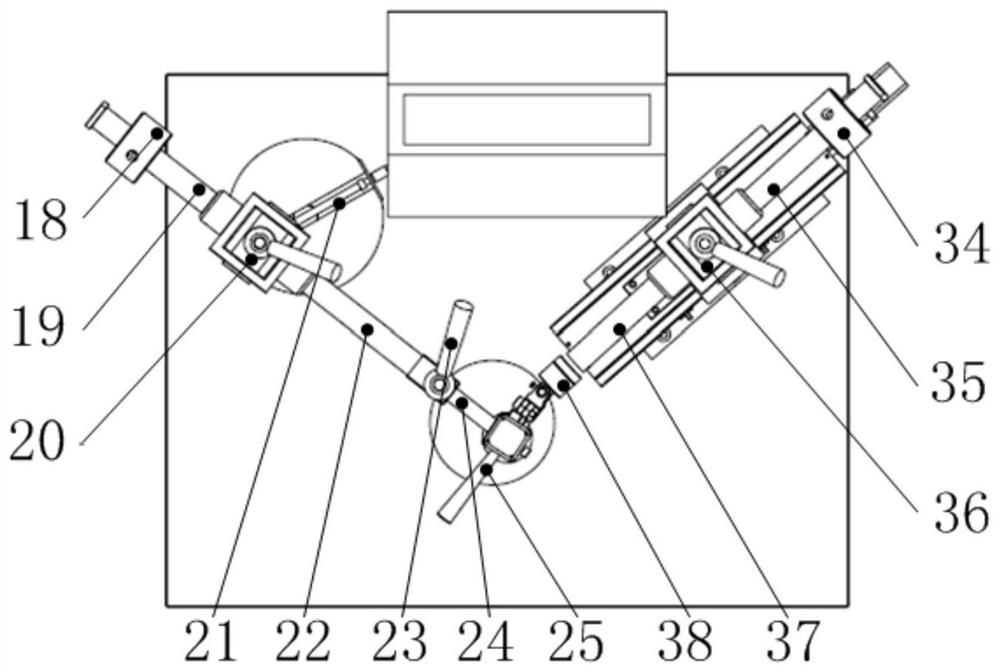

[0045] The structure of the automatic ring belt error polishing numerical control uniaxial equipment of the present invention is as follows figure 1 As shown, it includes: base system 1, swing arm system 2, translation arm system 3, active disc system 4, mirror body rotation system 5, numerical control system 6 and electric control cabinet 7. Based on the traditional manual single-axis polishing machine, starting from the controllable constant speed rotation of the grinding disc and the numerical control movement of the translation axis, through numerical control, the automatic removal of the fixed ring belt of the workpiece material is realized, and the ring belt processing, uniform removal, and Smooth etc. The specific structure of each system is as follows:

[0046] Base system 1: Base system 1 is the base of the CNC single-axis polishing machine. The s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com